Abstract

This report describes the extraction of selenium species contained in pharmaceutical tablets using either enzymatic hydrolysis or sodium dodecyl sulphate extraction (SDS). The selenium species were determined by ion chromatography coupled to inductively coupled plasma mass spectrometry. In the enzymatic extraction approach, proteolytic enzymes (protease/lipase) were used in a buffer containing 75 mM Tris–HCl at pH 7.5. It was found that the extraction efficiency was significantly improved relative to the use of the SDS approach. For example, the extraction recovery was more than 80% of total Se, where selenocystine Se-methyl-selenocysteine (SeMC) and selenomethionine (SeMet) in the samples were extracted. In contrast, chemical extraction of Se using SDS gave only 60% of total Se, while only two species, SeMC and SeMet, were found. In addition, SeMC was found to be unstable and degraded through oxidation in the extraction solution. Finally, the two enzyme methods were applied to commercial pharmaceutical tablets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Selenium (Se) is an essential micronutrient trace element required by both animals and humans. Insufficient Se intake brings with it an increased risk of thyroid and immune dysfunction, infections, cancer and diseases such as Keshan and Kashin–Beck disease [1, 2]. In recent years, increased research attention has focused on understanding the relationships between the Se species content in foods and supplement tablets and their nutritional benefits [3] such as absorption, tissue distribution, bioavailability and cancer preventative properties. Therefore, an analytical method is required to determine the identity and concentration of Se species present in foods and supplements [4]. There are various analytical methods [5–7], including sample preparation from yeasts and pharmaceutical tablets [8–11], are useful for the determination of selenium compounds in biological samples.

The preparation of sample is important for successfully assessing the concentration and range of selenium species. Liquid extraction is the most conventional extraction procedure [12] where different solutions can be used to extract the selenium species from various matrices. Such solutions include aqueous HCl [13], tetramethylammonium hydroxide (TMAH) [14], sodium dodecyl sulphate (SDS) leaching [15], hot water [16] and methanesulfonic acid [3]. Extraction efficiencies with average yields of 66–67% selenium in the form of selenomethionine were obtained from yeast after digestion using a 4 M methanesulfonic acid under reflux conditions [3, 13]. Alternatively sequential extraction was employed to separate water-soluble and insoluble selenium fractions from enriched yeast. Extracts were fractionated by preparative columns such as Superdex 75 and 200 [17].

Enzymatic hydrolyses have often been used in selenium speciation analysis. The right choice of enzymes, hydrolysed solution pH and temperature were key parameters for successful enzymatic extraction [18]. Proteinase K, a general protein hydrolyzing enzyme, was used for the recovery of selenium from yeast food supplements [19]. Mixtures of various enzymes have also been found highly efficient. Proteinase K, aminopeptidase, and carboxypeptidase Y were successfully used to extract selenium compounds from yeast [18]. Simultaneous use of proteinase K and aminopeptidase M was found to give the highest extraction of selenomethionine from yeast, 68% of the total selenium level [18]. In the method of using enzyme I β-glucosidase with mixture of endo- and exopeptidases or enzyme II protease XIV, both enzymatic procedures liberated in excess of 90% of the total selenium [20]. Selenomethionine in yeast was suggested to be bound physically as part of the cell wall rather than being incorporated chemically into the yeast’s protein [21], enzyme driselase was therefore chosen to increase Se extraction. Human serum [22], cod muscle [15] and wheat flour [23] were also treated enzymatically for selenium. Combined treatments using enzymes and traditional techniques, including enzymatic digestion and ultrasonic baths or ultrasonic probes, have also been reported [24, 25]. As an example, mushrooms have been treated by sequential and/or systematic enzymatic processes; the highest efficiency (89%) was obtained by three-step procedure using lysing enzyme and pronase [26].

In this paper, the extraction efficiency of Se species from pharmaceutical tablets using either enzymatic hydrolysis or chemical solution was investigated since an effective extraction method depends on sample matrix [4]. To achieve the aim, sodium dodecyl sulphate (SDS) and proteolytic enzymes (protease/lipase) were used to extract Se species from commercial pharmaceutical tablets. The Se species were determined by ion chromatography with inductively coupled plasma mass spectrometry (IC-ICP-MS).

Experimental

Chemicals and solutions

All reagents were of analytical reagent grade and obtained from Sigma-Aldrich (Sydney, NSW, Australia). Milli-Q water (a specific resistance of 18.2 MΩ cm, Millipore, Bedford, MA, USA) was used for preparing all solutions and standards. Stock solutions 500 mg L−1 (for Se) of Se-(methyl)-selenocysteine (SeMC), seleno-l-methionine (SeMet), seleno-l-cystine (SeCys2), 1,000 mg L−1 of Se(IV) and Se(VI) were obtained by dissolving the appropriate amount of the relevant compound in MQ water.

The enzymes, protease XIV and lipase VII were purchased from Sigma-Aldrich (Sydney, Australia). Tris(tris(hydroxymethyl)aminomethane)–HCl buffer (75 mM pH = 7.5) and 20 mM NH4H2PO4 (pH = 6.5) were prepared daily as required. Three different sources of Se samples were investigated. These were commercial tablets, Se-no-yeast™, Se-high-yeast™ and SeMC™ from Wholesale Nutrition (Saratoga, CA, USA, www.nutri.com).

Total Se determination

A 0.5 g portion of sample was weighed into PTFE vials and dissolved in a mixture of 2.0 mL of conc. HNO3 and 2.0 mL of 30% H2O2. After 17 h of contact time, total digestion was performed at 170°C for 15 min at 300 W in a microwave oven. The final solutions were made up to 25 mL in volumetric flasks with MilliQ water. A reference from NIST SRM rice 1568a with a certified Se content of 0.38 ± 0.04 µg g−1 was used for evaluation of the accuracy of the procedure. A digestion blank was also performed.

Extraction

In order to extract the protein-bound Se species in all samples, enzymatic hydrolysis and SDS extraction were performed as summarized below. Tris–HCL buffer 15 mL adjusted to pH 7.5 was added to 0.2 g of the sample in a 50 mL centrifuge tube, followed by the addition of 20 mg protease XIV and 10 mg lipase VII. The mixture was sonicated for 2 h, and then incubated in the dark for 12 h at 25°C. Hydrolysed samples were centrifuged at 4,000 rpm for 25 min and the supernatants filtered through a 0.45 µm membrane filter prior to analysis. Alternatively, a 15 mL solution of 1 M HCl was added to 0.2 g of the sample in a 50 mL centrifuge tube, followed by the addition of 0.6 g SDS. Further processing was the same as above.

Instrumentation

An Agilent 1100 liquid chromatography module equipped with a 4.6 mm × 10 mm guard column (G3154A/102) and a 4.6 mm × 150 mm separation column (G3154A/101; Agilent, Tokyo, Japan) was used. The stationary phase is based on porous polymethacrylate resin with 10 µm particle size and ion exchange capacity of 50 µeq/g. Samples were injected using an Agilent 1100 auto-sampler. The column effluent was passed via a length of PEEK tubing (50 cm, I.D. = 0.13 mm) to a Babington nebulizer attached to an Agilent 7500c ICP-MS (Tokyo, Japan), which served as an element-specific mass detector. The ICP-MS conditions were: RF power: 1,430 W; plasma gas (Ar) flow: 15 L min−1; auxiliary gas (Ar) flow: 1.0 L min−1; carrier gas (Ar) flow: 1.15 L min−1; sampling depth: 7.5 mm; integration time: 1 s; dwell time: 0.5 s. Selenium was detected at m/z 78 and m/z 80, respectively. The flow rate of H2 at 3.0 and He at 3.5 L min−1 was added to reaction cell, respectively to reduce the background singnal. Data was collected using single-ion monitoring (SIM) to ensure maximum sensitivity. The IC-ICPMS system was controlled and the data was processed using Agilent’s Chemstation software package.

Results and discussion

Determination of total selenium content by ICP-MS

The total selenium content in the samples was digested by microwave, and then was measured by ICP-MS. A reference from NIST SRM rice 1568a with a certified Se content of 0.38 ± 0.04 µg g−1 was used for evaluation of the accuracy of the procedure. The result of the reference rice sample was 0.36 ± 0.07 µg g−1, which was in good agreement with the certified value. The total selenium content obtained from samples was: Se (no yeast) tablets 131.0 ± 12.0 µg g−1; SeMC™ tablets 245.9 ± 3.4 µg g−1; Se (high Se yeast) tablets 65.4 ± 3.9 µg g−1. All values are for 3 repeats, with SD shown.

IC-ICP-MS for the speciation of selenium

In the LC-ICP-MS approach, ion-exchange chromatography is frequently used to separate both inorganic and organic selenium [3, 4, 12]. The selenium species are initially retained on the column by anion exchange and subsequently eluted by a competitive anion included in the mobile phases [12]. Cation or anion-exchange chromatography has been used in speciation of selenium. However, in this study, a new anion-exchange column (Agilent, G3154A/101) was investigated for the separation of both inorganic and organic selenium. A mobile phase containing 20 mM NH4H2PO4 at pH 6.5 was used to give the complete resolution of different Se containing compounds as shown in Fig. 1, where the elution order was SeCys2, SeMC, SeMet, selenite and selenate and total separation was achieved within a time of 12 min. In addition, Se specific detection was achieved using the isotope 78Se by ICP-MS. Detection limits (S/N = 3) obtained for Se species ranged from 1.0–2.0 µg L−1, low enough for the analysis of samples at µg L−1 level.

The extraction of selenium using SDS solution

Since SDS can solubilise proteins and render them water soluble by forming ion pairs, it is used for the extraction of selenoproteins from various matrices. Se containing amino acids can exist in free form or covalently bound in proteins. To release and characterize selenocompounds from proteins, a 15 mL solution of 1 M HCl was added to 0.2 g of the SeMC™ in a 50 mL centrifuge tube, followed by the addition of 0.6 g SDS, the data shows only SeMC and SeMet were extracted with recovery of 60% of the total selenium. Low yield indicated SDS could not completely solubilise the protein. In addition, the effect of SDS concentration on the extraction was also examined in the range of 2%–8% (w/w). The data shows the recovery was slightly reduced at high concentration and the best results at 4%. The results indicate that SDS can be used to extract the organic selenium species such as SeMC and SeMet because of formation of ion-pairs between SDS and such selenium species [15]. However, SDS cannot form the ion pairs with inorganic selenium such as Se(IV) and Se(VI). Hence, Se(IV) and Se(VI) were not observed in this case.

The extraction of selenium using enzymes

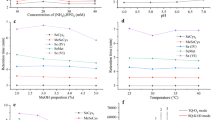

Enzymatic extractions are often used in the literature for selenium speciation analysis. The type of enzyme is important for successful enzymatic extraction [3]. In this case, a single enzyme (protease XIV) and two-enzyme system (protease XIV/lipase VII) were employed to extract selenium and also to compare their extraction efficiency. When using the protease XIV enzyme for the leaching of the SeMCTM tablets, only SeCys2, SeMC and SeMet were presented the extraction yielded percentage for SeCys2, SeMC and SeMet were 28%, 32% and 30%, respectively. No indication of the inorganic species Se(IV) and Se(VI) were observed. This indicates that protease XIV can be used to leach organic selenium species and confirmed its reported use for the extraction of selenium from Yeast [3, 20].

A dual mixture of protease XIV and lipase VII were used to extract selenium species in the SeMC™ tablets. The extraction yielded percentage for SeCys2, SeMC and SeMet were improved to 31%, 37% and 32%, respectively. The result shows that the mixed enzymatic extraction also give an additional unidentified Se species as shown in Fig. 2, probably selenium containing protein fragment [21]. The unidentified compound had a peak retention time of 3.4 min. The peak was not Se(IV) and was confirmed by the addition of known Se(IV) standard as shown Fig. 3. Unknown peak could be further identified by other techniques such as ESI-MS-MS [4]. The high extraction efficiency using a dual enzyme system suggests that Se containing proteins are hydrolysed to release “free” seleno-amino acids more efficiently following the cleavage of peptide bonds. Additional information needs to be gathered to establish whether the enzymes operate synergistically or simply target a broader range of peptide bonds [3, 20]. On the basis of these data, dual protease XIV and lipaseVII was used for further study.

Standards (150 µg L−1) were spiked to the extracted solution as Fig. 2

The effect of the amount of mixed enzymes was also tested. Recoveries for the Se varied, probably due to different rates of hydrolysis of the protein [4]. A mixture consisting of 20 mg protease XIV and 10 mg lipase VII gave satisfactory results and were chosen for further experiments.

In addition, buffering of the enzyme matrix solution with Tris–HCl was studied. Variable extraction efficiency for the various species was obtained. For example, the recovery of SeMet was obtained in greater amounts at lower levels of buffer (50 mM), while a higher concentration of buffer resulted in improved recovery of SeMC and SeMet. Thus, a solution of 75 mM buffer was chosen for all further experiments. In summary, a mixture consisting of 20 mg protease XIV and 10 mg lipase VII with 75 mM Tris–HCl was used to give the best recovery for the extraction of Se species.

Se species in pharmaceutical tables

The quantification of Se species is based on the calibration using known standards. Calibrations were obtained by plotting peak area against the concentration of the respective Se target species or total Se. Linear calibrations were obtained over a concentration range of 5–1,000 µg L−1 with correlation coefficients ranging from 0.9997–1.000 when 50 µL was injected. Detection limits (S/N = 3) obtained for Se species ranged 1–2 µg L−1, which is adequate for analysis at µg L−1 levels. The reproducibility of five replicates from a standard solution containing a mixture of the Se species was tested at 50 µg L−1 mixture. The results show a RSD in the range 1.2–2.6%. The method was used for the quantification of Se species in the extracts.

The proposed extraction method was used to leach Se species from three samples. Selenium species distribution is given in Table 1. From Table 1, it can be seen that the major Se species in the three types of tablets were SeMet and SeCys2. The lowest level of SeMet, comprising 19% of the extract total Se content, was in Se-no-yeast tablets. Tablets of SeMC™ gave 37% SeMC which is an important organically-bound Se source. Recently, SeMC has exhibited greater efficacy as a chemopreventative agent than any other Se-compound in experimental models of breast cancer [1–3]. To validate the method, the five Se compounds selected were spiked at a level of each 150 µg L−1 to the extracts, species recovery in the range of 97–104% was found available.

Conclusions

The study has shown that enzymatic hydrolysis and sodium dodecyl sulphate (SDS) digestion can be used for the extraction of organic Se species in tablets. However, higher extraction efficiency was obtained using enzymatic methods. In this case, a mixed proteolytic enzyme (protease XIV and lipase VII) extraction approach gave significantly improved recovery of more than 80% compared to SDS at 60%. In addition, the new type of anion-exchange column was used successfully for the separation of both inorganic and organic Se species with ICP-MS detection, reasonable resolution and detection sensitivity was obtained. The information obtained for individual Se species supplements provides a better understanding for potential animal and human health benefits.

References

Tan JA, Zhu W, Wang W, Li R, Hou S, Wang D, Yang L (2002) Selenium in soil and endemic diseases in China. Sci Total Environ 284:227

Tinggi U (2003) Essentiality and toxicity of selenium and its status in Australia: a review. Toxicol Lett 137:103

Wrobel K, Kannamkumarath SS, Caruso JA (2003) Hydrolysis of proteins with methanesulfonic acid for improved HPLC-ICP-MS determination of seleno-methionine in yeast and nuts. Anal Bioanal Chem 375:133

B’Hymer C, Caruso JA (2006) Selenium speciation analysis using inductively coupled plasma-mass spectrometry. J Chromatogr A 1114:1

Weixiao W, Jingyin L, Huimin D, Jing H, Shufang L (2006) Determination of selenium in biological materials using an ion-selective electrode. Microchim Acta 154:143

Ajtony Z, Szoboszlai N, Bella Z, Bolla S, Szakál P, Bencs L (2005) Determination of total selenium content in cereals and bakery products by flow injection hydride generation graphite furnace atomic absorption spectrometry applying in-situ trapping on iridium-treated graphite platforms. Microchim Acta 150:1

Bidari A, Hemmatkhah P, Jafarvand S, Milani Hosseini MR, Assadi Y (online first) Selenium analysis in water samples by dispersive liquid–liquid microextraction based on piazselenol formation and GC-ECD, Microchim. Acta, doi:10.1007/s00604-008-0003-8

Yang L, Sturgeon RE, Wolf WR, Goldschmidt RJ, Mester Z (2004) Determination of selenomethionine in yeast using CNBr derivatization and ID GC-ICP-MS and GC-MS. J Anal At Spectrom 19:1448

McSheehy S, Yang L, Sturgeon RE, Mester Z (2005) Determination of methionine and selenomethionine in a candidate selenium-enriched yeast reference material using species specific id with liquid chromatography-MS and ICP-MS. Anal Chem 77:344

Mester Z, Willie SN, Caruso JA, Fernandez ML, Fodor P, Goldschmidt RJ, Infante HG, Lobinski R, Maxwell P, McSheehy S, Polatajko A, Sadi BM, Sanz-Medel A, Sturgeon RE, Szpunar J, Wahlen R, Wolf W, Yang L (2006) Certification of a new selenized yeast reference material for selenomethionine, methionine and selenium and its use in an intercomparison exercise for quantitation of these analytes. Anal Bioanal Chem 385:168

Goenaga-Infante H, Sturgeon R, Turner J, Hearn R, Sargent M, Maxwell P, Yang L, Barzev A, Pedrero Z, Camara C, Huerta VD, Sanchez MLF, Sanz-Medel A, Emese K, Fodor P, Wolf W, Goldschmidt R, Vacchina V, Szpunar J, Valiente L, Huertas R, Labarraque G, Davis C, Zeisler R, Turk G, Rizzio E, Mackay LG, Myors RB, Saxby DL, Askew S, Chao W, Jun W (2008) Total selenium and selenomethionine in pharmaceutical yeast tablets: assessment of the state of the art of measurement capabilities through international intercomparison study CCQM P86 H. Anal Bioanal Chem 390:629

Yang L, Mester Z, Sturgeon RE (2004) Determination of methionine and selenomethionine in yeast by species-specific isotope dilution GC/MS. Anal Chem 76:5149

Yang L, Sturgeon RE, McSheehy S, Mester Z (2004) Comparison of extraction methods for quantitation of methionine and selenomethionine in yeast by species specific isotope dilution gas chromatography–mass spectrometry. J Chromatogr A 1055:177

Casiot C, Szpunar J, Lobinski R, Potin-Gautier M (1999) Sample preparation and HPLC separation approaches to speciation analysis of selenium in yeast by ICP-MS. J Anal Atom Spectrom 14:645

Huerta VD, Sanchez MLF, Medel AS (2004) Quantitative selenium speciation in cod muscle by isotope dilution ICP-MS with a reaction cell: comparison of different reported extraction procedures. J Anal Atom Spectrom 19:644

Gayon JMM, Thomas C, Feldmann I, Jakubowski M (2000) Comparison of different nebulisers and chromatographic techniques for the speciation of selenium in nutritional commercial supplements by hexapole collision and reaction cell ICP-MS. J Anal Atom Spectrom 15:1093

Chassaigne H, Chery CC, Bordin G, Rodriquez AR (2002) Development of new analytical methods for selenium speciation in selenium-enriched yeast material. J Chromatogr A 976:409

B’Hymer C, Caruso JA (2001) Canadian soil quality guidelines selenium environmental and human health effects. Can J Anal Sci Spectrosc 46:136

B’Hymer C, Caruso JA (2000) Evaluation of yeast-based selenium food supplements using high-performance liquid chromatography and inductively coupled plasma mass spectrometry. J Anal Atom Spectrom 15:1531

Larsen EH, Sloth J, Hansen M, Moesgaard S (2003) Selenium speciation and isotope composition in 77Se-enriched yeast using gradient elution HPLC separation and ICP-dynamic reaction cell-MS. J Anal Atom Spectrom 18:310

Polatajko A, Sliwka-Kaszynska M, Dernovics M, Ruzik R, Encinar JR, Szpunar J (2004) A systematic approach to selenium speciation in selenized yeast. J Anal Atom Spectrom 19:114

Encinar JR, Schaumloffel D, Ogra Y, Lobinski R (2004) Determination of selenomethionine and selenocysteine in human serum using speciated isotope dilution-capillary HPLC-inductively coupled plasma collision cell mass spectrometry. Anal Chem 76:6635

Huerta VD, Reyes LH, Gayon JMM, Sanchez MLF, Medel AS (2003) Total determination and quantitative speciation analysis of selenium in yeast and wheat flour by isotope dilution analysis ICP-MS. J Anal Atom Spectrom 18:1243

Bermejo P, Capelo JL, Mota A, Madrid Y, Camara C (2004) Enzymatic digestion and ultrasonication: a powerful combination in analytical chemistry. Trends Anal Chem 23:654

Capelo JL, Embun PX, Albarran YM, Camara C (2004) Enzymatic probe sonication: enhancement of protease-catalyzed hydrolysis of selenium bound to proteins in yeast. Anal Chem 76:233

Dernovics M, Stefanka Z, Fodor P (2002) Improving selenium extraction by sequential enzymatic processes for Se-speciation of selenium-enriched Agaricus bisporus. Anal Bioanal Chem 372:473

Acknowledgment

WH Wang gratefully acknowledges a grant from Australia Postgraduate Awards (APA) and Cooperative Research Centre for Contamination Assessment and Remediation of Environments (CRC CARE), Australia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Chen, Z., Davey, D.E. et al. Extraction of selenium species in pharmaceutical tablets using enzymatic and chemical methods. Microchim Acta 165, 167–172 (2009). https://doi.org/10.1007/s00604-008-0115-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-008-0115-1