Abstract

Many widely used polymers suffer main chain scission or crosslinking depending upon various physical parameters when exposed to radiation. Crosslinking and scission are two opposite consequences of irradiation. The preparation of pure Poly(vinyl fluoride) (PVF), Poly(vinylidene fluoride) (PVDF) and their isomorphic polyblends in different weight percentage proportion using solution cast technique is described. The effect of gamma irradiation on the surface microhardness of pure and polyblends of PVF and PVDF have been studied to detect radiation-induced crosslinking and radiational scissioning. The surface microhardness of the irradiated specimen was measured using Vickers method. The overall hardening of blend specimens at different dose level indicates occurrence of crosslinking. For lower radiation dose range of 0–1 Mrad and higher dose range of 1–25 Mrad, the maximum hardening is observed at 0.2 and 20 Mrad, respectively. However, beyond 15 Mrad, scissioning effect predominates in pure as well as polyblend specimens.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years the technology related to polymer blends has attained a prominent position as a major area of research and development in polymer science. In this era of polymers, when the polymeric materials are replacing most of the conventional materials, there is an increasing demand for new materials with improved properties in terms of toughness, strength and dimensional stability. Polymeric materials are widely used in industry; largely due to their valuable mechanical properties and chemical structure to form polymer blends. There are blends, which may be either block copolymer (two or more chemically different polymer chains connected together by a chemical bond) or polymer alloys (two or more chemically different polymers that are mechanically mixed. Co-crystallinity or Isomorphism is a rare situation in miscible polymer blends, reported by Natta et al. (1969). Isomorphism is believed to be possible when the polymer chains (blend) or monomer units (co-polymer) are similar in conformation and size in the crystalline state. Poly(vinyl fluoride) (PVF) and Poly(vinylidene fluoride) (PVDF) exhibit isomorphic characteristics. PVF and PVDF, which are vinyl fluoropolymers, have good weather resistance and are used for outdoor applications, observed by Kim et al. (1995). The mechanical properties of these polymers are good as the tensile strength of PVF and PVDF are 68.90–103.35 and 48.35 Mpa, respectively, reported by Hindeneru et al. (1990). A wide spectrum of material properties can be achieved by varying blend composition such as: mechanical, electrical, optical, chemical etc. The production of blend of polymers not only makes it possible to improve the properties of individual polymers, but also offers better processability of difficult to form high performance polymers. The blending thus offers new type of materials, characterized by controlled chemical constitution and morphology, which can be more precisely tailored to specific requirements. The manner in which the two polymers are blended affects the resultant mechanical property.

Polymeric materials are profoundly affected by ionizing radiations such as gamma rays, accelerated electrons, α-particle, protons and neutrons under different conditions, explored by Spadaro et al. (1989), Parasher et al. (1986) and Albana et al. (2003). The effect of such radiations on the physical and mechanical properties of these materials is of considerable importance due to their application in nuclear and space sciences. The radiation induced changes result from disturbance on the distinctive molecular or chemical structure of these materials. The effect of radiation on the mechanical properties of the polymer blends depends on the degree of compatibility and the extent of interaction between types of polymers, reported by Mishra et al. (1994), Katare et al. (1994), Agrawal et al. (1996) and Bajpai et al. (1994). The modification of polymers by radiation either to cross-link or to break molecules is a significant industrial process. Charlesby (1967) has observed radiational crosslinking, which is the process of formation of chemical bond between separate molecules or different proportions of a molecule. The term radiational scissioning refers to cleavage or degradation of the main chain of polymer molecules, when exposed to radiation by Charlesby (1953).

Vickers microhardness testing is found to be a non-destructive method for investigating the mechanical behaviour of polymeric materials. Microhardness testing had been utilized by various workers to obtain information on the structural features and mechanical property changes for polymer materials and blends reported by Tager (1978), Mason et al. (1991), Jawahri et al. (1992), Bajpai et al. (2001), Mishra et al. (2002) and Bajpai et al. (2003). Further, the important aspect of the microhardness testing of polymers at low loads is that whether the hardness number is dependent or independent of the load has also been dealt with by many workers like Lopez (1993) and Zhao et al. (1993). In the present study authors have utilized Vickers microhardness testing to study the radiation induced crosslinking and scissioning on the isomorphic polyblends of PVF and PVDF.

2 Experimental

2.1 Materials

For the preparation of the blends, the commercially available polymers PVF (BDH, UK), molecular weight 126,000 and PVDF (Aldrich, USA), molecular weight 140,000, in powder forms were used without further purification which were supplied by M/S Redox, Jabalpur.

2.2 Preparation of specimens

The solution cast technique has been utilized to prepare the pure and polyblend specimens of PVF and PVDF. The two polymers were dissolved in dimethylformamide, at a temperature of 60°C with constant stirring. A known quantity of this homogeneous solution was poured in glass mould. The solvent was allowed to evaporate by keeping glass mould inside the oven for nearly 6 h. The temperature of the oven was controlled automatically at 60°C. The specimens were obtained in the form of pellets of size 6 cm2 and 0.45-cm thickness.

2.3 Gamma irradiation

The gamma irradiation of the square shaped 0.45-cm-thick specimens were carried out with Co60 gamma chamber –900. Specimens were irradiated with various doses ranging from 0.2 to 25 Mrad (0.2, 0.4, 0.6, 0.8, 1, 5, 10, 15, 20, 25 Mrad). The average dose rate was 0.35 Mrad/h.

2.4 Microhardness measurement

Microhardness measurements on various specimens were carried out using mph 160 microhardness tester with a Vickers diamond pyramidal indenter attached to Carl Zeiss NU2 universal research microscope. The Vickers hardness number (H v) was calculated using the relation:

where L is load (in kg) and d is diagonal of indentation (in mm). Several indentations were obtained at various loads and the average hardness number was calculated.

3 Results and discussion

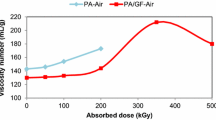

Figure 1 shows the effect of gamma radiation dose ranging from 0 to 25 Mrad on the microhardness (H v) of various specimens (pure PVF, PVDF and their polyblends) at the load of 60 g. The H v values of all the unirradiated specimens (0 Mrad) have also been shown. All the specimens exhibit the similar trend in the entire dose range.

The effect of gamma irradiation on the pure PVF and PVDF specimens suggests that microhardness tends to increase as evident from the higher values of H v for irradiated specimens as compared to corresponding unirradiated ones. The H v values for irradiated PVDF specimens are higher than those of irradiated PVF specimens. This feature is a reverse trend as compared to the order of magnitude of H v values obtained for corresponding unirradiated PVDF and PVF specimens (0 Mrad), respectively. Thus pure PVDF, which is relatively soft polymer as compared to pure PVF, can be cross-linked to a greater extent with doses of gamma irradiation. Infact, the level of microhardness of pure PVDF is found to be maximum amongst all the irradiated specimens as shown in the Fig. 1. The microhardness in both the pure polymers is maximum at the dose of 0.2 Mrad, thereafter, the H v value decreases and tends to saturate in the dose of range of 0.4–10 Mrad. However, the H v values in this dose range are still higher than the corresponding unirradiated specimens (0 Mrad). Beyond, the 10 Mrad, the level of microhardness again increases upto the dose of 20 Mrad. The increase in the value of H v for the irradiated PVF and PVDF polymer indicates the predominance of radiational crosslinking. The increase in H v with increase in the dose reveals increase in crosslink density between the chains in the respective polymers. However, the PVDF being crystallizable polymer in comparison to PVF shows greater degree of crosslinking, reported by Fava (1980) and Bajpai and Datt (1986). Since the maximum radiational crosslinking is observed at the dose of 0.2 Mrad in the low dose range (0–1 Mrad) and at 20 Mrad in high dose range (1–25 Mrad), these two dose levels can be regarded as the optimum level for radiation to achieve maximum crosslink density in the two polymers.

The microhardness of irradiated polyblend specimens of PVF and PVDF with different weight proportions indicate similar trend as observed for pure PVF and PVDF specimens. However, the levels of microhardness for isomorphic blend specimens are higher than PVF but lower than PVDF specimens. This trend in the microhardness is again reverse to that of unirradiated specimens. The gamma irradiation progressively increases the level of microhardness for isomorphic blend specimens with the increase in the content of PVDF from 10 to 90 wt% in the polyblend. However, the trend observed for unirradiated specimens is just reversed where the level of microhardness decreases with the increase in the content of PVDF between 10 and 40 wt% except for the blend specimens with 50 wt% of the two polymers which exhibits maximum hardening. Hence the blend morphology is altered remarkably as a consequence of gamma irradiation. In the isomorphic blend, PVDF crosslinks with PVF, this effect increases with both the radiation dose as well as the content of PVDF in the polyblend. The progressive increase in the radiation crosslink density also indicates the extent of miscibility of the two polymers, which yields hardened blends. Moreover, the maximum radiational crosslinking is observed for pure PVDF and amongst the polyblend with increasing PVDF content up to 90 wt% where it tends to approach the level of pure PVDF.

The effect of various doses of gamma irradiation on the microhardness of different polyblend specimens is observed to be similar to that indicated for pure polymers. The maximum radiational hardening is obtained at the dose of 0.2 and 20 Mrad for low- and high-dose range, respectively. Beyond 20 Mrad, all specimen exhibits decreasing trend in the microhardness, which is indicative of ultimate effect of irradiation leading to radiational damage at the higher dose of radiation where the scissioning reduces the average molecular weight. Thus PVF can be crosslinked with PVDF under gamma irradiation up to the optimum dose level.

4 Conclusion

The present study reveals that irradiation of pure PVF, PVDF and polymer blend of PVDF and PVF leads to significant change in the mechanical properties due to simultaneous occurrence of radiational crosslinking and radiational scissioning phenomenon. Thus PVF:PVDF isomorphic blends can be developed with optimum weight proportion as a material having a good mechanical properties.

Reference

Agrawal P, Bajpai R, Datt SC (1996) Hardening induced by gamma irradiation in PMMA: PCIFE. Polym Test 15:291–296

Albana C, Reyes J, Ichazo M, Gonzalez J, Hernandez M Rodriquez M (2003) Mechanical, thermal and morphological behavior of the polystyrene/polypropylene (80/20) blends, irradiated with γ-ray at low dose (0–70 Krad). Polym Degrad Stabil 80:251–261

Bajpai R, Datt SC (1986) Effect of load on the microhardness of polycarbonate. Indian J Pure Appl Phys 24:254–255

Bajpai R, Agrawal P, Datt SC (1994) Radiation effects of an electron beam on the microhardness of polymethylmethacrylate: polychlorotrifluoroethylene polyblends. Polym Int 34:249–251

Bajpai R, Mishra AK, Agrawal P (2001) Radiational hardening of PVDF: PS ternary blend. J Appl Poly Sci 92:3107–3111

Bajpai R, Dhagat NB, Katare R, Agarwal P, Datt SC (2003) Development of hardend PVF: PMMA polyblend, effect of gamma and electron irradiation. Bull Mater Sci 26:101–105

Charlesby A (1953) Effect of high energy radiation on long-chain polymers. Nature 171:167

Charlesby A (1967) Radiation research. North-Holland, Amesterdum, pp 265

Fava RA (ed) (1980) Methods of experimental physics polymer Part B: Crystal structure and morphology 16th edn. Academic, New York, pp 118

Hindeneru S, Hiroskik K Akida N (1990) Effect of gamma irradiation on the change of characteristics of polyurethane. J Appl Polym Sci 41:661–675

Jawahri J, Mreinio JC, Pastor JM (1992) Micro-Raman spectroscopy study of the process of microindentation in polymers part II Polyvinylidene fluoride. J Mater Sci 27:2237–2242

Katare R, Bajpai R, Datt SC (1994) Microhardness testing to detect radiation induced crosslinking in polystyrene: polymethylmethacrylate polyblends. Polym Test 13:107–112

Kim E, Lee JY, Kim BS, Lee C (1995) Pyroelectricity in stretched film of poly (vinylidene fluoride)/poly (vinylfluoride) blends. Bull Korean Chem Sci 16:1133–1134

Lopez J (1993) Microhardness testing of plastics: literature review. Polym Test 12:437–458

Mason W, Johnson PF, Warner JR (1991) Importance of load cell sensitivity in determination of the load dependence of hardness in recording microhardness tests. J Mater Sci 26:6576–6580

Mishra V, Bajpai R, Datt SC (1994) Radiation induced effects on the microhardness measurement of polymethyl methacrylate: polyvinylidene fluoride. Polym Test 13:435–440

Mishra V, Agarwal P, Datt SC (2002) Surface modification on PMMA: PVDF polyblend: hardening under chemical treatment. Bull Matter Sci 25:21–23

Natta G, Allegra G, Bassi IW, Carlini C, Chielini E, Montagholi G (1969) Isomorphism phenomena in isotactic poly (4-methyl-substituted α-olefins and in isotactic polyalkylvinylether). Macromolecules 2:311–315

Parasher P, Keller JM, Bajpai R, Datt SC (1986) Microhardness measurement of polypropylene, polyethylene-terephthalate polytertrafluroetyhylene. Macromol Chem Macromol Symp 20/21:465–474

Spadaro G, Calderaro E, Rizzo G (1989) Radiation induced degradation and crosslinking of low density polyethylene. Acta Polym 40:702

Tager A (1978) Physical chemistry of polymer. Mir Pub, Moscow pp 233–264

Zhao Z, Yang H, Liu B, Chen X (1993) J Macromol Sci B32:355–372

Acknowledgment

Authors are thankful to UGC-DAE for University Consortium (Department of Atomic Energy facilities), Kolkata center, Kolkata, India for providing irradiation facilities and support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, A.K., Bajpai, R. & Keller, J.M. Effect of irradiation on the surface microhardness of pure poly(vinyl fluoride), poly(vinylidene fluoride) and their isomorphic blends. Microsyst Technol 13, 589–592 (2007). https://doi.org/10.1007/s00542-006-0208-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-006-0208-x