Abstract

Using high-strength steels for pressure shafts and tunnel liners and taking into account significant rock mass participation allows the design of comparatively thin steel liners in hydropower projects. Nevertheless, during emptying of waterways, these steel linings may be endangered by buckling. Compared with traditional measures such as increased steel liner thickness and stiffeners, pressure relief valves are a very economical solution for protection of steel liners against critical external pressure and therefore buckling during emptying. A calculation procedure has been developed for the design of the required number and arrangement of pressure relief valves, and this has been used successfully in practice. Systematic model tests enabled the assumptions of the design method to be verified.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 Development of Highly Pressurized Waterway Systems

With the development of high-strength steels and high-head Pelton turbines, highly loaded pressure shafts and tunnels with pressures of more than 150 bar can be designed in new hydropower projects to increase the installed capacity of existing high-head power plants or build new pumped-storage power plants, for example. In such projects, the residual risk of pressure shaft failure has to be considered in an early stage of the design (Hachem and Schleiss 2009). The longitudinal profile, particularly sufficiently high rock overburden, significantly influences the residual failure risk of a pressure shaft (Schleiss 1988, 2002). If the rock overburden is high enough, a significant part of the internal pressure can be transferred to the surrounding rock mass. Thus, the thickness of the steel liner can be limited to reasonable values, which facilitates welding of high-strength steels. Failure of the steel liner could result in catastrophic damage. For such high-risk conditions, the rock overburden has to be increased so as to avoid hydraulic jacking even when the steel liner has failed (Schleiss 2002). If the minimum natural rock stresses are higher than the internal water pressure and if the rock mass quality is sufficient, the steel liner can even be omitted. Significant rock mass participation guaranteed by high rock overburden can limit the consequences and therefore the residual risk in the case of steel liner failure.

1.2 The Problem of Buckling of Steel Liners

High rock overburden has the disadvantage that, during emptying of the pressure shaft, the steel liner is loaded by high external water pressure. The latter then becomes the critical design load case for the steel liner. Traditionally, the stability of the steel liner against external pressure is ensured by sufficient thickness of the steel or by stiffeners (Amstutz 1969; Jacobsen 1977, 1990). These measures against buckling can significantly increase the weight and cost of the steel liner compared with the thickness required for the internal pressure load case. Existing steel liners often do not fulfil today’s safety requirements regarding buckling. The rehabilitation costs of these traditional measures may not only be excessive because of increasing steel prices worldwide but also because of the operational losses during time-consuming works. Fixing the steel liner with rock anchors may be an alternative solution for such rehabilitation works (Finger and Wieser 1980). Nevertheless, drilling in existing pressure shafts is difficult and time-consuming, and therefore electricity production losses can also be very high.

Use of pressure relief valves or check valves in the steel liner is a very economical alternative to ensure protection of the pressure shaft against buckling. These one-way valves are installed in the steel liner with a certain distance between them (Figs. 1, 3, 6). They open as soon as a certain external pressure builds up in the joint between the steel liner and the backfill concrete. Therefore, such pressure relief or check valves can avoid non-tolerable external pressures on the steel liner by drainage directly into the shaft or tunnel during emptying. In existing pressure shafts and tunnels, they can be installed relatively rapidly.

It should be mentioned that concrete linings in pressure tunnels and shafts are rarely endangered by buckling during emptying, since they are not absolutely tight. Even very low permeability owing to concrete porosity or small cracks can considerably reduce the effective water pressure acting on the outer side of the lining (Schleiss 1997).

1.3 Application of Pressure Relief Valves as a Measure Against Buckling

Pressure relief valves have been used successfully in several pressure shafts and tunnels in the past. Nevertheless, most of these applications were limited to short stretches with expected high groundwater inflow during emptying. For such local conditions, pressure relief valves protect the steel liners of Chivor in Columbia (since 1982), Rotenbrunnen in Switzerland (since 1957), Ackersand in Switzerland (since 1958), Bärenburg in Switzerland (since 1962), Turlough Hill in Ireland (since 1972), Schluchseewerke in Germany (three different steel liners of pressure shafts since 1931 and 1976), Vianden in Luxembourg (since 1980) and Draukraftwerke in Austria (since 1978). However, probably the first systematic application of pressure relief valves over the whole length of a steel-lined high-pressure tunnel was at the North Fork Stanislaus River Hydroelectric Project in California in 1989 (Johannesson et al. 1988; Schleiss 1989). In spring 2010, an existing pressure shaft in Switzerland (Belleplace, Emosson Dam) was systematically equipped with check valves to increase protection against buckling (Fig. 1).

In addition to pressure relief or check valves, other types of drainage systems have also been developed, which drain the joint between the steel liner and the backfill concrete using a pipe system. In the “Maggia system” developed in Switzerland, the drained water is evacuated by a so-called header pipe embedded in the backfill concrete along the steel liner towards the surface into the powerhouse. There, the drainage pipe is equipped with a valve that is opened during the emptying of the pressure shaft. The Maggia system has been successfully used in Switzerland in the pressure shafts of Robiei (since 1969) and Grimsel-Oberaar (since 1979, pumped storage). The header pipe drainage system will not be discussed further hereafter.

Results achieved with the operation of the projects mentioned above, in which steel liners have been equipped with pressure relief valves, are satisfactory. During emptying of the tunnels and shafts, no clogging of the valves by calcite deposition or mud was observed, which would have reduced their drainage effect. It is very important that, under internal water pressure, the pressure relief valves are always completely closed to avoid such clogging.

The first author had the opportunity to develop a design method for the pressure relief valves used in the steel liner of the high-head pressure tunnel of the North Fork Stanislaus River Hydroelectric Project in California. With piezometers installed in the gap between the steel liner and the backfill concrete, the external pressure could be measured on that prototype during emptying, which allowed verification of the design method in general. Furthermore, in the framework of a master’s thesis at the Laboratory of Hydraulic Constructions (LCH) at EPFL in Switzerland (Wyss 2003), the design method was systematically analysed for different valve configurations with the help of an experimental study. The design method, systematic verification and experiments are presented below. To give detailed insight into the particularities of steel liners protected against buckling by pressure relief valves, the drainage system which has been in successful operation since 1989 at the Collierville tunnel in California is briefly described.

2 Pressure Relief Valves to Counter External Pressure in the Steel Liner of the Collierville High-Pressure Tunnel

The lower stage of the water power plant of North Fork Stanislaus River in California has a useful head of 692 m, which results in a design discharge of 40 m3/s with installed capacity of 204 MW for two Pelton turbines. The headrace tunnel known as Collierville consists of an 11.8-km-long upper pressure tunnel, an almost 680-m-high vertical shaft and a lower high-pressure tunnel with length of 2.16 km (Fig. 2).

Alignment with a vertical shaft followed by a high-pressure tunnel leading to the powerhouse is rather unconventional compared with typical power plants in the Alps (Schleiss 1989). The relatively good rock quality consisting of mica schist and the high overburden allows the steel liner to be omitted in the vertical shaft and over most of the length of the high-head-pressure tunnel. The steel liner reaches from the powerhouse into the rock mass only until the overburden is high enough and a permeable lining is allowed. Thus, the high-pressure tunnel is only equipped with a steel liner over a length of 844 m (Fig. 2). The remaining length of 1292 m as well as the vertical shaft and the surge shaft are only lined with non-reinforced concrete. With a maximum inner water pressure of 70 bar, the high-pressure Collierville tunnel is still one of the highest loaded pressure tunnels without a steel liner lying in non-granite rock.

Nevertheless, alignment with a high overburden has the disadvantage that the steel-lined part of the pressure tunnel is submitted to very high external water pressure, reaching 500 m at the upper end of the steel liner during emptying of the headrace system. Protection against buckling could not be ensured economically using the normal approach of increasing the steel thickness or using stiffeners. Thanks to the use of check valves, a steel liner with diameter of 3.25 m was designed only for internal water pressure. Therefore, the steel liner thickness could be limited to 16 mm (steel ASTM 617 with f y = 680 N/mm2) over 75% of the total length (Schleiss 1988). For the remaining 25% of the length, the steel liner thickness was increased successively from 16 to 35 mm towards the powerhouse to account for the decreasing rock overburden (Fig. 2).

The steel liner was equipped with pressure relief valves (Figs. 3, 4) in such a way that the external water pressure acting during emptying could be limited to 8.2 bar. This is equal to a buckling safety of S = 1.50 for the steel liner with thickness of 16 mm and initial gap of 0.05%. To regulate safely the pressure of the seepage flow from the rock mass towards the steel liner below 8.2 bar during emptying, the steel liner was protected using two pressure relief valves every 6.1 m in the upper 60% of the steel-lined stretch. The two pressure relief valves were located alternatively at 1h30 and 7h30 and at 4h30 and 10h30, respectively. The lower 40% of the steel-lined part was equipped with only one pressure relief valve every 6.1 m. A commercial spherical check valve costing about US $50 was used, which fulfilled the tightness criteria in view of the high internal pressure (>70 bar) (Fig. 3). In total, 221 pressure relief valves with free orifice of 20 mm could be installed directly with a thread in the steel liner without increasing the steel liner thickness locally.

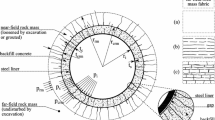

Calculation model for steel-lined pressure shafts and tunnels comprising steel liner (inner radius r s), gap between steel liner and backfill concrete, cracked backfill concrete (outer radius r c), loosened or grouted rock zone (outer radius r g) and undisturbed rock mass. The pressure distribution of seepage flow towards the emptied tunnel is shown with the pressure in the gap, p Gap, at the interface between backfill concrete and loosened (or grouted) rock zone, p c, and at the interface between loosened (or grouted) and undisturbed rock zone, p g

After the test filling in 1989, a first emptying of the high-head-pressure tunnel was performed. The external water pressure acting on the outer side of the steel liner was measured using piezometers installed along the steel liner in the backfill concrete. These pressure measurements confirmed that the check valves successfully limited the external water pressure acting on the steel liner to below the allowed design value of 8.2 bar. Regarding emptying speed, no restrictions have to be observed, since the check valves act immediately. Thanks to careful analysis of the rock mass bearing capacity and the systematic use of pressure relief valves, US $6 million of construction costs could be saved compared with a traditional design. Forty per cent of these savings were owed to the pressure relief valves (Johannesson et al. 1988). During regular emptying of the high-pressure tunnel to check the corrosion protection of the steel liner, the pressure relief valves worked perfectly.

3 Design Method

3.1 Calculation Model

The pressure relief valves in the steel liner have to drain the seepage flow from the rock mass in such a way that the external water pressure does not exceed the tolerable value for a certain steel liner thickness. Assuming radially symmetric permeability conditions, the discharge through the pressure relief valves is influenced by the head losses of the seepage flow across the following zones (Fig. 4):

-

Rock mass

-

Grouted or loosened rock zone around the pressure shaft or tunnel (if present)

-

Backfill concrete (non-reinforced, cracked)

-

Gap between steel liner and backfill concrete (opening depends on external water pressure)

-

Pressure relief valves.

Since the opening of the gap between the steel liner and the backfill concrete depends on the external water pressure, a mechanical–hydraulical coupled system is obtained, which has to be solved using an iterative approach.

3.2 Seepage Flow Through the Rock Mass

Assuming a groundwater level which is located above the tunnel and almost parallel to its axis, the seepage flow through the rock mass towards the tunnel is shown in Fig. 5 and can be estimated as follows for isotropic rock mass permeability (Rat 1973; Schleiss 1985, 1986):

where q is the seepage flow from the rock mass towards the tunnel shaft (or tunnel) per unit length, b is the height of the groundwater table above the shaft (or tunnel) at the considered section, r g is the outer radius of the loosened or grouted rock zone, p g is the water pressure at the outer border of the loosened or grouted rock zone, k r is the rock mass permeability and ρ w is the density of water.

Equation 1 is appropriate if the tunnel is located rather deep below the groundwater table (b > 10r g), which is normally the case for high rock overburden. For shallower cases, the seepage flow can be estimated more precisely using Rat’s (1973) approach. He also gives an analytical solution for the case where an impervious rock layer is situated a certain distance below the tunnel. More recent approaches for estimating the seepage flow towards a tunnel as well as the induced stresses can be found in Bobet and Nam (2007). In the case of anisotropic rock mass permeability, Eq. 1 may be applied by using the highest permeability, which gives a pessimistic rough estimate for the seepage flow towards the tunnel. More precise results for anisotropic rock mass permeability require numerical simulation of the seepage flow using the finite-element method.

3.3 Seepage Flow Through the Grouted or Loosened Rock Zone and the Backfill Concrete

Assuming a radially symmetric seepage flow according to Darcy’s law through a thick-walled cylinder corresponding to the grouted or loosened rock zone, the seepage per unit length can be obtained as

In the same way, the seepage flow through the backfill can be calculated as

where r g is the outer radius of the loosened or grouted rock zone, r c is the outer radius of the backfill concrete, r s is the outer radius of the steel liner, p g is the water pressure at the outer border of the loosened or grouted rock zone, p c is the water pressure at the outer side of the backfill concrete, p Gap is the water pressure in the gap between the backfill concrete and the steel liner, k g is the permeability of the loosened (k g > k r) or grouted rock zone (k g < k r) and k c is the permeability of the cracked backfill concrete.

The non-reinforced backfill concrete will normally crack under internal water pressure. Since only a few cracks will occur, but at least two as a result of symmetry, the permeability of the cracked backfill concrete will be on the order of 10−3 m/s, which is several orders of magnitude higher than the permeability of the rock mass (typically 10−5–10−7 m/s). Assuming such a high permeability of the backfill concrete is on the safe side for the design of the pressure relief valves; if a loosened rock zone exists near the backfill concrete owing to rock disturbance during excavation, its permeability would also be higher than the rock mass. The loosened rock zone is normally consolidated by grouting to limit the deformation of the steel liner under internal pressure. It should be noted that even perfect grouting cannot decrease the permeability below 1 Lugeon (about 10−7 m/s).

3.4 Flow Through the Gap towards the Pressure Relief Valves

The seepage flow towards the tunnel has to reach the pressure relief valves through the gap between the steel liner and the backfill concrete. A non-parallel, turbulent rough flow is assumed in the gap, in accordance with Louis (1967). Each pressure relief valve drains the gap in the radial direction, as can be seen in Fig. 6. A radially symmetric seepage flow in the gap towards the valves can therefore be assumed. The maximum radial flow distance R of the seepage in the gap towards the check valve is obtained from half of the maximum distance between two valves measured on the cylindrical surface of the gap (Fig. 6).

Cross-section of steel liner equipped with pressure relief valves (left). Radial symmetric seepage flow towards the valves in the unfolded cylindrical gap (right). The maximum radial distance R of the seepage flow towards the check valve corresponds to half of the maximum distance between any two valves

Assuming that the seepage flow in the gap approaches the pressure relief valves in a radially symmetric way and that the inflowing seepage from the rock mass is uniformly distributed on all the pressure relief valves, the gap flow according to Louis (1967) becomes

where p Gap is the water pressure in the gap between the backfill concrete and the steel liner, p Valve is the water pressure in the gap at the entrance to the pressure relief valve, r o is the radius of the valve orifice, r c is the outer radius of the backfill concrete, r s is the outer radius of the steel liner, R is the longest path of the seepage flow in the gap in radial direction towards the valve (about half of the maximum distance between two valves), D is the distance between the sections of the pressure relief valves in axial direction along the tunnel or shaft, n is the number of valves in the section, 2a is the width of the gap between backfill concrete and steel liner and ε is the absolute roughness of the gap (typically 0.15 mm for concrete–steel contact).

Since the steel liner is deformed under the water pressure acting in the gap (Fig. 4), the following relationship based on the tube formulae can be written:

where p Gap is the water pressure in the gap between the backfill concrete and the steel liner, r sm is the mean radius of the steel liner, t is the thickness of the steel liner, 2a o is the initial width of the gap between the backfill concrete and steel liner (if any) and E S is the elasticity modulus of steel.

If the initial gap (2a o) is neglected, the design of the pressure relief valves can be considered to be on the safe side.

3.5 Flow Through the Pressure Relief Valves

The flow through the gap reaching the pressure relief valves is released through them into the tunnel or shaft. The flow through each pressure relief valve is Q = q(D/n), assuming a uniform distribution. The characteristics of the pressure relief valve as a function of the pressure at its entrance can be obtained from the valve manufacturer or by a simple test. This relationship normally has the form

where C is the head loss constant of the valve, P Valve is the water pressure at the entrance to the valve, Q is the flow through each pressure relief valve, q is the seepage flow from the rock mass towards the tunnel shaft or tunnel per unit length, D is the distance between the sections of the pressure relief valves in axial direction along the tunnel or shaft and n is the number of valves in the section.

3.6 Design of the Configuration of the Pressure Relief Valves

Since, for continuity reasons, the discharge of seepage flow through the different zones as outlined above towards the pressure relief valves has to be the same, a non-linear system of six equations is obtained. This system of equations allows the derivation of the unknown water pressures p g, p c, p Gap and p Valve as well as the unknown width of the gap (2a) and the seepage flow from the rock mass q per unit length of the tunnel for a chosen configuration of pressure relief valves. The water pressure in the gap can then be compared with the critical buckling pressure of the steel liner reduced by a certain safety factor. If the water pressure in the gap is too high, the number of pressure relief valves has to be increased or their spacing has to be reduced.

4 Physical Confirmation of the Calculation Model

In the framework of a master’s thesis at the Laboratory of Hydraulic Constructions (LCH-EPFL) in Switzerland, the calculation model was verified by systematic tests for various valve configurations at a specially designed testing facility (Wyss 2003). Inside a vertical, cylindrical steel pressure vessel, the different zones such as rock (lean concrete), backfill concrete (cement mortar with three predefined cracks of about 1 mm) as well as the drained steel liner [polyvinylchloride (PVC) pipe] were modelled (Figs. 7, 8).

Experimental set-up for physical modelling of the steel liner drainage system with different pressure relief valve configurations. Left vertical cross-section showing the steel pressure vessel with pre-stressed steel bars for stabilizing the bottom and top cap of the cylinder as well as the inner PVC pipe (reproducing the liner) embedded in backfill concrete (cement mortar) and equipped with check valves. Right horizontal cross-section showing the above-mentioned elements and the gauges for radial displacement measurements of the liner (see also Figs. 8, 9)

The groundwater pressure was produced by a pump in the space between the cylindrical steel pressure vessel and the lean concrete representing the rock zone. The permeability of the lean concrete was determined by laboratory tests. The following measurements were carried out:

-

Pressure measurements with piezometer tubes at the transition of the different zones (Figs. 7, 8)

-

Radial deformation of the liner (PVC pipe) by long-base extensometer (Figs. 8, 9)

-

Total discharge furnished by the pump and flow through each pressure relief valve.

In total, 18 tests with six different configurations using a varying number and layout of pressure relief valves were performed as shown in Fig. 10. For a given configuration, the groundwater pressure and the opening degree of the pressure relief valves were varied.

The pressure measurements of the radial seepage flow through the rock zone modelled with lean concrete and the backfill cracked concrete modelled with cement mortar confirmed the theoretical values obtained by Eqs. 2 and 3 as expected. Regarding the radial flow in the gap between the liner and the backfill concrete towards the pressure relief valve, a certain doubt exists as to whether the radially symmetric theory can reproduce it correctly. Therefore, Eqs. 4 and 5, which describe the relationship between pressure and flow in the gap, are compared with the measurements of each test in Figs. 11 and 12. It can be seen that the calculation model is in good agreement with the measurements if a ±10% range of uncertainty of the absolute roughness of the gap of ε = 0.15 mm is considered.

Pressure head in the gap between steel liner and backfill concrete as a function of the seepage flow in the gap towards the valve: comparison of measurements (points) with calculated values (lines for valve configurations 1, 2 and 3, high valve density n = 4). The arrows indicate a ±10% range of uncertainty for the absolute roughness of the gap, ε

Pressure head in the gap between steel liner and backfill concrete as a function of seepage flow in the gap towards the valve: comparison of measurements (points) with calculated values (lines for valve configurations 4, 5 and 6, low valve density n = 1 and 2). Arrows indicate the ±10% uncertainty range for the absolute roughness of the gap, ε

5 Conclusions and Recommendations

The presented calculation method allows one to design the configuration and required number of pressure relief valves in a steel liner to protect it against high external water pressure during emptying. Nevertheless, the following recommendations should be considered:

-

The location of the pressure relief valves in each section (one or two valves) should alternate from 1h30 and 7h30 to 4h30 and 10h30 in the next section. Valves located at the tunnel invert or crown should be avoided because they hinder maintenance works in the tunnel.

-

The smallest free orifice diameter of the check valve should not be below 2 cm in view of the risk of clogging. The resulting holes in the steel liner for the threads of such valves (Figs. 1, 3) normally do not require a local increase of the thickness of the steel liner, as long as its thickness is not below 16 mm.

-

The permeability of the rock mass near the pressure shaft or tunnel as well as the elevation of the groundwater level has to be determined with a sufficient number of boreholes. The design of the required number of pressure relief valves should be based on conservative values of rock mass permeability, to take into account that the local permeability can be considerably higher than the measured values. The required number of pressure relief valves only slightly influences the costs.

-

If the tunnel or shaft is emptied over a long period of time for inspection or carrying out maintenance work such as rehabilitation of corrosion protection of the steel liner, the pressure relief valves should be unscrewed to avoid any clogging resulting from calcite deposits. The controlled and eventually replaced pressure relief valves should then be reinstalled only just before filling.

-

During placing of the backfill concrete behind the steel liner, the thread holes of the check valves should be closed temporarily with a greased screw which is at least 2 mm longer than the thickness of the steel liner.

The procedure for the design of pressure relief valves was applied successfully in 2010 for the Belleplace pressure shaft of Emosson Dam in Switzerland.

References

Amstutz E (1969) Das Einbeulen von Schacht–und Stollenpanzerungen. Schweizerische Bauzeitung 87(28):3–11

Bobet A, Nam SW (2007) Stresses around pressure tunnels with semi-permeable linings. Rock Mech Rock Eng 40(3):287–315

Finger W, Wieser H (1980) Zur Aufnahme des Aussendruckes bei Stollenpanzerungen. Neue Lösungen und ihre rechnerische Erfassung. Bauingenieur 55:241–251

Hachem FE, Schleiss AJ (2009) The design of steel-lined pressure tunnels and shafts. Hydropower Dams 16(3):142–151

Jacobsen S (1977) Buckling of circular rings and cylindrical tubes under external pressure. Water Power Dam Constr 29(12):460–467

Jacobsen S (1990) Recommendations on the design of steel linings for penstocks. Water Power Dam Constr 42(4):44–47

Johannesson P, Schleiss A, Korbin G (1988) Calaveras project high head pressure tunnel. Water Power Dam Constr 40(11):43–48

Louis C (1967) Strömungsvorgänge in klüftigen Medien und ihre Wirkung auf die Standsicherheit von Bauwerken und Böschungen im Fels. Veröffentlichung 30, Institut für Boden-und Felsmechanik, Universität, Karlsruhe

Rat M (1973) Ecoulement et répartition des pressions interstitielles autour des tunnels. Bull. Liaison Labo. Pont et Chaussées 68: 109–124 (ref. 1423)

Schleiss A (1985) Bemessung von Druckstollen. Teil I: Literatur, Grundlagen, Felshydraulik insbesondere Sickerströmungen durch Auskleidung und Fels. VAW-Mitteilung 78, Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie, ETH Zürich

Schleiss AJ (1986) Design of previous pressure tunnels. Water Power Dam Constr 38(5):21–29

Schleiss A (1988) Design criteria applied for the lower pressure tunnel of the North Fork Stanislaus River Hydroelectric Project in California. Rock Mech Rock Eng 21(2):161–181

Schleiss A (1989) Analyse der Gebirgstragfähigkeit bei der Bemessung des Hochdruckstollen Collierville in Kalifornien, vol 38. Salzburger Kolloquium für Geomechanik, pp 73–80

Schleiss AJ (1997) Design of concrete linings of pressure tunnels and shafts for external water pressure. In: Proceedings of Tunneling Asia ’97, New Delhi, pp 291–300

Schleiss A (2002) Berücksichtigung des Restrisikos bei der Konzeption und Bemessung von hochbeanspruchten Druckschächten. Int. Symposium Moderne Methoden und Konzepte im Wasserbau, Versuchsanstalt für Wasserbau, Hydrologie und Glaziologie (VAW), VAW-Mitteilung 175, pp 385–394

Wyss U (2003) Dimensionnement des blindages drainés contre le voilement. Travail de diplôme, Laboratoire de constructions hydrauliques LCH, EPFL

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schleiss, A.J., Manso, P.A. Design of Pressure Relief Valves for Protection of Steel-Lined Pressure Shafts and Tunnels Against Buckling During Emptying. Rock Mech Rock Eng 45, 11–20 (2012). https://doi.org/10.1007/s00603-011-0187-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-011-0187-9