Abstract

The statistics pertaining to accidents occurring at construction sites underscore the pressing requirement for a substantial and timely reevaluation of safety measures within the construction sector. Accidents do not occur randomly; rather, they arise from the presence of unsafe actions, hazardous conditions, or a combination of both. The majority of accidents stem from a combination of contributing causes, including unsafe acts and conditions. To enhance safety performance on a broader scale, this study undertakes an extensive analysis to identify these causes, evaluate their importance, and determine the countries that are most and least impacted by them. Ten African countries were selected as potential alternatives based on the frequency of infrastructure construction projects. A thorough review of existing literature was conducted to establish a three-level criteria framework. The framework was further refined through the Modified Delphi method to gather expert opinions. The weights assigned to the criteria were determined using the interval-valued Fermatean fuzzy analytical hierarchy process methodology. The Technique for Order Preference by Similarity to Ideal Solution method under the same fuzzy environment was then employed to rank the alternative countries. A sensitivity analysis was carried out to assess the robustness of the proposed methodology. The analysis revealed that the main cause of accidents was attributed to poor management, as it included ineffective project supervision, inadequate safety policies, poor organizational structure, and inappropriate scheduling/planning as the main underlying sub-factors. Additionally, it was observed that the sixth alternative country exhibited the highest susceptibility to accidents occurring at construction sites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The construction industry, given its distinctive characteristics, ranks among the most dangerous sectors. Construction projects face a multitude of risks, uncertainties, and complexities, largely due to the high frequency of accidents occurring within them [1]. Developed countries are actively striving to minimize the devastating damage and losses caused by construction accidents through preventive measures and risk mitigation practices. In contrast, developing countries suffer greatly from construction accidents, as they lack stringent regulations about construction safety, and both authorities and workers often lack awareness of the importance of construction safety [2].

Construction sites have a high rate of reported accidents compared to other industries in many countries [3]. In Africa, while the occurrence of accidents is significant, accurate data is scarce due to a lack of reliable statistics [4]. Accidents in the construction sector have serious consequences for workers, including physical harm, emotional trauma, and financial loss [5]. Additionally, these accidents lead to project delays and increased expenses [6].

In developing countries, there is a frequent reliance on inexperienced workers for the construction of cost-effective infrastructure, resulting in an increased risk of occupational injuries and accidents. Numerous factors contribute to these hazards, such as a deficiency in education, limited awareness of health and safety practices, and an insufficient understanding of risk assessment. Additionally, these workers encounter a difficult employment environment characterized by high unemployment rates, intense competition, and fluctuating workplace conditions [7]. In developing countries, construction workers face a much higher level of risk compared to their counterparts in industrialized countries. This heightened risk is primarily attributed to the concentrated global workforce in these regions, which magnifies the severity of accidents by ten to twenty times [8]. Although work-related accidents have significant social and economic consequences, it is possible to minimize such incidents by implementing preventive measures [9].

A significant body of research in Africa has been dedicated to exploring the underlying causes of accidents that occur on construction sites [4, 5, 10,11,12,13,14,15,16]. The majority of these studies have focused on specific countries, cities, or regions within countries. Moreover, these studies have primarily relied on the utilization of statistical techniques [11], cross-sectional research designs [10, 14], and interviews [12] to address and investigate the factors contributing to these accidents. However, there are a notable absence of the implementation of multi-criteria decision-making (MCDM) approaches, which have the potential to provide decision-makers with supplementary tools that offer increased flexibility and comprehensive insights [17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40].

Accurately pinpointing the key factors that contribute to construction site accidents requires the presence of a relevant and exceptional system. Without such a system, the findings from previous incomplete investigations fall short of providing the necessary details for safety decision-makers to effectively reduce accident rates on construction sites. Previous research has highlighted a substantial gap in comprehensive documentation and viable solutions when it comes to addressing the concerning frequency of accidents on construction sites in Africa. This research gap remains unresolved, as there is a continued need for in-depth investigations that combine qualitative analysis and multi-criteria decision-making (MCDM) methodologies to effectively tackle the issue. To address this gap, the current study seeks to bridge the two approaches by integrating them, thereby achieving a thorough examination. To improve the precision and completeness in dealing with imprecise and incomplete information, this study adopts interval-valued Fermatean fuzzy sets (IVFFSs) instead of Fermatean fuzzy sets (FFSs) [41,42,43]. IVFFSs, developed by Jeevaraj [44], demonstrate superior capabilities that surpass both interval-valued intuitionistic fuzzy sets (IVIFSs) and interval-valued Pythagorean fuzzy sets (IVPFSs). As a result, this study introduces a unique approach by integrating two methodologies, namely AHP and TOPSIS, within the interval-valued fermatean fuzzy environment.

The motivations for the proposed study are as follows.

-

Subjective weighting methods rely on decision-makers’ assessments and involve value judgments [45]. These methods, such as Analytical Hierarchy Process (AHP), Best–Worst Method (BWM), FUll Consistency Method (FUCOM), Level Based Weight Assessment (LBWA), and the Defining Interrelationships Between Ranked criteria (DIBR), utilize the subjective opinions of individual experts. In these methods, decision-makers compare each criterion with others and make pairwise assessments [45]. BWM is a comparison-based approach [46, 47]. It requires less comparison data, leading to better consistency in pairwise comparisons and more reliable weight results. Moreover, the BWM involves fewer pairwise comparisons (2n-3) and uses fewer matrices, making implementation faster. It demonstrates better consistency compared to existing subjective weighting methods and requires fewer comparative data. However, the BWM is sometimes considered unsuitable due to the large number of pairwise comparisons needed, particularly for solving complex non-linear models. FUCOM was developed by Pamučar, Stević [48] for determining criteria weights [49]. One significant advantage of this methodology is that it addresses the problem of redundancy in pairwise comparisons, which can be found in certain subjective models used for weight determination [50]. FUCOM only requires (n-1) pairwise comparisons for n criteria, whereas AHP requires n(n − 1)/2 comparisons and BWM requires (2n-3) comparisons [51]. Additionally, FUCOM has been shown to provide better results than AHP and BWM when considering the relationship between consistency and the number of criteria comparisons [48]. However, a main limitation of FUCOM is the lack of further studies validating its effectiveness, as identified in the literature review. The LBWA method was developed to address the need for a process that requires minimal pairwise comparisons between criteria and follows a rational and logical-mathematical algorithm [51,52,53]. Recent studies [51, 54,55,56,57] have outlined the advantages of the LBWA model, including its suitability for complex models with a large number of evaluation criteria. Unlike other methods, the LBWA does not become overly complex as the number of criteria increases. It allows for the calculation of weight coefficients using a small number of criteria comparisons. The LBWA offers flexibility for decision-makers to express their preferences and resolve inconsistencies through a logical algorithm when prioritizing criteria. Moreover, it is not restricted to integer values from a predefined scale. The DIBR method, proposed by Pamucar, Deveci [58], is a relatively new approach that produces effective results with minimal comparisons. Its main purpose is to determine criteria weight coefficients. One notable advantage of the DIBR method is its ability to improve decision-makers’ understanding of criteria relationships [59, 60]. It overcomes the challenge of defining connections between distant criteria, which often causes inconsistencies in subjective models like the AHP and BWM methods [61]. By considering relationships between adjacent criteria, the DIBR method eliminates this problem. This feature proves especially helpful when dealing with numerous criteria (more than eight) [62, 63]. Traditional models like the AHP [64, 65] struggle to achieve consistent results due to their limited nine-degree scale [66]. The DIBR method addresses this limitation by using a scale that encompasses the entire range of values from 0 to 1. This allows decision-makers to express preferences and criteria relationships objectively. Unlike other MCDM methods such as BWM, FUCOM, LBWA, and DIBR, the AHP method holds a major advantage in that it can yield reliable and statistically powerful results without relying on a large sample size. Even with a small sample size, AHP can provide valuable decision results and models, making it a preferable option when compared to other MCDM methods [67, 68]. AHP has demonstrated its ability to minimize bias and ensure the validation of subjective judgments through consistency analysis. By employing AHP, a high level of agreement can be achieved among judgments from multiple experts who may have different perceptions, experiences, and understandings of decision criteria [69, 70]. AHP offers additional benefits due to its ease of implementation and the availability of user-friendly software, such as Expert Choice, for analyzing AHP data. This simplifies the breakdown of complex decision problems into a hierarchical structure, enabling a more comprehensive understanding of all the criteria involved. Decision-makers can then compare criteria in pairs rather than assessing the relative importance of a large number of tangible and intangible criteria simultaneously [71, 72]. Unfortunately, despite the advantages offered by the AHP method, there has been a lack of research that extends its application to an interval-valued Fermatean fuzzy environment to identify the most significant factors contributing to construction site accidents in Africa. This absence of investigation is regrettable, as such an extension could greatly enhance the practicality of the AHP method in real-world scenarios where decision-making environments often involve conflicting factors. By employing the IVFF-AHP approach to identify the key factors that contribute to construction site accidents, it becomes possible to develop effective preventive measures for future incidents.

-

The Measurement of Alternatives and Ranking according to COmpromise Solution (MARCOS) technique, introduced by Stević, Pamučar [73], measures choices and ranks them as a compromise solution. Compared to the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) method, which follows similar principles, MARCOS exhibits greater stability. It remains robust even when changes are made to the measurement scales of decision attributes. Additionally, MARCOS provides reliable results in dynamic environments, unlike the TOPSIS model. Unlike TOPSIS, MARCOS does not suffer from the rank reversal problem, where eliminating the worst alternative alters the existing rankings. However, a limitation of MARCOS is its reliance on a single normalization technique (linear normalization). While it is a powerful decision-making tool, it does not handle fuzzy or ambiguous information. Pamučar and Ćirović [74] introduced the Multi-Attributive Border Approximation Area Comparison (MABAC) method in 2015, and since then, this multi-criteria approach has been widely applied to address various real-world issues. MABAC offers three key benefits: consistent outcomes even when the units of measurement change, stable solutions despite alterations in the criteria formulation, and a simplified algorithm suitable for handling large-scale problems [75]. Nevertheless, MABAC has room for improvement considering its structural limitations. One notable drawback in the conventional MABAC form lies in its normalization technique, which relies on a max–min normalization formula. However, utilizing a single normalization technique could potentially result in biased solutions. The Multi-Attribute Ideal-Real Comparative Analysis (MAIRCA) method was introduced by Pamučar, Vasin [76]. Unlike other popular MCDM methods like TOPSIS [77], MAIRCA has demonstrated greater stability. This method relies on linear aggregation techniques, making it a compensatory approach. MAIRCA was selected due to its straightforward mathematical calculations, solution stability, and potential for integration with other methods [77]. Typically, the MAIRCA model is employed to evaluate the disparity between ideal and actual assessments. By summing the gaps for each criterion, the total gap for each alternative can be determined. The ranking of alternatives occurs at the end of the process, where the highest-ranked alternative is the one with the smallest gap value. The alternative with the lowest total gap represents the option with scores closest to the ideal criteria values [78]. The VIšeKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) method was developed to optimize complex systems with multiple criteria [79]. It aims to rank and select alternatives when there are conflicting criteria, seeking a compromise solution [79]. While often compared to TOPSIS, the VIKOR method employs its own aggregation function and normalization method. In TOPSIS, the optimal point should be closest to the positive ideal solution and farthest from the negative ideal solution, making it suitable for cautious decision makers who prioritize both profit maximization and risk minimization [79]. In contrast, the VIKOR method is suitable for situations where profit maximization takes precedence over decision risk. Its key advantage lies in balancing the maximum group utility and minimum individual regret [79]. However, the VIKOR method has a drawback in its subjective initial weighting process for criteria, necessitating the combination with other methods to achieve more accurate and stable results. The TOPSIS method operates by selecting the best choice based on its proximity to the Positive Ideal Solution (PIS) and its distance from the Negative Ideal Solution (NIS). The PIS maximizes attributes that need to be maximized and minimizes those that need to be minimized. Conversely, the NIS maximizes minimizing criteria and minimizes maximizing criteria [80]. Notably, TOPSIS follows a transparent logic and applies to both qualitative and quantitative information. Moreover, it remains effective even when dealing with a large number of options and criteria [80]. According to de Farias Aires and Ferreira [81], TOPSIS exhibits fewer instances of rank reversals compared to other MCDM methods like AHP and various versions of AHP. Rank reversal refers to a change in the ordering of options when an option is added or removed, which can confuse decision-makers and should be minimized [82]. Furthermore, unlike AHP, TOPSIS can directly handle attributes that need to be both maximized and minimized. As previously mentioned, the complexity of MCDM procedures can hinder their practical use, but fortunately, TOPSIS offers a straightforward calculation process [83]. Chodha, Dubey [84] provided a comprehensive comparison of TOPSIS with other well-known MCDM techniques such as VIKOR and AHP. While VIKOR traditionally employs linear normalization and TOPSIS employs vector normalization, Bera, Shit [85] noted their natural similarities. However, due to vector normalization, TOPSIS demonstrates greater discriminative power [86]. Unfortunately, the utilization of the TOPSIS method in studies related to construction sites using IVFFSs has been limited so far, despite its potential advantages. This study aims to address the existing research gaps in both methodology and practical application by employing the IVFF-TOPSIS method to evaluate and rank different countries based on the key factors contributing to construction site accidents.

The main contributions of this study are as follows.

-

Effectively allocating resources for safety and health outcomes in the construction industry can be a complex task. However, decision-makers at African construction sites can address this challenge by utilizing evaluation criteria. By implementing these criteria, they can establish a practical framework to prioritize and allocate resources more efficiently, ultimately enhancing safety and health outcomes for workers.

-

This study stands out for its novel approach, as it integrates both the AHP and TOPSIS approaches within an IVFF environment. This combination of approaches allows for a more comprehensive and precise decision-making process, taking into consideration a diverse set of criteria.

-

The main focus of this research centers on the identification of factors that contribute to accidents at construction sites. However, the integrated IVFF model, which combines the AHP and TOPSIS methods, has a wide range of applications that go beyond the boundaries of the construction industry. This adaptable model provides a valuable tool for addressing complex problems related to MCDM methods in various sectors.

The research goals of this study are as follows: (i) providing a framework for implementing measures to prevent or minimize accidents; (ii) presenting valuable insights into construction safety management through a case study of selected Sub-Saharan African countries; and (iii) investigating the application of the novel integrated IVFF-AHP-TOPSIS methodology to identify and rank the most significant factors contributing to construction site accidents in addition to the ranking of ten African countries based on these identified causes of accidents across three different aspects. By doing so, this study will answer three subsequent questions: (*) what is the framework to be implemented to prevent or minimize accidents on construction sites? (**) what are the most significant factors contributing to construction site accidents? (***) what are the valuable insights for sustainable construction safety management?

The rest of the paper is organized as follows. After the initial introduction, a summary of relevant literature is presented in Sect. 2. Section 3 presented the proposed methodology. The case study application is given in Sect. 4. Section 5 describes the sensitivity analysis. The discussion of the findings and their potential managerial and practical implications are dealt with in Sect. 6. Finally, the last section deals with the conclusion and future research.

2 Literature review

Five sub-sections have characterized this section.

2.1 Decision-making approaches for accidents on construction site

The construction industry has become a subject of significant research interest due to its comparatively higher rate of accidents than other sectors on a global scale. Consequently, researchers have increasingly focused their attention on investigating the underlying causes behind these accidents [87,88,89]. For instance, Williams, Hamid [4] identified a significant number of factors that contribute to safety issues in construction, including those related to workers, contractors, construction sites, consultants, and clients. In a separate study, they identified 18 different types of accidents that occur on construction sites in South Nigeria and grouped them into seven categories [5]. Oni, Amusan [10] utilized a cross-sectional research design to evaluate the significance of construction operative training in mitigating the frequent occurrence of accidents on construction sites in Nigeria. Eguh and Adenaiya [11] collected data from multiple construction sites in Nigeria and conducted a thorough analysis using the SPSS method. Their analysis focused on closely monitoring and examining the occurrences of accidents on these construction sites. Falana and Ghazaly [12] investigated the diverse causes and effects of accidents on construction sites in Lagos State, Nigeria. Additionally, their study sought to propose potential solutions that would effectively minimize this problem as much as possible. Shittu, Popoola [13] utilized a survey design to assess how safety measures for hazard recognition influence the frequency of accidents occurring on construction sites in Abuja, Nigeria. Ijaola, Zakariyyah [14] utilized a cross-sectional survey research design to establish a pathway for the convenient identification and comprehension of accident causes in the construction industry. By developing key indicators and exploring various dimensions of accident causation, their research design aimed to facilitate an easier understanding of the factors contributing to accidents on construction sites. Eze, Ayuba [15] conducted an assessment of the impact of accident hazards on the Nigerian building industry in an effort to identify effective strategies for reducing accidents. They employed a survey methodology, administering questionnaires to gather data. The study’s primary findings indicate that the most frequently recorded accidents on construction sites tend to result in minor injuries that require less than one day off work. Okorie and Adindu [16] conducted descriptive survey research using structured questionnaires to examine the social and economic consequences of site accidents on the Nigerian economy. An overview of approaches related to accidents on construction sites is shown in Table 1.

2.2 Applications of MCDM approaches related to accidents occurrence on construction sites.

Multi-criteria approaches have been applied in several aspects of the construction site, including layout planning, accidents, hazards, health and safety, and safety management. The construction industry is widely recognized as a high-risk sector due to the complex interplay between the intensive use of labor and machinery, and the fast-paced and overlapping activities that can lead to accidents and fatalities. Gunduz and Khader [90] delved into the contextual factors that contribute to the risks at the construction site. Hatefi and Tamošaitienė [91] examined how different risk factors in construction projects are interconnected and evaluated overall risks. Bakhtavar and Yousefi [92] focused on the risks of working accidents in underground collieries. Kazaz, Erbas [93] looked at the trends of occupational accidents in different cities to identify the level of risk. Rostamzadeh, Abouhossein [94] prioritized the causal relationships among factors that contribute to construction falls, a major source of injury and death in the industry. Turskis, Dzitac [95] suggested a method to identify and rank the most influential people in accident prevention to ensure sustainable outcomes. Mohandes, Karasan [88] conducted a detailed investigation, specifically examining the causal factors that contribute to accidents within the construction sector. Their research involved capturing the causal interrelationships between these factors and assessing their levels of importance. Mohandes, Sadeghi [89] conducted a comprehensive analysis where they extensively identified and prioritized the crucial causes of accidents occurring on construction sites. Furthermore, they mapped the interrelationships among these causes. Table 2 provides the application of MCDM methods for accidents on construction sites.

2.3 Applications and extensions of the AHP method

Several studies have effectively addressed a range of decision-making problems using the analytical hierarchy process [96]. For instance, Bouraima, Qiu [97] examined the development strategy of the railway transportation system within the West African Economic and Monetary Union (WAEMU). The findings revealed that the primary opportunity lies in potential market growth, while the main strength is the capacity for long-distance rail haulage. Singh, Kumar [98] focused on the problem of parameter-influencing testing selection and ranking. Ayyildiz and Taskin Gumus [99] identified and weighed critical risk factors associated with hazardous material transportation operations. Karasan, Ilbahar [100] developed an integrated approach to seat design for passenger cars, from a customer-centric perspective. Dogan, Deveci [101] devised a decision-making model for evaluating autonomous vehicle alternatives. Gündoğdu, Duleba [102] introduced a new hybrid model to assess the quality of public transport service. Yilanci, Candan [103] explored the roles of energy and economic factors in environmental degradation within MINT economies. Çetinkaya, Özkan [104] proposed a methodological approach for evaluating wheat processing plant locations across the fifty states in the United States (US). Sivaprakasam and Angamuthu [105] put forward a new model for group decision-making, which focuses on recruiting the most qualified candidate for an assistant professor position in an institute. Jagtap and Karande [106] effectively addressed the industry’s challenge of selecting the most suitable non-traditional machining (NTM) process. They provided a solution that resolved this selection issue. Ayyildiz [107] presented an evaluation methodology for assessing the resilience of green supply chains in the post-COVID-19 era. Özkan, Erdem [108] provided a systematic evaluation methodology for assessing Asian countries using the data center security index. An overview of the various applications and extensions of the AHP method is provided in Table 3.

2.4 Applications and extensions of the TOPSIS method

Several studies have effectively addressed a range of decision-making problems using the TOPSIS method [109]. For instance, Rani, Mishra [110] proposed practical methods for effectively selecting renewable energy sources. Zhang, Zhao [111] evaluated the operational risk of subway stations. Yucesan and Gul [112] facilitated accurate decision-making in evaluating hospital service quality. Rouyendegh, Yildizbasi [113] addressed the selection of green suppliers with a focus on lean, agile, environmentally sensitive, sustainable, and durable criteria. Jin, Zhao [114] introduced a novel decision-making method that was applied to risk management in green buildings. Kutlu Gündoğdu and Kahraman [115] solved a multiple criteria selection problem in optimal site selection for electric vehicle charging stations. Abdullah, Goh [116] addressed flood management issues. Ayağ and Samanlioglu [117] evaluated and rank a set of enterprise resource planning (ERP) alternatives based on their weight, aiming to identify the most suitable option that fulfills a company’s needs and expectations. Reig-Mullor, Garcia-Bernabeu [118] assessed the performance of corporate environmental, social, and governance (ESG) factors. Narang, Kumar [119] presented a hybrid ranking method to address the issue of selecting stocks in a real-world scenario. An overview of the various applications and extensions of the TOPSIS method is provided in Table 4.

2.5 Research gaps

The main objective of this study is to address a specific issue concerning the increased risk of accidents at construction sites in Africa. This study stands out due to its unique methodology in analyzing the causes of construction site accidents in Africa, assessing their importance, and determining the country’s most and least impacted by them. Importantly, these aspects have not been previously explored or given adequate attention, creating a scientific gap in the existing literature (refer to Table 1). Additionally, this study introduces an innovative combination of the AHP and TOPSIS approaches under a specific fuzzy environment in assessing the causes of accidents at construction sites, which is a novel endeavor in the African context (refer to Tables 3 and 4). Furthermore, these methods are employed to identify and classify the causes of accidents at construction sites, as well as the African countries that experience the highest and lowest impact from these causes—a subject that has not been explored previously (refer to Tables 1, 2, 3, and 4).

3 The proposed integrated decision-making methodology

This study’s research design, as shown in Fig. 1, involved several steps. Firstly, a comprehensive literature review was conducted to develop a three-level criteria hierarchy of potential causes of construction site accidents. Next, experts’ opinions were used in the modified Delphi method to categorize and finalize these causes. Then, the IVFF-AHP method was used to determine the relative weights of the three-level criteria by constructing a pairwise comparison matrix. Finally, the IVFF TOPSIS method was employed to identify the most and least affected countries by this construction site accident causes.

3.1 Criteria determination

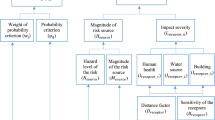

Examining the causes behind accidents is a multifaceted process of decision-making that encompasses various aspects. The inclusion of numerous variables that necessitate consideration adds difficulty to the task of identifying these causes. To address this issue, an extensive review of the literature was conducted to identify the most appropriate criteria, particularly concerning construction sites. The criteria that were identified as potential factors were further refined through consultation with a panel of experts. As a result, Fig. 2 indicates the criteria at all levels. To analyze the causes of accidents, the inner levels (Level-2 and Level-3) are provided in Table 5.

3.2 The modified Delphi method

The Delphi method involves collecting and analyzing the viewpoints of a group of unidentified specialists who communicate with one another through writing, analysis, and feedback layouts, all focused on a particular topic [124]. The approach relies on the sharing of expertise, abilities, and concepts among the group of experts until they reach a consensus [125]. The Modified Delphi method comprises five main steps [126], as depicted in Fig. 3. Steps 3 and 4 are reiterated until a consensus is achieved regarding the specific topic at hand [124]. Based on previous studies, determining the optimal number of experts for this strategy is not clearly defined. However, a decision-making group consisting of 5 to 50 experts is recommended. To ensure the effective implementation of the proposed framework in this study, it is crucial to carefully select qualified experts as a source of data collection. To recruit experts for the survey, several criteria were taken into account, including selecting top-tier individuals from both academia and industry who have a minimum of 10 years of experience in their respective professions. Additionally, it was required that they possess a bachelor’s degree or higher in order to be considered qualified.

3.3 Preliminary

Some basic explanations of intuitionistic fuzzy sets (IFSs), Pythagorean fuzzy sets (PFSs), Fermatean fuzzy sets (FFSs), and IVFFSs are introduced [41, 44, 127].

Definition 1

Let \(X=\varnothing\) be a given set. An IFS \(\widetilde{I}\) in \(X\) is shown as:

where \({\mu }_{\widetilde{I}}:X\to [\mathrm{0,1}]\) and \({v}_{\widetilde{I}}:X\to [\mathrm{0,1}]\) represents the degree of membership and the degree of non-membership of the component \(x\in X\) to \(\widetilde{I}\) and it holds that,

The degree of hesitancy is given as follows:

Definition 2

Let \(X\) be a non-empty set. A PFS \(\widetilde{P}\) in \(X\) is an expression given by:

where \({\mu }_{\widetilde{P}}:X\to [\mathrm{0,1}]\) and \({v}_{\widetilde{P}}:X\to [\mathrm{0,1}]\) define the two degrees of the component \(x\in X\) to \(\widetilde{P}\) and given that,

The degree of uncertainty is computed by:

Definition 3

Let \(X\) be a universe of discourse. An FFS \(\widetilde{F}\) in \(X\) is defined as:

where \({\mu }_{\widetilde{F}}:X\to [\mathrm{0,1}]\) and \({v}_{\widetilde{F}}:X\to [\mathrm{0,1}]\) refers to the two degrees of the component \(x\in X\) to \(\widetilde{F}\), where;

Definition 4

Let \(\widetilde{F}=\left({\mu }_{\widetilde{F}},{v}_{\widetilde{F}}\right)\), \({\widetilde{F}}_{1}=\left({\mu }_{{\widetilde{F}}_{1}},{v}_{{\widetilde{F}}_{1}}\right)\) and \({\widetilde{F}}_{2}=\left({\mu }_{{\widetilde{F}}_{2}},{v}_{{\widetilde{F}}_{2}}\right)\) be three FFSs. Then, some operations of FFSs are described as follows:

Definition 5

Let \(X=\mathrm{\varnothing }\) be a given set. An IVFFS \(\widetilde{F}\) in \(X\) is an expression provided by:

where \({\mu }_{\widetilde{F} }(x)\subseteq [\mathrm{0,1}]\) and \({v}_{\widetilde{F} }(x)\subseteq [\mathrm{0,1}]\) constitute the two degrees of the component \(x\in X\) to \(\widetilde{F}\), respectively. Also, for each \(x\in X\), \({\mu }_{\widetilde{F} }(X)\) and \({v}_{\widetilde{F} }(X)\) are immediate intervals and their inferior and superior bounds are designated by \({\mu }_{\widetilde{F} }^{L}\left(x\right), {\mu }_{\widetilde{F} }^{U}(x),{v}_{\widetilde{F} }^{L}(x)\) and \({v}_{\widetilde{F} }^{U}(x)\), respectively. Therefore, \(\widetilde{F}\) is described bellows:

where \(0\le {\left({\mu }_{\widetilde{F} }^{U}(x)\right)}^{3}+{\left({v}_{\widetilde{F} }^{U}(x)\right)}^{3}\le 1\).

For every \(x\in X\), the degree of hesitancy \({\pi }_{\widetilde{F} }(x)\) to \(\widetilde{F}\) as:

Definition 6

Let \(\tilde{F}=\left(\left[{\mu }_{\tilde{F}}^{L},{\mu }_{\tilde{F}}^{U}\right],\left[{v}_{\tilde{F}}^{L},{v}_{\tilde{F}}^{U}\right]\right)\), \(\tilde{F}_{1} = \left( {\left[ {\mu _{{\tilde{F}_{1} }}^{L} ,\mu _{{\tilde{F}_{1} }}^{U} } \right],\left[ {v_{{\tilde{F}_{1} }}^{L} ,v_{{\tilde{F}}}^{U} } \right]} \right)\) and \({\tilde{F}}_{2}=\left(\left[{\mu }_{{\tilde{F}}_{2}}^{L},{\mu }_{{\tilde{F}}_{2}}^{U}\right],\left[{v}_{{\tilde{F}}_{2}}^{L},{v}_{{\tilde{F}}_{2}}^{U}\right]\right)\) be three IVFFSs and \(\lambda >0\). Then some arithmetic operations of IVFFSs are denoted by Eq. (21)-(25):

Definition 7

Let \(\widetilde{F}=\left(\left[{\mu }_{\widetilde{F}}^{L},{\mu }_{\widetilde{F}}^{U}\right],\left[{v}_{\widetilde{F}}^{L},{v}_{\widetilde{F}}^{U}\right]\right)\) be an IVFFS. The score function \(S\left(\widetilde{F}\right)\) of \(\widetilde{F}\) is described.

Definition 8

Let \({\widetilde{F}}_{i}=\left(\left[{\mu }_{{\widetilde{F}}_{i}}^{L},{\mu }_{{\widetilde{F}}_{i}}^{U}\right],\left[{v}_{{\widetilde{F}}_{i}}^{L},{v}_{{\widetilde{F}}_{i}}^{U}\right]\right)(i=\mathrm{1,2},\dots ,n)\)be a category of IVFFSs and \(w={\left({w}_{1},{w}_{2},\dots ,{w}_{n}\right)}^{T}\) be a vector weight of \({\widetilde{F}}_{i}\) with \(\sum_{i=1}^{n} {w}_{i}=1\), then an IVFF weighted average operator is a framing IVVWA: \({\widetilde{F}}^{n}\to \widetilde{F}\), where.

Definition 9

Let \({\widetilde{F}}_{i}=\left(\left[{\mu }_{{\widetilde{F}}_{i}}^{L},{\mu }_{{\widetilde{F}}_{i}}^{U}\right],\left[{v}_{{\widetilde{F}}_{i}}^{L},{v}_{{\widetilde{F}}_{i}}^{U}\right]\right)(i=\mathrm{1,2},\dots ,n)\) be a set of IVFFSs and \(w={\left({w}_{1},{w}_{2},\dots ,{w}_{n}\right)}^{T}\) be a weight vector of \({\widetilde{F}}_{i}\) with \(\sum_{i=1}^{n} {w}_{i}=1\), thus an IVFF weighted geometric (IVFFWG) operator is a mapping IVVWG: \({\widetilde{F}}^{n}\to \widetilde{F}\), where.

Definition 10

Let \({F}_{1}=\left(\left[{\mu }_{{F}_{1L}},{\mu }_{{F}_{1U}}\right],\left[{v}_{{F}_{1L}},{v}_{{F}_{1U}}\right]\right),{F}_{2}=\left(\left[{\mu }_{{F}_{2L}},{\mu }_{{F}_{2U}}\right],\left[{v}_{{F}_{2L}},{v}_{{F}_{2U}}\right]\right)\in\) IVFFN. Let \({J}_{M}\left({F}_{i}\right),{J}_{H}\left({F}_{i}\right),{J}_{P}\left({F}_{i}\right)\) and \({J}_{C}\left({F}_{i}\right)\) be the membership, hesitancy, precise and complete score functions for \({F}_{i},(i=\mathrm{1,2})\). Then the ordering principle (O) for comparing arbitrary IVFFNs is defined below,

-

If \({J}_{M}\left({F}_{1}\right)<{J}_{M}\left({F}_{2}\right)\) then \({F}_{1}<{F}_{2}\)

-

If \({J}_{M}\left({F}_{1}\right)>{J}_{M}\left({F}_{2}\right)\) then \({F}_{1}>{F}_{2}\)

-

If \({J}_{M}\left({F}_{1}\right)={J}_{M}\left({F}_{2}\right)\) then

-

If \({J}_{H}\left({F}_{1}\right)<{J}_{H}\left({F}_{2}\right)\) then \({F}_{1}<{F}_{2}\)

-

If \({J}_{H}\left({F}_{1}\right)>{J}_{H}\left({F}_{2}\right)\) then \({F}_{1}>{F}_{2}\)

-

If \({J}_{H}\left({F}_{1}\right)={J}_{H}\left({F}_{2}\right)\) then

-

If \({J}_{P}\left({F}_{1}\right)<{J}_{P}\left({F}_{2}\right)\) then \({F}_{1}<{F}_{2}\)

-

If \({J}_{P}\left({F}_{1}\right)>{J}_{P}\left({F}_{2}\right)\) then \({F}_{1}>{F}_{2}\)

-

If \({J}_{P}\left({F}_{1}\right)={J}_{P}\left({F}_{2}\right)\) then

-

If \({J}_{H}\left({F}_{1}\right)<{J}_{H}\left({F}_{2}\right)\) then \({F}_{1}<{F}_{2}\)

-

If \({J}_{H}\left({F}_{1}\right)>{J}_{H}\left({F}_{2}\right)\) then \({F}_{1}>{F}_{2}\)

-

If \({J}_{H}\left({F}_{1}\right)={J}_{H}\left({F}_{2}\right)\) then

-

3.4 Interval-valued Fermatean fuzzy AHP method

The IVFF-AHP is an extension of the AHP to solve the MCDM problems. Alkan and Kahraman [127] introduced the IVFF-AHP method to find out the factors to be considered by organizations during the digitalization of the supply chain. Then, they selected the most appropriate strategy for digitalization using these factors. The main steps of the IVFF-AHP method are given below [127]:

Step 1. Construction of a hierarchical framework through the finding of main and sub-criteria. Suppose that \({C}_{j}\left(j=\mathrm{1,2},\dots ,m\right)\) be a set of \(m\) criteria with \({w}_{j}=\left({w}_{1},{w}_{2},\dots ,{w}_{m}\right)\), where \({w}_{j}>0\) and \(\sum_{j=1}^{m} {w}_{j}=1\) as the vector of the criteria weights. Let \({\psi }^{t}\) the reputation (weight) of experts \(t\) and \(k\) is the number of experts where \(\sum_{t=1}^{k} {\psi }^{t} =1\).

Step 2. The IVFF pairwise comparison matrix \(Z={\left({z}_{ij}\right)}_{m\times m}\) is constructed according to experts’ judgments using variables provided in Table 6.

Step 3. Each pairwise comparison (PC) matrix (\(Z\)) has found a consistency ratio (CR). A CR of a matrix is determined based on the procedure of Saaty’s classical consistency.

Step 4. Expert opinions are aggregated by using the \(\mathrm{IVFFWG}\) operator given in the Definition. 9. Let \({A}_{ij}^{t}=\left(\left[{\mu }_{ij}^{Lt},{\mu }_{ij}^{Ut}\right],\left[{v}_{ij}^{Lt},{v}_{ij}^{Ut}\right]\right)\) be the PC of criteria \(i\) and \(j\) by expert \(t\).

Step 5. The distinction in the computation matrix \(\mathrm{D}={\left({\mathrm{d}}_{\mathrm{ij}}\right)}_{\mathrm{m}\times \mathrm{m}}\) between the inferior and superior points the two degrees of functions through Eqs. (27) and (28):

Step 6. The interval generative matrix \(S={\left({s}_{ij}\right)}_{m\times m}\) is calculated by Eqs. (29) and (30):

Step 7. The uncertainty value \(T={\left({t}_{ij}\right)}_{m\times m}\) of the \({z}_{ij}\) is obtained.

Step 8. The uncertainty levels are multiplied with \(S={\left({s}_{ij}\right)}_{m\times m}\) matrix to find the matrix of unnoted weights \(R={\left({r}_{ij}\right)}_{m\times m}\) by Eq. (32):

Step 9. The computation of the normalized priority weights \({w}_{i}\) is as bellows.

3.5 Interval-valued Fermatean fuzzy TOPSIS method

The IVFF-TOPSIS is an expansion of TOPSIS to address MCDM issues. The TOPSIS method is frequently utilized for MCDM issues. In this part, the main steps of IVFF-TOPSIS are presented below [44]:

Let \(F=\left\{{F}_{1},{F}_{2},\dots ,{F}_{n}\right\}\) represents a group of \(n\) alternatives and assumes that \(M={\left({m}_{ij}\right)}_{n\times m}\) is the decision matrix, where \({m}_{ij}=\left(\left[{\mu }_{ij}^{Lt},{\mu }_{ij}^{Ut}\right],\left[{v}_{ij}^{Lt},{v}_{ij}^{Ut}\right]\right)\) showed the two degrees of ith alternative (Fi) concerning the jth criterion by expert \(t\).

Step 1. The establishment of the IVFF decision matrix \(M={\left({m}_{ij}\right)}_{n\times m}\) is made using the experts’ opinions.

Step 2. Expert opinions are aggregated through the usage of the \(\mathrm{IVPFWG}\) parameter provided in the Definition. 9.

Step 3. The IVFF weighted decision matrix is found as \({M}^{\mathrm{^{\prime}}}={\left({m}_{ij}^{\mathrm{^{\prime}}}\right)}_{n\times m}\), where \({m}_{ij}^{\mathrm{^{\prime}}}={m}_{ij}{w}_{j}\) based on Eq. 20.

Step 4. The rank matrix \(S={\left({s}_{ij}\right)}_{n\times m}\) is created by applying the ordering principle \(O\) defined given in Definition 10 to the weighted IVFF decision matrix M′. \(S={\left({s}_{ij}\right)}_{n\times m}\), where \({s}_{ij}=O\left({m}_{ij}^{\mathrm{^{\prime}}}\right)\) is calculated using Def. 7 for each \({m}_{ij}^{\mathrm{^{\prime}}}\).

Step 5. IVFF positive ideal solution for each criterion is defined:

Step 6. IVFF negative ideal solution for each criterion is defined as:

Step 7. The ordering principle O given in Definition 10 is applied to the IVFFPIS and IVFFNIS. The scores \(\left({J}_{M},{J}_{H},{J}_{P},{J}_{C}\right)\) that is sufficient to distinguish two arbitrary IVFFNs are found. \(O\left({P}_{I}\right)=\left\{O\left({P}_{1}\right),O\left({P}_{2}\right),\dots ,O\left({P}_{m}\right)\right\}\) and \(\left.O\left({P}_{I}\right)=\left\{O\left({N}_{1}\right),O\left({N}_{2}\right),\dots ,\right.O\left({N}_{m}\right)\right\}\).

Step 8. Because the aggregated performance and score functions of IVFFPIS and IVFFNIS alternatives are real numbers, the distances are calculated using the formula below,

where \({d}_{i}^{*}\left(O\left({F}_{i}\right),O\left({P}_{I}\right)\right)\), \({d}_{i}^{-}\left(O\left({F}_{i}\right),O\left({N}_{I}\right)\right)\) express the distance between alternative Fi and IVFFPIS, and IVFFNIS, respectively.

Step 9. Alternatives (Fi) can be evaluated according to the nearest coefficients. The suitable alternative is selected if it has a greater nearest coefficient. The relative closeness of an alternative Fi is calculated as the formula bellows:

4 Case study application

Once the criteria were established, five experts were consulted, as displayed in Table 7. These experts are currently involved in significant infrastructure development programs (building and construction) throughout Africa, including flagship projects related to infrastructure and services outlined in the African Union’s Agenda 2063. They were requested to provide their opinions on the criteria for causes of accidents at construction sites in ten different countries using a questionnaire by face-to-face interviews, based on the modified Delphi method.

4.1 Criteria weight assessment

Step 1. Firstly, weights of level-1 criteria were determined. For this purpose, experts analyzed the managerial, technical, and geographical factors.

Step 2. To establish a pairwise comparison (PC) of the level-1 criteria, the experts were tasked with utilizing linguistic variables in Table 6. The pairwise comparisons produced by the experts for the main criteria are presented in Table 8.

Step 3. Each matrix’s consistency was verified, and all were found to be consistent based on the consistency ratio (CR) values calculated and presented in Table 8.

Step 4. The experts’ opinions were then aggregated, taking into account their reputations, to determine the criteria weights using the IVFF-AHP method. Table 9 shows the aggregated evaluation matrix for level-1 criteria.

Step 5. Difference matrix between lower and upper values was generated based on Eqs. (27) and (28) and presented in Table 10.

Step 6. The interval generative matrix was generated based on Table 10 and Eqs. (29) and (30) as given in Table 11.

Step 7. The uncertainty value for each criterion was calculated as given in Table 12.

Step 8. Unnormalized weights were calculated based on Tables 11 and 12 via Eq. 32. The weights before normalization are shoen in Table 13.

Step 9. Finally, weights are normalized and criteria weights are determined. The results of Level-1 criteria are presented in Fig. 4, which highlights that the managerial (M) criterion is the most critical, with a weight of 0.6121. Following in critical importance is the technical (T) criterion, which weighs 0.2311, while the geographical (G) criterion is lastly ranked, with a weight of 0.1568.

The same experts were then consulted to evaluate the inner levels of criteria. To this end, they established PC matrices for level-2 criteria based on their professional judgment. Table 14 presents the matrices for the PC of level-2 criteria for each main criterion.

Once the consistency of all matrices has been determined, the experts proceed to establish PC matrices for level-3 criteria under level-2. As an example, Table 15 shows the PC matrices for the level-3 criteria related to site conditions (G1).

After testing the level-3 comparison matrices for consistency, it was determined that all of them are consistent. The weights of criteria for the two inner levels are then calculated by applying the IVFF-AHP steps again. The resulting weights of criteria for each expert at level-2 and level-3 are shown in Figs. 5 and 6, respectively.

The sub-criteria’s weights in level-2 (Fig. 5) are determined by multiplying their weights with those of the level-1 criteria. Among all level-2 criteria, management (M3) is the most significant criterion, which is not surprising since it falls under the managerial aspect which is the most important criterion under level-1 criteria. Project (M1) and contract (M2) follow closely in second and third place, with final weights of 0.1276 and 0.1230, respectively. This ranking highlights the critical role of the managerial aspect and the parameters listed below in causing construction site accidents, emphasizing the need for companies to consider these factors when making decisions. The equipment and tools (T2) sub-criterion under the technical aspect rank fourth, indicating also their importance in identifying causal factors of accidents. Conversely, the criterion (G2- Design) is the least important and falls under the geography main criteria. This suggests that it is more appropriate to focus on criteria that are more essential in preventing or minimizing accidents, rather than prioritize this criterion.

After a thorough consideration of all level-3 criteria depicted in Fig. 6, it has been concluded that the lack of effective project supervision (M31) is the most significant cause of accidents, with a weight of 0.1244. This implies that the occurrence of accidents is closely associated with the effectiveness of project supervision. The absence of safety policies (M32) and a poor organizational structure (M33) follow closely in second and third place, with final weights of 0.1193 and 0.1180, respectively. The weight of inappropriate scheduling and planning (M11) has been determined to be 0.0658, placing it in the fourth position in terms of importance. This factor is responsible for the inadequate management of employees, machinery, and assets, which can have serious consequences at construction sites in the form of accidents.

4.2 Assessment of alternatives

This section provides a ranking of ten African countries from various regions (Table 16) based on their level of exposure to accidents at construction sites. The ranking is determined by analyzing the causes of accidents and consulting the same experts who evaluated the initial set of criteria. The experts use the same linguistic terms to analyze the selected countries against specific criteria, and the results are presented in Table 17 (see online Appendix), which contains the alternative evaluation matrices. The countries are ranked in order, beginning with the most susceptible to accidents at construction sites.

After aggregating expert opinions based on their reputation, the IVFF-TOPSIS method is applied to obtain rankings of the ten African countries evaluated in this study. As shown in Fig. 7, Guinea received the highest score of 0.7897, making it the country with the highest rate of construction site accidents. This result can be attributed to a large number of recent notable projects, including railway, dam, and iron ore mine projects, which have experienced recurrent accidents due to insufficient safety policies, poor organizational structures, inadequate planning, and unclear contract provisions regarding safety issues. Following Guinea, Burkina Faso, and the Benin Republic received scores of 0.6848 and 0.6502, respectively, placing them in the second and third positions. The country with the lowest accident rate was Togo, which received a score of 0.2660. This finding can be explained by Togo’s smaller land area, fewer people, and fewer active infrastructure projects compared to the other countries included in the study.

5 Sensitivity analysis

A sensitivity analysis is used to examine and discuss the proposed methodology. This involves modifying the weights of two of the main level-1 criteria while leaving the third criterion unchanged. Specifically, the weights of the second and third criteria are gradually increased to match that of the first criterion, while the weight of the last criterion remains the same. The weights of the second and third criteria are then swapped, and the weights of the lower-level criteria are updated accordingly. By evaluating the methodology’s response to these weight changes, any changes in outcomes can be identified, which can aid decision-makers in prioritizing criteria and streamlining the analysis process. Figure 8 presents the updated weights of the level-3 criteria.

To explore the impact of criteria weights on the proposed methodology, the level-1 criterion weights are modified, causing changes in the overall weights of the level-3 criteria. Specifically, when the first criterion is considered managerial and the second is technical, the weight of “inappropriate scheduling/planning-(M11)” decreases from 0.0658 to 0.0248, while the weight of “costly modern equipment and tools-(T23)” increases from 0.042 to 0.1102. The updated criteria weights are then subjected to IVFF-TOPSIS steps to evaluate their impact on the final scores of countries. When the first criterion is managerial and the second criterion is technical, Nigeria’s (NG) final score decreases from 0.5396 to 0.4737, while Ethiopia’s (ETH) score increases from 0.4648 to 0.6238, and Burkina Faso’s (BF) score decreases from 0.6848 to 0.5700. Across all scenarios, the final scores of the countries are converging, with Guinea (GN) consistently obtaining the highest overall score. Figure 9 provides a visual representation of the final results of the sensitivity analysis.

The rankings of the countries are found to be influenced by changes in the weights of the main criteria. For example, when the weights are adjusted, Burkina Faso (BF) drops from second to sixth place in the final rankings. The rankings of the countries are presented in Fig. 9. However, it can be observed that Guinea (GN) consistently has the highest rate of construction site accidents, based on the sensitivity analysis results shown in Fig. 9. Thus, it can be concluded that Guinea (GN) is the most exposed to accidents in this regard. Furthermore, Benin Republic (BN) is consistently among the top three countries most exposed to construction site accidents in all scenarios, as demonstrated by Figs. 9 and 10. Conversely, it can be concluded that Niger (NE) is the least exposed to accidents among all alternatives in every scenario.

6 Discussion, managerial and practical implications

The study examines the causes of accidents on construction sites and ranks them according to their severity level, using a real-life scenario. Additionally, it determines which countries are most and least affected by these accidents through a comparative analysis. To achieve this, a three-level criteria framework is established by identifying criteria for accidents at different levels and determining their weights using IVFF-AHP, a tool that captures uncertainty in expert judgments [127]. The study then uses TOPSIS, a commonly used methodology, to rank countries in the IVFF environment. The hybrid methodology IVFF-AHP-TOPSIS evaluates causal accidents at construction sites and ranks countries based on these accidents using information from previous research and expert opinions.

The study shows that poor project supervision is the leading cause of accidents on construction sites. To prevent accidents, it is essential to prioritize effective supervision mechanisms during the project execution phase. This can be achieved by establishing proactive risk management schemes through efficient supervision mechanisms. By reducing accidents, organizations can maintain their reputation and enhance stakeholder satisfaction, including employees, customers, and shareholders. Furthermore, the study revealed that the absence of safety policies and inadequate organizational structures are also significant contributors to accidents. Developing effective safety policies and guidelines to govern the execution of projects can help reduce the likelihood of accidents. It is also vital to establish a well-designed organizational structure that ensures a clear delegation of roles and responsibilities. This can help reduce miscommunication and errors that could potentially result in accidents. In addition to these factors, inappropriate scheduling and planning were also identified as major contributors to accidents. Therefore, organizations should prioritize effective scheduling and planning measures to minimize accidents. Effective scheduling and planning can help ensure that all activities are correctly sequenced and adequately resourced, reducing the likelihood of accidents.

The high risk of accidents on construction sites in Guinea makes it a less favorable alternative, whereas Niger and Togo are better alternatives due to their lower accident risks. The study’s findings have been communicated to the respondents, and the ranking of countries aligns with the expectations of experts. This study is the first to use MCDM to conduct a causal and comparative analysis of construction site accidents across African countries, making it a significant contribution to the literature.

This study represents the first instance in which IVFF AHP has been integrated with IVFF TOPSIS methodology to perform a causal analysis of accidents on construction sites and conduct a comparative analysis of ten countries based on these causes of accidents. In terms of research implications, this study offers several valuable insights for researchers who are researching construction safety management. Firstly, this study provides a detailed list of factors and their sub-factors that contribute to accidents on construction sites, thereby shedding light on the area of accident causation analysis for concerned researchers. Secondly, the study ranks these contributing factors based on their criticality, allowing researchers to build their models using the most significant factors identified in this study.

In terms of managerial implications, the study first identifies all potential causes and sub-causes that may contribute to accidents in developing countries. Furthermore, the study provides insight into the significance and ranking of these causes concerning accident occurrence. This information can help safety decision-makers prevent or reduce the occurrence of accidents by focusing their attention on improving the identified causes. Additionally, the study highlights the causes and sub-causes that can serve as drivers for accident prevention on construction sites. This information can help safety managers better understand how to prevent accidents from happening.

In essence, this study has devised a methodological framework that overcomes the limitations of previous studies which relied on statistical techniques, cross-sectional research designs, and interviews. The new framework sheds light on the extent to which various factors contribute to accidents on construction sites. It represents the initial effort to reveal the direct impact of identified accident causes. The outcomes derived from this methodological framework can serve as a preliminary step in developing conceptual models and formulating testable hypotheses for other developing countries in Africa.

7 Conclusion

This study aims to identify the causes of accidents during construction and analyze the extent to which each causal factor affects different countries. Understanding the main causes of accidents and their impact is essential for stakeholders in the construction industry. The study provides an in-depth analysis of the process of identifying the causes of accidents, their weights, and the countries that are most and least affected. To determine the causes of accidents at construction sites, the study conducted a literature review and consulted with five experts through a modified Delphi method. The IVFF-AHP method was used to calculate the weights of the causal factors, while the IVFF-TOPSIS technique is applied to rank ten countries based on the weighted accident causes.

The findings of the study indicate that effective measures such as supervisory mechanisms, adequate safety policies, well-designed organizational structure, and good planning are crucial for addressing the root causes of accidents at construction sites. This study is very significant since it first sheds light on accident causation analysis, allowing concerned researchers to build models using the most significant factors identified in Africa countries. Secondly, it provides valuable insights for researchers studying construction safety management by revealing the importance and ranking of accident causes. Furthermore, safety decision-makers can utilize this information to prevent or reduce accidents. Lastly, the newly developed integrated model represents a significant scientific advancement in the field.

While the study has made valuable contributions, it is important to acknowledge some limitations. Firstly, the study did not consider the causal accidents related to contractors, labor, owners, consultants, and external factors. Therefore, future research could be directed toward exploring these important areas. Secondly, the study did not investigate the interrelationships among the causes of accidents on construction sites using mapping techniques. Such an analysis could add significant value to future research on the topic. Thirdly, the findings may not apply to other developing countries with unique conditions and circumstances since the data was only collected from ten countries. This highlights the need to replicate the research framework used in this study from scratch in other locations and subsequently compare the results with those of this study. Fourth, the study did not consider the dynamic nature of the identified causes, which could have influenced the results. Therefore, future research should consider such dynamism and conduct thorough comparisons with the findings of this study to further advance the understanding of the causes of accidents on construction sites. Lastly, while our proposed methodology offers numerous benefits, it does have a limitation. Although it is effective in addressing various decision-making problems, it faces challenges when dealing with a large number of experts due to the absence of a consensus-reaching process. Therefore, it is imperative to extend the proposed methodology by developing a consensus-based model that incorporates a consensus coefficient, which would require further research. Furthermore, the current multi-criteria framework can be applied to tackle other complex decision-making issues, including the selection of renewable energy sources, assessment of sustainability, achievement of transportation decarbonization, and implementation of the circular economy. These areas present valuable opportunities for future exploration and application of the proposed methodology.

Data availability

Data sharing is not applicable to this article.

Code availability

Not applicable.

References

Zhang F et al (2019) Construction site accident analysis using text mining and natural language processing techniques. Autom Constr 99:238–248

Al-Khaburi S, Amoudi O (2018) Analysis of accident causes at construction sites in Oman. Jordan J Civil Eng 12(2)

De Silva N, Rathnayake U, Kulasekera K (2018) Under-reporting of construction accidents in Sri Lanka. J Eng Des Technol

Williams OS, Hamid RA, Misnan MS (2018) Accident causal factors on the building construction sites: a review. Int J Built Environ Sustain 5(1)

Williams OS, Hamid RA, Misnan MS (2019) Causes of building construction related accident in the south-western states of Nigeria. Int J Built Environ Sustain 6(1):14–22

Stević Ž et al. (2022) Assessment of causes of delays in the road construction projects in the Benin republic using fuzzy PIPRECIA method. Math Probl Eng

Okorie V, Musonda I (2020) An investigation on supervisor’s ability and competency to conduct construction site health and safety induction training in Nigeria. Int J Constr Manag 20(5):357–366

Boadu EF, Wang CC, Sunindijo RY (2020) Characteristics of the construction industry in developing countries and its implications for health and safety: an exploratory study in Ghana. Int J Environ Res Public Health 17(11):4110

Rafindadi ADU, Napiah M, Othman I, Mikić M, Haruna A, Alarifi H, Al-Ashmori YY (2022) Analysis of the causes and preventive measures of fatal fall-related accidents in the construction industry. Ain Shams Eng J 13(4):101712

Oni O et al (2019) Relevance of construction site operative training in reducing accidents on construction sites in Nigeria. Int J Civil Eng Technol 10(5):979–990

Eguh T, Adenaiya O (2020) Monitoring and analysis of site accidents on construction site in Nigeria. FIG Working Week 2020, Smart surveyors for land and water management pp 1–13

Falana J, Ghazaly NM (2019) Examination of causes and effects of accident on construction sites:(case study of lagos, lagos state, Nigeria). Int J Adv Sci Technol 28(16):1687–1694

Shittu AA et al. (2022) Impact of hazard recognition measures on the rate of accidents on construction sites in Abuja, Nigeria. J Build Perform 13(1).

Ijaola IA et al (2021) Key indicators and dimensional causes of accident on construction sites. Int J Built Environ Sustain 8(1):81–89

Eze CJ, Ayuba P, Shittu AA (2018) Assessment of accident hazard in Nigerian building industy

Okorie VN, Adindu CC (2020) An exposition of the socio-economic impacts of construction site accidents in Nigeria. J Surv Constr Property 11(1):38–47

Badi I, Bouraima MB, Muhammad LJ (2022) Risk assessment in construction projects using the grey theory. J Eng Manag Syst Eng 1(2):58–66

Badi I, Bouraima MB, Muhammad LJ (2022) The role of intelligent transportation systems in solving traffic problems and reducing environmental negative impact of urban transport. Decis Mak Anal 1(1):1–9

Kovač M et al. (2021) Novel spherical fuzzy MARCOS method for assessment of drone-based city logistics concepts. Complexity

Kiptum CK et al (2022) Sustainable strategies for the successful operation of the bike-sharing system using an ordinal priority approach. J Eng Manag Syst Eng 1(2):43–50

Bouraima MB et al (2023) Integrated intelligent decision support model for ranking regional transport infrastructure programmes based on performance assessment. Expert Syst Appl p 119852

Bouraima MB et al. (2023) An integrated fuzzy MCDM model for prioritizing strategies for successful implementation and operation of the bus rapid transit system. Ann Oper Res

Bouraima MB et al (2023) Assessment of alternative railway systems for sustainable transportation using an integrated IRN SWARA and IRN CoCoSo model. Socioecon Plann Sci 86:101475

Bouraima MB et al. (2023) Prioritization of strategies for a sustainable regional transportation infrastructure by hybrid spherical fuzzy group decision-making approach. Neural Comput Appl

Bouraima MB et al (2021) Assessing the performance of Sub-Saharan African (SSA) railways based on an integrated Entropy-MARCOS approach. Oper Res Eng Sci Theory Appl 4(2):13–35

Pamucar D, Deveci M, Gokasar I, Delen D, Köppen M, Pedrycz W (2023) Evaluation of metaverse integration alternatives of sharing economy in transportation using fuzzy Schweizer-Sklar based ordinal priority approach. Decis Supp Syst p 113944

Pamučar D et al (2023) Selection of healthcare waste management treatment using fuzzy rough numbers and Aczel-Alsina Function. Eng Appl Artif Intell 121:106025

Simic V et al. (2023) Neutrosophic CEBOM-MACONT model for sustainable management of end-of-life tires. Applied Soft Computing

Badi I, Kridish M (2020) Landfill site selection using a novel FUCOM-CODAS model: a case study in Libya. Sci African 9:e00537

Badi I et al (2021) Optimal site selection for sitting a solar park using a novel GIS-SWA’TEL model: a case study in Libya. Int J Green Energy 18(4):336–350

Bouraima MB et al (2022) Evaluation of factors affecting road maintenance in Kenyan counties using the ordinal priority approach. J Comput Cognitive Eng 00(00):1–6

Bouraima MB et al (2022) Prioritization road safety strategies towards zero road traffic injury using ordinal priority approach. Oper Res Eng Sci Theory Appl 5(2):206–221

Badi I, Stević Ž, Bouraima MB (2023) Overcoming obstacles to renewable energy development in Libya: an MCDM approach towards effective strategy formulation. Decis Mak Adv 1(1):17–24

Badi I, Stević Ž, Bouraima MB (2023) Evaluating free zone industrial plant proposals using a combined full consistency method-grey-cocoso model. J Ind Intell 1(2):101–109

Qiu YJ et al (2023) Strategies for enhancing industry 4.0 adoption in East Africa: an integrated spherical fuzzy swara-waspas approach. J Ind Intell 1(2):87–100

Ali A, Ullah K, Hussain A (2023) An approach to multi-attribute decision-making based on intuitionistic fuzzy soft information and Aczel-Alsina operational laws. J Decis Anal Intell Comput 3(1):80–89

Sahoo SK, Goswami SS (2023) A comprehensive review of multiple criteria decision-making (MCDM) Methods: advancements, applications, and future directions. Decis Mak Adv 1(1):25–48

Pamucar D, Biswas S (2023) A novel hybrid decision making framework for comparing market performance of metaverse crypto assets. Decis Mak Adv 1(1):49–62

Tešić D et al (2023) Development of the MCDM fuzzy LMAW-grey MARCOS model for selection of a dump truck. Rep Mech Eng 4(1):1–17

Chatterjee S, Chakraborty S (2023) A Multi-criteria decision making approach for 3D printer nozzle material selection. Rep Mech Eng 4(1):62–79

Senapati T, Yager RR (2020) Fermatean fuzzy sets. J Ambient Intell Humaniz Comput 11(2):663–674

Senapati T, Yager RR (2019) Fermatean fuzzy weighted averaging/geometric operators and its application in multi-criteria decision-making methods. Eng Appl Artif Intell 85:112–121

Senapati T, Yager RR (2019) Some new operations over Fermatean fuzzy numbers and application of Fermatean fuzzy WPM in multiple criteria decision making. Informatica 30(2):391–412

Jeevaraj S (2021) Ordering of interval-valued Fermatean fuzzy sets and its applications. Expert Syst Appl 185:115613

Mukhametzyanov I (2021) Specific character of objective methods for determining weights of criteria in MCDM problems: entropy, CRITIC and SD. Decis Mak Appl Manag Eng 4(2):76–105

Rezaei J (2015) Best-worst multi-criteria decision-making method. Omega 53:49–57

Rezaei J (2016) Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega 64:126–130

Pamučar D, Stević Ž, Sremac S (2018) A new model for determining weight coefficients of criteria in mcdm models: full consistency method (fucom). Symmetry 10(9):393

Prentkovskis O et al (2018) A new methodology for improving service quality measurement: delphi-FUCOM-SERVQUAL model. Symmetry 10(12):757

Zagradjanin N, Pamucar D, Jovanovic K (2019) Cloud-based multi-robot path planning in complex and crowded environment with multi-criteria decision making using full consistency method. Symmetry 11(10):1241

Žižović M, Pamucar D (2019) New model for determining criteria weights: level based weight assessment (LBWA) model. Decis Mak Appl Manag Eng 2(2):126–137

Korucuk S et al (2023) Assessment of ideal smart network strategies for logistics companies using an integrated picture fuzzy LBWA–CoCoSo framework. Manag Decis 61(5):1434–1462

Biswas S et al (2021) An extended LBWA framework in picture fuzzy environment using actual score measures application in social enterprise systems. Int J Enterpr Inf Syst (IJEIS) 17(4):37–68

Ecer F et al (2021) Assessment of renewable energy resources using new interval rough number extension of the level based weight assessment and combinative distance-based assessment. Renew Energy 170:1156–1177

Torkayesh AE et al (2021) An integrated BWM-LBWA-CoCoSo framework for evaluation of healthcare sectors in Eastern Europe. Socioecon Plann Sci 78:101052

Ögel İY, Ecer F, Özgöz AA (2023) Identifying the leading retailer-based food waste causes in different perishable fast-moving consumer goods’ categories: application of the F-LBWA methodology. Environ Sci Pollut Res 30(12):32656–32672

Biswas S et al (2022) A new spherical fuzzy LBWA-MULTIMOOSRAL framework: application in evaluation of leanness of MSMEs in India. Math Probl Eng 2022:1–17

Pamucar D et al (2021) Circular economy concepts in urban mobility alternatives using integrated DIBR method and fuzzy Dombi CoCoSo model. J Clean Prod 323:129096

Tešić D et al (2022) Modification of the DIBR and MABAC methods by applying rough numbers and its application in making decisions. Information 13(8):353

Božanić D, Pamucar D (2023) Overview of the method defining interrelationships between ranked criteria ii and its application in multi-criteria decision-making. In: Computational Intelligence for Engineering and Management Applications: Select Proceedings of CIEMA 2022 (pp 863-873). Singapore: Springer Nature Singapore

Asadabadi MR, Chang E, Saberi M (2019) Are MCDM methods useful? A critical review of analytic hierarchy process (AHP) and analytic network process (ANP). Cogent Eng 6(1):1623153

Pamucar D et al (2022) Prioritization of sustainable mobility sharing systems using integrated fuzzy DIBR and fuzzy-rough EDAS model. Sustain Cities Soc 82:103910

Deveci M et al (2022) An analytics approach to decision alternative prioritization for zero-emission zone logistics. J Bus Res 146:554–570

Alosta A, Elmansuri O, Badi I (2021) Resolving a location selection problem by means of an integrated AHP-RAFSI approach. Rep Mech Eng 2(1):135–142

Biswas TK, Das MC (2020) Selection of the barriers of supply chain management in Indian manufacturing sectors due to COVID-19 impacts. Oper Res Eng Sci Theory Appl 3(3):1–12

Tešić D et al. (2023) DIBR–DOMBI–FUZZY MAIRCA model for strategy selection in the system of defense. Discrete Dynamics in Nature and Society

Darko A et al (2019) Review of application of analytic hierarchy process (AHP) in construction. Int J Constr Manag 19(5):436–452

Ayyildiz E, Erdogan M, Taskin Gumus A (2021) A Pythagorean fuzzy number-based integration of AHP and WASPAS methods for refugee camp location selection problem: a real case study for Istanbul. Turkey. Neural Comput Appl 33(22):15751–15768

Liu Y, Eckert CM, Earl C (2020) A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst Appl 161:113738

Yildiz A et al. (2022) An integrated interval-valued intuitionistic fuzzy AHP-TOPSIS methodology to determine the safest route for cash in transit operations: a real case in Istanbul. Neural Comput Appl pp 1–16

Moslem S, et al. (2023) A systematic review of analytic hierarchy process applications to solve transportation problems: from 2003 to 2019. IEEE Access

Ayyildiz E, Taskin A (2022) A novel spherical fuzzy AHP-VIKOR methodology to determine serving petrol station selection during COVID-19 lockdown: a pilot study for İstanbul. Socio Econ Plan Sci 83:101345

Stević Ž et al (2020) Sustainable supplier selection in healthcare industries using a new MCDM method: measurement of alternatives and ranking according to COmpromise solution (MARCOS). Comput Ind Eng 140:106231

Pamučar D, Ćirović G (2015) The selection of transport and handling resources in logistics centers using multi-attributive border approximation area comparison (MABAC). Expert Syst Appl 42(6):3016–3028

Torkayesh AE et al (2023) A systematic literature review of MABAC method and applications: an outlook for sustainability and circularity. Informatica 34(2):415–448

Pamučar D, Vasin L, Lukovac L (2014) Selection of railway level crossings for investing in security equipment using hybrid DEMATEL-MARICA model. In: XVI international scientific-expert conference on railway, railcon (pp 89-92)

Pamucar DS, Pejcic Tarle S, Parezanovic T (2018) New hybrid multi-criteria decision-making DEMATELMAIRCA model: sustainable selection of a location for the development of multimodal logistics centre. Econ Res Ekonomska Istraživanja 31(1):1641–1665

Gigović L et al (2016) The combination of expert judgment and GIS-MAIRCA analysis for the selection of sites for ammunition depots. Sustainability 8(4):372

Khan MJ et al (2022) Improved generalized dissimilarity measure-based VIKOR method for Pythagorean fuzzy sets. Int J Intell Syst 37(3):1807–1845

Akram M, Dudek WA, Ilyas F (2019) Group decision-making based on pythagorean fuzzy TOPSIS method. Int J Intell Syst 34(7):1455–1475

de Farias Aires RF, Ferreira L (2019) A new approach to avoid rank reversal cases in the TOPSIS method. Comput Ind Eng 132:84–97

Deveci M, Canıtez F, Gökaşar I (2018) WASPAS and TOPSIS based interval type-2 fuzzy MCDM method for a selection of a car sharing station. Sustain Cities Soc 41:777–791

Garg H, Shahzadi G, Akram M (2020) Decision-making analysis based on Fermatean fuzzy Yager aggregation operators with application in COVID-19 testing facility. Math Probl Eng 2020:1–16

Chodha V et al (2022) Selection of industrial arc welding robot with TOPSIS and entropy MCDM techniques. Mater Today Proc 50:709–715

Bera B et al (2022) Susceptibility of deforestation hotspots in Terai-Dooars belt of Himalayan Foothills: a comparative analysis of VIKOR and TOPSIS models. J King Saud Univ Comput Inf Sci 34(10):8794–8806

Youssef AE (2020) An integrated MCDM approach for cloud service selection based on TOPSIS and BWM. IEEE Access 8:71851–71865

Halabi Y et al (2022) Causal factors and risk assessment of fall accidents in the US construction industry: a comprehensive data analysis (2000–2020). Saf Sci 146:105537

Mohandes SR et al (2022) A comprehensive analysis of the causal factors in repair, maintenance, alteration, and addition works: a novel hybrid fuzzy-based approach. Expert Syst Appl 208:118112

Mohandes SR et al (2022) Causal analysis of accidents on construction sites: a hybrid fuzzy Delphi and DEMATEL approach. Saf Sci 151:105730

Gunduz M, Khader BK (2020) Construction project safety performance management using analytic network process (ANP) as a multicriteria decision-making (MCDM) tool. Computational intelligence and neuroscience, 2020.

Hatefi SM, Tamošaitienė J (2019) An integrated fuzzy DEMATEL-fuzzy ANP model for evaluating construction projects by considering interrelationships among risk factors. J Civ Eng Manag 25(2):114–131

Bakhtavar E, Yousefi S (2018) Assessment of workplace accident risks in underground collieries by integrating a multi-goal cause-and-effect analysis method with MCDM sensitivity analysis. Stoch Env Res Risk Assess 32(12):3317–3332

Kazaz A, Erbas I, Simsek R (2021) A regional perspective for work accidents: Evaluating the amount of work accidents on a city basis by the help of multi-criteria decision making methods. J Constr Eng Manag Innov 4(1):037–051

Rostamzadeh S et al (2022) An integrated DEMATEL-ANP approach for identification and prioritization of factors affecting falls from height accidents in construction industry. Int J Occup Saf Ergon 29:1–31

Turskis Z et al (2019) A fuzzy group decision-making model for determining the most influential persons in the sustainable prevention of accidents in the construction SMEs. Int J Comput Commun Control 14(1):90–106

Dos Santos M, de Araújo Costa IP, Gomes CFS (2021) Multicriteria decision-making in the selection of warships: a new approach to the AHP method. Int J Anal Hierarchy Process 13(1).

Bouraima MB et al (2020) A study on the development strategy of the railway transportation system in the West African Economic and Monetary Union (WAEMU) based on the SWOT/AHP technique. Sci African 8:e00388

Singh V, Kumar V, Singh V (2023) A hybrid novel fuzzy AHP-Topsis technique for selecting parameter-influencing testing in software development. Decis Anal J 6:100159

Ayyildiz E, Taskin Gumus A (2021) Pythagorean fuzzy AHP based risk assessment methodology for hazardous material transportation: an application in Istanbul. Environ Sci Pollut Res 28(27):35798–35810

Karasan A et al (2022) Customer-oriented product design using an integrated neutrosophic AHP & DEMATEL & QFD methodology. Appl Soft Comput 118:108445