Abstract

To improve the non-repeatable runout (NRRO), repeatable runout (RRO), and nonlinearity of the position signal in hard-disk drives (HDDs), we established criteria for the off-track direction and for the bit direction. Position-signal nonlinearity and NRRO degradation are largely due to the interaction between track width, erase band size, and the sensitivity distribution of the head. So one criterion is for position-signal sensitivity. The other criterion is for burst-bit density, which causes RRO degradation. Using these criteria to compare, theoretically and experimentally, the effectiveness with which the quality of the position signal could be maintained using amplitude and phase patterns confirmed that the phase pattern is superior to the amplitude pattern.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The only way to increase the capacity of the magnetic hard-disk drives (HDDs) used in products such as video recorders and music players as well as in computers and still make them smaller is by increasing the recording density. This results in narrower tracks on the disk, however, and makes it is harder to position the read/write head accurately because the quality of the position signal (servo signal) deteriorates as the tracks become narrower.

There are some problems in accurately determining the effective width of the read head and the erase-band width of the write head (Luo et al. 1995; Madison et al. 1996; Davidson and Simmons 1996; Yasuna et al. 1999). These problems degrade the quality of the position signal, increasing the non-repeatable runout (NRRO) in the servo loop of the head positioning system (Numasato et al. 1999) and the repeatable runout (RRO) in servo writing system and thus degrading the accuracy with which the magnetic heads can be positioned. Position-signal nonlinearity, for example, reduces the positioning sensitivity of the following-control loop and can destabilize the control system. We therefore previously developed a method for evaluating the position-signal in off-track direction (Akagi et al. 2002), and in his paper we report a method we developed for evaluating the position-signal in both the bit and off-track directions. We present two criteria useful for improving positioning accuracy—one for the off-track direction, and the other for the bit direction.

It is important to clarify which servo pattern is best for head positioning: the amplitude pattern, the phase pattern, or the frequency pattern. Hughes and Messner (2003) compared the position-signal quality obtained with these three patterns for the new servo pre-formatting process using patterning techniques such as magnetic printing (Sugita et al. 2000; Ishida et al. 2001). They said that the phase pattern was the best choice for preformatted media. In this paper, we also clarify why the phase pattern is superior from the viewpoint of geometry.

2 Theory and modeling

2.1 Position-signal generation

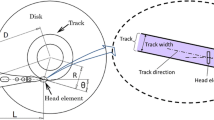

We assume that the readback signal is the superposition of a sign-alternating Lorentzian pulse with a given 50% amplitude pulse width (pw50). The sensitivity profile of a giant-magneto-resistive (GMR) head has a nearly normal distribution in the off-track direction, and a servo pattern written on a disk has a uniform distribution with a blunt-edged shape. The amplitude of the readback signal is obtained by convolution of the sensitivity profile of the head and the magnetization profile of the media (Fig. 1). The readback signal is given by multiplication of the Lorentz pulse and the convolution as follows

where a(x) is the sensitivity of the read head, S(x) the magnetization profile of the media, and f(t) is the readback signal at position x. And the readback signal fread(t) at position x is represented according to Patapoutian (1996) by using the Lorentz pulse as follows

The demodulating process can be described as follows. Using the Discrete Fourier Transform (DFT) fit the actual waveform to the DFT waveform by four to eight over-samplings. It is possible to demodulate the position signal for both of the amplitude pattern and phase pattern by calculating with the Fourier coefficients and the time t given by t = T/N n (where T is a period of the signal, N the sampling number, and n = 1,2⋖N). Then fread(t) can be defined as F(n), so the Nth order Fourier polynominal is

and the Fourier coefficients are

where L is burst cycle number and m is the harmonics order. The servo burst signal can be generated using these coefficients. The burst signal amplitude for the amplitude pattern is given by

and the burst signal phase for the phase pattern is given by

Thus, we could generate Bursts 1–4 in the amplitude pattern or Bursts 1 and 2 in the phase pattern (see Figs. 2, 9). For example, the position signal (POS) from the Bursts 1 and 2 in the amplitude pattern is given by

where C1 and D1 are Fourier coefficients of Bursts 3 and 4. And the position signal (POS) from Bursts 1 and 2 in the phase pattern is given by

The position error signal (PES) can be generated as follows. The difference between the amplitudes of Bursts 1 and 2 in the amplitude pattern is defined as an N-POS signal, and that between the amplitudes of Bursts 3 and 4 is defined as a Q-POS signal. The SPOS signal is generated by connecting the N-POS and the Q-POS signals at a point where is a quarter of the track pitch (Tp) as follows

where the factor j determines the smoothness at the point connecting the N-POS and Q-POS signals. When j is greater than 2, the PES can be generated smoothly at the N-POS and Q-POS connecting point. As the head sensitivity and magnetization profiles are not linear, we can determine the right condition to generate linear N-POS or Q-POS curves by choosing the parameter j in Eq. 8. The PES in the phase pattern is generated by connecting the POS signals directly. Finally, the position sensitivity Kp, defined as the amplitude change ratio in the off-track direction, is obtained as the difference between SPOS signals (Fig. 3).

2.2 Comparison of simulation and experiment

The position signal generated by a convolution of the head-sensitivity and magnetization profiles is nonlinear. Figure 4 compares the calculated Kp curve and experimental data. In this case, j was set to 8 and the actual Kp value was measured by vibrating the actuator within 0.02 μmp–p in the off-track direction. The experimental data were obtained from an actual HDD whose read track-width (Twr) and erase-band width (ΔE) had been measured. The calculated curve approximated the observed data. As we can see in Fig. 4, the Kp is greatest at the center of the track (i.e., at the “write” center line) and at the edges and is least midway between the center and the edges (i.e., at the N-POS and the Q-POS connecting points).

3 Servo-signal evaluation and optimization

3.1 Criterion in the off-track direction

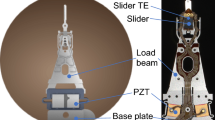

The sensitivity distribution across the track-width of the read head in a HDD depends on fluctuations in the manufacturing process, such as mask misalignment. Moreover, the erase bandwidth (ΔE) of the write head depends on the geometric error in the head structure. As the Twr is designed to be less than the Tp, it is possible that a nonsensitive zone in the position signal will appear in the off-track direction (Fig. 2). This means that the position sensitivity will be nonlinear if the geometric relation between Twr and Tp is not set properly. The Kp is described in the block diagram in Fig. 3, where C is a compensator, df the force disturbance, dp the position disturbance, dm the mechanical disturbance, and pes is the position error signal. According to this system, the position disturbance caused by circuit noise (dp) is strongly affected by the Kp varying in the off-track direction. In this block diagram, df, dp, and dm can be sources of NRRO (Numasato et al. 1999).

As previously mentioned, the Kp value tends to increase and decrease periodically. When the Kp is small, drive performance deteriorates. One of the factors that reduce the Kp is the geometric mismatch between track-width Twr and track-pitch Tp. We defined the Twr/Tp value for the criterion of position-signal quality, and the calculated Twr/Tp and NRRO are plotted in Fig. 5a against the minimum Kp. The Twr/Tp-versus-Kp curve was calculated using the model described previously, and the NRRO-versus-Kp curve was calculated using following-servo model shown in Fig. 3. As the minimum Kp increases, Twr/Tp decreases. Though the NRRO does not increase until the minimum Kp reaches 8 dB (Twr/Tp = 61%), it is clear that in this case a nonlinear limit, which does not affect drive performance, is determined under conditions where the read track width is more than 61% of the servo pitch. This percentage depends on the head and the disk, but NRRO always begins to increase around 60%. If the servo Tp is set to less than about 60% of the data Tp (reduced servo-pitch format), nonlinearity will not cause any problems. In case of the amplitude pattern, increasing the Twr by 10% of the Tp when the Twr/Tp ratio was less than about 60% decreased the NRRO by 15% of the Tps.

Another factor that reduces Kp is the erase-band width ΔE, and the calculated relation between Kp and ΔE/Tp is shown in Fig. 5b. The minimum Kp increases as ΔE/Tp increases. We can thus also use the ΔE/Tp value as a criterion in the off-track direction.

3.2 Criterion in the bit direction

The signal quality in the bit direction is affected by the pattern timing-jitter caused by circumferential misalignment of the servo burst pattern. According to Patapoutian, if this is assumed to be a Lorentzian signal, the optimal burst is obtained when the product of burst frequency and 50% amplitude-pulse-width (pw50) is set to 0.303 (Patapoutian 1996). Let us now define criteria tac/tob and tjitter/tac, where tac is the actual period of servo burst signals, tob is the optimal period of burst signals, and tjitter is the timing jitter embedded in the servo pattern during servo-writing. The relation between f × pw50 and the signal S/N is shown in Fig. 6, where the signal S/N is seen to reach a maximum at the point where tac/tob is 1.0 (where f multiplied by pw50 is 0.303). The signal S/N is under -1 dB when the burst frequency is set optimally and tjitter/tob is within 15% of the period of servo burst signals.

3.3 Comparison of amplitude and phase patterns

At all values of Twr the Kp of the phase pattern is 5 dB higher than that of the amplitude pattern (Fig. 7). The phase pattern is also superior to the amplitude pattern with regard to the ΔE value (Fig. 8).

We evaluated the amplitude and the phase patterns with our model, and Fig. 9 compares these patterns. The phase pattern written with a conventional servo method is formed as a step-shaped pattern. In terms of the Twr/Tp criterion, marked Kp deterioration is seen in the amplitude pattern. The Kp deterioration is less obvious in the phase patterns and decreases as the number of steps is increased. If there are more than three steps, the phase pattern for NRRO is hardly affected by the Twr/Tp criterion. Figure 10 shows that the amplitude pattern is affected by changes in the ΔE/Tp value. The phase pattern is strongly affected by tjitter/tac value, and RRO increases steeply with increasing tjitter/tac (Fig. 11).

4 Discussion

Concerning track-width direction, the Twr/Tp and ΔE/Tp criteria can determine the quality of the position signal. The experimental results and calculation results showed clearly that the phase pattern is superior to the amplitude pattern. The reason the phase pattern is superior in the off-track direction can be explained this way: if the sensitivity profile of the read head has a long broad foot, the read head can sense a pattern far from the center of the head. In other words, the crosstalk of the read head makes it possible to read a far pattern that can include other information, especially in the phase pattern. In the amplitude pattern, though, there are no patterns next to a burst pattern in the track-width direction. The experimental results on head crosstalk are plotted against Twr/Tp in Fig. 12. It is obvious that the crosstalk level, especially in the phase pattern, is high when the Twr/Tp is large.

The step-type phase pattern is not ideal because the size of the erase band increases as the number of steps increases. If a contact magnetic pattern (Sugita et al. 2000; Ishida et al. 2001) can be utilized, the servo pattern should be an ideal phase pattern. If not, a three-step phase pattern is sufficient when the erase-band is narrow.

In terms of the bit direction, the criteria tac/tob and tjitter/tac can also determine the quality of the position signal. The S/N deterioration was within 1 dB when the burst frequency was set optimally and the tac/tob was 1.0. The amplitude pattern was also superior to the phase pattern in terms of the tjitter/tac value. The phase pattern tended to be affected by the jitter pattern caused by motor jitter, and that made the RRO worse. The amplitude pattern was not affected by jitter if the length of the pattern was less than 30% of burst cycle. The jitter level in the phase pattern should be under 4.5%.

5 Conclusion

To improve the NRRO, RRO, and nonlinearity in position accuracy of HDDs, we established two kind criteria for optimizing position-signal quality. One, the Twr/Tp (or, correspondingly, the ΔE/Tp), was for the off-track direction. In the amplitude pattern, as long as the Twr/Tp ratio was less than 0.6, the NRRO was reduced by 15% of the Tp whenever the Twr was increased by 10% of the Tp. The other criterion, the tac/tob, was for the bit direction. When the tac/tob was 1.0, S/N deterioration was 1 dB or less when the burst frequency was set optimally and tjitter/tob was within 15% of the period of servo burst signals.

Evaluating the amplitude pattern and phase pattern with our model, we showed that the position-signal quality of the phase pattern was superior to that of the amplitude pattern in the off-track direction. We also showed that head crosstalk made it possible to improve the position-signal quality in the track-width direction.

References

Akagi K, Shishida K, Ito T (2002) Analysis and improvement of the position signal nonlinearity of high-track-density disk drives. Trans Inst Electron Inf Commun Eng C 85-C(1):23–30 (in Japanese)

Davidson R, Simmons R (1996) Prediction of limitations placed on magnetoresistive head servo systems by track edge writing for various pole tip geometries. J Appl Phys 79(8)15:5671–5673

Hughes EC, Messner WC (2003) Characterization of three servo patterns for position error signal generation in hard drives. In: Proceedings of the American control conference, Denver, Colorado

Ishida T, Miyata K, Komura N, Takaoka T (2001) Demodulation of servo tracking signals printed with a lithographically patterned master disk. IEEE Trans Magn 37(4):1412–1415

Luo Y, Lam TT, Zhu J (1995) Density and phase dependence of edge erase band in MR/thin film head recording. IEEE Trans Magn 31(6):3105–3107

Madison MR, Arnoldussen TC, Chang TY, Wood RW, Scott FD II (1996) Erase band and transition charge-model and MFM. IEEE Trans Magn 32(5):3878–3880

Numasato H, Usui K, Hamada Y, Yamaguchi T (1999) An analysis method of head positioning error for magnetic disk drives. (An analysis method of PES in track-following mode.) Trans Jpn Soc Mech Eng C 65(636):213–219 (in Japanese)

Patapoutian A (1996) Optimal burst frequency derivation for head positioning. IEEE Trans Magn 32(5):3899–3901

Sugita R, Kinoshita T, Saito O, Muranoi T, Nishikawa M, Nagao N (2000) A novel magnetic contact duplication technique for servo-writing on magnetic disks. IEEE Trans Magn 36(5):2285–2287

Yasuna K, Usui K, Yamaguchi T, Akagi K, Ohtsu T, Shishida K (1999) Influence of pole trimming on track-following accuracy. IEEE Trans Magn 35(5):2265–2267

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akagi, K., Yasuna, K. & Shishida, K. Optimizing servo-signal design for a hard-disk drives. Microsyst Technol 11, 784–789 (2005). https://doi.org/10.1007/s00542-005-0581-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-005-0581-x