Abstract

A linear sweep anodic stripping voltammetric method was developed for copper determination in commercial ethanol fuel samples by using a gold microelectrode. Under the optimized conditions, a linear range from 0.05 to 1.0 μM was obtained, with detection limit of 22 nM. The method was employed to determine copper ions in six commercial ethanol fuel samples and the results were compared with those obtained by FAAS. This study showed that for most samples both methods produced concordant results. However, for two samples, copper is distributed in its labile and complexed forms leading to copper contents contrasting with those obtained by flame atomic absorption spectroscopy (FAAS). It was observed that acidification of the samples is a very efficient way to recover copper from its complexed forms. After acidification, the copper contents obtained were concordant with those obtained by FAAS. Thus, the method can be employed to the reliable copper determination in commercial ethanol fuel samples. Moreover, this is the first work providing some insights about copper speciation in commercial ethanol fuel samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ethanol from sugar cane has been used as automotive fuel in Brazil since the 1970s [1] and its use as an alternative energy source has significantly contributed to reduce CO2 emission levels in Brazil. This fuel was initially used as an additive in gasoline which enhances its octane number, replacing the organolead compounds [2, 3]. Nowadays, ethanol is used in Brazil as a new car fuel option with economic and environmental advantages [4]. Thus, ethanol is an attractive alternative fuel because it is a renewable bio-based resource and it is less pollutant than petroleum derivatives. These characteristics indicate that ethanol fuel will play an important role in worldwide energetic policies in the next years.

The presence of trace metal ions in ethanol fuel plays an important role in the engine maintenance, since metallic species can accelerate the corrosion of engines or promote the formation of gums and sediments [5]. In addition, these metals can be released to the atmosphere by combustion of ethanol fuel representing an expressive source of pollution, mainly in big cities [6]. The main sources of metal ions are associated to the sugar cane ethanol production process, storage and transportation [7]. Thus, the development of analytical methods to determine trace metal ions in ethanol fuel is a relevant research field. The determination of metals in ethanol fuel is especially difficult due to their low concentrations and the lack of certified reference samples. The literature has presented works employing electrothermal atomic absorption spectroscopy for metal ions determination in ethanol fuel [6, 8, 9] and petroleum-based fuels [10]. Flame atomic absorption spectroscopy (FAAS) can also be used after a preconcentration step [11–13].

Regarding the importance of analytical methods for metal ions determination in ethanol fuel and their implementation in routine analysis, the cost of analysis must be taken into consideration. In this context, electroanalytical techniques play an important role, because these techniques often provide high sensitivity and precision with relatively low instrumental costs. Stripping analysis have become very popular for metal determination because they present very low detection limits, extremely high sensitivity, multi-element and speciation capability, besides their suitability for on site and in situ applications [14, 15]. The high sensitivity and consequently the low detection limits obtained with stripping analysis techniques are consequences of the preconcentration step, which enhances the analyte concentration at electrode surface. Some works have shown that stripping voltammetry can be successfully applied to metal ions determination in ethanol fuel reaching detection limit values compatible with those obtained by AAS [16–19]. Recently, we have developed a solid paraffin-based modified carbon paste electrode, which was successfully employed for determination of Ni [20] and Cu [21] in commercial ethanol fuel samples.

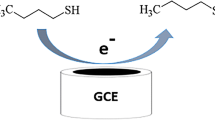

One of the most important advances in stripping analysis has been the advent of microelectrodes. Xie et al. [14] have presented a complete and very instructive review about the application of microelectrodes for determination of metal ions in aquatic systems. Compared with conventional dimension electrodes, microelectrodes present several attractive features, such as improvement of mass transport due to radial diffusion, enhancement of signal–noise ratio, low background currents and immunity to ohmic drop [14, 22]. This last characteristic is very attractive, since it enables the use of microelectrodes in high resistive media without the necessity of supporting electrolyte, minimizing chemical contamination of the samples. Thus, microelectrodes and microelectrode arrays have been widely employed for metal ions determination in different matrices [23–30].

Thus, the objective of this work was to employ a gold microelectrode to develop an anodic stripping voltammetric method for copper determination directly in commercial ethanol fuel samples. The use of a microelectrode allows to perform both preconcentration and detection step directly in the commercial samples, which means a great simplification in the analytical procedure comparing to other electroanalytical methods proposed in the literature for metal ions determination in ethanol fuel.

Experimental

Reagents and solutions

Stock solutions of copper were prepared by dissolving copper chloride (Sigma, 99.99%) in analytical purity grade ethanol from Merck. Voltammetric experiments carried out in analytical grade ethanol were performed using 0.1 mM lithium perchlorate (Mallinckrodt) as supporting electrolyte. In the commercial ethanol fuel samples, voltammetric experiments were performed without supporting electrolyte addition. Sulphuric (Aldrich) was used to acidify the commercial samples. Standard stock solutions of copper 1,000 mg L−1 in 1 wt.% HNO3, atomic absorption standard solution (Aldrich) were employed for the analysis of commercial ethanol fuel samples by FAAS. Commercial ethanol fuel samples were acquired from different local gas stations.

Apparatus and procedures

Cyclic and linear sweep anodic stripping voltammetric experiments were performed using an AUTOLAB PGSTAT 30 potentiostat coupled to a microcomputer and controlled by GPES 4.9 software. The voltammetric experiments were carried out in a two-electrode cell (capacity of 5.0 mL) located inside a homemade Faraday cage constructed with aluminum sheets. A 25 μm diameter (φ) gold microelectrode from Metrohm was used as working electrode. A Pt wire was employed simultaneously as auxiliary and pseudo-reference electrode. Previously to each measurement, the microelectrode surface was mechanically polished with an aqueous suspension of alumina powder (0.3 μm). Nitrogen was bubbled through the solution for 15 min before each series of measurement. Copper electrodeposition step was performed in stirred Cu2+ solutions at controlled-potential conditions.

Comparative experiments for the determination of total copper were performed by FAAS using a spectrometer from Perkin-Elmer model Analyst 100. A copper hollow cathode lamp from Perkin-Elmer was used in these experiments. The analytical procedure adopted in FAAS analysis was the same used by Oliveira et al. [17].

Results and discussion

Copper voltammetric behavior

Preliminary, the cyclic voltammetric behavior of Cu2+ in analytical grade ethanol containing 0.1 mM LiClO4 was evaluated. Figure 1 shows the cyclic voltammogram recorded at 100 mV s−1 in presence of 0.1 mM Cu2+.

During the cathodic scan it can be observed that copper promotes an intensification of the current at potentials more negative than −0.5 V vs. Pt. This behavior indicates that Cu2+ is reduced to its metallic state. However, contrasting with the observed by Baldo and Danielle [23], it was not observed cathodic voltammetric peaks associated with Cu2+ reduction. On the reversal of the scan direction, a nucleation loop typical for the growth of a metallic phase onto the solid microelectrode surface [23] is observed. Finally, an anodic stripping voltammetric peak is observed on the anodic scan at +0.45 V vs. Pt. A cyclic voltammogram was recorded in these same conditions but using an Ag/AgCl/KCl saturated reference electrode (Ag/AgClsat). This experiment has shown that Pt pseudo-reference electrode potential is shifted (+400 ± 20) mV (N = 3) against Ag/AgClsat.

Analytical experimental conditions optimization

Aiming to develop an analytical method for copper determination using linear sweep anodic stripping voltammetry, all experimental parameters were submitted to optimization studies. The first optimized parameter was the deposition potential (E dep). The optimization of E dep was performed in a 0.1 μM Cu2+ ethanolic solution using a deposition time (t dep) of 600 s. Figure 2 shows the influence of this parameter on anodic stripping peak currents (i p).

From Fig. 2 it can be observed that i p values increase by increasing E dep from −0.5 to −0.8 V vs. Pt, remaining almost constant for more negative potentials. For E dep less negative than −0.5 V vs. Pt it was not observed anodic stripping voltammetric peak, indicating a very high overvoltage associated to copper electrodeposition in ethanolic media. The voltammograms obtained with E dep = −1.0 V vs. Pt have presented drastic distortions of the background current, besides that, the voltammetric peaks at this experimental condition were very broad. These features have increased the dispersion of i p values to unacceptable levels as can be observed by the large error bar obtained at E dep = −1.0 V vs. Pt. This behavior could be associated with the simultaneous solvent/supporting electrolyte discharge at −1.0 V vs. Pt, which decreases the efficiency of copper electrodeposition and could promote partial deactivation of the electrode surface. Thus, based on these observations, E dep = −0.8 V vs. Pt was adopted for the subsequent experiments. The effect of t dep on voltammetric response of a 0.1 μM Cu2+ solution in analytical-grade ethanol was evaluated from 300 to 1,500 s. The results have shown an increase of i p until t dep = 900 s, which was adopted in the subsequent experiments.

The last optimized parameter was the scan rate (ν), this study was performed in a 0.1 μM Cu2+ ethanolic solution with E dep = −0.8 V vs. Pt and t dep = 900 s, raging ν from 20 to 200 mV s−1. It was observed a linear relationship between i p and ν according to the equation: i p(pA) = 1.3 ν (mV s−1) (n = 6), with linear correlation coefficient equal to 0.9993. This result is consistent with an electrode process involving surface immobilized species. Based on this study the scan rate of 150 mV s−1 was selected for analytical applications.

Analytical curve

Under the previously optimized conditions, an analytical curve was constructed. It was observed that i p values lineally increase by increasing Cu2+ concentration in the range from 0.01 to 0.25 μM. At higher Cu2+ concentrations negative deviation from linearity was observed probably due to electrode surface saturation. The analytical curve was linear according to equation: \(i_{\text{p}} \left( {{\text{nA}}} \right) = 0.01 + 1.5\,C_{{\text{Cu}}^{2 + } } \left( {{\text{ $ \mu $ M}}} \right)\) with linear correlation coefficient equal to 0.9988. The detection limit (DL) was found to be 4.1 nM, evaluated by the equation: DL = 3 SD/(analytical curve slope), where SD is equivalent to the standard deviation of the average of the signal of five measurements of the blank at the peak potential of copper anodic stripping. The obtained linear range is not the most appropriated for Cu2+ determination directly in commercial ethanol fuel samples because the literature has shown that copper concentration in this kind of sample is between 0.1 and 0.5 μM [6, 17, 18]. These values are above the superior limit of the obtained linear range. Thus, aiming to avoid sample dilution steps, the analytical curve was rebuilt using t dep = 300 s, keeping the other parameters as previously optimized. The new analytical curve has presented a linear range from 0.05 to 1.0 μM, according to the equation: \(i_{\text{p}} \left( {{\text{nA}}} \right) = 0.02 + 1.0\,C_{{\text{Cu}}^{2 + } } \left( {{\text{ $ \mu $ M}}} \right)\) with linear correlation coefficient equal to 0.9998. The DL found with this new analytical curve was 22 nM. Therefore, this new experimental condition allows employing the gold microelectrode for copper determination directly in commercial ethanol fuel samples.

Commercial samples analysis

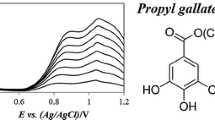

The proposed analytical method, using t dep = 300 s, was employed for Cu2+ determination in commercial ethanol fuel samples acquired from local gas stations. The Cu2+ determination in these samples was performed in triplicate by standard addition method. The linear sweep voltammograms used to construct the standard addition curve for one of the analyzed samples (sample 1 in Table 1) are presented in Fig. 3. These voltammograms were recorded directly in the commercial ethanol fuel sample without addition of supporting electrolyte.

Linear sweep anodic stripping voltammograms recorded in a commercial ethanol fuel sample, ν = 150 mV s−1. Working electrode: gold microelectrode φ = 25 μm. E dep = −0.8 V vs. Pt; t dep = 300 s. Solid line Commercial ethanol fuel sample. Dashed lines Commercial ethanol fuel sample (5 mL) + successive additions of 10 μL of Cu2+ 0.1 mM standard solution

From Fig. 3, it can be observed that the anodic stripping peak obtained in the commercial sample is about 100 mV less positive than the observed in synthetic Cu2+ ethanolic solutions. This fact can be attributed to the difference in the composition between the synthetic and commercial samples, which can affect the potential of the open-pseudo-reference electrode. Making a correlation between the properties of the species in solution and the surface of the electrode is a very difficult task regarding the complexity of the commercial samples. In addition, this is unnecessary regarding the objectives of this work. These same experiments using an Ag/AgClsat reference electrode has confirmed the above discussed, since in these experimental conditions the copper anodic stripping peak was observed at −0.05 V vs. Ag/AgClsat for both synthetic and commercial sample. However, to keep the experimental set up as simple as possible the system containing only two electrodes was used in the subsequent experiments. Despite this displacement at peak potential, it was observed that the voltammetric peak increases with the successive copper additions, demonstrating that this peak is really associated to copper anodic stripping. Standard addition curve was linear according to the equation: \(i_{\text{p}} \left( {{\text{nA}}} \right) = 0.44 + 1.1\,C_{{\text{Cu}}^{2 + } } \left( {{\text{ $ \mu $ M}}} \right)\). The copper concentration determined in this sample was (0.406 ± 0.07) μM, which is in good agreement with the concentration obtained by FAAS (0.406 ± 0.008) μM. The obtained t and F values were 0.7 and 1.3, respectively. These values have not exceeded the critical t and F values (2.78 and 19.0, respectively. P = 0.05 with four degrees of freedom). Thus, these results demonstrate that there is not statistical difference either in the concentration determined or in the precision of both the analytical methods, suggesting the absence of systematic errors in the developed electroanalytical method.

Despite the success of the proposed method for copper determination in this commercial sample, it was observed that the analysis of another sample (sample 2 in Table 1) has provided a copper concentration of (0.167 ± 0.025) μM, which is significantly bellow the found by FAAS (0.234 ± 0.019) μM. In this case the calculated t-value (3.7) has exceeded the critical ones, confirming the significance of the difference between the results obtained by both methods. According to the results obtained in synthetic Cu2+ ethanolic solutions, a well defined an intense voltammetric peak should be observed for solutions containing more than 0.2 mM Cu2+. However, the voltammetric peak obtained for sample 2 was broad and poorly defined. This result suggests that cooper present in the commercial sample is partially complexed with organic species. As a consequence, the proposed method detects copper only in its free form, leading to results contrasting with those obtained by FAAS (total copper). Baldo and Danielle [23] have observed this same effect in the analysis of copper in “grappa” by anodic stripping voltammetry. According to these authors, the acidification of the sample is an appropriated procedure to recover copper from its complexed forms. Based on this work, the analyzed samples were acidified with sulphuric acid.

To establish the optimal acid concentration, linear sweep anodic stripping voltammograms were recorded in the commercial samples at different H2SO4 concentrations. The voltammograms recorded in the sample 2 after the addition of different amounts of H2SO4 are presented in Fig. 4.

Linear sweep anodic stripping voltammograms recorded in a commercial ethanol fuel sample (sample 2 in Table 1) containing different H2SO4 concentrations: (A) 0, (B) 0.5, (C) 1.0, (D) 10 mM. Working electrode: gold microelectrode φ = 25 μm. E dep = −0.8 V vs. Pt; t dep = 300 s, ν = 150 mV s−1

From Fig. 4 it can be observed that current values increase by increasing the H2SO4 concentration up to 1.0 mM, for higher acid concentrations i p values remain almost constant. This result suggests that acidification is also efficient to recover the copper present in commercial ethanol fuel samples. It was also observed that the voltammetric peak shifts for less positive potentials by increasing the acid concentration. This behavior can be attributed to the effect of the sample composite on pseudo-reference potential as previously discussed. The increase of i p values can not be attributed to an increase of the sample conductivity with the acidification, since the addition of the same concentrations of LiClO4 have not promoted any change on the voltammetric peak.

In order to check the efficiency of the samples acidification, six commercial ethanol fuel samples were analyzed by the proposed method with and without the addition of acid. The obtained results were compared with those obtained by FAAS as shown in Table 1.

Table 1 shows some variability of labile to complexed copper ratio for the different analyzed samples. Most of these samples present low complexing capacity, thus the results obtained without acidification reflect their total content of copper. However, for samples 2 and 3 the acidification was necessary in order to obtain concordance between the results obtained by the proposed method and by FAAS. The results obtained for these samples with and without acidification have shown that sample 2 and 3 present, respectively, 29% and 43% of copper in its complexed form. It is interesting to observe that the copper contents of low complexing capacity samples it is not affected by acidification procedure. This is an important result because it demonstrates that acidification does not introduce systematic errors in the proposed method.

Conclusions

The results obtained in this work have demonstrated that a gold microelectrode can be successfully employed for copper determination directly in commercial ethanol fuel samples. The proposed method provides some great advances in electroanalysis of copper in this kind of matrix. This is the first work in which both preconcentration and detection step is performed directly in the commercial sample without supporting electrolyte addition or pretreatment steps. Thus, the developed method allows copper determination in a fast and simple way with low reagent consumption. Moreover, this work is the first in literature using an electroanalytical technique to provide some insights about the speciation of copper in commercial ethanol fuel samples. The obtained results have shown that acidification of the samples is a very efficient way to recover copper from its complexed forms. In addition, this procedure does not introduce systematic errors in the proposed method.

References

Wheals AE, Basso LC, Alves DMC, Amorin HV (1999) Fuel ethanol after 25 years. Trends Biotechnol 17:482

Macedo IC (1998) Greenhouse gas emissions and energy balances in bio-ethanol production and utilization in Brazil. Biomass Bioenergy 14:77

Rosillo-Calle F, Cortez LAB (1998) Towards proalcool II: a review of Brazilian bioethanol programme. Biomass Bioenergy 14:115

Sandelim K, Backman R (1999) A simple two-reactor method for predicting distribution of trace elements in combustion systems. Environ Sci Technol 33:4508

Taylor DB, Synovec RE (1993) Chromatographic determination of copper speciation in jet fuel. Talanta 40:495

Saint’Pierre TD, Frescura VLA, Curtius AJ (2006) The development of a method for the determination of trace elements in fuel alcohol by ETV–ICP-MS using isotope dilution calibration. Talanta 68:957

Bruning IMRA, Malm EB (1982) Identificação e quantificação das impurezas presentes no etanol. Bol Tec Petrobrás 25:217

Oliveira AP, Morais M, Neto JAG, Lima EC (2000) Simultaneous determination of Al, Cu, Fe, Mn and Ni in fuel ethanol by GFAAS. Atom Spectrosc 23:39

Saint’Pierre TD, Aucelio RQ, Curtius AJ (2003) Trace elemental determination in alcohol automotive fuel by electrothermal atomic absorption spectrometry. Microchem J 75:59

Dias FS, Santos WNL, Costa ACS, Welz B, Vale MGR, Ferreira SLC (2007) Application of multivariate techniques for optimization of direct method for determination of lead in naphtha and petroleum condensate by electrothermal atomic absorption spectrometry. Microchim Acta 158:321

Gomes LAM, Padilha PM, Moreira JC, Dias-Filho NL, Gushiken Y (1998) Determination of metal ions in fuel ethanol after preconcentration on 5-amino-1,3,4-thiadiazole-2-thiol modified silica gel. J Braz Chem Soc 9:494

Padilha PM, Padilha CCF, Rocha JC (1999) Flame AAS determination of metal ions in fuel ethanol after preconcentration on acid carboxymethylcellulose (CMCH). Chim Anal 18:299

Roldan PS, Alcântara IL, Castro GR, Rocha JC, Padilla CCF, Padilla PM (2003) Determination of Cu, Ni and Zn in fuel ethanol by FAAS after enrichment in column packed with 2-aminothiazole-modified silica gel. Anal Bional Chem 375:574

Xie X, Stüben D, Berner Z (2005) The application of microelectrodes for the measurements of trace metals in water. Anal Lett 38:2281

Lam MT, Murimboh J, Hassan NM, Chakrabarti CL (1999) Competitive ligand exchange/adsorptive cathodic stripping voltammetry (CLE/AdCSV) for kinetic studies of nickel speciation in aqueous environmental samples containing heterogeneous, macromolecular, organic complexants. Anal Chim Acta 402:195

Bergamini MF, Vital SI, Santos AL, Stradiotto NR (2006) Determinação de chumbo em álcool combustível por voltametria de redissolução anódica utilizando um eletrodo de pasta de carbono modificado com resina de troca iônica Amberlite IR 120 Eclet. Quim 31:45

Oliveira MF, Saczk AA, Okumura LL, Fernandes AP, Moraes M, Stradiotto NR (2004) Simultaneous determination of zinc, copper, lead, and cadmium in fuel ethanol by anodic stripping voltammetry using a glass carbon–mercury–film electrode. Anal Bioanal Chem 380:135

Munoz RAA, Angnes L (2004) Simultaneous determination of copper and lead in ethanol fuel by anodic stripping voltammetry. Microchem J 77:157

Tartarotti FO, Oliveira MF, Balbo VR, Stradiotto NR (2006) Determination of nickel in fuel ethanol using a carbon paste modified electrode containing dimethylglyoxime. Microchim Acta 155:397

Takeuchi RM, Santos AL, Padilha PM, Stradiotto NR (2007) A solid paraffin-based carbon paste electrode modified with 2-aminothiazole organofunctionalized silica for differential pulse adsorptive stripping analysis of nickel in ethanol fuel. Anal Chim Acta 584:295

Takeuchi RM, Santos AL, Padilha PM, Stradiotto NR (2007) Copper determination in ethanol fuel by differential pulse anodic stripping voltammetry at a solid paraffin-based carbon paste electrode modified with 2-aminothiazole organofunctionalized silica. Talanta 71:771

Buffle J, Tercier-Waeber M-L (2005) Voltammetric environmental trace-metal analysis and speciation: from laboratory to in situ measurements. Trends Anal Chem 24:172

Baldo MA, Danielle S (2006) Voltammetric monitoring and speciation of copper ions in Italian “grappa” with platinum microelectrodes. Electroanalysis 18:633

Abdelsalam ME, Denuault G, Daniele S (2002) Calibrationless determination of cadmium, lead and copper in rain samples by stripping voltammetry at mercury microelectrodes—effect of natural convection on the deposition step. Anal Chim Acta 452:65

Hutton EA, Ogorevic B, Hocevar SB, Smyth MR (2006) Bismuth film microelectrode for direct voltammetric measurement of trace cobalt and nickel in some simulated and real body fluid samples. Anal Chim Acta 557:57

Palchetti I, Laschi S, Mascini M (2005) Miniaturised stripping-based carbon modified sensor for in field analysis of heavy metals. Anal Chim Acta 530:61

Legeai S, Soropogui K, Cretinon M, Vittori O, Oliveira AH, Barbier F, Loustalot MFG (2005) Economic bismuth-film microsensor for anodic stripping analysis of trace heavy metals using differential pulse voltammetry. Anal Bioanal Chem 383:839

Feinberg JS, Bowyer WJ (1993) Heavy metal determination and speciation: anodic striping voltammetry employing microelectrodes. Michrochem J 47:72

Tysczuk K, Korolczuk M (2007) Fast simultaneous adsorptive stripping voltammetric determination of Ni(II) and Co(II) at lead film electrode plated on gold substrate. Electroanalysis 19:1539

Xie X, Berner Z, Stüben D, Albers J (2005) Electrochemical behavior and analytical performance of an iridium-based ultramicroelectrode array (UMEA) Sensor. Microchim. Acta 150:137

Acknowledgements

Part of this work was developed at Minho University, Portugal, in a cooperation project. The authors are grateful to CAPES contract no. BEX 1088068 (ALS) and BEX 1087061 (RMT) for financial support for this project. The authors also thank the financial support from FAPESP (contract no. 03/05567-7 (ALS) and no. 03/09334-7 (RMT)). ALS and RMT are grateful to Prof. Maria José Medeiros, and especially to her student Cristina S. S. Neves for all help and friendship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takeuchi, R.M., Santos, A.L., Medeiros, M.J. et al. Copper determination in ethanol fuel samples by anodic stripping voltammetry at a gold microelectrode. Microchim Acta 164, 101–106 (2009). https://doi.org/10.1007/s00604-008-0039-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-008-0039-9