Abstract

Planes of weakness like schistosity and foliation affect the strength and deformational behaviors of rocks. In this paper, an attempt has been made to study the elastic and strength behavior of slate rocks obtained from foundation of Sardasht dam site in Iran. Wet and dry specimens with different orientation of foliation were evaluated under uniaxial, triaxial, and Brazilian tests. According to the results obtained, slate mechanically pronounced U-shaped anisotropy in uniaxial and triaxial compression tests. In addition, the degree of anisotropy for the slates tested in current study was relatively high, showing the effect of foliation plane on strength and elastic parameters. It was concluded that stiffness of the samples decrease as the angle of anisotropy reaches 30–40°. This change was more pronounced for wet comparing to dry samples. However, the tensile strength obtained during Brazilian tests indicated that there is no apparent relationship between angle of anisotropy and tensile strength. However, increasing the water saturation decreased the tensile strength of the samples. The calculated elastic moduli referring to different anisotropy angles could be valuable for the design of various engineering structures in planar textured rock masses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Anisotropy is the inherent characteristics of rocks in civil, mining, and petroleum engineering projects. According to Amadei (1996) many rocks near the Earth’s surface show well-defined fabrics in the form of bedding, stratification, layering, foliation, fissuring or jointing. These rocks can then have properties (e.g. physical, dynamic, thermal, mechanical, hydraulic, etc.) which vary in different directions inducing anisotropic behavior. The extent of anisotropy may differ from the microstructures in intact laboratory-sized specimens to large fracture planes in a rock mass. For non-fractured rocks, anisotropy is a characteristic of intact foliated metamorphic rocks (e.g., slates, gneisses, phyllite, schist, etc.). Anisotropy is also a characteristic of intact laminated, stratified or bedded sedimentary rocks, such as shales, sandstones, siltstones, limestones, and coal. Due to variety of rocks with anisotropic behavior, neglecting the effect of anisotropy may increase the error in stress measurements (Hakala et al. 2007; Min et al. 2003), displacement controls (Wang et al. 2003), and damage estimation during underground construction (Everitt and Lajtai 2004; Song et al. 2004). The rock anisotropy has also remarkable effect on tunnel boring machine (TBM) rock-cutting performance (Gong et al. 2005) and is considered important in drilling operations in petroleum and geothermal engineering (Stjern et al. 2003) and in a broader sense in different rock engineering projects (Amadei et al. 1983; Barla 1974).

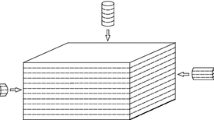

Two anisotropic models are commonly used to describe the behavior of rocks which include orthotropic and transversely isotropic models. The orthotropic model, which is characterized by nine independent elastic constants and three orthogonal planes of elastic symmetry, has been applied mainly for studying coal deposits (Ko and Gerstle 1976; Szwilski 1984). The transversely isotropic (TI) model is characterized by five independent elastic constants and one plane of elastic symmetry. This model is one of the most popular models in rock engineering due to its simplicity and applicability in determination of anisotropic parameters with limited data (Hakala et al. 2007; Song et al. 2004; Exadaktylos 2001; Nasseri et al. 2003; Gonzaga et al. 2008). Due to the popularity of this type of rock, close attention has been paid to mechanical behavior of rocks showing anisotropic behaviors (Nova 1980; Jyh Jong et al. 1997; Gatelier et al. 2002; Tien and Tsao 2000; Saroglou and Tsiambaos 2008; Tavallali and Vervoort 2010). Many research works have also been carried out to measure the strength of various rocks with TI behaviour, e.g. Donath (1964), Hoek (1968), Attewell and Sandford (1974) and Brown et al. (1977) on shale and slate; Deklotz et al. (1966), Akai et al. (1970), McCabe and Koerner (1975), Nasseri et al. (1996, 1997) and Singh et al. (2001) on gneiss and schist; Ramamurthy (1988) on phyllites; Horino and Ellicksone (1970), Rao et al. (1986) and Al-Harthi (1998) on sandstones; Pomeroy et al. (1971) on coal; Allirote and Boehler (1970) on diatomite and Tien and Tsao (2000) on artificial materials. As a result of these studies, it has been noted that the maximum strength can be observed at angles β = 0° or β = 90°, whereas the minimum strength occurs at an approximate angle of β = 30°. See Fig. 1. Here, β is the angle between the plane of weakness (i.e., foliation or bedding planes) and direction of maximum loading applied on the sample (Fig. 1, left).

Schematic representation of a transversely isotropic rock with only a single foliation plane (left) and its strength variation under uniaxial test as a function of orientation of the foliation plane with respect to direction of maximum applied stress (right) (modified from Hudson and Harrison 1997)

In this paper, strength and elastic properties of slate samples taken from Sardasht dam site of Iran were studied under uniaxial, triaxial, and Brazilian tests to determine their elastic and strength behavior. Stiffness and strength corresponding to different angles of anisotropy were plotted and the results presented and interpreted.

2 Different Types of Anisotropy

In 1989, Singh et al. classified anisotropy based on the shape of the curve exhibited by plotting the uniaxial strength versus the angle of anisotropy, generally known as β (Singh et al. 1989). Their classification introduced two types of anisotropy including cleavage or planar anisotropy and bedding plane anisotropy. This classification was based on maximum and minimum strengths at respective angles of β = 0 and 90°, strength at various directions, and the shape of the anisotropic curve plotted for σ c and β. There are various types of anisotropy which will be briefly explained below.

2.1 Inherent Anisotropy

Most metamorphic rocks, such as schist, slate, gneisses, and phyllite, display strong directional strength contrast due to the segregation of constituent minerals, in response to high pressure and temperature gradients of magma which are associated with tectonic stresses (Ramamurthy 1993). In this type of anisotropy, the weak surfaces are related to the rock formation processes, such as the foliation and schistose planes which are developed during the formation of rocks. Hence weak planes control the strength in different loading directions (Ramamurthy 1993).

2.2 Induced Anisotropy

In induced anisotropy, the weak planes are developed due to fracturing, weak planes, and faults. Such weaknesses affect the strength behaviors of rocks with respect to the direction of applied stresses. There are various factors which can influence the anisotropic behavior of this type of rocks. Although many studies have been done to examine all of these factors and their respective behaviors, most of them have not yet been well understood (Ramamurthy 1993).

2.3 Cleavage or Planar Anisotropy

The cleavage or planar anisotropy is observed in some metamorphic and chemical rocks in which the forming particles are crystallized in the defined directions. The strength of this type of rocks is more at β = 90° compared to that of β = 0°. This anisotropy is further divided into the U-shape and the undulatory anisotropy types (Ramamurthy 1993).

2.4 U-shaped Anisotropy

In this type of anisotropy, the rock strength is larger at β = 90° than β = 0°. This anisotropy is induced by cleavages. Slates, which have a set of cleavage, are classified under this type of anisotropy (Ramamurthy 1993).

2.5 Undulatory Anisotropy

This is a type of cleavage anisotropy with more than one cleavage sets. Coal and biochemical diatomite are in this category (Ramamurthy 1993).

2.6 Bedding Plan Anisotropy

This type of anisotropy is exhibited in sedimentary rocks such as sandstones and shale. This anisotropy originates from the bedding planes formed due to the agitation in sedimentation phase. This type of rocks show their maximum strength at β = 0°, whereas their minimum strength occurs at angles from β = 20° to β = 40°. In these types of rocks, anisotropy curve is known as anisotropy shoulder due to its shape (Ramamurthy 1993).

3 Core Sample

Figure 2 shows the samples cored with different angle of anisotropy from the slates observed at the outcrop in Sardasht dam site in Iran. Attempts were made to obtain the samples with the same angle of anisotropy and the same homogeneity but it was barely possible to practice this consistently for all samples. So in many cases, homogeneity of the samples with the same angle of anisotropy was different. The slate samples are mainly composed of quartzite and meta-sandstone, whereas larger calcite veins constitute the remaining body of the rocks. More than 17 boreholes were drilled and core samples with lengths of between 15 and 80 cm were collected at a depth interval of 14.7–140 m. Samples taken from boreholes No. 6, 10, 12, and 13 with low quality for mechanical testing were discarded from the analysis in this study. The best approach in the laboratory to evaluate the anisotropy of any physical property is by using rock samples with spherical shapes (Vickers and Thill 1969; Hrouda et al. 1993). This will avoid uncertainties due to rock heterogeneity between different samples; however, practically it is trivial to cut sphere shape samples from a block of rock but it is easier to work on cylinder-shaped cores. Despite some simplified assumptions in this approach, the ease of sample preparation is perhaps the reason for using a cylinder-shaped sample with specific dimensions for doing standard rock mechanical tests, including uniaxial and triaxial compression tests in the lab.

As shown in Fig. 2, cores were taken at different angle of anisotropy from 0° to 90°. Coring and sample preparation were done according to the ISRM suggested methods (ISRM 1983). The cores had a diameter of 54 mm and length to diameter ratio of 2:3. This is a standard NX sample. Sample ends were ground and flattened to an accuracy of ±0.01 mm and parallel to each other. The deviation in the diameter and undulation of the end planes were less than 0.2 mm and the vertical deviation was <0.001 radian.

After accurate measurements of each sample dimensions, it was subjected to ultrasound cleaning in distilled water and then placed inside a 105 °C oven for at least 24 h. The dry mass of the specimens was measured after they cooled down to the room temperature. Samples which were supposed to be tested in saturated conditions were immersed into seawater within a container maintained at a pressure slightly <1 atm (760 mmHg) for 14 days. They were then placed in a big plastic container filled with sufficient seawater to fully cover the samples. Finally, the samples were weighed again to obtain their wet masses. Despite all attempts being made, it was still difficult to achieve a fully saturated sample by simply immersing the specimens into water or water vacuum. Therefore, we use the term “wet samples” rather than saturated samples in current study. To compare the results of dry and wet samples, samples with the same angle of anisotropy and homogeneity were tested. Figure 3 shows thin sections of slate samples before saturation.

3.1 Physical Properties of Core Samples

Following the standard test procedures outlined in ISRM (1981), physical properties such as bulk density and porosity were determined for both wet and dry slate rock samples. The range of values obtained from 27 tests for each property is presented in Table 1.

As it is seen in Table 1, there is a minor difference in density of the wet and dry samples.

4 Compressive and Tensile Strength Tests

To study the anisotropic behavior of slates, uniaxial and triaxial tests as well as Brazilian test were conducted on the core samples taken from different boreholes drilled in Sardasht dam site. The results are presented in the following subsections.

4.1 Uniaxial Tests

Jaeger et al. (2007) pointed out that only two elastic parameters, i.e., Young’s modulus and Poisson’s ratio, are required for defining the behavior of isotropic homogeneous body, whereas nine elastic constants must be determined to describe the behavior of an orthotropic anisotropic body. These nine parameters, however, are reduced to five constants to describe the deformational behavior of a transverse anisotropic rock through the analysis of experimental data. In this kind of anisotropy, two Young moduli being parallel (E) and perpendicular (E′) to the foliation plane, two Poisson’s ratios of parallel (υ) and perpendicular (υ′) to the foliation planes, and a shear modulus (G′) are used to describe the behavior of rocks.

In the current study, standard uniaxial and triaxial rock mechanical tests were performed according to the ISRM suggested method (ISRM 1981, 1983) on slate samples with different angles of anisotropy. A hydraulic compression machine was used to perform the tests. The system consists of a main frame, a hydraulic pump unit, a controller, strain gages, a load cell, data acquisition modules, and a computer. The strain and load data were acquired by a LabVIEW system and stored in the computer workstation. Figure 4 shows the uniaxial and triaxial test devices used for this study. The parameters obtained from this test are elastic parameters (i.e., Young’s modulus and Poisson’s ratio) and rock’s cohesion and friction angle. For measuring axial (ε a) and diametrical (ε d) strains, electrical resistance strain gauges were mounted, two axially and two diametrically, on opposite sides at the mid-height of the specimens. After the failure of each specimen, the pieces of failed rock were collected to investigate the relationship between the isotropy plane and the failure plane. The values of apparent elastic modulus and Poisson’s ratio were measured with secant elastic modulus method at 50 % of ultimate strength, and then the five independent elastic constants were calculated.

4.1.1 Determination of Elastic Constants for Transverse Isotropic Slates

For the purpose of this study, 30 sets of uniaxial tests were conducted on both wet and dry slate samples with different angles of anisotropy. Statistical data regarding the five elastic constants obtained for the dry and wet samples are presented in Tables 2 and 3, respectively. These are the results of data obtained from testing two samples with different angles of anisotropy using the conventional equations (Cowin 1985). Such a practice was conducted through analysis of around 98 measurements of rock elastic parameters by Amadei et al. (1987) who concluded that for most intact transversely isotropic rocks, the ratio of E/E′ varies between 1 and 4. According to Worotnicki and CSIRO (1993), the degree of anisotropy is less than 1.5 for 80 % of the rocks. Figure 5 compares the Young’s and shear modulus of dry and wet samples obtained from the uniaxial tests.

In uniaxial compression conditions, the theoretical predictions of apparent elastic modulus (E θ ) can be calculated as described by Amadei (1996) and Barla (1974). The apparent elastic moduli measured from the experiment are shown in Fig. 6. For the Sardasht slate, the measured apparent Young’s modulus varies from 16 to 57 GPa for the dry and from 56 to 14 GP for the wet samples.

From Fig. 6, it is also seen that the apparent Young’s modulus of wet samples is less than that of the dry samples. As is seen from this figure, the minimum values for apparent Young’s modulus is at β = 30°–40°. It was also found that the degree of modulus anisotropy for wet samples is higher than that of the dry samples indicating the effect of water content on the strength properties of wet samples. This information will be used to establish various interrelations between parameters, for example principle stresses. For instance, Amadei (1996) concluded that high anisotropy can introduce remarkable errors in the calculated magnitudes of the principal stresses.

As mentioned, transversely isotropic rocks such as slates exhibit maximum uniaxial compressive strength at angles from β = 0° and β = 90°, whereas minimum strength may occur at angles from β = 30° to β = 45°. Figure 7 shows the results of UCS measurements at different angles of anisotropy.

From Fig. 7, it can be inferred that strength of slates are highly anisotropic as a large reduction in strength is observed at an angle of β = 30° for dry sample (i.e., strength value of around 11 MPa). It should be noticed that the maximum strength obtained during UCS tests for dry samples was 64 MPa at an angle of β = 0°.

An estimation of strength anisotropy can be obtained by calculating the ratio of UCS defined as ratio of maximum UCS, σ c(max), to the minimum UCS, σ c(min). In this case, σ c(max) will be the value corresponding to the angle of β = 0°, whereas β = 30° is angle at which the minimum value of UCS can be observed. The anisotropy ratio, in this regard, can be defined as

This is the Ramamurthy criterion (RC) proposed for determination of strength anisotropy (Ramamurthy 1993). After calculations, strength anisotropy (RC) of the dry samples was equal to 4.6 whereas that of the wet samples was 6.4. This indicates the change in rock properties due to water content.

4.2 Triaxial Test

Studies of the effect of confining pressure on the strength and elastic modulus showed that elastic constants and strength of anisotropic rocks increase with an increase in confining pressure. This increase is often related to the closure of the micro cracks and pore spaces during the confinement phase. Preferential orientation of micro cracks along the foliation planes is another cause of anisotropy at microscopic level (Corthesy et al. 1993). Hobbs (1964) studied the effect of confining pressure on the elastic modulus of seven coals sampled parallel to the bedding plane and found that in most cases this property increases with increasing the confining pressure up to 40 MPa. Moreover, Homand et al. (1993) evaluated the variation of elastic modulus as a function of confining pressure through some triaxial lab tests of coal samples and suggested that Young’s and shear modulus can be expressed as power function of (1 + σ 3) when confining pressure increases up to 40 MPa for specimens tested at β = 0°, 45° and 90°. In spite of the fact that many research works have been carried out to study the effect of confining pressure on the elastic and strength behavior of anisotropic rocks, the data available over the entire range of anisotropy angle at the confined and unconfined states of stress is very rare. For this reason, in this paper, uniaxial compressive as well as triaxial tests were conducted to study the strength and elastic properties of slate rock samples in dry and wet conditions. Triaxial tests of this study consisted of 35 triaxial tests performed on dry and wet samples.

Triaxial compressive tests were carried out using a 150-MPa capacity triaxial cell placed in a 5MN capacity loading frame. Three different confining pressures applied during the triaxial tests were 10, 20, and 30 MPa, respectively. The specimens were first subjected to the given confining pressure and then the axial load was applied until the specimen failed. For the entire measurements, five elastic properties, apparent Young’s modulus as well as peak strength of the samples under different angle of anisotropy were recorded. Tables 4 and 5, respectively, give statistical values of the elastic parameters obtained for dry and wet samples under triaxial tests. Figures 8 and 9, respectively, show the peak strength of dry and wet slate samples at different confining pressures as a function of anisotropy angle (β).

These figures show the simultaneous effect of confining pressure and water content on the failure strength of slate samples. As it is depicted in these figures, the amount of water content of wet samples influences their strength behavior as they show less strength compared to dry samples during the triaxial tests. On the other hand, an increase in confining pressure increases the strength of both wet and dry samples. It is clear from these figures that the maximum strength values are observed at an angle β = 0° for both wet and dry samples for different confining pressures. Although in general the minimum strength values are expected to be observed at angle β = 30°, it is seen that this occurs at an angle of β = 45° for confining pressures greater than 10 MPa. A similar observation was reported by Singh et al. (1989) for quartzitic and carbonaceous phyllites for confining pressures greater than 70 MPa.

Figures 10 and 11 show the change in apparent Young’s modulus of slate samples under wet and dry conditions. From these figures, it is observed that the variation of apparent Young’s modulus as a function of anisotropy angle β at different confining pressures follow a U-shaped trend similar to their strength anisotropy curves. This behavior can be attributed to the effect of anisotropy where it reduced mechanical strength of rock. Generally speaking, from Figs. 10 and 11, it can be concluded that the degree of anisotropy on the apparent modulus gets suppressed at higher confining pressures.

4.3 Brazilian Tests

The Brazilian test has proved to be a simple, fast, and relatively reliable technique for tensile strength estimation of rock (Jaeger et al. 2007). In addition to compressive strength, tensile strength plays an important role in determination of the load bearing capacity of rocks, their deformation, fracturing, crushing, etc. Tensile strength is a key parameter since often rocks are much weaker in tension than in compression. The Brazilian tensile strength test is a well-known indirect method of determining the tensile strength of rocks. It is frequently used in rock engineering because the test is easy to conduct using uniaxial compression test machines. The Brazilian test was developed in 1943 (Carneiro and Barcellos 1953) and has been mainly used in investigations of homogeneous rocks (Chen and Hsu 2001; Chen 2008). For example, the size effect of the specimen has been the subject of several studies (Newman and Bennett 1990; Bazant et al. 1991; Kafka et al. 1996; Rocco et al. 1999a, b). There are only few studies discussed on the tensile strength of anisotropic rocks (Amadei 1996; Chen et al. 1998; Hakala et al. 2007; Gao et al. 2010; Tavallali and Vervoort 2010). Very few systematic studies on the influence of transverse-isotropy on tensile strength of rocks have been conducted (Barla and Innaurato 1973; Kwasniewski 2009; Tavallali and Vervoort 2010; Cai 2013; Li and Wong 2013). Therefore, the result presented in this paper may be found useful.

The Brazilian tests for the purpose of this study were carried out according to the ISRM- and DGGT-recommendations (ISRM 1978; DGGT 2008). The disc of rock was loaded up to the failure point with an unchanged loading rate of 200 N/s. The foliation planes were found to be the true planes of weakness, characterized by reduced cohesive and tensile strength. Anisotropy angle (β) was the angle between the loading direction and structural plane similar to other tests. More than 34 Brazilian tests were conducted where results corresponding to 28 samples were found acceptable for dry and wet samples. The lab evaluations in terms of determination of a tensile strength follow the ISRM-regulation, although it is noticed that the development of fracture planes may partially violate the assumptions of a pure tensile fracture (Dan 2011). The results obtained after performing this test on dry and wet core samples are presented in Tables 6 and 7, respectively. Figure 12 compares the values of tensile strength for dry and wet samples.

Looking at Tables 6 and 7, it is concluded that there is no clear relationship between the angle of anisotropy and tensile strength of the slate samples. However, it can be indicated that water saturation has a quite high impact on the tensile strength of rock samples.

5 Conclusions

In this paper, anisotropic behavior of slate rocks taken from Sardasht dam site was studied through lab experiments. Uniaxial and triaxial compression tests as well as Brazilian tests were carried out on both dry and wet samples with different angles of anisotropy (β). The elastic and mechanical parameters of the samples were calculated for the entire tests. Five elastic parameters of transverse isotropic slate were calculated using the least square method and solving the compliance matrix obtained for two set of samples with the same or different angle of anisotropy. The results indicated that these properties change as a function of angle β. The rock strength as a result of uniaxial and triaxial tests showed to have a U-shaped behavior with lower values for wet comparing to dry samples. It was also indicated that as the confining pressure increases in traixial tests, elastic and strength properties of rocks increase due to crack closure. The results obtained from Brazilian tests indicated that there is no apparent relationship between tensile strength and angle of anisotropy. However, water saturation has a remarkable effect on the tensile strength of slate samples as it causes the tensile strength to be decreased for the wet samples.

References

Akai K, Yammamoto K, Ariola M (1970) Experimentele forschung Uber anisotropische eigenschaften von kristallinen schierfern. In: Proceedings on rock mechanics, vol 11. Belgrade, pp 181–6

Al-Harthi AA (1998) Effect of planar structures on the anisotropy of Ranyah sandstone. Saudi Arabia Eng Geol 50:49–57

Allirote D, Boehler JP (1970) Evaluation of mechanical properties of a stratified rock under confining pressure. In: Proceedings of the Fourth Congress on ISRM, vol 1. Montreux, pp 15–22

Amadei B (1996) Importance of anisotropy when estimation and measuring in situ stresses in rock. Int J Rock Mech Min Sci 33(3):293–326

Amadei B, Rogers JD, Goodman RE (1983) Elastic constants and tensile strength of anisotropic rocks. In: Proceedings of the fifth international congress of rock mechanics 1983, pp A189–96

Amadei B, Savage WZ, Swolfs HS (1987) Gravitational stresses in anisotropic rock masses. Int J Rock Mech Min Sci 24:5–14

Attewell PB, Sandford MR (1974) Intrinsic shear strength of brittle anisotropic rock-I: experimental and mechanical interpretation. Int J Rock Mech Min Sci 11:423–430

Barla G (1974) Rock anisotropy: theory and laboratory testing. Rock Mech 1:31–69

Barla G, Innaurato N (1973) Indirect tensile testing of anisotropic rocks. Rock Mech 5:215–230

Bazant ZP, Kazcmi MT, Hasegawa Maznrs (1991) SIZC effect in Brazthau split-cyhndcr tests: measurements and fracture analysis. ACI Mater J 88:325–332

Brown ET, Richard LR, Barr MV (1977) Shear strength characteristics of Delabole slate. In: Proceedings conference on rock engineering. New Castle Upon Tyne, pp 31–51

Cai M (2013) Fracture initiation and propagation in a Brazilian disc with a plane interface: a numerical study. Rock Mech Rock Eng 46(2):289–302

Carneiro F, Barcellos A (1953) International association of testing and research laboratories for materials and structures. RILEM Bull 13:99–125

Chen C, Hsu SC (2001) Measurement of indirect tensile strength of anisotropic rocks by the ring test. Rock Mech Rock Eng 34(4):293–321

Chen C, Pan E, Amadei B (1998) Fracture mechanics analysis of cracked discs of anisotropic rock using the boundary element method. Int J Rock Mech Min Sci 35:195–218

Chen C, Chen CS, Wu JH (2008) Fracture toughness analysis on cracked ring disks of anisotropic rock. Rock Mech Rock Eng 41(4):539–562

Corthesy R, Gill DE, Leite MH (1993) An integrated approach to rock stress measurement in anisotropic non-linear elastic rock. Int J Rock Mech Min Sci 30(4):395–411

Cowin SC (1985) The relationship between the elasticity tensor and the fabric tensor. Mech Mater 4:137–147

Dan DQ (2011) Brazilian test on anisotropic rocks—laboratory experiment. Numerical simulation and interpretation. Institut für Geotechnik, Freiberg

Deklotz EJ, Brown JW, Stemler OA (1966) Anisotropy of schistose gneiss. In: Proceedings of the first congress, vol 1. International society of rock mechanics, Lisbon, pp 465–70

DGGT (2008) Lndirekter Zugversuchan Gesteinsproben—Spaltzugversuch. Deutschen Gesellschaftfur Geotechnik—Bautechnik. Ernst & Sohn, Berlin; 8-b, pp 623–7

Donath F (1964) Strength variation and deformational behavior in anisotropic rock. In: Judd WR (ed) State of stress in the Earth’s crust. Elsevier, New York, pp 281–298

Everitt RA, Lajtai EZ (2004) The influence of rock fabric on excavation damage in the Lac du Bonnett granite. Int J Rock Mech Min Sci 41(8):1277–1303

Exadaktylos GE (2001) On the constraints and relations of elastic constants of transversely isotropic geomaterials. Int J Rock Mech Min Sci 38(7):941–956

Gao Z, Zhao J, Yao Y (2010) A generalized anisotropic failure criterion for geomaterials. Int J Solids Struct 47:3166–3185

Gatelier N, Pellet F, Loret B (2002) Mechanical damage of an anisotropic porous rock in cyclic triaxial tests. Int J Rock Mech Min Sci 39:335–354

Gong QM, Zhao J, Jiao YY (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Sp Technol 20(2):183–191

Gonzaga GG, Leite MH, Corthesy R (2008) Determination of anisotropic deformability parameters from a single standard rock specimen. Int J Rock Mech Min Sci 45(8):1420–1438

Hakala M, Kuula H, Hudson JA (2007) Estimating the transversely isotropic elastic intact rock properties for in situ stress measurement data reduction: a case study of the Olkiluoto mica gneiss, Finland. Int J Rock Mech Min Sci 44(1):14–46

Hobbs DW (1964) The strength and stress–strain characteristics of coal in triaxial compression. J Geo 72:214–231

Hoek E (1968) Brittle failure of rock. In: Stagg KG, Zienkiewicz OC (eds) Rock mechanics in engineering practice. Willey, London

Homand F, Morel E, Henry JP, Cuxac P, Hammade E (1993) Characterization of the moduli of elasticity of an anisotropic rock using dynamic and static methods. Int J Rock Mech Min Sci 30:527–535

Horino FG, Ellickson ML (1970) A method of estimating strength of rock containing planes of weakness. Report of investigation 7449, US Bureau of Mines

Hrouda F, Zdenek P, Wohlgemuth J (1993) Development of magnetic and elastic anisotropies in slates during progressive deformation. Phys Earth Planet Int 77:251–265

Hudson J, Harrison J (1997) Introduction to rock mechanic. Elsevier science LTD, London

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech 15:99–103

ISRM (1981) Suggested method for determining uniaxial compressive strength and deformability of rock materials. In rock characterization testing and monitoring. Int J Rock Mech Min Sci 18(6):113–116

ISRM (1983) Suggested methods for determining the strength of rock materials in triaxial compression: revised version. Int J Rock Mech Min Sci 20:285–290

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics, 4th edn. Chapman & Hall, London

Jyh Jong L, Yang MT, Hsieh H-Y (1997) Direct tensile behavior of a transversely isotropic rock. Int J Rock Mech Min Sci 34:837–849

Kafka V, Cejp J, Kvet V, Vokoun D (1996) On the size effect in the Brazilian split-cylinder test. Acta Techruca CSA Ceskoslovensk Akadcnne I’ed 41(4):385–404

Ko HY, Gerstle KH (1976) Elastic properties of two coals. Int J Rock Mech Min Sci Geomech Abstr 13(3):81–90

Kwasniewski M (2009) Testing and modeling of the anisotropy of tensile strength of rocks. In: Proceedings of the international conference on rock joints and jointed rock masses. Tucson, Arizona, USA, January 7–8

Li D, Wong L (2013) The Brazilian disc test for rock mechanics applications: review and new insights. Rock Mech Rock Eng 46(2):269–287

McCabe WM, Koerner RM (1975) High pressure shear strength of and anisotropic mica schist rock. Int J Rock Mech Min Sci 12:219–228

Min KB, Lee CI, Choi HM (2003) An experimental and numerical study of the in situ stress measurement on transversely isotropic rock by overcoring method. In: Proceedings of the third international symposium on rock stress. Kumamoto, Japan, pp 189–95

Nasseri MHB, Seshagiri Rao K, Ramamurthy T (1996) Engineering geological and geotechnical responses of schistose rocks from dam project areas in India. Eng Geol 44:183–201

Nasseri MH, Rao KS, Ramamurthy T (1997) Failure mechanism in schistose rocks. Int J Rock Mech Min Sci 34(3–4):219

Nasseri MHB, Rao KS, Ramamurthy T (2003) Anisotropic strength and deformational behavior of Himalayan schists. Int J Rock Mech Min Sci 40:3–23

Newman DA, Bennett DG (1990) Effect of specimen size and stress rate for the Brazilian IcSI. A statistical analysis. Rock Mech Rock Eng 23(2):123–134

Nova R (1980) Failure of transversely isotropic rocks in triaxial compression. Int J Rock Mech Min Sci 17:325–332

Pomeroy CD, Hobbs DW, Mahmoud A (1971) The effect of weakness plane orientation on the fracture of Barnsley hard coal by triaxial compression. Int J Rock Mech Min Sci 8:227–238

Ramamurthy T (1988) Strength, modulus responses of anisotropic rocks. In: Hudson JA (ed) Compressive rock engineering, vol 1. Pergamon, Oxford, pp 313–329

Ramamurthy T (1993) Strength, modulus responses of anisotropic rocks. In: Hudson JA (ed) Compressive rock engineering. Pergamon, Oxford, vol 1, pp 313–29

Rao KS, Rao GV, Ramamurthy T (1986) A strength criterion for anisotropic rocks. Indian Geotec J 16(4):317–333

Rocco C, Gumen GV, Planas J, Elices M (1999a) Size effect and boundary conditions in the Brazilian test: theoretical analysis. Mat Struct 32:437–444

Rocco C, Guinea GV, Planas J, Elices M (1999b) Size effect and boundary conditions III the Brazilian test: experimental verification. Mat Struc 32:210–217

Saroglou H, Tsiambaos G (2008) A modified Hoek–Brown failure criterion for anisotropic intact rock. Int J Rock Mech Min Sci 45:223–234

Singh J, Ramamurthy T, Rao GV (1989) Strength anisotropies in rocks. Indian Geotec J 19(2):147–166

Singh VK, Singh D, Singh TN (2001) Prediction of strength properties of some schistose rocks from petrographic properties using artificial neural networks. Int J Rock Mech Min Sci 38(2):269–284

Song I, Suh M, Woo YK, Hao T (2004) Determination of the elastic modulus set of foliated rocks from ultrasonic velocity measurements. Eng Geol 72(3–4):293–308

Stjern G, Agle A, Horsrud P (2003) Local rock mechanical knowledge improves drilling performance in fractured formations at the Heidrun field. J Petrol Sci Eng 38:83–96

Szwilski AB (1984) Determination of the anisotropic elastic moduli of coal. Int J Rock Mech Min Sci Geomech Abstr 21(1):3–12

Tavallali A, Vervoort A (2010) Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int J Rock Mech Min Sci 47:313–322

Tien YM, Tsao PF (2000) Preparation and mechanical properties of artifice transversely isotropic rock. Int J Rock Mech Min Sci 37:1001–1012

Vickers BL, Thill RE (1969) A new technique for preparing rock spheres. J Sci Instrum 2:901–902

Wang CD, Tzeng CS, Pan E, Liao J (2003) Displacements and stresses due to a vertical point load in an inhomogeneous transversely isotropic half-space. Int J Rock Mech Min Sci 40(5):667–685

Worotnicki G, CSIRO (1993) Triaxial stress measurement cell. In: Hudson JA (eds) Compressive rock engineering, vol 3. Pergamon Press, Oxford, pp 329–94

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gholami, R., Rasouli, V. Mechanical and Elastic Properties of Transversely Isotropic Slate. Rock Mech Rock Eng 47, 1763–1773 (2014). https://doi.org/10.1007/s00603-013-0488-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-013-0488-2