Abstract

In supply chain network (SCN) management, multi-objective Pareto optimization means the network can meet the demand for both minimal cost and minimal lead-time in SCN. Due to the compromise between cost and lead-time, it is a non-trivial issue to search for multi-objective Pareto optimal solutions (POS) in SCN. Furthermore, with the wide application of the internet, an increasing number of SCN applications have been based on the internet. As a result, the complexity of SCN increases exponentially with the number of suppliers increasing. It is really a big challenge to find the global multi-objective POS within a limited time in SCN management. In order to solve this problem, first, this paper proposes an artificial bee colony (ABC) optimization algorithm with two improvements: (1) a novel solution framework designed to extend the application field of the SCN based on complex network; (2) the acceleration of search speed by adopting naive Bayes classifier. Second, the paper provides a case example of optimizing a three-echelon SCN with the objective of minimizing both cost and lead-time. After the simulation with this example, it turns out that the enhanced ABC algorithm can satisfy the requirements of: (1) finding the global multi-objective POS; (2) improving the speed of finding optimal solutions in SCN management.

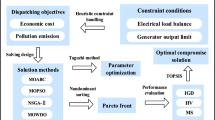

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, with the drastic change of business environment, corporations are required to evaluate and configure their supply chain management (SCN) to provide customers with high-quality products/services at the lowest possible cost and within the shortest possible lead-time (Gou et al. 2017; Pishvaee et al. 2011) to support their sustainable development (Kleindorfer et al. 2005; Linton et al. 2007). The supply chain of manufacturing, processing and delivering resources is typically a large complex network (Aslam and Ng 2010; Tan 2001; Zhou et al. 2017), its operation management requiring optimization based on complex network. Suppliers are growing exponentially because of the wide application of e-commerce systems, which makes the supply chain network ever more complex and difficult to be optimized. Therefore, multi-objective Pareto optimization in complex SCN is one of the fundamental functions in e-commerce operation management.

The optimization in SCN management refers to discovering the best flow patterns (i.e. choices of resources) for a family of products (Goetschalckx et al. 2002). The flow pattern in SCN management involves selections through which materials (raw materials, partially processed, and finished products) and information (demand data, due date, delivery, assembly cost and lead-time) are allocated in order to satisfy its multi-objective functions (Corner and Buchanan 1995; Ke et al. 2017; Li et al. 2017; Nasiri et al. 2010; Nemati and Alavidoost 2018; Schtz et al. 2009; Zhang et al. 2016).

In order to determine an efficient flow pattern for every product in a family, it requires: (1) the selection of a supplier (or suppliers) for every component used in the product portfolio, (2) the selection of a manufacturing plant (or plants) for every sub or final component assembly, and (3) the selection of transport options to deliver every product to customers (Moncayo-Martnez and Zhang 2011). In a typical case of SCN, there often exist many suppliers for the same raw materials or components, as well as multiple manufactures to conduct the sub or final assembly, and also a number of distributors to deliver products to customers. Different resource selections in the flow pattern will generate different costs and lead-times, thus it is necessary to design a multi-objective optimization model to get the global optimal solution of this combinatorial selection to reach an optimized balance between total cost and lead-time for SCN management. This is not an easy task due to high complexity, which requires simultaneous optimization of cost and lead-time, both often contradicting with each other. Moreover, it involves mutiple products in different hierarchy sharing common components and subassemblies, and the existence of a large number of resource options across the supply chain (Goetschalckx et al. 2002). However, aggregating all these objectives through weighted sum can transform the multi-objective problem into a single one. Every objective is multiplied by a weighted factor, and the sum of the weighted object is the objective function (Moncayo-Martnez and Zhang 2011; Kamali et al. 2011; Wang et al. 2011; Yuce et al. 2013, 2014, 2015). This alternative method is a collection of different criteria under certainty, which helps decision-makers to find the trade-off proposals and Pareto optimal solutions.

Existing literatures have proposed various models to solve the multi-objective optimization for SCN design. For instance, (Shaw et al. 2012) proposed an integrated approach for selecting appropriate suppliers in SCN through fuzzy-AHP and fuzzy multi-objective linear programming, which neglected the importance of complex network structure. Shen et al. (2013) proposed a fuzzy multi-criteria approach for green suppliers evaluation. Moncayo-Martnez and Zhang (2013) proposed an approach based on ant colony optimization (ACO) to minimize the total supply chain cost and the products lead-time simultaneously to ensure delivery of products without delay. Mastrocinque et al. (2013) adopted the artificial bee colony (ABC) algorithm to deal with the multi-objective supply chain model to find the optimum configuration in a given SCN situation that could minimize the total cost and the total lead-time. Hence, the nature-inspired optimization algorithms for SCN management is a hot topic. However, these algorithms neglected the influence of exponential growth in suppliers to the convergence speed of seeking multi-objective Pareto solutions.

The majority of studies on SCN have considered only one product and one manufacturing plant (Shu et al. 2016). But, in reality, most enterprises involve more than one product and multiple manufacturing plants in different regions. Hence, our study is fit to be a solution for complex SCN with multiple products and manufacturing plants, in which both the cost and the lead-time are considered as the objective functions, and are optimized in a three-echelon supply chain management. With the wide application of internet-based e-commerce platform, suppliers are increasing exponentially. Therefore, it is significant to find global multi-objective POS in a three-echelon SCN to support multiple products and manufacturing plants under such requirement of the age.

This is a Bulldozer SCN topology, different nodes show different assembling processes: (a) The black nodes represent the processing of raw materials or intermediate materials. (b) The green nodes depict the final assembly of products. (c) The red nodes represent the delivery of products to target markets. Arrow lines among nodes indicate their supply relationship, and dotted lines in each node represent their choices

To solve these problems, the complex network structure is for the first time taken into consideration as the basic solution framework with the ABC algorithm. We proposed a novel ABC algorithm based on complex network (ABC-CN) to find POS in a three-echelon SCN. Now, to satisfy the need of increasing suppliers in e-commerce platforms, we propose a new ABC algorithm based on complex network and naive Bayes classifier (ABC-CN-NBC), improving its capability of accelerating the convergence speed of seeking global POS. The major contributions of this paper can be highlighted as follows:

-

Solutions are modelled in complex network structures to simulate the contemporary nature of SCN;

-

The proposed ABC-CN and ABC-CN-NBC have the capability of discovering global POS in a complex three-echelon SCN;

-

The speed of seeking global POS is further accelerated to satisfy the need from the wide application of e-commerce.

The organization of this paper is as follows: materials and methods are depicted in Sect. 2; the optimized results of the test example are given in Sect. 3; the simulated results are analysed in Sect. 4; and the final conclusion is drawn in the last section.

2 Materials and methods

2.1 Problem representation

The previous researches on SCN have mostly considered only one product and one manufacturing plant, as Shukla et al. (2013) did. Nowadays, multiple products and manufacturing plants are explored, as is shown from Shu et al. (2016). Three-echelon model has been adopted by many researchers (Shu et al. 2016; Shukla et al. 2013; Pasandideh et al. 2015; Seifert et al. 2012), which can construct a more complexed network. To demonstrate the advantage of the proposed optimization algorithm, three-echelon model with multiple products is designed in this paper: wheel loader (WHL), track loader (TRL), track-type tractor (TTT), and manufacturing plants (main assembly in node \(a_{17}\), subassembly in node \(a_{20}\), common subassembly in node \(a_{12}\) etc.) as shown in Fig. 1. In this SCN, every blackspot with its connected line in each node represents a choice with its cost and lead-time.

The three-echelon SCN can be modelled as a complex network with a set of individual nodes represented by \(\lbrace a_{1}, a_{2}, a_{3}, \ldots ,a_{i},\ldots , a_{n} \rbrace \), with each node containing all possible blackspots as its links which can be marked by \(a_{ij} (j=0, 1, 2, \ldots , N_{i})\), and \(N_{i}\) is the number of blackspots available to a node \(a_{i}\). At the same time, we use two objectives of cost and lead-time to represent the degree of satisfaction of enterprises and customers, and the following formulas are introduced to describe this matter:

Equation 1 shows the main objective function, where PC is the total cost and LT is the total lead-time. \(\omega _{1}\) and \(\omega _{2}\) are the weights to balance importance between total cost and total lead-time, and \(\omega _{1} + \omega _{2} = 1\).

Equations 2 and 3 show the summation of cost. \(\xi \) is the interest per month or per week at \(a_{i}\), \(\mu _{i}\) denotes the average demand of products per unit time. The cost of each link in \(a_{ij}\) is represented by \(C_{ij}\). If \(a_{ij}\) is selected, \(y_{ij}\) equals to 1, or 0 otherwise.

where \(T_{ij}\) is the processing lead-time of the jth resource option in node \(a_{i}\), \(S_i\) is the set of blackspots denoting input to node \(a_{i}\), \(a_k\) is the activity chosen from \(S_i\) and LT\(_k\) is the cumulative lead-time of node \(a_{k}\).

where LT\(_{i}\) is the total lead-time of node \(a_i\), and LT represents the total lead-time of the SCN.

For any \(a_{i} (i=1,2 \ldots N)\), Eqs. 6 and 7 aim to ensure that only one option (blackspot) can be selected.

Equation 8 validates its relationships of lead-time among nodes.

2.2 Expressed solutions

Optimization of a complex supply chain network refers to a combinatorial optimization issue. Many sub-networks can be extracted from a complex SCN. In the proposed algorithms of ABC-CN and ABC-CN-NBC, a set of feasible solutions, named as “solution vector”, is defined. The solution vector is structured as fragments of supply chain network. As a complex supply chain network in this paper, the major hypothesis includes: (1) multiple products in multiple assembling centres; (2) multiple objective optimization; (3) one-way production flow. For instance, a three products supply chain illustrated in Fig. 2, there will be different sub-networks for a complex network, includes: (1) sub-network for all products A, B and C; (2) sub-network for unique product A, B or C; (3) sub-network for product A\( \cup \)B, A\(\cup \)C, or B\(\cup \)C.

In the Bulldozer SCN topology illustrated in Fig. 1, nodes \(a_{35}\), \(a_{22}\) and \(a_{26}\) are three final assembling nodes for products WHL, TRL and TTT, respectively, and these three products are assembled by a range of common supply nodes, e.g. \(\lbrace a_{1}, a_{2}, a_{3}, \ldots , a_{16}, a_{17} \rbrace \). Hence, it is the first type of sub-network for all products, such as the fragment from node \(a_{1}\) to \(a_{17}\). Sub-network for two products is the second type, such as the fragment nodes for both TRL and TTT for nodes \(a_{18}\) to \(a_{20}\). The sub-network for a unique product is the third type, and its fragment can range from node \(a_{31}\) to \(a_{38}\), fragment from node \(a_{21}\) to \(a_{24}\), and fragment from node \(a_{25}\) to \(a_{30}\). For a more universal complex network-oriented solutions, it can be modelled as Fig. 2.

Every sub-network in Fig. 2 can be modelled as feasible solutions as Fig. 3. In Fig. 3, \(\lbrace \mathrm{SV}_1, \mathrm{SV}_2,\dots , \mathrm{SV}_L \rbrace \) represents all possible solution vectors (SV) for the solution space of the SCN optimization problem, \(\mathrm{SV}_i (i \in L)\) indicates the \(i_{th}\) iteration of the maximal iteration of L. For any solution vector \(\mathrm{SV}_i\), it has three parts, such as option sequence, fitness value and Bayesian probability sequence. Option sequence of \(\lbrace O_1, O_2,\dots , O_k \rbrace \) is the selection sequence formed by its selection of each node \(a_i\) in a sub-network, and Bayesian probability sequence of \(\lbrace P_1, P_2,\dots , P_k \rbrace \) is the probability sequence with its initial probability of equal chance for each selection.

Based on the nature of SCN, the cost and lead-time should be computed from its topology. When calculating the cost of a product, it can be considered as a combinatorial optimization issue (Moncayo-Martnez and Zhang 2011). The complex network topology should be taken into consideration when the lead-time of a node is computed, since it is influenced by its sub-nodes directly.

In Fig. 1, each node refers to an activity, each blackspot in a node indicates an available option of a certain activity and each arrow line refers to the mutual relations between two nodes. The ABC algorithm is fit for solving the combinatorial optimization issue (Moncayo-Martnez and Zhang 2011; Bolaji et al. 2013; Zhang et al. 2017, 2016). Hence, it is the most crucial to design a good solution expressed based on complex networks for the ABC algorithm.

As a combinatorial issue, solutions in the ABC algorithm can be expressed as \(A_{i}=(a_{1}, a_{2}, a_{3}, \ldots , a_{n})^{T} \). The combination of different nodes forms the distribution routing in a SCN of its corresponding products. At the same time, node \(a_{i}=(a_{i1}, a_{i2}, a_{i3}, a_{i4}, a_{i5})^{T} \) is also a five-dimensional vector including the sequence number of nodes, options of blackspots, lead-times of blackspots, costs of blackspots and chosen probabilities of blackspots.

2.3 Methods

In this paper, to solve these problems mentioned in Sect. 2.1 with solutions expressed in Sect. 2.2, basic ABC algorithm (ABC), proposed ABC algorithm based on complex network (ABC-CN), and the enhanced ABC algorithm based on complex network and naive Bayes classifier (ABC-CN-NBC) are adopted to evaluate their capability and feasibility.

2.3.1 Basic ABC algorithm

The basic ABC algorithm is a novel optimization approach in 2006 by Karaboga, which mimicks the behaviour of bees in collecting honey (Pham et al. 2006). Karaboga et al. (2014) have shown that ABC has been widely applied in feature selection (Schiezaro and Pedrini 2013), real-parameter optimization (Akay and Karaboga 2012), job scheduling (Banharnsakun et al. 2012), travelling salesman issues (Yang and Pei 2013), and combinatorial problems (Bolaji et al. 2013). In previous work, it is proved that the ABC algorithm has better performance in handling optimization for continuous problems than other classical optimization algorithms, such as stochastic simulated annealing, genetic algorithm, ant colony optimization (Ebubekir 2010), etc. Various UCI data sets have been used to demonstrate the effectiveness of ABC compared with ant colony optimization, particle swarm optimization, and bat algorithm (Schiezaro and Pedrini 2013). Sharma and Bhambu (2016) have found its advantages in 35 objective functions. Bolaji et al. (2013) have drawn a conclusion that it is a potential advantage for this to be easily hybridized with different metaheuristic algorithms and data structures. Therefore, we adopt ABC algorithm as the fundamental approach of our proposed algorithms.

2.3.2 ABC algorithm based on complex network

The research on complex networks begins with the effort of defining new concepts and measures to characterize the topology of real networks (Boccaletti et al. 2006). Out degree, Uni-assembly node, Multi-assembly node and Final-assembly node are defined in Definitions 1, 2, 3 and 4. Based on these definitions, different types of nodes can be detected with its \(OutDegree(a_{i})\) value and relationships. Sub-networks can be detected and extracted from the SCN with the procedure expressed in the Step 1 in the proposed Algorithms 1 and 2.

Definition 1

Out degree of node \(a_{i}\). \(OutDegree(a_{i})\) equals the number of arrow lines that start from node \(a_{i}\) to other nodes.

Definition 2

Uni-assembly node. The node \(a_{i}\) belongs to a uni-assembly node when its \(OutDegree(a_{i})=1\).

Definition 3

Multi-assembly node. The node \(a_{i}\) belongs to a multi-assembly node when its \(OutDegree(a_{i})=k\) to support assembling k products, \(k \ne 1\).

Definition 4

Final-assembly node. The node \(a_{i}\) belongs to a final-assembly node when its child nodes are all delivering nodes.

The ABC algorithm can carry on parallel processing via sub-network decomposition. Employed bees and scout bees cooperate to detect, evaluate, and identify best solution obtained so far with greedy principle to filter the generated solutions. After exceeding certain limited iterations, a new solution will be generated to avoid falling into a local optimal solution. The parallel computing model and greedy principle in the proposed ABC-CN will accelerate the convergence speed of seeking global POS in a SCN. The detailed procedure is depicted in the Step 2 of Algorithm 1.

2.3.3 ABC algorithm based on complex network and naive Bayes classifier

In Algorithm 1 mentioned in Sect. 2.3.2, it is a good solution to solve the problem with a complex network. However, it still needs to be accelerated as the number of suppliers increases. The chosen probabilities of blackspots in each node is equal in the basic ABC Algorithm 1. The ABC algorithm generates solutions randomly, which will increase the cost of seeking the global POS. Henceforth, it is necessary to search for a solution with metaheuristics.

The naive Bayes classifier is one of top 10 algorithms in data mining (Wu et al. 2007). It is useful for extracting classification rules based on its Bayes probability. In order to accelerate the speed of the proposed Algorithm 1, the principle of the naive Bayes classifier is adopted as illustrated in Algorithm 2 (ABC-CN-NBC).

3 Results

In order to evaluate the proposed two novel algorithms effectively, a test example is used and the following situations are put forward:

-

A total of three products has to be made in the production of Bulldozer SCN, [Wheel Loader (WHL), Track Loader (TRL) and Track-Type Tractor (TTT)]. This SCN covers the whole process from raw materials to manufacturers and distributors.

-

Each product can be assembled with a flow pattern that requires the selection of a supplier (or suppliers) for every component used by the product mix.

-

Each node has a number of selective options, in which each one of them represents a single decision that has its own cost and lead-time for assembling this product.

-

All the experimental data are under ideal conditions with high stability. There are no other external influencing factors, such as the shortage of raw materials, bad weather under uncertainty.

The network topology which represents the Bulldozer SCN is depicted in Fig. 1. In Fig. 1, the entire SCN has a total of 38 nodes, with a varying number of 2 to 4 blackspots (choices) in each node. Each assembly node can represent an enterprise. Among these nodes, \( a_{22}, a_{26}\) and \(a_{35} \) are Final-assembly nodes for assembling the final products, \(a_{17}\) and \(a_{20}\) are Multi-assembly nodes, and most other nodes are Uni-assembly nodes. After extracting sub-networks from Fig. 1, the set of \(\lbrace a_{1}, a_{2}, a_{3}, \ldots , a_{16}, a_{17}\rbrace \) can be formed as a sub-network to provide public intermediate products of product WHL, TRL and TTT. Nodes of \( a_{18}, a_{19}\) and \(a_{20}\) can be formed as another sub-network to serve the two products of TRL and TTT. The set of \(\lbrace a_{25}, a_{26}, a_{27}, a_{28}, a_{29}, a_{30} \rbrace \) can be formed as a sub network for serving only one product of TTT. The set of \(\lbrace a_{21}, a_{22}, a_{23}, a_{24} \rbrace \) can be aggregated as a sub-network for serving the TRL product, and the set of \(\lbrace a_{31}, a_{32}, a_{33}, a_{34}, a_{35}, a_{36}, a_{37}, a_{38} \rbrace \) can be clustered as a sub-network for the WHL product.

In Table 1, we list 30 nodes of raw materials or intermediate products. Every node has 2 to 5 options, and each option has a different cost \( C_{ij} \) (in $) and lead-time \( T_{ij} \) (in days) required.

Table 2 is the set of target markets for the three final products, and each delivery node has 2 options with parameters of lead-time \( T_{ij} \) (in days) and delivery cost \( C_{ij} \) (in $). In the following Tables 1 and 2, \(N(a_{i})\) represents a node, SN(i) is sequence number, OP(j) means options in each node, LT\((T_{ij})\) is the lead-time of each option, \(C(C_{ij})\) represents the cost of each option, and ICP\((P_{j})\) is initial choosen probability for each option.

3.1 The capability of searching global optimal solution with different methods

In order to measure the global optimization effect of the proposed algorithms, we, respectively, draw the Pareto front line chart of the basic ABC, the proposed ABC-CN and ABC-CN-NBC algorithms, as shown in Fig. 4. In Fig. 4, we can clearly observe the Pareto frontal value of three different methods in the same data set optimization where the abscissa is the total lead-time (LT), and the ordinate is the total cost of the business (PC). And with the increase in LT, PC shows a gradual downward trend. Moreover, it is obvious that the curve of Pareto fronts obtained by the ABC-CN algorithm is lower than that of the basic ABC algorithm, which proves that the proposed ABC-CN algorithm has a stronger advantage than ABC in finding the global optimal solution. The curve of Pareto peak obtained by ABC-CN-NBC algorithm is lower than that of the ABC-CN algorithm, which proves that the ABC-CN-NBC algorithm has a better advantage than the ABC-CN algorithm in finding the global optimal solution. Therefore, in the same data set, the ABC-CN-NBC algorithm has a better global optimum than the ABC algorithm, and it has a stronger global search capability.

To facilitate the observation and comparison of the search results of the proposed algorithms, we list the results of 9 different weights of PC and LT. In Tables 3 and 4, we can see the different results based on these two proposed approaches. Each approach takes into account the different weights of cost and lead-time. Each weight corresponds to a different solution. Table 3 shows the results of using the proposed ABC-CN. When the weight ranges from \( \omega _{1}=0.1\) to \( \omega _{1}=0.9\), the PC (in $) is obtained for 129,445,800, 129,042,720, 128,847,720, 127,200,600, 127,253,100, 126,444,600, 12,592,448, 125,809,512 and 125,830,608, and the LT (in days) is 30, 35, 42, 40, 43, 54, 57, 30 and 54, respectively. Table 4 gives the results of using the proposed ABC-CN-NBC. When the weight of the PC (in $) ranges from \( \omega _{1}=0.1\) to \( \omega _{1}=0.9\), the PC (in $) is obtained for 129,130,020, 129,025,980, 128,411,820, 127,350,300, 126,512,292, 126,038,328, 125,816,928, 125,764,500 and 125,715,660, and LT (in days) is 30, 30, 40, 40, 49, 51, 52, 57 and 61, respectively.

Mastrocinque et al. (2013) use the basic ABC algorithm to solve the same problem (Mastrocinque et al. 2013). Using the same raw data, when the weight of the PC (in $) changes from \(\omega _{1}=0.1\) to \(\omega _{1}=0.9\), PC (in $) are obtained from 129,652,620, 129,051,300, 128,485,608, 128,332,908, 127,023,480, 126,821,568, 126,500,100, 126,421,236 and 126,572,640, and the LT (in days) are 30, 31, 34, 36, 46, 54, 58, 70 and 60, respectively. In Fig. 5, we adopt three algorithms for global optimal solutions under different weights of PC (in $). Figure 5a is a line graph of global optimal solutions for PC (in $) with the changing weight of PC (in $). Each point on the line is the global optimal solutions when the weight of PC (in $) changes from \( \omega _{1}=0.1\) to \(\omega _{1}=0.9\). When the weight of the objective function of PC (in $) is increasing, the global optimal solutions have a tendency to decrease. Figure 5b is a line graph of global optimal solutions for LT (in days) with the varying weight of PC (in $). When the weight of the PC (in $) objective function is increasing, the weight of LT (in days) in the objective function decreases, and the global optimal solutions value is gradually increased.

Through Fig. 5, both ABC-CN and ABC-CN-NBC have achieved better optimal solutions, while the ABC-CN-NBC has better global POS compared with ABC-CN. The results show that our proposed algorithms have achieved a better feasibility and efficiency.

3.2 The convergence speed of searching global POS with different algorithms

In order to test the efficiency of our proposed algorithms, we test the convergence speed of finding global POS with the metric of minimal iterations(\(\delta \)), defined in Definition 5, with different weights of \(\omega _1\) and \(\omega _2\). Figure 6 illustrates the capability of searching global POS with Boxplot graph. The ABC-CN with the red Boxplot can reduce the number of minimal iterations to search the global POS in the Bulldozer SCN. Moreover, the ABC-CN-NBC has good performance with its heuristic optimization of the naive Bayes classifier.

Definition 5

(Minimal iterations\(\delta \)) It refers to minimal number of iterations when their fitness values have micro change.

Minimal iterations (\(\delta \)) with ABC, ABC-CN and ABC-CN-NBC. The convergence speed of searching global POS is accelerated with ABC-CN and ABC-CN-NBC in Fig. 6a–c obviously

Figure 7b is the value of GlobalMins for WHL product obtained by ABC-CN under different weights of PC. When the value of GlobalMins becomes unchangeable, it indicates that the global optimal solution is obtained. From \( \omega _{1}=0.1, \omega _{2}=0.9\) to \( \omega _{1}=0.9, \omega _{2}=0.1\) , the iterations of the global optimal solution are 169, 58, 147, 143, 179, 89, 116, 139 and 284. Figure 7c is the value of GlobalMins for WHL product obtained by ABC-CN-NBC under different weights of PC (in $). When the value of GlobalMins becomes unchangeable, it indicates that the global optimal solution is obtained. From \( \omega _{1}=0.1, \omega _{2}=0.9\) to \( \omega _{1}=0.9, \omega _{2}=0.1\) , the iterations of the optimal solution are 180, 145, 122, 107, 251, 157, 74, 109 and 52. The results show that our proposed ABC-CN and ABC-CN-NBC algorithms with its better capability that can accelerate the convergence speed of searching better global multi-objective POS.

4 Discussion

As mentioned in Sect. 3 of experimental results, we fully take into account the real situation (a three-echelon SCN supports assembling multiple products and multiple manufacturing centres). The experimental results show that the proposed two algorithms have achieved a faster convergence speed of finding better global POS when compared with the basic ABC algorithm.

Complex network-oriented solution can improve the capability of finding global POS for multi-objective optimization in a SCN. As explained in Sect. 2.3.2, the objective of cost is a combinatorial issue, while the objective of lead-time should be computed based on the assembling flow in the SCN. Therefore, it will be not effective when it is simply regarded as an optimization of combinatorial issue with these two objectives of cost and lead-time. In Sect. 2.3.2, we have defined different types of nodes to extract sub-networks from a SCN. Finding global POS from sub-networks is more efficient as illustrated in Fig. 5. The results are much effective with the use of the principle of divide and conquer (DC). The DC technique is the basis of efficient algorithms for all kinds of problems, such as sorting, multiplying large numbers, finding closest pair of points, and many others.

The complexity of solutions can be decreased efficiently when extracting sub-networks from a complex SCN. In Fig. 1, the Bulldozer SCN is composed of 38 nodes and 105 options for a total possible solutions of \(1.284 \times 10^{16}\) from Eq. 9. That is to say, it is really a non-trivial problem. Hence, the DC technique should be adopted to decrease its complexity.

Naive Bayes classifier can accelerate the convergence speed based on information of classification. Metaheuristics is an efficient approach to an optimization problem. As depicted in Eq. 9, the set of solutions is too large to be completely sampled. Bayesian theory is to estimate subjective probability for partial unknowns under incomplete information, and then to use Bayesian formula to update the probability of occurrence. Finally, the optimal decision is made by using expected value and updated probability. However, the traditional ABC does not update its probability of each option in a node, and the probability of an option to be selected is generated randomly. In this way, the previous result will not have an active effect on the next solution which results in a certain amount of waste of resources.

5 Conclusions

Optimization of three-echelon SCN with multiple products and multiple manufacture centres is really a challenge to get multi-objective Pareto solutions. To solve this problem, this paper proposes a novel ABC algorithm with complex network to satisfy the optimization requirement of SCN structure. After exemplifying with a real Bulldozer SCN, our proposed ABC-CN can find better global POS than the traditional ABC.

In addition, with the increase of suppliers in a SCN, the optimization method should be accelerated to support a more complex SCN. This paper adopts naive Bayes classifier to update the selection probability of options in each node. The proposed ABC algorithm with complex network and naive Bayes classifier (ABC-CN-NBC) can get the multi-objective Pareto optimal solutions within a limited time.

We hope that the proposed algorithm of ABC-CN-NBC is a small step to solve the complex three-echelon SCN optimization issue. It will help logistics managers in making operation management decision for their suppliers. For engineers, this paper proposes an interesting approach to find a global bi-objective optima in SCN problems. Based on the guidance from naive Bayes classifier, the convergence speed can be accelerated in limited time.

The limitations and disadvantages of this paper can be summarized as: only two objective functions are considered in the three-echelon SCN management problems, and only naive Bayes classifier is adopted to give guidance. In the future, we recommend the following research directions: (1) more heuristic approaches should be proposed to solve three-echelon SCN management issue; (2) other optimization objectives should be investigated; (3) inventory problems in a complex SCN should be considered to validate its extension capability.

References

Akay B, Karaboga DA (2012) Modified artificial bee colony algorithm for real-parameter optimization. Inform Sci 192:120–142. https://doi.org/10.1016/j.ins.2010.07.015

Aslam T, Ng AHC (2010) Multi-objective optimization for supply chain management: a literature review and new development. In: 2010 8th international conference on supply chain management and information systems (SCMIS) pp 1–8

Banharnsakun A, Sirinaovakul B, Achalakul T (2012) Job shop scheduling with the best-so-far ABC. Eng Appl Artif Intel 25:583–593. https://doi.org/10.1016/j.engappai.2011.08.003

Boccaletti S, Latora V, Moreno Y et al (2006) Complex networks: structure and dynamics. Phys Rep 424:175–308. https://doi.org/10.1016/j.physrep.2005.10.009

Bolaji AL, Khader AT, Al-Betar MA et al (2013) Artificial bee colony algorithm, its variants and applications: a survey. J Theor Appl Inform Tech 47:434–459

Corner JL, Buchanan JT (1995) Experimental consideration of preference in decision making under certainty. J Multi-Criteria Decis Anal 4:107–121

Ebubekir K (2010) Bees algorithm: theory, improvements and applications. Cardiff University, Cardiff University

Goetschalckx M, Vidal CJ, Dogan K (2002) Modeling and design of global logistics systems: a review of integrated strategic and tactical models and design algorithms. Eur J Oper Res 143:1–18. https://doi.org/10.1016/S0377-2217(02)00142-X

Gou QL, Liang L, Huang ZM et al (2017) Supply chain management, sustainability, and productivity efficiency evaluations Introduction. Int J Inf Tech Decis 16:899–905

Kamali A, Ghomi SMTF, Jolai FA (2011) multi-objective quantity discount and joint optimization model for coordination of a single-buyer multi-vendor supply chain. Comput Math Appl 62:3251–3269. https://doi.org/10.1016/j.camwa.2011.08.040

Karaboga D, Gorkemli B, Ozturk C et al (2014) A comprehensive survey: artificial bee colony (ABC) algorithm and applications. Artif Intell Rev 42:21–57. https://doi.org/10.1007/s10462-012-9328-0

Ke, Huang H, Gao X (2017) Pricing decision problem in dual-channel supply chain based on experts belief degrees. Soft Comput. https://doi.org/10.1007/s00500-017-2600-0

Kleindorfer PR, Kalyan S, Wassenhove LN (2005) Sustainable operations management. Prod Oper Manag 14:482–492. https://doi.org/10.2139/ssrn.1424488

Li R, Hu S, Wang Y et al (2017) A local search algorithm with tabu strategy and perturbation mechanism for generalized vertex cover problem. Neural Comput Appl 28:1775–1785. https://doi.org/10.1007/s0052

Linton JD, Klassen R, Jayaraman V (2007) Sustainable supply chains: an introduction. J Oper Manag 25:1075–1082. https://doi.org/10.1016/j.jom.2007.01.012

Mastrocinque E, Yuce B, Lambiase A (2013) A multi-objective optimization for supply chain network using the bees algorithm. Int J Eng Bus Manag 5:1–11. https://doi.org/10.5772/56754

Moncayo-Martnez LA, Zhang DZ (2011) Multi-objective ant colony optimisation: a meta-heuristic approach to supply chain design. Int J Prod Econ 131:407–420. https://doi.org/10.1016/j.ijpe.2010.11.026

Moncayo-Martnez LA, Zhang DZ (2013) Optimising safety stock placement and lead time in an assembly supply chain using bi-objective MAXMIN ant system. Int J Prod Econ 145:18–28. https://doi.org/10.1016/j.ijpe.2012.12.024

Nasiri GR, Davoudpour H, Karimi B et al (2010) A lagrangian-based solution algorithm for strategic supply chain distribution design in uncertain environment. Int J Inf Tech Decis 9:393–418. https://doi.org/10.1142/S0219622010003877

Nemati Y, Alavidoost MH (2018) A fuzzy bi-objective MILP approach to integrate sales, production, distribution and procurement planning in a FMCG supply chain. Soft Comput. https://doi.org/10.1007/s00500-018-3146-5

Pasandideh SH, Niaki ST, Asadi K et al (2015) Bi-objective optimization of a multi-product multi-period three-echelon supply chain problem under uncertain environments: NSGA-II and NRGA. Inform Sci 292:57–74. https://doi.org/10.1016/j.ins.2014.08.068

Pham DT, Ghanbarzadeh A, Ko E et al. (2006) The bees algorithm a novel tool for Complex optimisation problems. Intel Prod Mach Syst. https://doi.org/10.1016/B978-008045157-2/50081-X

Pishvaee MS, Rabbani M, Torabi SA (2011) A robust optimization approach to closed-loop supply chain network design under uncertainty. Appl Math Model 35:637–649. https://doi.org/10.1016/j.apm.2010.07.013

Schiezaro M, Pedrini H (2013) Data feature selection based on artificial bee colony algorithm. Eurasip J Image Vid 1:1–8. https://doi.org/10.1186/1687-5281-2013-47

Schtz P, Tomasgard A, Ahmed S (2009) Supply chain design under uncertainty using sample average approximation and dual decomposition. Eur J Oper Res 199:409–419. https://doi.org/10.1016/j.ejor.2008.11.040

Seifert RW, Zequeira RI, Liao S et al (2012) A three-echelon supply chain with price-only contracts and sub-supply chain coordination. Int J Prod Econ 138:345–353. https://doi.org/10.1016/j.ijpe.2012.04.006

Shaw K, Shankar R, Yadav SS et al (2012) Supplier selection using fuzzy AHP and fuzzy multi-objective linear programming for developing low carbon supply chain. Expert Syst Appl 39:8182–8192. https://doi.org/10.1016/j.eswa.2012.01.149

Sharma S, Bhambu P (2016) Artificial bee colony algorithm: a survey. Int J Comput Appl 149:11–19. https://doi.org/10.1504/IJAIP.2013.054681

Shen L, Olfat L, Govindan K et al (2013) A fuzzy multi criteria approach for evaluating green suppliers performance in green supply chain with linguistic preferences. Resour Conserv Recycl 74:170–179. https://doi.org/10.1016/j.resconrec.2012.09.006

Shu T, Gao X, Chen S et al (2016) Weighing efficiency-robustness in supply chain disruption by multi-objective firefly algorithm. Sustainability 8:1–27. https://doi.org/10.3390/su8030250

Shukla A, Lalit VA, Venkatasubramanian V et al (2013) Optimizing efficiency-robustness trade-offs in supply chain design under uncertainty due to disruptions. Int J Phys Distrib Logist Manag., pp 623–647. https://doi.org/10.1108/09600031111147844

Tan KC (2001) A framework of supply chain management literature. Eur J Med Chem 7:39–48. https://doi.org/10.1016/S0969-7012(00)00020-4

Wang L, Tian F, Soong BH et al. (2011) Solving combinatorial optimization problems using augmented lagrange chaotic simulated annealing. Differ Equ Dyn Syst. https://doi.org/10.1007/s12591-011-0084-4

Wu X, Kumar V, Quinlan JR et al (2007) Top 10 algorithms in data mining. Knowel Inf Syst 14:1–37. https://doi.org/10.1007/s10115-007-0114-2

Yang W, Pei Z (2013) Hybrid ABC/PSO to solve travelling salesman problem. Int J Comput Sci Math 4:214–221. https://doi.org/10.1504/IJCSM.2013.057246

Yuce B, Packianather MS, Mastrocinque E et al (2013) Honey bees inspired optimization method: the bees algorithm. Insects 4(2013):646–662

Yuce B, Mastrocinque E, Lambiase A et al (2014) A multi-objective supply chain optimisation using enhanced bees algorithm with adaptive neighbourhood search and site abandonment strategy. Swarm Evol Comput 18:71–82

Yuce B, Mastrocinque E, Packianather MS et al (2015) The bees algorithm and its application. In: Vasant PM (ed) Handbook of research on artificial intelligence techniques and algorithms, chap 4, pp 122–151. https://doi.org/10.4018/978-1-4666-7258-1.ch004

Zhang S, Lee CKM, Yu KM, Lau HCW (2017) Design and development of a unified framework towards swarm intelligence. Artif Intell Rev 47:253–277

Zhang LL, Lee C, Zhang S (2016) An integrated model for strategic supply chain design: formulation and ABC-based solution approach. Expert Syst with Appl 52:39–49

Zhou XY, Tu Y, Han J et al (2017) A class of Level-2 Fuzzy decision-making model with expected objectives and chance constraints: application to supply chain network design. Int J Inf Tech Decis 16:907–938

Zhang C, Yang Y, Du Z et al (2016) Particle swarm optimization algorithm based on ontology model to support cloud computing applications. J Amb Intel Hum Comp 7:633–638. https://doi.org/10.1007/s12652-015-0262-2

Acknowledgements

The authors are grateful to the financial support by the National Natural Science Foundation of China (No. 61572225), the Natural Science Foundation of the Science and Technology Department of Jilin Province, China (No. 20180101044JC), the Foundation of the Education Department of Jilin Province, China (No. JJKH20180465KJ), the Foundation of Social Science of Jilin Province, China (No. 2017BS28) and the Foundation of Jilin University of Finance and Economics (No. 2018Z05).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Communicated by V. Loia.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, J., Wu, D., Chen, Y. et al. Fast artificial bee colony algorithm with complex network and naive bayes classifier for supply chain network management. Soft Comput 23, 13321–13337 (2019). https://doi.org/10.1007/s00500-019-03874-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-019-03874-y