Abstract

Because it is difficult to adapt ceramic technology to prevent ceramic fractures, attention has been directed at the development of a new metal alloy, the surface of which can be treated to be made more scratch-resistant than cobalt chromium alloy. A niobium (Nb) alloy of zirconium (Zr–2.5Nb) has recently been introduced as a bearing surface for the femoral component in hip arthroplasty. The advantage is that the surface of the metal can be transformed into a relatively thick (micrometers) zirconium oxide (i.e., zirconia) ceramic-like material, thus combining the benefits of ceramic and metal in one component. The oxide layer is not a coating but rather the surface zone of the metal alloy. The oxide/metal interface is continuous, without pores or voids which might be detrimental to oxide adhesion. The ceramic like zirconia surface layer is highly adherent to the metal alloy and further supported the use of this novel alloy as a scratch-resistant counterface for total joint replacement prostheses. Laboratory studies have demonstrated the superior wear performance of oxidized zirconium against polyethylene in comparison with cobalt–chromium alloy. This paper comments the advantage of this new bearing surface for hip replacement.

Résumé

S’il est connu depuis longtemps que les têtes en céramique assurent un meilleur couple de frottement face au polyéthylène que les têtes en métal, la céramique présente l’inconvénient du risque de fracture. C’est pour éviter ces inconvénients qu’un nouveau matériau a été créé pour les prothèses de hanche et de genou: il s’agit de l’oxinium qui présente les avantages de la résistance mécanique du métal et les avantages de la surface d’une céramique pour ce qui concerne le couple de frottement. Il s’agit d’un alliage de zirconium-niobium (Zr2.5Nb) qui est oxydé sur 5 microns d’épaisseur et qui a le nom d’oxinium. C’est l’oxydation en surface du métal qui assure la céramisation. Cet oxyde n’est pas un revêtement appliqué mais une transformation de la surface métallique d’origine en céramique d’oxyde de zirconium due à la saturation en oxygène. Il n’y a donc pas de discontinuité des caractéristiques mécaniques observée dans le cas de couches céramiques déposées. Ceci permet d’obtenir un oxyde dense, à grains fins, d’une épaisseur d’environ 5 microns et sans craquelure. Les études en laboratoire ont montré la supériorité de ce nouveau matériau lorsqu’il est comparé avec le chrome cobalt dans les couples de frottement avec le polyéthylène. Ces papiers commentent les avantages et la place de ce nouveau matériau dans les prothèses totales de hanche.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hip arthroplasty is one of the most successful and one of the most effective treatment for osteoarthritis of the hip joint. Long-term studies of selected patient cohorts, and the Scandinavian knee registries, have demonstrated high survivorship rates after more than 15 years. On the basis of this success, hip replacement is being performed on increasingly in younger and more active patients. However, there are at least two problems that a young or active patient faces with regard to the prosthetic joint. First, the use of the implant is more intense and secondly the patient’s life expectancy is longer and the potential total number of loading cycles is increased proportionally.

In chronological order, the factors limiting the longevity of a hip prosthesis are the surgical technique, fixation of the implant to the bone, osteolysis (often associated with wear of the bearing), fatigue failure of the implants, and long-term skeletal remodeling. No implant system can overcome inadequate surgical technique. The durability of implant fixation in the patients has been improved during the last 20 years. So today a large proportion of re-operations are for loosening of the components mostly caused by degradation of parts of the supporting bony structures into fibrous or granulation tissue initiated by polyethylene wear particles [1–3]. Thus, further improvement in the success rates depends on the reduction or avoidance of such wear particles.

Wear is dependent on materials. The desired goal of alternative bearing surfaces is a reduction in biologically active particulate wear debris and thus a reduction in the occurrence of osteolysis and aseptic loosening. Polyethylene wear with production of articulate debris may lead to the development of osteolysis. While osteolysis was first noted in association with cementless knee replacements, it has been found also in cemented hip replacements. The etiology of the osteolysis relates to the response of the macrophage to particulate debris. If debris gains access to the metaphyseal bone it will be phagocyted with production of cytokines which, in turn, stimulate osteoclasts to cause bone resorption. In addition to the biological response of the macrophages to polyethylene debris, increased pressure in the joint may be responsible for a pumping action increasing ingress of debris into bone. Osteolysis is a complication of hip arthroplasty which can relate to polyethylene wear.

New bearings for hip arthroplasty have been introduced with the aim of reducing the number of biologically active wear particles. There are two approaches:

-

1.

To improve the wear resistance of polyethylene through cross-linking [4].

-

2.

The avoidance of polyethylene and utilization of alternative bearings.

This second approach has fueled the development and introduction of new metal bearings and ceramics to improve the wear characteristics of the femoral and acebatulum components. However, metal on metal bearings and alumina components have demonstrated some limits.

Metal metal components: limits in young patients

The metal on metal bearing has the highest level of number of wear particle

Although metal on metal hip has a decreased linear and volumetric wear compared with metal on PE couple, the number of particles generated are greater (100–500 times increase in the number). Because metal particles are considerably smaller than PE particles, the total number of histiocytes required to store the particles are however lower. In vitro, low to moderate concentrations of metal particles stimulate the release of cytokines than can lead to osteolysis. At higher concentration, metal particles are cytotoxic leading to cell death and may increase the ions release in blood and urine.

The CoCr particles released are extremely small, estimated at 20–80 nm (0.020–0.080 μm), some 250 times smaller than a red blood cell.

Although the volumetric wear from metal-on-metal articulations is low, the calculated number of metal wear particles is higher than for the same volume of polyethylene wear. At low nonlethal doses, metal particles can stimulate macrophages to release various intercellular mediators, proinflammatory and bone resorbing cytokines, initiating a cascade of reactions which can lead to osteolysis and aseptic loosening.

Ion release increases the level of cobalt and chromium in serum and urine of patients

Elevated metal ions (Co and Cr) seen in the blood and urine of patients receiving a metal on metal bearing is well documented in multiple publications. These metal ions have multiple potential sources: the metal on metal articulation, impingement, corrosion secondary to modularity (head/neck junction or junction between metal liner and acetabular component of a modular implant). One prevalent concern with regard to metal-on-metal articulations is the potential for long term adverse effects mediated by elevated serum metal ion levels and remote site deposition of metal particles. In a prospective randomized study with 2 years follow-up MacDonald et al. [5] evaluated polyethylene versus metal bearings. Patients receiving a metal-on-metal articulation had significantly elevated erythrocyte and urine metal ions compared with patients receiving a polyethylene insert.

Hypersensitivity to metal ions may generate immunological allgergological response in patients with predisposing conditions

All metals in a biologic environment corrode and the ions released can combine with proteins and activate the immunosystem. Nickel is the most common level sensitizer in humans followed by Co and Cr. Immune response to metallic particulates remains a matter of controversy. Recently, some groups described specific histology changes in the tissues around revised metal on metal hips. The clinical relevance of these findings is not clear but may be a cause of pain and synovitis.

Alumina ceramic components in hip arthroplasty and the risk of fracture

The history of alumina ceramic femoral heads for total hip arthroplasty started in France with Boutin who implanted the first alumina hip in 1970. Alumina (Al2O3) ceramics belong to the group of oxide ceramics. Whilst the classical ceramics like earthenware, stoneware, and porcelain consist of several phases of silicates with different melting temperatures and receive their density increase during firing by melting processes, the so called liquid phase sintering, the oxide ceramics are rather pure oxides of the least noble metals and reach their final density essentially via solid state reactions, mostly diffusion processes. The medical grade alumina ceramic, according to international standards, consists more than 99.5% of closely packed corundum crystals. Corundum is the colorless version of ruby and sapphire. The latter owe their colors to very small amounts, of metal ions like Co, Cr, Fe, or Mn dissolved in their lattices, whilst corundum is nearly completely free from these ions. In the early 1980s most manufacturers introduced today’s versions based on general progress in material science, as e.g. employing HIPing (Hot Isostatic Pressing) for achieving the nearly theoretical density without exaggerated grain growth. Modern alumina ceramics have a low porosity, low grain size, high density, and high purity. Thus, hardness, fracture toughness, and burst strength are increased. Alumina heads are used because of their wear characteristics and because of their superior smoothness [6, 7]. However, for many surgeons, these advantages are counterbalanced by the fear of ceramic fracture and by the difficult revision procedure when fracture of alumina ceramic head occurs. The ceramic head has an excellent compression strength and currently a 32 mm head tested in compression sustains a 102-kN load. This exceeds the mechanical resistance of the femoral diaphysis to static load (only 20 kN). So probably the risk of fracture with alumina has nothing to do with the activity or the weight of the patients. Jumping and sports may be allowed if the compression load is not reached during these activities. But ceramic fractures can be explained by the propagation of a crack initiated in the material by the imperfection of the material or by a specific event that initiates the crack. Because of the grain structure of the material, the initial crack will grow and lead to a fracture fatigue. This probably explains why the fracture do not usually occur during a strenuous activity but rather occurs suddenly without warning, without extra load, with a patients sitting or even during the night in bed. The specific event in relation with the crack most be researched several days or weeks previously.

It is important to recognize a fracture of a ceramic head early, because the abrasive effect of alumina particles can cause catastrophic destruction of bone, or metallosis because of metallic debris originated from the metallic stem, neck taper or socket metal back.

Ceramic debris may not be bioinert as initially assumed because osteolysis has been described in some patients with a ceramic-on-ceramic bearing. Recently, some studies have demonstrated inflammatory and cytotoxic reactions on the cellular level, but the relationship to material, size, and particle number remains uncertain however it seems that there is less inflammatory reaction than that found with metal on metal or metal on polyethylene bearings in well functioning prosthese. Ion toxicity is not an issue with ceramics because of their high corrosion resistance.

Treatment of ceramic fractures must be adequate to avoid additional problems later. The revision must be done emergently to retrieve all component fragments, to clean the joint from ceramic debris, to do an early debridment and extensive synovectomy. If this is possible a new ceramic head can be used on the old Morse taper after inspection of the surface of the cone. But when a fracture of a ceramic head occurs, many debris of alumina of different size are generated in the joint. Even with a synovectomy, the surgeon must be aware that it is never possible to clean totally the joint from all the alumina debris. A simple metallic head must be avoided because the remaining ceramic debris are trapped into the polyethylene of the socket and give rise to severe and quick damage to a metallic femoral head. If the Morse taper has been damaged because the fracture has not been quickly revised, it is necessary to change the stem to get a new taper. If the fracture is quickly revised the cone is usually not damaged and an other ceramic head may be discussed on the old taper even if this is not recommended by the manufacturer: this may avoid a femoral stem revision which may be a difficult procedure.

New metal counterface: oxidized zirconium (oxinium); advantages of ceramic and metal

Because it is difficult to adapt ceramic technology to prevent ceramic fractures, attention has been directed at the development of a new metal alloy, the surface of which can be treated to be made more scratch-resistant than cobalt chromium alloy.

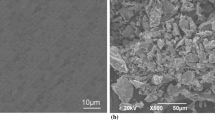

A niobium (Nb) alloy of zirconium (Zr–2.5Nb) has recently been introduced as a bearing surface for the femoral component in hip arthroplasty. The advantage is that the surface of the metal can be transformed into a relatively thick (micrometers) zirconium oxide (i.e., zirconia) ceramic-like material, thus combining the benefits of ceramic and metal in one component. The oxide layer is not a coating but rather the surface zone of the metal alloy [8, 9].

The oxide/metal interface is continuous, without pores or voids which might be detrimental to oxide adhesion. The ceramic like zirconia surface layer is highly adherent to the metal alloy and further supported the use of this novel alloy as a scratch-resistant counterface for total joint replacement prostheses. Laboratory studies [10–12] have demonstrated the superior wear performance of oxidized zirconium against polyethylene in comparison with cobalt–chromium alloy. Wear was evaluated with knee simulator comparatively with chrome cobalt implant. The wear rate was 89% less than for the CoCr. The analysis of the wear particle size suggested that the size of the particles were equivalent with oxinium and CoCr but the number was significantly less for oxinium. This was in contrast to the observation of the size of particles observed with cross-linked polyethylene that reduced the size of particles while increasing the number of particles, a phenomenon which could increase the biologic response of the macrophages. These findings suggest that the use of oxinium may reduce the wear rate by more than six times and may increase the survival ship of the knee prosthesis.

The advantage is that a relatively thick (micrometers) zirconium oxide can be formed on the surface to produce a highly adherent ceramic-like layer, thus wedding the benefits of a ceramic and metal in one component. The ceramic oxide is not a coating but only the surface zone of the metal alloy. Oxinium has the advantages of a ceramic counterface in terms of low fraction, resistance to abrasive scratching, and immunity to corrosive roughening without the brittleness of an all ceramic component.

References

Dowson D, Tahery S, Wallbridge N (1987) The role of counterface imperfections in the wear of polyethylene. Wear 119:277–293

Greer KW, Hamilton JV, Cheal EJ (1995) Polyethylene wear in orthopedics. In: Wise DL, Trantolo DJ, Altobelli DE, Yaszemski MJ, Gresser JD, Schwartz ER (eds) Encyclopedic handbook of biomaterials and bioengineering, part B: applications, vol 1. Marcel Dekker, New York, pp 613–638

Saikko U, Colonius O, Keranen J (2001) Effect of counterface roughness on the wear of conventional and crosslinked ultrahigh molecular weight polyethylene studied with multidirectional motion pin on disk device. J Biomed Mater Res 57:506–512

Bragdon CR, Jasty M, Muratoglu OK, O’Connor DO, Harris WH (2003) Third-body wear of highly cross-linked polyethylene in a hip simulator. J Arthroplasty 18:553–561

MacDonald SJ, McCalden RW, Chess D et al (2003) Metal-on-metal versus polyethylene in total hip arthroplasty: a randomized clinical trial. Clin Orthop Relat Res 406:282–296

Clarke I, Willmann G (1994) Structural ceramics in orthopaedics. In: Cameron H (ed) Bone implant interface. St. Louis, Mosby, pp 203–252

Oonishi H, Wakitani S, Murata N et al (2000) Clinical experience with ceramics in total hip replacement. Clin Orthop Relat Res 379:77–84

Benezra V, Mangin S, Treska M, Spector M, Hunter G, Hobbs LW (1999) Microstructural investigation of the oxide scale on Zr–2.5 Nb and its interface with the alloy substrate. Mat Res Soc Symp Proc 550:337–342

Mishra A, Davidson J (1993) Zirconia/zirconium: a new abrasion resistant material for orthopaedic applications. Mater Tech 8:16–21

Good V, Ries MD, Barrack RL et al (2003) Reduced wear with oxidized zirconium femoral heads. J Bone Joint Surg 85A:105–110

Ries MD, Salehi A, Widding K, Hunter G (2002) Polyethylene wear performance of oxidized zirconium and cobalt chromium knee components under abrasive conditions. J Bone Joint Surg 84A(Suppl 2):129–135

Sprague J, Salehi A, Tsai S et al (2003) Mechanical behaviour of zirconia, alumina and oxidized zirconium modular heads. In: Brown S, Clarke IC, Gustafson A (eds) ISTA, vol 2. International Society for Technology in Arthroplasty, Birmingham, 2004, pp 31–36

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hernigou, P., Mathieu, G., Poignard, A. et al. Oxinium, a new alternative femoral bearing surface option for hip replacement. Eur J Orthop Surg Traumatol 17, 243–246 (2007). https://doi.org/10.1007/s00590-006-0180-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00590-006-0180-2