Abstract

Leak-off pressure and lost circulation data are generally thought to be reflective of minimum stress. We propose an alternative interpretation should be considered where the data may reflect a shear failure along zones of pre-existing weakness rather than opening of tensile fractures against the minimum stress. This mechanism has been discussed in a small number of borehole stability and hydraulic fracture papers, but has not been widely applied to leak-off test or lost circulation interpretation. In this paper, we will revisit and expand the concept introduced recently by Couzens-Schultz and Chan (J Struct Geol, doi:10.1016/j.jsg.2010.06.013, 2010) based on abnormally low leak-off tests in an active thrust belt to the analysis of lost circulation observations in modern-day deltaic environments. In the Gulf of Mexico, lost circulations historically are interpreted as a representation of the minimum horizontal stress due to initiating or reopening of a fracture in tensile mode. However, shear failure or fault reactivation can occur at pressures well below the minimum far-field stress that is typically considered a safe upper bound for mud pressure if pre-existing planes of weakness such as faults or fracture networks exist. We demonstrated a mud loss event is shown to be inconsistent with the tensile failure mode in a normal stress environment, but in good agreement with expectations for shear failure along pre-existing faults.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Accurate in situ stress characterization has significant influence on field development plans. The magnitude and direction of the in situ principal stresses also affect the acoustic and electrical rock properties that are used for quantitative interpretation (QI), seismic imaging, reservoir presence and quality predictions, and pore pressure and fracture gradient predictions in exploration settings. During appraisal and development phase, for example, a well-constrained stress model will impact casing design, identification of drilling hazards, choice of well trajectory and stability criteria, completion and depletion strategy, and studies of fault reactivation, subsidence, and reservoir compaction.

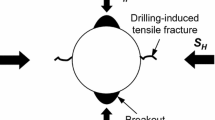

In modern-day deltaic environments, vertical stress, S v, is often assumed to be one of the principal stresses and is usually derived from density logs along with some empirical relationship for the shallow section where logs are unavailable. Pressure values obtained from leak-off tests (LOT) and other fracture treatments are routinely associated with the minimum horizontal principle stress, S h. While most S h observations are limited to discrete points, numerous efforts have been made to predict Sh based on empirical relationships or continuum mechanics (e.g., Bell 1990, 2003; Breckels and van Eekelen 1982; De Bree and Walters 1989).

Recent global exploration into deep water fold and thrust belts has yielded some interesting observations in which several leak-off pressure (LOP) interpretations lead to stress states that are inconsistent with geological observations (see Couzens-Schultz and Chan 2010 for a more detailed discussion). To explain the inconsistencies, Couzens-Schultz and Chan (2010) proposed that shear failure occurs during some LOT’s, and this can be used in addition to traditional methodologies to constrain the stress state in an area in a way that is consistent with all other observations.

The original hypothesis primarily focused on characterizing in situ stress in compressional settings where the discrepancies between observations from LOP and geological/geophysical data are the most obvious. In this paper, we highlight an unusual lost circulation event observed in deepwater Gulf of Mexico. This loss event occurred at a much lower pressure than the regionally calibrated minimum horizontal stress model. Using a similar approach to that used in compressional settings, we illustrate the possibility of fluid-invasion-induced shear failure as a potential mechanism for this event in a normal faulting stress regime.

One of the key differences between the conventional tensile failure interpretation of a loss event and our alternate interpretation is the characterization of in situ stress. The two interpretations will lead to two different estimates of S h that could have a significant influence on how a regional scale geomechanics model will be calibrated. A tensile mode implies a large stress drop at the formation or location where the lower-than-expected lost circulation or leak-off pressures are observed, while shear reactivation of a pre-existing fault may favor a higher in situ minimum stress despite the lower observed failure pressure.

2 The Mud Loss Event at Well A

Stress models that are regionally calibrated against LOT and lost circulation data have been successfully deployed in most of our deepwater Gulf of Mexico fields. However, a recent loss event at one of the development wells appears to violate the locally calibrated pre-drill in situ stress model. The loss occurred when the wellbore was re-entered for a cleanout trip after the downhole data acquisition was completed. When the bottom-hole assembly (BHA) reached the target, the pumps were turned on, and losses were reported when the downhole equivalent circulating density (ECD) pressure gradient reached 10.32 ppg (1 pounds per gallon ≈ 119.83 kg/m3) measured by an annular pressure gauge on the logging while drilling (LWD) collar. A total of 200 barrels of synthetic oil-based mud were lost before the downhole pressure gradient was lowered to 10.11 ppg by changing the pump rate and the losses stopped. On a subsequent pass of the BHA, the loss zone was identified on the resistivity log, which highlights where the oil-based mud invaded the formation. The losses occurred in a 60-foot thick section of mudrocks about 200 feet below the base of the objective sand (Fig. 1).

Wireline logs across the loss zone at Well A. Left track shows gamma ray log. The next track shows resistivity; the blue resistivity log was measured while drilling and the black resistivity log was measured after drilling (MAD pass) during a trip out. The Red zone in the resistivity track shows where oil-based muds penetrated the formation, highlighting the lost circulation zone. The right track shows pore pressure gradient. The blue line is hydrostatic, the orange line is overburden, the green curve is the estimated minimum horizontal stress and the black line is the maximum equivalent circulating density (ECD) seen during the mud loss event. The maximum ECD is consistently 0.8–1.2 ppg less than the lowest bound of the estimated minimum stress (color figure online)

The loss event occurred in low permeability mudrock at a pressure significantly less than the predicted S h. At the top of the loss zone, overburden stress, based on density log integration, is 13.1 ppg. The pre-drill minimum horizontal stress, based on the regional model, is 11.2–11.3 ppg. The lost circulation pressure is constrained to be between 10.1 ppg, where losses were controlled to 10.3 ppg, which is the highest pressure seen at that depth. Therefore, the lost circulation pressure is 0.8–1.2 ppg lower than the pre-drill minimum horizontal stress prediction.

We consider four potential explanations for why the lost circulation pressure was significantly less than the predicted minimum horizontal stress: (1) the mud loss event was related to a lithologic effect; (2) the loss was induced by hole cleaning; (3) the minimum horizontal stress was in fact less than expected; or (4) the mud loss event occurred due to shear failure on a fault or fracture zone. Within the shallow depth of the field, loss events have been tied to anomalously hard tight zones and hard intervals at sand–shale interfaces. In this case, the loss zone is clearly in mudrock, and the petrophysical characteristics of the mudrocks in the loss zone appear similar to the surrounding mudrocks. Therefore, we discount lithologic changes as a contributor. During hole cleaning, a pack off event may have forced mud into the formation; however, the absence of spikes in the recorded downhole annular pressure and the similarity of the MWD annular and internal pressure records suggest that the loss was unrelated to hole cleaning. Minimum stress may be locally lower than predicted, requiring the stress models for field development and drilling plans to be updated to include local stress drops. However, because such stress drops have not been observed in other wells in the area, it is in our view unlikely that minimum stress would vary widely over short vertical distances. Instead, our hypothesis is that the stress model is approximately correct and the loss event occurred because of shear failure on a fault zone penetrated by the well. In the following section, we investigate that possibility by back calculating the implied stress state for shear failure and comparing that to the pre-drill minimum stress prediction.

3 Shear Failure Interpretation

We used the approach applied by Couzens-Schultz and Chan (2010) to characterize the in situ stress assuming a shear failure mechanism during the loss event. Figure 2 summarizes the conceptual model for how drilling fluid could invade a fracture system, reactivate it, and create volume during shear dilation. For further discussion of this mechanism and its assumptions, please see Couzens-Schultz and Chan (2010). Figure 2c illustrates how stresses consistent with shear failure on a fracture or fault can be determined. The method requires (1) defining the shear failure envelope using a cohesion and a coefficient of friction, (2) shifting the failure envelope by a critical change in pore pressure required to slip on the fractures or faults, which in this case is assumed to be the lost circulation pressure, and (3) using the vertical stress, S v, as one of the principal stresses.

We use the stress polygon (see Zoback et al. 1987) to constrain the potential stress state at a given depth (NF normal faulting, SS strike slip, RF reverse faulting). S v is the overburden stress. a Conventional interpretation of stress from a leak-off pressure (LOP). b Our new alternative interpretation of stress states represented by shear failure on a pre-existing weak zone during a leak-off test, where the range of possible stresses is shown by the red polygon. c We constrain the stress state in (b) by assuming a frictional failure envelope and using the known S v and LOP. (Modified after Couzens-Schultz and Chan 2010) (color figure online)

For the failure criterion, we assume that cohesion on the fracture or fault system is negligible. This is consistent with an uncemented fracture zone. In practice, we typically have no measurements to constrain the sliding coefficient of friction on a fault. In mudrocks, it can range from almost 0–0.7 depending on geopressures and lithology. At Well A, the fluid pressure is just slightly above hydrostatic, making a low coefficient of friction less likely. The mudrocks in the upper portion where the loss event occurred consist of 55–60 % silt and 40–45 % clay minerals. The clay mineral composition is 30–40 % mixed-layer clays, 40–55 % illite, and 10–15 % chlorite and kaolinite. Fault rock dominated by mixed-layer clays tends to have lower coefficients of friction (0.2–0.4), whereas those dominated by silts tend to have high friction angles (0.6–0.7, Lockner and Beeler 2002). Illite-dominated fault rock falls in an intermediate range (0.4–0.5, Lockner and Beeler 2002). Since the mudrocks in this interval are about half silt and more than half the clay mineral content is illite, chlorite, and kaolinite, we chose to investigate the sensitivity of our results using a range of friction coefficients from 0.4 to 0.6. For simplicity, we show the results using a coefficient of friction of 0.5 in Figs. 3 and 4.

Stress polygon at the depth of the lost circulation zone. Vertical axis shows the maximum horizontal stress and horizontal axis shows the minimum horizontal stress; 0.5 was used as the coefficient of friction in the calculations; see text for justification. The gray vertical line shows the estimated minimum horizontal stress from the regional model. The green box shows the range of stresses consistent with tensile opening of fractures at the observed lost circulation pressures. The blue lines show the ranges of stresses consistent with shear failure along an optimally oriented fracture at the observed lost circulation pressures (color figure online)

Stress polygon from Fig. 4 highlighting three stress scenarios in the normal-fault stress field. A lower hemisphere stereoplot is shown for each stress scenario showing the poles to the nearby fault planes. The range of colors in the stereoplots shows where the observed lost circulation pressures are consistent with shear failure on a fault plane in that orientation. Where the plots are dark red, the pressure needed to reactivate a fault in that direction is higher than the highest observed ECD pressure. In all three stress cases, faults oriented similar to the two faults that seismically tip out near Well A will fail in shear at the observed ECD pressures (color figure online)

Applying the failure criterion described above and the method described in Couzens-Schultz and Chan (2010) to the loss event in the Well A, we arrive at the stress polygon shown in Fig. 3. The blue area in the stress polygon shows the stress states of all viable Mohr circles that represent shear failure on pre-existing fault or fracture zone at the lost circulation pressure. The area is bounded by the results for high and low values (10.1 and 10.3 ppg, respectively) for the loss event. The original work from Couzens-Schultz and Chan (2010) was primarily focused on interpreting abnormally low LOT and mini-fracture data in compressional settings. Their work utilizes the horizontal section of the blue line in the reverse-fault regime for interpreting the LOT values that would otherwise be inconsistent with geological observations. In this paper, we apply the same conceptual model to investigate shear failure in the normal-fault stress regime and are therefore interested in the vertical portion of the blue line.

The pre-drill in situ minimum horizontal stress, S h, prediction from the regional model is shown as the dark gray line in Fig. 3. If we interpret the loss event at Well A as a result of tensile failure against S h, then the lost circulation pressure implies that the S h lies outside the stress polygon (red box in Fig. 3). In this situation, the formation would not be able to sustain the stress contrast between overburden S v and S h and should be undergoing active normal faulting. Therefore, it is not likely that loss event reflects minimum stress.

If we interpret the loss event to be a result of shear failure along a fracture or fault zone, then the lost circulation pressure implies that the in situ S h is very close to the pre-drill S h prediction, well within the bounds of a stable formation (vertical blue zone in Fig. 3). We can get a similar result using a coefficient of friction equal to 0.4 or 0.6, but any higher or lower, and the result will no longer match the pre-drill S h prediction. Assuming that shear failure is the failure mechanism that trigger the lost event, we now consider what faults might be reactivated and how favorable those fault orientations are for reactivation. The original well plan was designed to avoid major faults near the objective section; however, the well does penetrate the objective near the seismically resolvable tips of two faults (Fault A and Fault B). Comparison of the Well A logs to the logs in a nearby bypass well implies that some section is missing beneath the objective in Well A where the losses occurred, supporting a possible fault cutout. From seismic, we can determine the trend and the dip of these two nearby fault planes and use that along with local knowledge of the regional stress orientations to determine whether one or both of these faults are favorably oriented for slip.

Caliper analysis for breakouts has been performed with other nearby offset wells to determine the S H orientation in the area that indicated the S H orientation is approximately NW–SE. In addition to borehole breakout analysis, we have compared stress orientations supported by faults with seafloor expression and those supported by fractures picked from downhole image logs from offset wells. The results further support the E–W SH orientation assumed at the Well A location. The stress magnitudes are constrained for S v from density log integration and Sh from our stress calculations above, S H, however, remains uncertain. Three scenarios were examined to illustrate end-member scenarios for the loss event (S H = S v; S H = S h; S H = (S v + S h)/2). With the stress magnitudes and orientation defined, we can calculate the critical fluid pressure needed to initiate failure on a fault plane oriented in any direction.

In Fig. 4, lower hemisphere stereoplots show the critical fluid pressure needed to reactivate a fault of any given direction. The plots show the pole to any fault plane. The color bar is set to critical fluid pressures between 10.1 and 10.3 ppg, which corresponds to the ECD mud pressures observed during the loss event at Well A. Where the plot is dark red, the pressure needed to reactivate a fault in that orientation is higher than the highest observed ECD pressure. The ECD pressures observed in the well would reactivate faults that lie in the orange to blue color band. Note that the lowest possible ECD pressure that could reactivate a fault is about 10.2 ppg and the observed losses occurred somewhere between 10.1 and 10.3 ppg. The two faults near the loss zone in Well A are plotted as circles on the stereoplot. Several stress scenarios are consistent with Fault B being reactivated in shear failure by the ECD pressures observed in Well A. Meanwhile, Fault A could also be reactivated if the two horizontal stresses are close to equal in magnitude. Unfortunately, operational constraints limited our ability to re-enter the wellbore and obtain further evidences of the proposed fault movements.

4 Conclusions

Tensile opening of fractures is the conventional failure interpretation used to explain losses in impermeable sections. This interpretation is widely used for calibrating fracture gradient and/or minimum horizontal stress, S h, from loss events. Couzens-Schultz and Chan (2010) concluded that leak-off pressure in compressional stress regimes sometimes reflects shear failure along pre-existing weak zones, such as faults or fractures, rather than tensile fracture failure. In this paper, we extend their hypothesis to explain a loss event in a normal faulting stress regime. A loss event that occurred just beneath the objective sand in Well A is not consistent with the regional stress model, which is well constrained by high-quality leak-off test and lost circulation pressure data from several wells. The lost circulation pressure was about 0.8–1.2 ppg lower than expected. We rule out lithologic effects and hole cleaning as likely explanations for the loss event. We propose that the lost circulation pressure does not directly reflect minimum stress. Instead, it reflects the critical pressure needed to cause shear failure on a fault zone. We complete the analysis by identifying three candidate fault orientations for reactivation and determining the ECD mud pressure required to initiate shear failure on those faults. The ECD pressures needed closely match the observed ECD pressures during the loss event. Finally, the minimum horizontal stress needed to match the observed ECD pressures and allow shear reactivation on the faults is in agreement with the predicted minimum stress from the regional model. Therefore, no modification to the regional stress model is needed. This directly impacts future wellbore stability modeling and water injection performance modeling for the field.

Abbreviations

- S v :

-

Vertical stress

- S H :

-

Maximum horizontal stress

- S h :

-

Minimum horizontal stress

References

Bell JS (1990) Investigating stress regimes in sedimentary basins using information from oil industry wireline logs and drilling records. Geol Soc Lond Spec Pub 48(1):305–325. doi:10.1144/GSL.SP.1990.048.01.26

Bell JS (2003) Practical methods for estimating in situ stresses for borehole stability applications in sedimentary basins. J Petrol Sci Eng 38:111–119

Breckels IM, van Eekelen HAM (1982) Relationship between horizontal stress and depth in sedimentary basins. In: Society of Petroleum Engineers. SPE-10336. doi:10.2118/10336-PA

Couzens-Schultz BA, Chan AW (2010) Stress determination in active thrust belts: an alternative interpretation of leakoff pressure measurements. J Struct Geol. doi:10.1016/j.jsg.2010.06.013

De Bree P, Walters JV (1989) Micro/minifrac test procedures and interpretation for in situ stress determination. Int J Rock Mech Min Sci Geomech Abstr 26(6):515–521

Lockner DA, Beeler NM (2002) Rock failure and earthquakes. In: International handbook of earthquake and engineering seismology, International Geophysics, vol 81, Part A, pp 505–538

Zoback MD, Mastin L, Barton C (1987) In situ stress measurements in deep boreholes using hydraulic fracturing, wellbore breakouts and Stonely wave polarization. In: Stefansson O (ed) Rock stress and rock stress measurements, proceedings of conference in Stockholm, Sweden. Centrek Publ, Lulea, pp 289–299

Acknowledgments

We thank Shell International Exploration & Production Incorporated (SIEP) and Shell Exploration & Production Company (SEPCo) for permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chan, A.W., Hauser, M., Couzens-Schultz, B.A. et al. The Role of Shear Failure on Stress Characterization. Rock Mech Rock Eng 47, 1641–1646 (2014). https://doi.org/10.1007/s00603-014-0585-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0585-x