Abstract

This paper presents a flip-chip based packaging technique for encapsulating MEMS electrostatic actuators for biomedical applications. High-performance electrostatic inchworm actuators are used to demonstrate the packaging technique. A wall structure is put around the actuator surrounding it completely but leaving a small clearance where the actuator shuttle can extend off the edge of the chip. A cap chip is fabricated separately, and flip-chipped onto the actuator. Au–Au thermal bonding technique is used to fix the cap. Finally, rendering the surfaces of the clearance hydrophobic prevents the water ingress when the actuator operates in water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microfabricated devices and systems have always been very popular in biomedical applications since the earliest days of micromachining (Wise 2007). First examples of micromachined biomedical systems are introduced more than 40 years ago (Wise et al. 1970). With the advances in micromachining and integration of microsystems, more and more biomedical systems are being explored.

Researchers started to study on microactuators when they need to control biological objects or their environment at the microscopic scale. Several studies have been published which integrate microactuators within micromanipulators (Lee et al. 1995), microsurgery tools (Lal 1998), micropumps (Zengerle et al. 1995), and microneedles (Muthuswamy et al. 2005).

Depending on the actuation nature, integrating microactuators within biomedical devices is not straightforward. Particularly, electrostatic actuators are not easily integrated with biomedical applications. There are two main reasons behind this fact. First, the environment can be very harsh for the electrostatic actuator to work properly. The body liquid, which is ionic and contains biological particles, can cause corrosion, particulate contamination, and stiction. Second, electrolysis and polarization can hinder the device operation. Although there are approaches in the literature to avoid electrolysis and polarization by applying high frequency signals (Sounart et al. 2005), these methods do not provide a solution for the former challenges (Panchawagh et al. 2007).

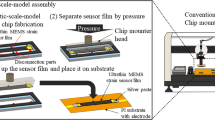

Recently, an interesting encapsulation method is introduced by researchers including the authors of this paper which utilizes closely placed hydrophobic surfaces (Dy and Ho 2009; Erismis et al. 2009; Panchawagh et al. 2007). The actuator is surrounded by a wall structure completely but a clearance which allows the shuttle to extend off the edge of the device. A separately fabricated cap is flip-chipped onto the actuator. Finally, the surfaces of the clearance are rendered hydrophobic which enables the actuator to work in aqueous environments.

This paper presents the details of this encapsulation technique and provides further discussions for the integration of electrostatic actuators in biomedical applications.

2 Design and fabrication

The basic idea behind the encapsulation technique is demonstrated in Fig. 1. A wall structure is surrounded around the actuator, but it leaves a clearance to let the shuttle of the actuator extend off the edge of the chip. The chips are designed in such a way that the clearance is kept minimal from all directions (2–3 μm). Furthermore, dummy fingers are put around the clearance to increase the roughness and to enhance the hydrophobic effect (Yoshimitsu et al. 2002). A cap chip, fabricated either from silicon or glass is then flip-chipped onto the actuator chip to encapsulate it.

2.1 Actuator chip

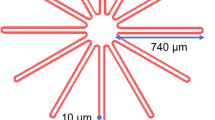

The electrostatic inchworm actuators used in this study are fabricated using a commercially available multi-project-wafer MEMS process, SOIMUMPs (Miller et al. 2008). SOIMUMPs provides 25 μm thick Si structural layer with 2 μm lateral critical dimensions. The actuators are designed to operate at low voltages (9–12 V) in order to be more compatible with the biological environment and they are capable of generating large forces (0.2–0.4 mN) with ± 50 μm ranges (+ 50 to −50 μm). Furthermore, they are integrated with a microneedle (25 × 80 × 1,500 μm) to demonstrate a possible biomedical positioning application. The details of the design and fabrication are previously presented (Erismis et al. 2008) (Fig. 2).

The wall surrounding the actuator is slightly taller than the actuator shuttle by approximately 1.2 μm which is the total thickness of the two metal layers (two Cr/Au evaporations) of the SOIMUMPs process. It has two openings, one from the front and one from the back. The back opening is for the electrical connections, and the front opening creates the clearance.

Dummy fingers (4 μm wide, 8 μm pitch) are placed on the front side of the wall in order to enhance the hydrophobic effect near the clearance (Yoshimitsu et al. 2002). Similarly, some dummy fingers are also placed on the shuttle of the actuator where it is just extending off the clearance.

The clearance is tried to be kept as small as possible in order to withstand large pressure differences between the inside and outside of the encapsulation. It is 2 μm wide from the right and left which is the minimum lateral gap achievable from the SOIMUMPs process. And it is again 2 μm wide from the bottom as this is the thickness of the buried SiO2 layer. However, the top dimension of the clearance is dependent on both the actuator and the cap design.

2.2 Cap chip, glass or silicon

Both silicon and glass caps can be used for the encapsulation. Silicon caps can be fabricated with the SOIMUMPs process together with actuators which makes them very practical. On the other hand glass caps have the advantage of being transparent and allowing to see through them and observe the actuators after the encapsulation.

Figure 3 shows the schematics of the encapsulation technique using glass caps, and some SEM images of an encapsulated actuator. The glass cap has a gold rim which coincides with the gold on the wall of the actuator chip during the flip-chip in order to achieve the Au–Au thermal bonding. The thickness of this metal rim is 0.31 μm (10/300 nm TiW/Au sputter). However, this makes the clearance approximately 1.5 μm wide from the top after the encapsulation (1.2 μm from the actuator chip, 0.31 μm from the cap chip). This could still work but in order to increase the tolerance, we introduced a shallow glass etch (1st glass etch, Fig. 1). This shallow etch (~1.5 μm using buffered HF) increases the width to approximately 3 μm. Yet, we introduced a second buffered HF etch (~2.5 μm, Fig. 1) to lower the ground inside the gold rim in order to increase the room between the actuator and the ceiling of the cap after the flip-chip.

Silicon caps have a similar wall structure like the actuator chip, but the wall structure is closed on the front side in order to minimize the top width of the clearance. However, the metal stack (~1.2 μm thick two Cr/Au evaporations) on the wall is not closed at the front, which makes the clearance after the flip-chip approximately 2.4 μm wide from the top. Similar to the actuator chip, the wall has some dummy fingers on the front side in order to enhance the hydrophobic effect (Fig. 4).

2.3 Flip-chip and further

The chips are aligned to each other using FC-6 flip-chip tool and Au–Au thermal bonding is performed at 350°C. This temperature is not enough to melt the metal but still a successful bonding could be achieved. However, during the handling of the bonded devices, we observed that the bonding strength should be increased if the devices are going to be used for real applications. The caps (both glass and silicon) could be easily peeled off while trying to hold encapsulated devices with pointy tweezers without precaution. Au studs (Figs. 1, 4d) or epoxy sealing after the flip-chip is seen to increase the strength yet we still consider these solutions as optional because they were not necessary for the proof-of-the-concept.

Rendering the surface hydrophobic is the last step of the encapsulation and it is performed by Teflon deposition in an ICP (inductively coupled plasma) system. The contact angle of a Si/SiO2 surface was originally around 31° and switched to 109° after the treatment.

We did not observe any significant performance change of the actuators after the encapsulation (Fig. 5a). Furthermore, encapsulated actuators could successfully operate in water after the Teflon deposition. An air bubble is formed due to the hydrophobic surfaces and water ingress is prevented. One device could work in water for 1 week without a significant problem (Fig. 5b).

3 Conclusions

A water-tight packaging technique to encapsulate electrostatic actuators is presented. The basic idea behind the technique is flip-chipping a cap on the actuators while leaving a small clearance to let the actuator shuttle extend off the device, and rendering the surfaces of the clearance hydrophobic afterwards. The clearance is kept as small as possible to withstand large pressure differences, and some dummy fingers are used to increase the roughness and hence the hydrophobic effect.

An encapsulated device could operate in water for 1 week using this technique. Despite this success, we do not ignore further challenges to be tackled before achieving a successful integration of electrostatic actuators with the biomedical applications. First of all, the surface chemistry of the clearance may change by time if the biological environment includes some proteins liking to attach to hydrophobic surfaces. Moreover, if in vivo applications are in mind, foreign body reaction can cause the encapsulation to fail. Yet we think that with the advances in biocompatible surface treatments, this encapsulation technique will be successfully utilized for those applications.

References

Dy E, Ho CM (2009) Development of a cytomic force transducer for experimental mechanobiology. MEMS’09, pp 391–394

Erismis MA, Neves HP, Puers R, Van Hoof C (2008) A low voltage, large displacement, large force inchworm actuator. IEEE J Microelectromech Sys 17:1294–1301

Erismis MA, Neves HP, De Moor P, Van Hoof C, Puers R (2009) Low voltage electrostatic inchworm actuators in aqueous environments. Procedia Chem Eurosensors 1:686–689

Lal A (1998) Silicon-based ultrasonic surgical actuators. 20th Annual Int. Conf. of the IEE Eng. in Medicine and Biology Society, pp 2785–2790

Lee AP, Ciarlo DR, Krulevitch PA, Lehev S, Trevino J, Northrup MA (1995) A practical microgripper by fine alignment, euthectic bonding and SMA actuator. Transducers, pp 368–371

Miller K, Cowen A, Hames G, Hardy B (2008) SOIMUMPs Design Hand book. http://www.memscap.com/mumps/documents/SOIMUMPs.dr.v5.pdf

Muthuswamy J, Okandan M, Jain T, Giletti A (2005) Electrostatic microactuators for precise positioning of eural microelectrodes. IEEE Tras Biomed Eng 52:1748–1755

Panchawagh HV, Faheem FF, Heremann CF, Serrell DB, Finch DS, Mahajan RL (2007) A flip-chip encapsulation method for packaging of MEMS actuators using surface micromachined polysilicon caps for BioMEMS applications. Sens Actuators A Phsy 134:11–19

Sounart TL, Michaske TA, Zavadil KR (2005) Frequency dependent electrostatic actuation in microfludic MEMS. IEEE J Microelectromech Sys 14:125–133

Wise KD (2007) Integrated sensors, MEMS, and microsystems: reflections on a fantastic voyage. Sens Actuators A Phsy 136:39–50

Wise KD, Angell JB, Starr A (1970) An integrated circuit approach to extracellular microelectrodes. IEEE Trans Biomed Eng 17:238–247

Yoshimitsu Z, Nakajima A, Watanabe T, Hashimoto K (2002) Effects of surface structure on the hydrophobicity and sliding behavior of water droplets. Langmuir 18:5818–5822

Zengerle R, Ulrich J, Kluge S, Richter M, Richter A (1995) A bidirectional silicon micropump. Sens Actuators A Phsy 50:81–86

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Erismis, M.A., Pereira Neves, H., De Moor, P. et al. A water-tight packaging of MEMS electrostatic actuators for biomedical applications. Microsyst Technol 16, 2109–2113 (2010). https://doi.org/10.1007/s00542-010-1136-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-010-1136-3