Abstract

We present rock mechanical test results and analytical calculations which demonstrate that a negative surface charge, resulting from sulfate adsorption from the pore water, impacts the rock mechanical behavior of high-porosity chalk. Na2SO4 brine flooded into chalk cores at 130 °C results in significantly reduced bulk modulus and yield point compared with that of NaCl brine at the same conditions. The experimental results have been interpreted using a surface complexation model combined with the Gouy-Chapman theory to describe the double layer. The calculated sulfate adsorption agrees well with the measured data. A sulfate adsorption of about 0.3 μmol/m2 and 0.7–1 μmol/m2 was measured at 50 and 130 °C, respectively. Relative to a total sites of 5 sites/nm2 these values correspond to an occupation of 4 % and 8–13 % which sufficiently explains the negative charging of the calcite surfaces. The interaction between charged surfaces specifically in the weak overlaps of electrical double layer gives rise to the total disjoining pressure in granular contacts. The net repulsive forces act as normal forces in the grains vicinity, counteracting the cohesive forces and enhance pore collapse failure during isotropic loading, which we argue to account for the reduced yield and bulk modulus of chalk cores. The effect of disjoining pressure is also assessed at different sulfate concentrations in aqueous solution, temperatures, as well as ionic strength of solution; all together remarkably reproduce similar trends as observed in the mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The interaction between seawater and chalk has been a subject of extensive research simply because seawater injection is an important method for pressure support as well as secondary recovery. In North Sea chalk reservoir, water injection has been highlighted as a significant challenge as it has led to reservoir compaction and seabed subsidence, while on the other hand, compaction has also become an important drive mechanism for Improved Oil Recovery (IOR). In Ekofisk and Valhall water is injected up to 15000 BWPD (barrels water per day) at one injector (Christian et al. 1993; Ali et al. 1994). The reservoir temperature at Ekofisk is 130 °C and Valhall is 92 °C, while the temperature of the injected water is normally colder than reservoir temperature. When the formation water (generally with a higher salinity than seawater and very low sulfate content) is displaced by seawater, physico-chemical alterations are triggered such as dissolution, precipitation, and changes in surface charge and potential.

The change of mechanical properties in sedimentary rocks due to physico-chemical interaction between the aqueous solutions and rock surface are well documented (Rehbinder et al. 1948; Westwood et al. 1974; Ishido and Mizutani 1980; Seto et al. 1997; Liang and Hueckel 2007). In particular for chalk, a number of studies have interpreted the mechanical behavior of chalk as a result of aqueous chemistry effect in terms of, for example, chalk solubility in aqueous solution (Newman 1983), enhanced solubility of chalk from the intergranular contacts by a dissolution/precipitation process and chemistry related to thin films (Heggheim et al. 2005), precipitation of magnesium-bearing minerals that triggered enhanced dissolution of chalks (Madland et al. 2009, 2011; Megawati et al. (2011). In Andreassen and Fabricius (2011) Biot critical frequency is proposed to describe chalk mechanical failure and yield when exposed to different pore fluids. However, it is clear that for single-phase flooding of aqueous solutions and with similar core properties, the Biot critical frequency stays the same and it cannot explain the mechanical behavior demonstrated in different aqueous chemistry as reported in Heggheim et al. (2005), Korsnes et al. (2008b). Madland et al. (2009, 2011).

In Madland et al. (2009, 2011) it was demonstrated that magnesium in seawater triggered precipitation of new minerals, both magnesium-bearing carbonates and silicates. The precipitation of secondary minerals led to a net transport of calcium out of the core, which was interpreted as dissolution of calcite. The dissolution of calcite, triggered by secondary mineral formation, affected deformation rate at a constant stress level demonstrated by the creep response. Cores flooded with MgCl2 had a higher creep rate than reference cores flooded with NaCl. In addition the creep development under MgCl2 flooding followed a linear trend with time, while that under NaCl flooding showed a logarithmic time behavior. The effect of magnesium on the chalk strength shown by mechanical yield under isotropic loading, however, was not significantly demonstrated.

In Korsnes et al. (2008b), it was shown that presence of sulfate in the pore fluid significantly affects the chalk mechanical properties. It was observed that the yield was significantly lower for chalk cores flooded with synthetic seawater (SSW) than those flooded with SSW without sulfate. The mechanism attributed to the physico-chemical interaction of sulfate ions in pore water and chalk surface, however, was not clearly discussed.

Sulfate ions are generally bound on interfaces between aqueous solution and calcite surface in response to electrostatic forces (Hingston et al. 1972; Bolan et al. 1986; Charlet et al. 1993). In several studies, sulfate adsorption on chalk surfaces has been related to wettability change from mixed wet into more water wet (Strand et al. 2006; Zhang et al. 2006; Zhang 2006; Karoussi and Hamouda 2007). Hiorth et al. (2010) calculated the surface charge and the resulting disjoining pressure for different aqueous solution. They verified that aging the cores with sodium sulfate leave the cores to be negatively charged. The overlap of this negatively charged layer exerts a disjoining pressure which accounts for the stability of the water film between chalk and fluid interfaces and eventually makes the core more water wet (Hiorth et al. 2010).

The objective of the present study is to discuss how intermolecular forces resulting from rock–fluid interactions due to the presence of sulfate in pore water affect mechanical behavior of chalk. Because mechanical properties measured under isotropic compression are less scattered and highly repeatable as shown from previous studies (Heggheim et al. 2005; Risnes et al. 2005; Madland et al. 2006, 2008, 2009, 2011; Korsnes et al. 2006, 2008a; Zangiabadi et al. 2009), this type of test is chosen here to study the various effects of sulfate–chalk interaction in more detail. The rock–fluid interaction is discussed in terms of dissolution, precipitation, and surface charge. Information about the chalk–fluid interaction is based on the net chemical change in and out of the core. Surface charge depends on the pH and the adsorbed species from the solution. In particular, sulfate will adsorb from the solution and a negative surface charge is created at the pore surface. The results are novel as we investigate the effect of sulfate by the use of simple brines, such as NaCl and Na2SO4. In addition, we also consider different chalk materials from quarries in Belgium, Denmark, and US for the laboratory tests. As chemical interactions are known to be temperature dependent and concentration of dissolved ions are of importance, rock mechanical test and adsorption experiments were performed at different temperatures with different brine compositions.

2 Experimental

2.1 Material

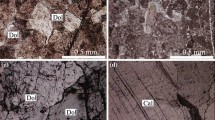

Three types of outcrop chalk cores from Stevns Klint (SK) near Copenhagen, Denmark, Lixhe (L) near Liège, Belgium, and Kansas (KA) from Niobrara, Kansas quarry, US were used. The petrophysical properties of the chalks are summarized in Table 1. The carbonate content was measured based on 0.5 M NaOH titration after reacting with an excess of 0.5 M HCl. The accuracy of this method for chalk is 0.7 % or better (Nguyen and Fabricius 2008). BET (N2) specific surface area (SSA) was measured by Micromeritics Gemini III 2375. The non-carbonate fraction was extracted by dissolving chalk powder with 2 M Acetic acid (CH3COOH) stepwise and thereafter the residue was analyzed for the SSA. In Table 1 we have also calculated the calcite SSA from known bulk SSA, non-carbonate SSA, and the composition. Petrophysical properties of Liège and Stevns Klint chalk are described in Hjuler (2007), and Kansas chalk properties are described in Bottjer (1986).

Routine core preparations are similar with all previous UiS chalk studies (Risnes et al. 2003, 2005; Korsnes et al. 2008b). No clear bedding could be identified in all the chalk blocks collected from the quarries. However, for homogeneity all the core plugs were drilled in the same direction from the same block. The core was drilled with an oversized core bit and circulating water for cooling. After drying 120 °C overnight, the oversized samples were then shaped in a Lathe machine to get a diameter of 3.7 or 3.81 cm and then cut to approximately two times the diameter size by a diamond saw. The cylindrical core plugs were then dried again to achieve constant dry weight. Saturation was performed in a vacuum chamber and the pressure was lowered to 4–5 Pa before distilled water (DW) was introduced. Precautions in storing the saturated samples were taken to ensure and maintain full water saturation. Porosity was determined from the difference between the dry weight and the water-saturated weight.

Different aqueous fluids were used in the adsorption test as well as mechanical test. The composition of fluids and the pH are listed in Table 2. The brine was prepared with DW and then filtered, degassed, and stored in a capped bottle. Precautions to avoid evaporation were taken during storing the solutions.

2.2 Adsorption Test

Performing sulfate adsorption measurements simultaneously while mechanically testing may give less accuracy due to mixing zones in the triaxial cell. Hence the adsorption measurements were performed separately in a Hassler cell which was housed in a heating cabinet. Parallel core plugs from the same block as that of mechanical tests were used. The measurements were performed by flooding cylindrical chalk cores with Na2SO4, by which the introduction of the fluid into chalk cores is also similar to the flooding process during the rock mechanical test. A series of tests were performed on the same core by varying several parameters such as temperatures, Na2SO4 concentrations, and flooding rates. As such, any difference in the adsorption results are certainly associated with the parameter being varied. Prior to introducing Na2SO4, the cores which were initially DW saturated were cleaned with NaCl brine having equal ionic strength as the respective fluid and equilibrated overnight at the respective temperature; 50 and 130 °C. In several tests, DW was also used for cleaning instead of NaCl to learn the chromatographic behavior of not only SO 2−4 (anion) but also the Na+ (cation) during the adsorption process. The concentration of 0.024 M Na2SO4, which is typical sulfate concentration in seawater, is generally chosen to have adequate separation between tracer and sulfate within a reasonable duration time. Adsorption behavior with lower sulfate concentration 0.01 M Na2SO4 was also checked. Thiocyanate in KSCN, was used as a non-adsorbing tracer and the concentration is the same as concentration of Na2SO4 being used (0.024 and 0.01 M). The tabulated brine compositions are presented in Table 2. We use sufficiently high flow rates (0.2 ml/min) to ensure that the mass transport in bulk solution does not limit the reaction rate. This flow rate is also favorable for suppressing delay time due to dead volume of experimental setup (≃12 ml) and variety of pore volumes (PVs) from sample to sample. For the sake of interest, a flooding rate 0.1 ml/min was also used in some tests. In most tests 3–6 throughput PVs of effluent were collected, which as shown from the results to be enough to reach steady-state concentration of sulfate and the tracer. The amount of sulfate adsorbed is basically the area of SO 2−4 curve relative to the tracer (SCN−) curve.

2.3 Mechanical Tests

Mechanical tests with isotropic stress were conducted in a hydraulically operated Triaxial cell. The aim has thus not been to capture strength variations from complete yield curves, but rather to select a repeatable type of test in order to study the various effects of sulfate-chalk interactions in more detail. The Triaxial cell is equipped with a heating jacket controlled by an external regulating system. Axial displacement is measured by an external LVDT (Linear Voltage Displacement Transducer, uncertainty ± 0.05 mm), and in some of the experiments carried out, lateral strain displacement (extensometer) was also measured. Due to the fact that the strain developed during loading is stress and time dependent, all the tests within similar chalk type were conducted with similar loading rate. A high pressure pump was used, providing a loading rate of about 0.2 and 0.3 bar/min for SK/L cores, and KA cores, respectively. In the course of rock mechanical tests, the core, which was initially DW saturated, was firstly confined with 5 bar pressure and cleaned with 2 PVs of DW at ambient temperature. Thereafter the pore pressure and confining pressure was simultaneously increased to 7 and 14 bar, respectively. The system was then heated to the test temperature, and thereafter approximately 3 PVs of respective brine was flooded. The respective brine was pre-heated prior to any flooding through the core. The system was equilibrated overnight at this condition with a continuous brine flooding at rate of 1 PV/day before initiating isotropic loading. Different ions may be originally present and bound at the reactive sites on clays or calcite surfaces. However, since the core was cleaned thoroughly with sufficient volumes of DW, this should not influence the final experimental results. Nevertheless, to confirm this we also pre-flooded the core with 0.657 M NaCl prior to introducing 0.219 M Na2SO4. Isotropic loading was started at a confining pressure of 14 bar and pore pressure of 7 bar (initial effective stress of 7 bar) which is then assumed as a reference point for strain calculation. A period of creep, which is time-dependent deformation at constant stress, was then followed at a certain stress level beyond the yield point. Throughout the mechanical test pore pressure is kept constant at 7 bar. Since different chalk types exhibit different yield, we have used creep stress levels of 10.7 MPa for both SK and L cores, and 18.9 MPa for KA cores. These stress levels correspond to approximately 30 % above the average values of yield and are also comparable with those used in previous studies (Madland et al. 2008, 2009, 2011). Throughout the mechanical test, respective brines were continuously injected at 1 PV/day. Effluent was collected daily and the ion concentrations were measured by an Ion-Exchange Chromatograph (ICS-3000 Dionex). From normal distribution test, the measurements were subjected to 5 and 10 % uncertainties for SO 2−4 and SCN−, and Ca2+, respectively.

3 Rock Mechanical Test Results

Rock mechanical properties under isotropic loading can be described by yield and bulk modulus. Yield point, which is the onset of pore collapse failure was determined by the intersection of tangents to the stress–strain curve in the elastic and following plastic domain (Fig. 1). All the yield values presented are calculated as an average of yield points observed from the path of stress-axial strain and stress-radial strain. Bulk modulus (K) is calculated from the linear slope of stress (s) versus volumetric strain \((\epsilon_{\rm v})\) within the elastic phase as follows:

where

Due to the fact that only some of the tests are equipped with radial measurement, by assuming an isotropic condition, the bulk modulus was determined according to the Eq. 3. The bulk modulus is thus calculated as one-third of the slope of axial stress-axial strain curve during isotropic loading prior to any point of yield.

3.1 Liège(L) Chalk

3.1.1 Effect of Sulfate Content and Ionic Strength

The effect of sulfate content of the injected fluid at 130 °C for L chalk is remarkably demonstrated in the stress–strain plot where increasing sulfate content of the injected fluid results in increased reduction of yield point (Fig. 1). In Fig. 2 the yield and bulk modulus are shown as a function of Na2SO4 concentration of the brine at 130 °C. There is a clear correlation towards reduced yield and bulk modulus with increasing sulfate concentration in the injected fluid. For the bulk modulus, the result from sample C/L11 (Table 3) is probably somewhat too low to be compared with other data points of zero sulfate content and clearly associated with the high-porosity value. Nevertheless, compared with that of zero sulfate content all the data points show that in going from 0.024 to 0.219 M sulfate content yield and bulk modulus decrease by 15–30 % and 25–65 %, respectively. Apparently, varying sulfate content affects both yield and bulk modulus during isotropic loading.

There may be also an ionic strength effect as shown by the reduced yield of sample A4/L19 relative to that of E/L17 where the sulfate content is kept constant (Table 3). From the relative decrease of the average yield of cores flooded with Na2SO4, NaCl and DW at 130 °C the effect of ionic strength and sulfate content in a simple manner can be distinguished. Increasing ionic strength at 130 °C, as shown by the yield of core exposed to 0.657 M NaCl relative to that of DW, results in 11% decrease in the yield. On the other hand, comparison between the yield of cores exposed to 0.219 M Na2SO4 and 0.657 M NaCl shows that increasing sulfate content at constant ionic strength contributes to an additional 19 % reduction. Ultimately, the yield point has decreased 28 % by increasing both sulfate concentration and ionic strength of the solution as shown by the yield with 0.219 M Na2SO4 relative to that with DW. Note also that this is in comparable order with the sum of ionic strength effect and sulfate content effect. In summary the effect of sulfate overrides the effect of ionic strength and thus it primarily accounts for the reduced yield and bulk modulus.

3.1.2 Effect of Temperature

The effect of temperature on L chalk is illustrated in Fig. 3 for constant ionic strength (I = 0.657). It can be seen that the yield reduction of cores exposed to Na2SO4 relative to that of NaCl are obvious at 130 °C, whereas at 50 °C the difference is rather negligible. In Table 3 the values can be also compared and in Fig. 4 the average yield values are presented for all the chalk types. Hence temperature is another important parameter, and it turns out that by lowering the temperature to 50 °C the effect of sulfate is lost. Note also that the yield of core flooded with NaCl at 130 °C is more or less similar to that at 50 °C. Thus, as shown in the coming sections, the importance of temperature will be particularly linked to sulfate adsorption.

3.2 Stevns Klint(SK) Chalk

3.2.1 Effect of Sulfate Content and Ionic Strength

The yield and bulk modulus of SK cores flooded with varying concentration of Na2SO4 at 130 °C are presented in Fig. 5a and b, respectively. For the data points of low sulfate content (<0.024 M) there is some difference in the initial porosity, and thereby the effect of sulfate as observed in the bulk modulus is rather scattered. Sample DW/SK36 of zero sulfate content has higher porosity compared with sample E/SK11 with 0.01 M sulfate and therefore unlike the L chalk, the yield for DW flooding in this case is not the highest (Table 4). Nevertheless, to a general extent the data points show a similar behavior as those of L cores in which increasing sulfate content of the injected fluid results in reduced yield and bulk modulus. Note that sample A1/SK1 having the lowest initial porosity yields at significantly reduced stress compared to other sample of similar porosity (E/SK11) (see Table 4). This clearly shows that there is an impact induced by the presence of sulfate in the injected fluid which is equally important as initial porosity in controlling the failure mechanism.

From the relative decrease of average yield under 0.219 M Na2SO4, 0.657 M NaCl and DW flooding, increasing ionic strength results in 13 % reduction in the yield, while increasing sulfate content results in another 20 % reduction. These combined effects as shown by the measured yield with 0.219 M Na2SO4 relative to the DW consistently results in 33 % reduction which is in excellent agreement with the total of each individual effect.

3.2.2 Effect of Temperature

Temperature is another important parameter, and it turns out that by lowering the temperature to 50 °C while keeping the ionic strength constant, the effect of sulfate is lost. At 50 °C the yield of cores exposed to 0.219 M Na2SO4 solution and 0.657 M NaCl solution are quite similar. This can be seen in Table 4 and Fig. 4.

3.3 Kansas(KA) Chalk

3.4 Effect of Sulfate Content and Ionic Strength

For KA chalk a consistent trend of decreasing yield point and bulk modulus with increasing sulfate content is demonstrated in Fig. 6a and b, respectively. The effect of ionic strength seems to be minor for KA chalk as 0.657 M NaCl flooding results in similar yield as that of DW flooding. The effect of sulfate content, however, is major as shown by the significant reduction in yield as well as bulk modulus for cores exposed to 0.219 M Na2SO4. By comparing the yield of cores exposed to DW, 0.657 M NaCl and 0.219 M Na2SO4 it can be seen in Table 5 that increasing ionic strength in KA chalk results in only a 1 % reduction in the yield, while increasing sulfate content results in additional 24 % reduction. Relative to that of DW, 0.219 M Na2SO4 gives a 25 % reduction in the yield which is in excellent agreement with the sum of the individual effect.

3.4.1 Effect of Temperature

Although there is approximately 5 % reduction in the yield as a result of 0.219 M Na2SO4 flooding at 50 °C this magnitude is clearly less compared with that at 130 °C (Table 5). Thus, similar effects of temperature are also demonstrated in KA chalk and it becomes evident that at 50 °C the effect of sulfate on the mechanical failure is minor (Fig. 4). At 130 °C, however, all the chalk cores tested consistently show reduced yield and bulk modulus with increasing sulfate content (Fig. 7a, b).

3.5 The Creep Trend

When stress is kept constant, creep starts developing with time. In Fig. 8 creep rates developed during brine flooding of constant ionic strength at 130 and 50 °C are plotted as a function of time. An interesting behavior is demonstrated in which the creep rate curves for all the chalk types flooded with 0.219 M Na2SO4 at 50 and 130 °C are superimposed on one another and they evolve with a fairly similar rate with time (Fig. 8a). Since the outcrops used in the present study are from different origins, and the fact that the mineralogy may vary, it is interesting to note that irrespective of the initial porosity and the non-carbonate content the behavior of time-dependent deformation is identical under 0.219 M Na2SO4 flooding. Note that the stress level for all tests with KA chalk is 18.9 MPa effective axial stress, while the stress level for both SK and L chalk is 10.7 MPa. Note also that all the tests with 0.657 M NaCl flooding do not show similar behavior (Fig. 8b). Thus, the rate-controlling mechanism may be more specifically related to interaction between sulfate ions in the aqueous solution and calcite surface. At 50 °C the effect is of sufficient degree to counteract granular friction and hence results in similar macroscopic creep independent of initial porosity, stress level, and mineralogy. At 130 °C the effect is also sufficient to significantly influence the mechanical failure during isotropic loading and hence results in reduced yield and bulk modulus. In the discussion section, it will be shown how the interaction in terms of adsorption process could likely account for the mechanical behavior observed.

4 Sulfate Adsorption Results

Pure core flooding in a Hassler cell as previously described in Sect. 2.2 was carried out on different chalk cores to quantify any sulfate adsorption. The measured sulfate adsorption obtained from all the chalk types will allow estimation of properties such as surface charge and surface potential. The adsorption has been calculated from the following equation:

where m 0i and m i(t) are the injected and effluent concentration of ion i, respectively.

In Fig. 9, a typical sulfate retention at 130 °C following the introduction of adsorption fluid, and sulfate desorption following DW flooding are illustrated. It can be seen that the adsorption occurs significantly during the first few PVs flooded. This observation verifies that the rapid step of adsorption process seems to be dominating (Rajan 1978; Zhang et al. 1987; Davis and Kent 1990).

All the sulfate adsorption obtained from the different chalk types, temperatures, flooding rates, and sulfate concentration are presented with respect to surface area of calcite and solid mass (Table 6). It can be seen that the adsorption of sulfate on calcite surfaces is generally within 0.7–1 μmol/m2 and 0.3–0.4 μ mol/m2 at 130 and 50 °C, respectively. Total sulfate adsorption at 130 °C is 2–3 times higher compared with that at 50 °C, and sulfate adsorption of L chalk with respect to solid mass is the highest. Relative to a sites density of 2 sites/nm2 (Hiorth et al. 2010) and 5 sites/nm2 (Davis and Kent 1990), sulfate adsorption at 130 °C corresponds to 20–33 % and 8–13 % site occupation, respectively. Sulfate adsorption at 50 °C corresponds to 9–11 % and 3–5 % relative to the sites density of 2 and 5 sites/nm2, respectively.

The increased adsorptive capacity at high temperature is often ascribed to increased affinity of sulfate due to desolvation of water molecules following breakage of hydrogen bonds above 100 °C (Hachiya et al. 1984a, b). BET(N2) specific surface area shows also that L chalk has the highest specific surface area compared with SK and KA chalk (Table 1), and therefore the adsorption with respect to solid mass is expected to be higher in L chalk.

The chemical analyses of effluent from core L3 initially flooded with DW show some degree of dissolution; as much as 0.5 mmol of calcium produced for 3 PVs of 0.024 M Na2SO4 flooded at 130 °C. However, the other tests (L2, L1, SK2, SK1, and KA1) first flooded with NaCl having similar ionic strength with 0.024 M Na2SO4 at both 50 and 130 °C show negligible dissolution; in the order of 0.1 mmol Ca2+ produced.

Sulfate desorption test by DW flooding performed on core L3 (Fig. 9) shows that sulfate ions also can desorb by an amount comparable to the adsorption (0.4–0.5 mmol). Although only a single desorption test is performed here, the results suggest that sulfate ions are attached weakly, which would require the attachment to be on the outer-sphere coordination with the surface. In line with the conceptual calcite surface model by Stipp (1999), and Van Cappelen et al. (1993) they are probably attached with the hydrolysis layer. With respect to this model, the spatial distribution of adsorbed sulfate basically can be envisioned to follow the electrical double layer (EDL) model that the sulfate distribution is denser in the Stern layer and distributed diffusely in the diffuse layer. The adsorption of sulfate in the Stern layer, as presented in the calculation, was also balanced through adsorption of positive ions (in this case Na+) in the diffuse layer.

5 Discussion

Briefly the mechanical test results have shown the following:

-

1.

The mechanical yield is generally highest for distilled water (except for one SK chalk DW/SK36) at 130 °C.

-

2.

The mechanical yield is reduced when the ionic strength is increased at 130 °C. The magnitude of this effect, however, varies for the different chalk types, and is negligible for KA chalk.

-

3.

The mechanical yield and bulk modulus are reduced by increasing sulfate concentration at 130 °C. This feature is consistently shown in Fig. 7 where the yield and bulk modulus from the different chalk types are normalized with respect to that of DW.

-

4.

Irrespective of chalk types, stress level and initial porosity, creep develops with a fairly similar rate over time under flooding of 0.219 M Na2SO4 at 50 and 130 °C.

-

5.

The effect of sulfate which has been demonstrated by the mechanical behavior during isotropic loading is temperature dependent. By lowering temperature to 50 °C the effect on the mechanical failure as shown by the yield and bulk modulus is more or less lost (Fig. 4). At high temperature 130 °C, however, the effect is stronger and influences both mechanical failure and creep.

The adsorption tests show:

-

1.

Sulfate adsorption is temperature dependent, and approximately two times higher at 130 than at 50 °C.

-

2.

The degree of sulfate adsorption is different depending on the type of chalk and is proportional to the surface area of the specific chalk tested.

The main observations are that there is an important effect of temperature and the concentration of sulfate in the pore water. Thus, any theory that is to explain the observed data must at least respect these two observations. In the following, we would like to discuss our results in terms of dissolution/precipitation and surface charge.

5.1 Dissolution and Precipitation

It might be asserted that anhydrite precipitation and chalk dissolution account for the observed mechanical behavior and the loss of sulfate demonstrated in the adsorption experiments. Anhydrite may be expected to form at high temperature but not at low temperature. Previous study, for example has reported microscale observation of anhydrite formed on tested cores exposed to seawater flooding at 130 °C (Madland et al. 2011). If anhydrite is formed, the pore water would be undersaturated with respect to calcium and as a result calcite will dissolve as follows:

In our case with constant aqueous chemistry flooding, this would result in continuous precipitation of anhydrite, a net loss of sulfate in the core, and a net gain in the carbonate. The loss of sulfate can be easily monitored by analyzing the effluent, and the net gain in carbonate can be observed in the alkalinity of the effluent.

In Fig. 10 the ionic composition and pH of the effluent from SK cores flooded with 0.219 M Na2SO4 during mechanical test at 50 and 130 °C are presented. It can be seen that no loss in sulfate and sodium is observed after 2 PVs flooded onwards and the ionic composition is steadily maintained at the influent concentration. Effluent pH is generally between 7 and 8 at 50 °C, and only slightly higher than 8 at 130 °C. In terms of dissolution, calcium production seems to be minor and in comparable order with that of 0.657 M NaCl flooding (Fig. 11a, b). Calcium concentration after 0.219 M Na2SO4 flooding is approximately at 6 and 2 mM for test temperature of 130 and 50 °C, respectively. This is in line with the effluent alkalinity as shown by the pH data which demonstrate that the net gain in carbonate at 130 °C is somewhat higher than that of 50 °C. In this respect, pure calcite dissolution has the wrong temperature dependence. Overall observations clearly show that anhydrite precipitation and calcite dissolution are not the case here.

Chemical analyses of core effluent during mechanical test on SK cores flooded with 0.219 M Na2SO4. Effluent pH is shown in the secondary axis. Calcium concentration is within 0.002 and 0.006 M at 50 and 130 °C, respectively. Note the concentration of SO 2−4 and Na+ is basically the same as that of the influent. a Sample B/SK18 at 50 °C, b Sample A1/SK22 at 130 °C

We have calculated chemical equilibrium of calcite with 0.024 and 0.219 M Na2SO4 at different temperatures using PHREEQC (Parkhurst and Appelo 1999) and EQAlt (L. M. Cathles, unpublished data). Saturation index (SI) and calcium production calculated from these geochemical models are summarized and compared in Table 7. In EQAlt the calculation is performed for a pore pressure of 10 bar, and hence phases calculations are handled better than in PHREEQC. Note also that all the experimental measurements were performed with constant pore pressure of 7 bar. These might explain the difference in the saturation index between the two models for the case with 0.219 M Na2SO4 at 130 °C. Despite the difference, nevertheless, the geochemical models confirm the experimental results that anhydrite precipitation is unlikely and pure calcite dissolution is not the case.

5.2 Effect of Surface Charge

Sulfates adsorb to the calcite surface and create a negative surface charge. This surface charge may give rise to a pressure which can be described by the total disjoining pressure if two charged surfaces approach each other (see Fig. 12). In the following we will demonstrate by analytical calculations how it is possible to relate surface charge to the adsorption of sulfate.

Analytical calculations based on surface complexation model (Van Cappelen et al. 1993; Pokrovsky et al. 1999) are used here to verify with the measurement data as well as to calculate surface electrical properties. The dominant reactions are shown in Table 8. For the complexes, the activity (a) is assumed to be equal to the concentration (m). The mass action constants (C) of the reactions are taken from the geochemical model presented in Hiorth et al. (2010). The number of adsorption sites (T s) will probably vary from sample to sample; however, a number of 2 sites/nm2 (Hiorth et al. 2010) and 5 sites/nm2 (Davis and Kent 1990) were used. The pH is constrained by measuring the pH of the brine at the inlet (pH: 6.2 Table 2) and at the outlet (average pH: 7–8).

The outer-sphere surface complex >CaSO −4 (>represents crystal lattice) is assumed to be dominant, and thus it represents the amount of sulfate adsorbed. The dominance of outer-sphere complex is also suggested by a number of sulfate adsorption studies on goethite (Davis and Leckie 1980; Hayes et al. 1987; Fukushi and Sverjensky 2007). A Simple diffuse layer model (Stumm et al. 1970; Dzombak and Morel 1990) is used here, and the explicit diffuse layer calculation (Borkovec and Westall 1983) is not considered. Also, no difference is made between surface and Stern potential. The charge of the double layer, σDL, can be found from Grahame equation as follows:

where \(\xi_0 =\exp\{-F \psi_0/R T\}, F\) is Faraday’s constant 9.6485 × 104 C/mol, ψ0 is the surface potential (Volt), \(\rho_{\infty,{\rm i}}\) is the number of particles i per m2 in the bulk (far from the charged surface), R is the ideal gas constant 8.314 J/K mol, T is the temperature in K, Z i is the valence number of ion i, \(\varepsilon_0\) is permittivity constant 8.84 × 10−12 F/m, and \(\varepsilon\) is the dielectric constant corrected for temperature and brine concentration.

For the case with Na2SO4, the Grahame equation above can be written as follows:

where

For the surface species we do not distinguish between the activities (a) and the concentrations (m), i.e. m > = a >. The total number of surface sites, T s (in mol/l), are conserved; hence:

The surface charge can be calculated by summing over all the surface species (Van Cappelen et al. 1993):

where \(S=\rho_{\rm grain} \cdot SSA,\) which is surface area with respect to grain volume, the unit for S is m2/l, ρgrain is typical grain density for chalk (2.71 g/cc) and SSA is specific surface area for calcite listed in Table 1. The surface charge in the diffusive layer (σDL) must be equal and opposite in sign to the surface charge (σ), i.e. σ = −σDL. We can then combine all the equations (Eqs. 6–10 and Table 8) for solving surface potential and the corresponding properties.

In Fig. 13 sulfate adsorption and surface potential calculated for a pH range of 2–12, different Na2SO4 concentrations, temperature of 50 and 130 °C, site density of 2 sites/nm2 and 5 sites/nm2 are illustrated. It can be seen that sulfate adsorption on calcite surfaces and the surface potential is significantly pH dependent. Fig. 13a and b demonstrated that at low pH below 4 surface potential is constant and it becomes more negative with increasing concentration of Na2SO4. This sulfate concentration dependence and pH independence confirm that at least in this pH range sulfate ion is a potential determining ion for calcite (Pierre et al. 1990; Zhang and Austad 2006). At pH below 4, in addition, it can be seen also that the adsorption curve flattens out with pH and decreases gently with sulfate concentration (Fig. 13c, d). As a comparison Charlet et al. (1993) showed that sulfate adsorption on δAl2O3 reached a plateau at sulfate concentration above 10−3 M and at a constant pH of 3 ± 0.3. The calculations also predicted that the largest adsorption of sulfate is at low pH below 4 (Fig. 13c, d). Figure 13e and f likewise shows that with increasing pH the density of sulfate bounded complex >CaSO −4 relative to the total sites is decreasing from approximately 50 % to less than 15 %.

pH dependence and Na2SO4 concentration dependence of sulfate adsorption calculated for T s of 2 sites/nm2 and 5 sites/nm2 and temperature of 130 and 50 °C. a Calculated surface potential at 130 °C, b calculated surface potential at 50 °C, c calculated sulfate adsorption at 130 °C, d calculated sulfate adsorption at 50 °C, e site occupancy at 130 °C, f site occupancy at 50 °C

In Fig. 14 the calculated sulfate adsorption with respect to calcite surface area is compared with the measured values. Here the adsorption is obtained by integrating the sulfate adsorption curves from pH 6.24 (influent) to 8 (effluent) since the pH inside the core is not known. It can be seen that 5 sites/nm2 gives a better fit with the data if we consider all the chalk types tested.

In addition to the adsorption comparison, in Fig. 15 surface potential obtained from the analytical calculations was compared with published zeta potential measurements (Zhang and Austad 2006). The \(\zeta\)-potential measurement was performed at ambient temperature on 4.0 wt % chalk suspension in 0.573 M NaCl where the pH was kept constant at 8.4 and sulfate concentration was increased by adding concentrated solution of Na2SO4 gradually. With 2 sites/nm2 and 5 sites/nm2, we can see that the predicted surface potential (ψ0) exceeds the \(\zeta\)-potential. This is expected as the \(\zeta\)-potential is measured at a certain distance from the surface. If we assume that the shear plane where the \(\zeta\)-potential is measured is located at a distance \(\kappa_{\zeta}\) from the Stern layer, we have the following relation between the surface potential and the \(\zeta\)-potential (Revil et al. 1999a):

where κ−1 is the Debye screening length, given in Eq. (13). The distance of the shear plane \(\kappa_\zeta\) is dependent on the surface topology, but by assuming that \(\kappa_\zeta = 3\) Å (Revil et al. 1999a), the surface potential can be corrected to approximate the zeta potential. Calculated surface potential at 3 Å (denoted by ψ A ) is also plotted in Fig. 15. It can be seen that 5 sites/nm2 gives a good fit to the \(\zeta\)-potential measurement as shown by ψ A at low sulfate concentration and by ψ0 at high sulfate concentration.

\(\zeta\)-Potential measurement (Zhang and Austad 2006), calculated surface potential (ψ0), and calculated potential at 3 Å(ψ A ), ambient temperature

5.3 The Impact of Disjoining Pressure on Yield Point and Bulk Modulus

Mechanical behavior of high-porosity chalk has been regarded as frictional material failing in a shear failure mode. The open structure of the rock matrix enhances failure mechanism often referred to as pore collapse by distributed shear failures occurring within the material (Fjær et al. 2008, pp. 66; Risnes et al. 2005; Blanton 1981). Although the material is under isotropic compression, on a grain scale the localized failure may be still shear failure which involves not only normal forces but also shear forces (Guéguen and Bouteca 1997; Risnes et al. 2003, 2005). An analogue of this situation is borehole breakouts which also occur in isotropic stress field and isotropic material parameters (Fjær et al. 2008, pp. 162).

In this paper we have observed that when the chalk is exposed to sulfate-rich water at 130 °C the yield point is lower than that as exposed to NaCl brine with the same ionic strength. A possible explanation for the reduction in yield can be found by considering the disjoining pressure. Grains will acquire a negative surface charge due to the sulfate adsorption, and the negative charge will be neutralized by a diffusive layer close to the surface. Close to grain–grain contacts the diffusive layer from each grain surface will overlap and give rise to a repulsive force, described by the disjoining pressure (Eq. 12). The repulsive forces will effectively reduce the short-range (cohesive) forces and thus, lower the normal component in the granular contacts. According to the Mohr’s hypothesis this would mean lower critical shear forces to induce shear failure between grains. This mechanism will apparently enhance the pore collapse failures.

The disjoining pressure for identical charged surfaces in the weak overlap approximation of the double layer is given as follows (Israelachvili 1985):

where D is thickness of water film (nm), I is the ionic strength of the solution, T is temperature (K), ψ0 is the surface potential (mVolt), κ is the inverse of Debye length (nm−1), and \(\varepsilon\) is the dielectric constant of the solution corrected for temperature and brine concentration (Revil et al. 1999b). The Hamaker constant (A) of the calcite–water system is set to \(5 \times 10^{-21} \) J (Israelachvili 1985). It should be mentioned that the exact value is not fully known and that rigorous calculation which considers retardation effect as well as contribution from the zero-frequency and dispersion energy is probably required for validation. Clearly a negative net pressure means an excess of the attractive component which prevails at small distances and a positive net pressure means an excess of the repulsive component. With increasing distance the attractive component is diminishing and thus the total interaction approaches the electrical repulsive forces.

In Fig. 16a and b the contribution of each parameter (I and ψ0) is illustrated in a simplified manner. The ionic strengths are chosen within the order of the adsorption fluid and the surface potential is simply chosen within a reasonable order. It can be seen that increasing surface potential results in consistent increase in the magnitude of disjoining pressure while increasing ionic strength does not directly add to the total disjoining pressure.

In Fig. 17a and b the disjoining pressure curves have been calculated from surface potential obtained from the sulfate adsorption data integrated with pH from the core inlet to the core outlet, different Na2SO4 concentrations, different temperatures, and constant total sites of 5 sites/nm2. It can be seen that the temperature dependence of sulfate adsorption significantly affects the calculated surface potential and apparently the magnitude of the disjoining pressure.

Assuming that the height of the peak of the disjoining pressure represents the strength of the repulsive forces, we expect that there should be a strong correlation between the height of the peak and the yield point of the chalk samples. Such correlation is remarkably shown in Fig. 18a with respect to the yield point. A similar trend, although more scattered, is also shown for the bulk modulus in Fig. 18b.

6 Conclusion

The effect of sulfate on the chalk mechanics has been demonstrated during isotropic loading as well as during time-dependent deformation (creep). It is observed that the mechanical behavior due to sulfate adsorption is dependent on the sulfate concentration and temperature. At 130 °C the effect of sulfate influences both mechanical failure and creep. All the chalk types have consistently shown reduced yield and bulk modulus with increasing sulfate concentration of the injected fluid at 130 °C. Comparison of yield point of cores exposed to DW, 0.657 M NaCl, and 0.219 M Na2SO4 at 130 °C shows that the effect of sulfate is significant and it overrides the ionic strength effect. At 50 °C, however, the effect of sulfate is lost and no significant difference in the yield and bulk modulus between cores exposed to Na2SO4 and NaCl was observed. At 130 °C and 50 °C (independent of stress level, initial porosity and chalk mineralogy) the creep developed at similar rate over time under 0.219 M Na2SO4 flooding.

Chemical analyses of core effluent and geochemical models have shown that anhydrite precipitation and or calcite dissolution is unlikely to account for the sulfate retention and the mechanical behavior. The retention of sulfate instead has been satisfactorily explained in terms of sulfate adsorption process interpreted by surface complexation model (Van Cappelen et al. 1993; Pokrovsky et al. 1999) together with Gouy–Chapman theory to describe the electrical double layer. The analytical calculations gave fairly good agreement with the measured sulfate adsorption and compared favorably with \(\zeta\)-potential measurement data from Zhang and Austad (2006). The calculations also predict a substantial pH dependence of sulfate adsorption that the adsorption is constantly large at pH below 4 and gradually decreases with increasing pH. Additional experimental and analytical studies are likely necessary to investigate these findings more systematically.

The reduced yield and bulk modulus has been related to sulfate adsorption which leads to a negative (pH dependent) surface charge. We have suggested that the negative surface charge gives rise to significant repulsive forces close to the granular contacts, accommodating local shear failures between grains and apparently enhancing the pore collapse failures. The total disjoining pressure of chalk cores exposed to different Na2SO4 concentrations at 130 °C correlated well with the reduced yield and bulk modulus from the isotropic tests. The correlation remarkably reproduced the same trend as observed in the yield and bulk modulus as a function of Na2SO4 concentrations. For proper description of mechanical strength variations, full suit of triaxial tests should be further carried out. Any variations in friction angle and cohesion in addition to the movements of end cap due to the type of brine and testing temperature will also be included in future work.

References

Ali N, Singh P, Peng C, Shiralkal G, Moschovidis Z, Baack W (1994) Injection-above-parting-pressure-waterflood pilot, valhall field, Norway. SPE Reservoir Engineering, SPE 22893

Andreassen K, Fabricius I (2011) Biot critical frequency applied to description of failure and yield of highly porous chalk with different pore fluids. Geophysics 75: E205–E213

Blanton TL (1981) Deformation of chalk under confining pressure and pore pressure. SPE J 21(1):43–50. doi:10.2118/8076-PA

Bolan NS, Syers JK, Tillman RW (1986) Ionic strength effects on surface charge and adsorption of phosphate and sulfate by soils. J Soil Sci 37:379–388

Borkovec M, Westall J (1983) Solution of the poisson-boltzmann equation for surface excesses of ions in the diffuse layer at the oxide-electrolyte interface. J Electroanal Chem 150:325–337

Bottjer DJ (1986) Campanian-maastrichtian chalks of southwestern arkansas: Petrology, paleoenvironments and comparison with other North American and European chalks. Cretac Res 7:161–196

Charlet L, Dise N, Stumm W (1993) Sulfate adsorption on a variable charge soil and on reference minerals. Agric Ecosyst Environ 47:87–102

Christian T, Currie J, Lantz T, Rismyhr O, Snow S (1993) Reservoir management at ekofisk field. The 68th SPE Annual Technical Conference and Exhibition, San Antonio, 3–6 Oct., SPE 26623

Davis J, Kent D (1990) Surface complexation modelling in aqueous geochemistry. Rev Miner Geochem 23:177–260

Davis JA, Leckie J (1980) Surface ionization and complexation at the oxide/water interface iii. adsorption of anions. J Colloid Interface Sci 74:32–43

Dzombak DA, Morel FMM (1990) Surface complexation modelling. Hydrous ferric oxide. Wiley, Hoboken

Fjar E, Holt RM, Horsrud P, Raaen AM, Risnes R (2008) Petroleum related rock mechanics, 2nd edn, Elsevier, Oxford

Fukushi K, Sverjensky DA (2007) A surface complexation model for sulfate and selenate on iron oxides consistent with spectroscopic and theoretical molecular evidence. Geochim Cosmochim Acta 71:1–24

Guéguen Y, Bouteca M (1997) Mechanics of fluid-saturated rocks volume 89 of International Geophysics Series. Elsevier Academic Press, London

Hachiya K, Sasaki M, Ikeda T, Mikami N, Yasunaga T (1984a) Static and kinetic studies of adsorption-desorption of metal ions on a γ−al 2 O 3 surface. ii. kinetic study by means of pressure-jump technique. J Phys Chem 88:27–31

Hachiya K, Sasaki M, Saruta Y, Mikami N, Yasunaga T (1984b) Static and kinetic studies of adsorption-desorption of metal ions on a γ−al 2 O 3 surface. i. static study of adsorption-desorption. J Phys Chem 88:23–27

Hayes KF, Roe AL, Brown JGE, Hodgson KO, Leckie JO, Parks GA (1987) In situ x-ray adsorption study of surface complexes : 33 selenium oxyanions on α-feooh. Sci Agric 238:783–786

Heggheim T, Madland MV, Risnes R, Austad T (2005) A chemical induced enhanced weakening of chalk by seawater. J Pet Sci Eng 46:171–184

Hingston FJ, Posner AM, Quirk JP (1972) Anion adsorption by goethite and gibbsite. i. the role of the proton in determining adsorption envelopes. J Soil Sci 23:177–192

Hiorth A, Cathles LM, Madland MV (2010) The impact of pore water chemistry on carbonate surface charge and oil wettability. Transp Porous Media. doi:10.1007/s11242-010-9543-6

Hjuler ML (2007) Diagenesis of upper cretaceous onshore and offshore chalk from the North Sea area. Ph.D. thesis Institute of Environment and Resources, Technical University of Denmark

Ishido T, Mizutani T (1980) Relationship between fracture strength of rocks and ζ-potential. Tectonophysics 67:13–23

Israelachvili J (1985) Intermolecular and surface forces. Academic Press, New York City

Karoussi O, Hamouda A (2007) Imbibition of sulfate and magnesium ions into carbonate rocks at elevated temperatures and their influence on wettability alteration and oil recovery. Energy Fuels 21:2138–2146

Korsnes R, Strand S, Hoff, Pedersen T, Madland M, Austad T (2006) Does the chemical interaction between seawater and chalk affect the mechanical properties of chalk? In: Cottheim AV, Charlier R, Thimus JF, Tshibangu JP (eds) Multiphysics coupling and long term behaviour in rock mechanics. pp 427–434. ISBN 0 415 41001 0

Korsnes R, Wersland E, Madland M, Austad T (2008a) Anisotropy in chalk studied by rock mechanics. J Pet Sci Eng 60:183–193

Korsnes RI, Madland MV, Austad T, Haver S, Rosland G (2008b) The effects of temperature on the water weakening of chalk by seawater. J Pet Sci Eng 60:183–193

Liang BH, Hueckel T (2007) Creep of saturated materials as a chemically enhanced rate-dependent damage process. Int J Numer Anal Methods Geomech 31:1537–1565

Madland M, Finsnes A, Alkafadgi A, Risnes R, Austad T (2006) The influence of co2 gas and carbonate water on the mechanical stability of chalk. J Pet Sci Eng 51:149–168

Madland M, Hiorth A, Omdal E, Megawati M, Hildebrand-Habel T, Kornes R, Evje S, Cathles L (2011) Chemical alteration induced by rock-fluid interaction when injecting brines in high porosity chalks. Transp Porous Media. doi:10.1007/s11242-010-9708-3

Madland MV, Hiorth A, Korsnes RI, Evje S, Cathles L (2009) Rock fluid interactions in chalk exposed to injection of seawater, MgCl2, and NaCl2 brines with equal ionic strength. EAGE-2009 A22

Madland MV, Midtgarden K, Manafov R, Korsnes RI, Kristiansen T, Hiorth A (2008) The effect of temperature and brine composition on the mechanical strength of kansas chalk. In: International Symposium SCA

Megawati M, Andersen P, Korsnes R, Hiorth H, Madland M (2011) The effect of aqueous chemistry ph on the time-dependent deformation behaviour of chalk experimental and modelling study. In: Pore2Fluid IFP Energies nouvelles Paris, Nov 16–18

Newman GH (1983) The effect of water chemistry on the laboratory compression and permeability characteristics of some north sea chalks. SPE AIME 35(5):976–980. doi:10.2118/10203-PA

Nguyen SH, Fabricius IL (2008) Determination of carbonates by titration. Retrieved from Sediment Laboratory, Danish Technical University, Lyngby

Parkhurst L, Appelo CAJ (1999) User’s guide to PHREEQC (version 2)—a computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Water-Resources Investigations Report 99-4259. US Department of the interior US Geological Survey, Denver. ftp://brrftp.cr.usgs.gov/pub/dlpark/geochem/unix/phreeqc/manual.pdf

Pierre A, Lamarche R, Mercier R, Foissy A, Persello J (1990) Calcium as potential determining ion in aqueous calcite suspensions. J Dispers Sci Technol 11:611–635

Pokrovsky O, Schott J, Thomas F (1999) Dolomite surface speciation and reactivity in aquatic systems. Geochim Cosmochim Acta 63:3133–3143

Rajan SSS (1978) Sulfate adsorbed on hydrous alumina, ligand displaced, and changes in surface charge. Soil Sci Soc Am J 42:39–44

Rehbinder PA, Schreiner LA, Zhigach KF (1948) Hardness reducers in drilling: a physico-chemical method of facilitating mechanical destruction of rocks during drilling. Council for Scientific and Industrial Research, Melbourne, vol 194, p 69492585

Revil A, Pezard PA, Glover PWJ (1999a) Streaming potential in porous media 1. theory of the zeta potential. J Geophy Res 104:20021–20031

Revil A, Schwaeger H, Cathles LM, Manhardt PD (1999b) Streaming potential in porous media 2. theory and application to geothermal systems. J Geophy Res 104:20033–20048

Risnes R, Haghighi H, Korsnes RI, Natvik O (2003) Chalk-fluid interactions with glycol and brines. Tectonophysics 370:213–226

Risnes R, Madland MV, Hole M, Kwabiah NK (2005) Water weakening of chalk—mechanical effects of water-glycol mixtures. J Pet Sci Eng 48:21–36

Seto M, Nag DK, Vutukuri VS, Katsuyama K (1997) Effect of chemical additives on the strength of sandstone. Int J Rock Mech Min Sci 34(3–4):280.e1–280.e11

Stipp SLS (1999) Toward a conceptual model of calcite surface: Hydration, hydrolysis, and surface potential. Geochim Cosmochim Acta 63:3121–3131

Strand S, Hognesen EJ, Austad T (2006) Wettability alteration of carbonates—effects of potential determining ions ca2+ and so2- 4 and temperature. Colloids Surf A-Physicochem Eng Asp 275:1–10

Stumm W, Huang CP, Jenkins SR (1970) Specific chemical interactions affecting the stability of dispersed systems. Croat Chem Acta 42:223–244

Van Cappelen P, Charlet L, Stumm W, Wersin P (1993) A surface complexation model of the carbonate mineral-aqueous solution interface. Geochim Cosmochim Acta 57:3505–3518

Westwood ARC, Macmillan NH, Kalyoncu RC (1974) Chemomechanical phenomena in hard rock drilling. Trans AIME 256:106–111

Zangiabadi B, Korsnes R, Hildebrand-Habel T, Sutarjana I, Lian A, Madland MV (2009) Chemical water weakening of various outcrop chalks at elevated temperature. DEStech Publications Inc., Lancaster, pp 543–548

Zhang GY, Zhang XN, Yu TR (1987) Adsorption of sulfate and fluoride by variable charge soils. J Soil Sci 38:29–38

Zhang PM (2006) Water-based EOR in fractured chalk—wettability and chemical additives. Ph.D. thesis Department of Petroleum, University of Stavanger

Zhang PM, Austad T (2006) Wettability and oil recovery from carbonates: effects of temperature and potential determining ions. Colloids Surf A-Physicochem Eng Asp 279:179–187

Zhang PM, Tweheyo MT, Austad T (2006) Wettability alteration and improved oil recovery in chalk: the effect of calcium in the presence of sulfate. Energy Fuels 20:2056–2062

Acknowledgments

The authors acknowledge the Norwegian Research Council, BP Norge and the Valhall co-venturers, including Hess Norge AS, and Total E&P Norge AS, ConocoPhillips and the Ekofisk co-venturers, including TOTAL, ENI, Statoil and Petoro for financial support. Nicholas Thompson is acknowledged for checking the language. We also thank Marc Hettema for fruitful discussion. Giovanni Barla and two anonymous reviewers are kindly acknowledged for constructive comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Megawati, M., Hiorth, A. & Madland, M.V. The Impact of Surface Charge on the Mechanical Behavior of High-Porosity Chalk. Rock Mech Rock Eng 46, 1073–1090 (2013). https://doi.org/10.1007/s00603-012-0317-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-012-0317-z