Abstract

Rock mass integrity is regarded as an important index to evaluate rock mass quality. Core drilling technology is one of the effective methods used for this. To overcome the problem of core discing and core breakage from the drilling process, a new evaluation method was proposed: a rock mass integrity index (RMIBT) based on high-definition digital borehole televiewer data. The RMIBT values were obtained by measuring the mass proportions of the length of the rock mass without macroscopic fractures on the borehole wall. Their scoring criteria were determined based on rock quality designation. It was applied in multiple deep rock excavations and therefore proved to be useful, especially where core discing occurs, in specific spatial distributions of structural planes, as well as logging errors from core breakages induced by drilling. In addition, the RMIBT can be used to assess dynamically the integrity of macroscopic rock masses and the evolution of fractures in the excavation damaged zone, thus providing a basis for the evaluation of rock masses in deep rock excavations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rock mass integrity is one of the key controlling factors for evaluating rock mass quality. Meanwhile, this index is an important reference for designing the excavation and support plans of rock engineering projects. Therefore, how to evaluate the integrity of engineering rock masses is of great significance to the construction of rock engineering works (Bieniawski 1973; Barton et al. 1974; Feng and Hudson 2011; Feng et al. 2013).

Core drilling technology has been widely used to assess rock mass integrity Takahashi et al. (2004). Rock quality designation (RQD) and the integrity coefficient K v of rock masses measured using acoustic wave method are the most representative and extensively used. However, the application of these coefficients to hard rock in deeply buried engineering works displays disadvantages as well. If elastic wave tests are used in deep rock masses, the wave velocity of rock masses is generally greater than that of rocks so that the measured results are invalid (Sayers 1988; Falls and Young 1998), but the measured wave velocity of a rock mass can describe the degree of rock mass integrity: the greater the wave velocity, the higher the rock mass integrity. The RQD, proposed by Deere in 1964, as an index, has been extensively used in various major engineering projects (Deere 1964, 1989). However, core discing and core breakage during drilling in the deep hard rock engineering lead to unreliable core information (Dyke 1989; Ishida and Saito 1995; Kaga et al. 2003). In addition, core information, as disposable information, fails to reflect the dynamic evolution of rock mass integrity. Moreover, deep hard rocks are mainly jointed masses, and the joints formed in the excavation process of surrounding rock tend to change the rock mass integrity. Furthermore, cracking in a rock mass is precursor information predicting problems from rockburst in deep mining and rib spalling. Hence, it is of significance to have a dynamic evaluation of the influence of fractured surrounding rock on the safety of deep mining engineering operations.

A digital borehole camera can intuitively reflect the geologic features in the boreholes without being affected by factors including core discing and core breakage, and it can evaluate the rock mass integrity by observing the fracturing of a rock mass at different stages of an excavations (Li et al. 2013). This research presented a rock mass integrity index based on a digital borehole televiewer (RMIBT) to meet the needs for better rockmass characterisation in deep located excavations. This method was applied in the deep underground laboratory in Jinping, and at Baihetan hydropower station, China. By comparing the RMIBT and RQD values with the acoustic wave velocities, the RMIBT method was verified as being reliable. Moreover, the idea behind the proposal of this evaluation method, and some relevant problems facing its application, were also discussed.

2 Evaluation of Rock Mass Integrity Based on RMIBT

2.1 RMIBT Formulae

The RMIBT coefficient refers to the mass proportion of the length of intact rock masses without macroscopic fractures on the borehole wall. It is calculated thus:

where L is the total length of the section to be estimated with unit of m; l 1, l 2, l 3, l 4, and l 5 represent the interval lengths of the rock masses without macroscopic fractures in the evaluated section with lengths being in ranges of 0.1–0.3, 0.3–0.5, 0.5–0.75, 0.75–1 m, and longer than 1 m, separately. Any section with a length below 0.1 m means it is broken: l i is divided according to the grading standards of joint spacing proposed by the International Society for Rock Mechanics, engineering practices in China and other countries, and the division bases in relevant specifications (Palmstrom 1996, 2005; Lau et al. 1987) and calculated using Eq. (2). where a i is the coefficient of the ith interval, and a 1 = 0.19, a 2 = 0.41, a 3 = 0.63, a 4 = 0.77, and a 5 = 1. a i is determined by global optimisation by genetic algorithm (see Sect. 5.2); \( l_{j}^{i} \) denotes the length of rock mass in the ith interval; n i represents the segments of rock masses in the ith interval.

Figure 1 illustrates the borehole walls and the distributions of rock masses in each length range obtained by using borehole televiewer technology. Based on this figure, this section evaluated is 3 m in length, where there are five, three, and one segments in the length ranges of l 1, l 2, and l 4 with the total lengths of segments in these ranges being 0.64, 1.07, and 0.91 m, respectively. Therefore, for this section, the RMIBT value is calculated as follows:

2.2 Classification of RMIBT

Although RQD is inapplicable to deep rocks under high stress undergoing core discing and core breakage, it can be applied in other conditions (see Sect. 3.1). RMIBT shows the characteristics of being consistent with RQD on the condition that is applicable for RQD and agrees with another method (acoustic wave velocities) in the case when RQD is inapplicable. Hence, classification of the RMIBT is based on the existing classifications of RQD, as shown in Table 1.

3 Engineering Application

To validate the feasibility of the RMIBT in deep engineering, the rock cores in deep engineering were classified initially. Then, the fractures in these rock masses (observed by borehole camera) were compared with the corresponding cores, as well as different kinds of cores with the corresponding sections imaged using the borehole camera. By doing so, the deep rock cores were classified into six categories based on the differences in the prevailing coring situations. Meanwhile, RMIBT was used in the deep underground laboratory in Jinping, and at Baihetan hydropower station, so as to analyse the applicability of the RMIBT in deep hard rocks. Besides, the feasibility of the RMIBT, its similarity to RQD and the wave velocity K v of rock masses were investigated in the corresponding sections.

3.1 Classification of Cores Drilled in Deep Hard Rock Masses Based on Rock Core Integrity and the Development Characteristics of the Structural Planes

After conducting the observations using the borehole camera on the cores drilled, the cores from the deep rock masses were analysed by comparing the obtained RQD values. It is known that there are a total of six types of cores in the deep rock masses investigated here.

I-Type Intact cores with few structural planes developed. Since structural planes are not formed under these conditions, and the RQD values acquired were close to the maximum value of 1, the RQD can reflect real conditions reflecting rock mass integrity (Fig. 2a).

II-Type Cores in massive structures with developed structural planes. Being separated by the penetrating fractures in the borehole, cores are in bulk sections. Under such conditions, the RQD values can describe the actual rock mass integrity (Fig. 2b).

III-Type Broken cores with produced structural planes. Since cores are broken due to the development of structural planes, the obtained RQD values are smaller than, or approximate to, 0. Therefore, the RQD can reflect rock mass integrity (Fig. 2c).

IV-Type Disc-shaped cores. Core discing refers to the phenomena whereby cores are broken into discs in the drilling and coring process after rock masses are excavated. Core discing is generally found in deep hard rocks. In the section with disc-shaped cores, the RQD values of intact or relatively intact cores are close to 0, which fail to reflect the rock mass integrity (Fig. 2d).

V-Type Broken cores with developed structural planes. When there are structural planes inclined perpendicular to the axis of boreholes, the cores drilled are broken. Under such circumstances, broken cores in a length being equal to, or longer, than 1 m are generated although there is only a single fracture. Thus, the RQD obtained cannot accurately reflect the rock mass integrity (Fig. 2e).

VI-Type Broken cores induced by the drilling, some cores with undeveloped structural planes are likely to be broken while being drilled from deep hard rocks. Therefore, the RQD obtained cannot accurately describe the rock mass integrity (Fig. 2f).

Therefore, RQD values cannot be applied to an evaluation of rock mass quality in all deep rocks. RMIBT calls for two conditions to be satisfied when applying it in a deep rock mass: (1) in the case that RQD is applicable, RMIBT needs to exhibit consistent performance with RQD, and match wave velocity data: (2) in the case that RQD is inapplicable, RMIBT should present good consistency with local wave velocity data.

3.2 Application of the RMIBT in the Deep Underground Laboratory in Jinping

The deep underground laboratory for Phase II in Jinping was constructed with its largest burial depth of 2375 m, setting a new world record. It is composed of four staggered experimental tunnels, each of which is 130 m in length and contains two laboratories measuring some 65 m in length. That is, the underground laboratory consists of four tunnels and eight laboratories (Fig. 3). From west to east, there are experimental tunnels numbered 1–4, respectively. The axes of these experimental tunnels are all parallel to that of the auxiliary tunnel. These tunnels present an axis azimuth of 58° (westward from north) and the cross section excavated is in a gate shape measuring 14 × 14 m.

Eleven boreholes in the deep underground laboratory at Jinping were selected as samples for the purposes of this research. Their layout may be seen in Fig. 3. The comparison of the RQD and RMIBT results from of these boreholes is shown in Table 2. The longer the length of IV-, V- and VI-type cores in the boreholes, the larger the difference between the RMIBT and RQD. When there are no IV-, V- or VI-type cores, or their lengths are small, the RMIBT results obtained are similar to RQD values.

The C-03 borehole was taken as an example to illustrate the influence of IV-, V-, and VI-type cores on the integrity of the whole rock mass. Being 60 m long, the C-03 borehole was divided into 20 segments with each evaluation unit being 3 m long. According to the classification of cores mentioned in Sect. 3.1, the RQD and RMIBT values of these segments were calculated. As seen from Table 3, there were seven, three, one, three, one, and five segments of the I-type intact cores, II-type disc-shaped cores, III-type lumpy cores, IV-type broken cores, V-type broken cores, and VI-type broken cores, respectively.

As shown in Figs. 4 and 5, the RQD values of the I-, II-, and III-type cores are close to the RMIBT values, showing an average error of 6.5%. In contrast, an apparent difference is found between the RQD and the RMIBT values of the IV-, V-, and VI-type cores with an average error of 52.7%. This is caused by the discing and breaking of the cores.

By comparing acoustic wave velocities, RQD, and RMIBT of the rock mass in borehole C-03, as demonstrated in Fig. 6, it can be found that the RQD and acoustic wave velocity corresponded well with RMIBT in segments without broken and disc-shaped cores. While the RQD values of the segments (where the actual acoustic wave velocities are high) with broken and disc-shaped cores are less than 0.4. In comparison, the RMIBT values of about 0.8 can preferably reflect the rock mass integrity.

A similar conclusion was obtained from the calculation when applied to other holes in the Jinping underground laboratory. That is, the RQD values of the I-, II-, and III-type cores are similar to the RMIBT values, while an obvious difference is found between the RQD and the RMIBT values of the IV-, V-, and VI-type cores.

3.3 Application of the RMIBT in Baihetan Hydropower Station

There are two powerhouses under the left and right banks of Baihetan hydropower station. Thereinto, the one under the right bank has a burial depth of 420–520 m, while the other one is buried some 260–330 m beneath the left bank. The underground powerhouse area is located in monoclinal strata, which are NE 42°–45° trended with a south-eastward inclination of 15°–20°. Mainly containing basalt, the surrounding rocks contain fresh and hard rock masses with good integrity. They are mostly in bulks and secondary bulks, together with small amounts of block fractures. The surrounding rocks mainly consist of III1 types, while a few IV-type surrounding rocks are found locally. Figure 7 shows the borehole layout, while Table 4 displays the results of the comparison between the RQD and RMIBT values at each borehole, which are the same as those obtained from Jinping underground laboratory.

By taking borehole L-320-0-1, which is 27.9 m in depth, in the Baihetan hydropower station as an example, 11 segments were acquired by dividing the borehole into evaluation units of 2.5 m in length. Based on the classification of rock cores (Sect. 3.1), the RQD and RMIBT values of each segment were calculated. According to the results obtained (Table 5), it was found that there are four segments of I-type intact cores, one segment of II-type disc-shaped cores, five segments of III-type lumpy cores, and one segment of IV-type broken cores.

As shown in Fig. 8, the RQD, acoustic wave velocity and RMIBT data were compared. It can be found that there is a structural plane whose inclination is perpendicular to the axis of the boreholes with a trace length of 1.1 m in segment A (7.5–10 m) of the borehole. The cores drilled at this place were broken. Under such conditions, although there was only a single fracture, broken cores with a total length of 1.2 m were obtained so that the RQD values of segment A failed to reflect the rock mass integrity with any accuracy. The RQD and acoustic wave velocities of other segments are similar to the RMIBT values.

4 Evolution of RMIBT During Excavation

During excavation of tunnels or caverns in high-stress regimes, the integrity of surrounding rocks changes with the development of the excavation damaged zone. That is, new fractures are supposed to develop in the originally intact surrounding rocks owing to excavation disturbance or ageing effects. As a result, the integrity of surrounding rocks decreases; however, the results obtained using traditional methods of evaluating rock mass integrity are not comprehensive and therefore fail to mirror this change. Therefore, they cannot describe the exact conditions reflecting rock mass integrity.

4.1 RMIBT Evolution Due to Excavation of 4# Lab. in Jinping Deep Underground Laboratory

This study investigated the evolution of rock mass integrity due to the excavation disturbance caused during the first two steps according to the pre-set borehole C-07 which was 33.5 m long in the deep underground laboratory in Jinping (Fig. 9).

The RMIBT value of the borehole before being excavated was calculated as 0.51 by taking the segment from 27 to 29.5 m depth as an example. The result showed that the rock mass integrity was fair. As excavation in S1 was completed, four new fractures were observed in the section on 3 August, 2015 and the RMIBT value was computed as 0.37, while, when the excavation in S2 was finished, five additional fractures were observed. At this time, the RMIBT value was found to be 0.23. This indicates that the rock mass integrity in the evaluated section changed from fair to very poor (Figs. 10, 11). The ranges of influences of the fractured zones reached 1.4 m.

4.2 RMIBT Evolution Due to the Excavation of the Main Powerhouse in Baihetan Hydropower Station

By studying the pre-set borehole L-330-0-2 in the arch of the powerhouse under the left bank of Baihetan hydropower station, this research investigated the change in rock mass integrity caused by excavation disturbance. Being 27.4 m in depth and 110 mm in diameter, the borehole is a borehole pre-set under the anchor cavern, and above the powerhouse, to observe the evolution of damaged zones in the powerhouse area. The section over a length of 1.5 m from 24.5 to 26 m deep was evaluated based on the borehole televiewer placed in the position shown in Fig. 12.

As shown in Fig. 13, the initial RMIBT obtained from the pre-set borehole was 1, which suggested that it was an excellent rock mass. When excavation in S1 was completed, three additional fractures were found, which decreased the RMIBT to 0.81, while, when excavation in S2 was completed, fractures were continuously generated: four new fractures were found and the integrity coefficient decreased to 0.52. Therefore, the rock mass integrity in the evaluated section evolved from excellent to fair. The fractured zones have a range of influence of 0.8 m (Fig. 14).

5 Discussion

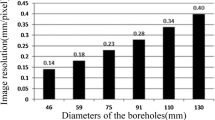

5.1 Influence of the Length of Evaluation Units on the RMIBT

The integrity coefficients calculated using different lengths L of evaluation unit are dissimilar, and practice indicates that the longer the evaluation unit, the more obvious this was. Therefore, certain standards require to be used to determine the lengths of the evaluation units used. The lengths of evaluation units are mainly influenced by two factors: evaluation purpose and the total length L of the evaluated section. The lengths of the units for estimating macroscopic geological conditions and the evolution of fractures in excavation damaged zone are quite different. Moreover, the length of the evaluation units varies with that of the evaluated section. In general, the evaluated sections in macroscopic geological surveys are tens, or even hundreds, of metres long. Therefore, when the evaluation units are short, many calculations are needed. While estimating the range of excavation damaged zones, the lengths of boreholes are short, as the excavation damaged zones are basically within a range of 1–3 m in deep rock masses with large sections. Therefore, evaluation units with different lengths were adopted for different evaluated sections.

In macroscopic geological surveys, the evaluation units are supposed to be longer with the increase of the length of the evaluated sections, as shown in Fig. 15. When the borehole is 60 m deep, the RMIBT values acquired with an evaluation unit of 3 m in length can preferably reflect the microscopic quality of rock masses. The evaluated section in excavation damaged zones is generally short as the zones range from 1 to 3 m in deep rock masses with large sections. Under such conditions, evaluating at the metre-scale is not justifiable, and therefore, 100 or 200 mm unit lengths are used in the evaluation of rock mass integrity in excavation damaged zones through acoustic wave tests. Practice indicates that the results acquired with evaluation units of 100 or 200 mm are similar, so it is suggested that any evaluation of excavation damaged zones uses an evaluation unit some 200 mm long (Fig. 16). In addition, the results obtained under such conditions correspond well with those obtained from acoustic wave tests.

5.2 Determination of a i

It can be found from the classification of RMIBT values that rock masses without macroscopic fractures on the borehole wall longer than 1 m can be considered intact: their corresponding RMIBT value is 1 so that coefficient a 5 can be determined as also being 1. Therefore, to determine the value of a i , we just need to select suitable values of a 1, a 2, a 3, and a 4. Based on the global optimisation abilities of a genetic algorithm (Feng and Yang 2001, 2004), a i is determined by globally optimising the borehole samples. In this way, the determination of coefficients is changed to solve for a i in Eq. (3). By solving Eq. (3) using a genetic algorithm, multiple groups of a i values can be obtained. The acquired a i values, which make the RMIBT values closest to the core RQD values (excluding IV-, V-, and VI-types), are optimal. That is, the optimised a i values only require the minimisation of the absolute difference between the RMIBT and RQD sample values. What must be noted is that the IV-, V-, and VI-type cores cannot accurately reflect rock mass integrity according to the classification of cores demonstrated in Sect. 3.1. Therefore, the IV-, V-, and VI-type cores are not taken into account in the calculation of a i values.

where L is the total length of the evaluated section; l i represents the length of the intact rock mass in the ith evaluated interval; a i shows the coefficient of the corresponding intervals (1 ≤ i ≤ 4).

Fourteen boreholes in the deep underground laboratory in Jinping (different from those shown in Sect. 3.2), ten boreholes in the Jinping II diversion tunnel, and eight boreholes in the Baihetan hydropower station (dissimilar to those presented in Sect. 3.3) were selected as samples for analysis. In addition, data were also collected from four boreholes in Wudongde hydropower station and six boreholes in Hongtoushan mine. Using an evaluation unit some 3 m long, these boreholes were divided into 207 samples without considering the IV, V, and VI RQD values which cannot reflect the rock mass integrity in each borehole. The borehole obtained information is summarised in Table 6. Using Eq. (3), based on global optimisation by genetic algorithm, the acquired optimal solutions are a 1 = 0.19, a 2 = 0.41, a 3 = 0.66, and a 4 = 0.74.

After obtaining the final a i values, all evaluation units are arranged in the descending order of their RQD values. By comparing the RMIBT values calculated by using the acquired a i values, it can be found from Fig. 17 that the overall error rate is 5.9%.

6 Conclusions

To evaluate more accurately the integrity of deep rock masses, this research proposed a new method—RMIBT method for evaluating the integrity of deep rock mass based on the results acquired using high-definition, digital borehole televiewers. RMIBT is proven to be more applicable to the evaluation of deep hard rock, and especially to the assessment of core discing, given a specific spatial distribution of the structural planes, as well as core breakage induced by drilling. Moreover, the RMIBT can dynamically estimate the macroscopic rock mass integrity and the evolution of fractures in excavation damaged zones. The application of the RMIBT to works at Jinping underground laboratory and Beihetan hydropower station indicates that the proposed system provides an alternative and practical method in the integrity evaluation of deep buried engineering projects.

References

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech Rock Eng 6(4):189–236

Bieniawski ZT (1973) Engineering classification of jointed rock masses. Civil Eng S Afr 15:335–343

Deere DU (1964) Technical description of rock cores for engineering purposes. Rock Mech Rock Eng 1(1):17–22

Deere DU (1989) Rock quality designation (RQD) after 20 years. US Army Corps Engrs Contract Report GL-89-1. Waterways Experimental Station, Vicksburg

Dyke CG (1989) Core discing: Its potential as an indicator of principal in situ stress directions. IMHEF-LMH 17(6):681–684

Falls SD, Young RP (1998) Acoustic emission and ultrasonic-velocity methods used to characterise the excavation disturbance associated with deep tunnels in hard rock. Tectonophysics 289(1–3):1–15

Feng X, Hudson JA (2011) Rock engineering design. CRC Press, Boca Raton

Feng X-T, Yang CX (2001) Genetic evolution of nonlinear material constitutive models. Comput Methods Appl Mech Eng 190(45):5957–5973

Feng X-T, Yang CX (2004) Coupling recognition of the structure and parameters of non-linear constitutive material models using hybrid evolutionary algorithms. Int J Numer Meth Eng 59(9):1227–1250

Feng X, Zhang C, Qiu S, Zhou H, Jiang Q, Li S (2013) Dynamic design method for deep tunnels at hard rocks. Science Press (in Chinese)

Ishida T, Saito T (1995) Observation of core discing and in situ stress measurements; stress criteria causing core discing. Rock Mech Rock Eng 28(3):167–182

Kaga N, Matsuki K, Sakaguchi K (2003) The in situ stress states associated with core discing estimated by analysis of principal tensile stress. Int J Rock Mech Min Sci 40(5):653–665

Lau JSO, Auger LF, Bisson JG (1987) Subsurface fracture surveys using a borehole television camera and acoustic televiewer: reply. Can Geotech J 24(4):499–508

Li S-J, Feng X-T, Wang CY (2013) ISRM suggested method for rock mass fractures observations using a borehole digital optical televiewer. Rock Mech Rock Eng 46(3):635–644

Palmstrom A (1996) Characterizing rock masses by the RMI for use in practical rock engineering, part 1: the development of the rock mass index (RMI). Tunn Undergr Space Technol 11(2):175–188

Palmstrom A (2005) Measurements of and correlations between block size and rock quality designation (RQD). Tunn Undergr Space Technol 20(4):362–377

Sayers CM (1988) Inversion of ultrasonic wave velocity measurements to obtain the microcrack orientation distribution function in rocks. Ultrasonics 26(35):743–749

Takahashi T, Takeuchi T, Sassa K (2004) ISRM suggested methods for borehole geophysics in rock engineering. Int J Rock Mech Min Sci 41(6):885–914

Acknowledgements

The work is financially supported by the National Natural Science Foundation of China (Grants Nos. 41320104005, 11232024 and 51579043), and the State Key Research Development Program of China (Grant No. 2016YFC0600702). The authors appreciate the value added through discussion of the work with Dr. Ya-Xun Xiao.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, HS., Feng, XT., Li, SJ. et al. Evaluation of the Integrity of Deep Rock Masses Using Results of Digital Borehole Televiewers. Rock Mech Rock Eng 50, 1371–1382 (2017). https://doi.org/10.1007/s00603-017-1173-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1173-7