Abstract

Most of the current failure mode, effects, and criticality analysis (FMECA) methods use the risk priority number (RPN) value to evaluate the risk of failure. However, the traditional RPN methodology has been criticized to have several shortcomings. These shortcomings are addressed in this paper. Therefore, an efficient and simplified algorithm to evaluate the risk of failure is needed. This paper proposes a new approach, which utilizes the intuitionistic fuzzy set ranking technique for reprioritization of failures in a system FMECA. The proposed approach has two major advantages: (1) it resolves some of the shortcomings of the traditional RPN method, and (2) it provides an evaluation of the redundancy place, which can assist the designer in making correct decisions to make a safer and more reliable product design. In numerical verification, an FMECA of a silane supply system is presented as a numerical example. After comparing results from the proposed method and two other approaches, this research found that the proposed approach can reduce more duplicate RPN numbers and get a more accurate, reasonable risk ranking.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Failure mode, effects, and criticality analysis (FMECA) is a structural and preventive reliability analysis technology. The purpose of FMECA is to verify possible failure modes and also discuss the reason for failure, which should yield preventive and improved strategies, thereby raising product reliability. From the failure mode, any unit’s fault can be discussed and improved. Failure mode has a significant effect on working objectives and should have priority strategies that formulate to solve it and prevent failures.

FMECA was first developed as a formal design methodology in the 1960s by the aerospace industry with their obvious reliability and safety requirements. The American army began using FMECA in the 1970s, and in 1974 it produced the army standard “MIL-STD-1629: procedures for performing a failure mode effects and criticality analysis”. In 1980, there also was a second print of MIL-STD-1629A (US Department of Defense Washington, DC 1980). Today, FMEA has been adopted in many places, such as the aerospace, military, automobile, electricity, mechanical, and semiconductor industries. FMECA combines failure mode and effect analysis (FMEA) with criticality analysis (CA). In order to assign limited resources to the most serious risk items, FMEA uses the risk priority number (RPN) methodology to rank and assess the design risk of potential failure modes. The RPN is developed by assigning potential failure modes a rank from 1 to 10, with respect to the severity of the failure mode effect (S), its probability of occurrence (O), and the likelihood of its being detected in later design evaluation tests (D). The RPN is a mathematical product of the three aforementioned factors, calculated as \( S \times O \times D \in [1,\,1,000] \). A failure mode that has a higher RPN is assumed to be more important and is given a higher priority than those with lower RPN values.

The fundamental problem with FMECA is that it attempts to quantify risk without adequately quantifying the factors that contribute to risk. Bowles (2003) proposed an assessment of RPN prioritization in an FMECA. He points out that the traditional RPN, though well documented and easy to apply, is seriously flawed from a technical perspective. In particular cases, the RPN can be misleading. Also, Sankar and Prabhu (2001) proposed a modified approach for prioritization of failure modes in FMEA called risk priority rank (RPR). This technique extends risk prioritization beyond the conventional RPN method. The ranks 1 through 1,000 are used to represent increasing risk of the 1,000 possible severity-occurrence-detection combinations. Wang et al. (1995) proposed an inductive bottom-up risk identification and estimation methodology, combining FMECA and the Boolean representation method (BRM). However, it might be difficult to construct Boolean representation tables for some components of a system, especially during the early conception and design phases, when the relationships between components are unclear or difficult to precisely represent.

Bowles and Pelaez (1995) were the first persons to propose a technique using membership function in FMECA. This approach uses fuzzy logic to directly work with linguistic terms in making criticality assessments. Xu et al. (2002) proposed a fuzzy logic-based FMEA technique and a prototype assessment expert system. It broadens the method by Bowles and Pelaez (1995) from only criticality analysis to failure modes and effects analysis, and it constructs a fuzzy assessment system to perform it. It is useful for constructing an FMEA using the information and an expert’s expertise, which often is uncertain or vague in the design phase; in particular, a mechanical system usually has no crisp inputs and outputs, and the relationships between the failure modes and effects are very complex, subjective, and qualitative. In 2003, an improved FMEA methodology, which utilizes the fuzzy rules base and grey relation theory to model the entire system, was presented by Pillay and Wang (2003). However, these methods have the same problem of high duplication rate. Seyed-Hosseini et al. (2006) proposed the decision making trial and evaluation laboratory (DEMATEL) approach for reprioritization of failures in a system. The method is an effective procedure for analyzing the structure and relationships between components of a system or a number of available alternatives. However, the calculation of this approach is very complex and time-consuming. To overcome the aforementioned shortcomings and the shortcomings of the conventional RPN calculation, this paper proposes a new technique for reprioritization of failures in a system FMECA.

This paper is organized into six sections. Section 2 discusses the traditional RPN method and its shortcomings. Section 3 introduces the definition of the intuitionistic fuzzy set and its operations. Section 4 proposes a new approach for FMECA and describes an algorithm of the intuitionistic fuzzy set ranking technique. An example that is drawn from a silane supply system is used with the intuitionistic fuzzy set ranking technique for reprioritization of failures in FMECA. Some comparisons with the listed approaches are then discussed in Sect. 5. The final section makes conclusions based on our findings.

2 RPN methodology

In this section, we will introduce the components of RPN calculation, severity, occurrence, and detection, with respect to the types of scales on which they are measured. We will also point out the shortcomings of the conventional RPN.

2.1 Conventional RPN method

Traditionally, the prioritization of failures for corrective actions is performed by developing an RPN method. The RPN is developed by assigning each potential failure mode a rank from 1 to 10 with respect to the severity of the failure mode effect (\( S \)), its probability of occurrence (\( O \)), and the likelihood of its being detected in subsequent design evaluation tests (\( D \)). Tables 1, 2, and 3 show the criteria and ranking system (Ford Motor Company 1988) for these parameters. The RPN value, ranging from 1 to 1,000, is a mathematical product of the three parameters; i.e., \( S \times O \times D \in [1,\,1,000] \). Failure modes with high RPN values are assumed to be more important and are given higher priorities than those with lower RPN values.

2.2 The shortcomings of the conventional RPN

The shortcomings of the conventional RPN have been analyzed extensively by Sankar and Prabhu (2001) and Bowles (2003). The first shortcoming is that RPN elements are not equally weighted with respect to one another in terms of risk. As a result, some (\( S,\,O,\,D \)) scenarios produce RPN values that are lower than other combinations but potentially more dangerous. For example, the scenario (extreme severity, relatively low rate of occurrence, high detection), with an RPN of \( 8 \times 4 \times 3 = 96 \), is lower than the scenario (minor severity, relatively low rate of occurrence, very remote detection), with an RPN of \( 3 \times 4 \times 9 = 108 \), even thought it should have a higher priority for corrective action.

The second shortcoming is that the RPN scale itself has some nonintuitive statistical properties. The initial and correct assumption observation is that the scale starts at 1 and ends at 1,000, often leading to incorrect assumptions in the middle of the scale. Table 4 contains some common faulty assumptions (Sankar and Prabhu 2001). The RPN scale is not continuous. It indeed has many “holes” in the scale. That means that many of the numbers in the range of 1–1,000 cannot be formed from the product of S, O, and D. While it is true that the numbers cover a range from 1 to 1,000, 88% of that range is actually empty; only 120 of the 1,000 numbers can be generated from the product of S, O, and D. Thus, all multiples of 11 (i.e., 11, 22, 33, …, 990) cannot be formed and are hence excluded. Similarly, all multiples of 13, 17, 19, etc. are excluded. 1,000 is the largest number, but 900 is the second largest followed by 810, 800, 729, and 720.

The third shortcoming of the conventional RPN method is that the RPN elements have many duplicate numbers. Because 1,000 numbers are produced from the product of S, O, and D, but only 120 of them are unique, there must be many duplicate numbers. Figure 1 shows the 1,000 RPN numbers that are generated from all possible combinations (Bowles 2003). Note that nearly every RPN value is nonunique, some being recycled as many as 24 times. In general, each of the rankings can be formed in several different ways (only six RPN values are formed by a single, unique combination of S, O, and D). For example, as shown in Table 5, 36 can be formed from 21 different combinations of \( S \), \( O \), and \( D \).

The fourth shortcoming of the conventional RPN method is the difficulty with judging evaluation criteria. For example, it may be difficult or even impossible to precisely determine the probability of failure events in FMECA. In addition, it uses available information and an expert’s expertise, which is often uncertain or vague in the design phase. In particular, a highly technical system usually has no crisp inputs or outputs, and the relationships between the associated failure modes and effects are very complex, both subjectively and qualitatively.

3 Intuitionistic fuzzy set methodology

In this section, we introduce the definitions and properties of the intuitionistic fuzzy set methodology and seven arithmetic operations of the methodology.

3.1 Definitions and properties of intuitionistic fuzzy sets

Zadeh (1965) proposed fuzzy sets to describe fuzzy phenomena under a specific attribute. A fuzzy set \( F \) is a class of objects, along with a grade of membership function. This membership function, \( \mu_{F} (x) \), \( x \in X \), assigns a grade membership to each object that ranges between 0 and 1. This single value combines the evidence for \( x \in X \) and the evidence against \( x \in X \), without indicating how much there is of each value. The notion of an intuitionistic fuzzy set was proposed by Atanassov (Atanassov 1983). An intuitionistic fuzzy set \( A \) for a given underlying set E is represented by a pair \( \langle \mu_{A} ,\,\nu_{A} \rangle \) of functions \( E \to [0,1] \). For \( x \in E \), \( \mu_{A} (x) \) gives the degree of membership to A, and \( \nu_{A} (x) \) gives the degree of non-membership; moreover, \( 0 \le \mu_{A} (x) + v_{A} (x) \le 1 \) must hold.

The uncertainty of \( x \) can be described as the differential value of \( (1 - \nu_{A} (x)) - \mu_{A} (x) \). If the differential value is small, it means that the value of x is more certain. If the differential value is great, it means that the computation is more uncertain about x. When \( 1 - \nu_{A} (x) = \mu_{A} (x) \), the intuitionistic fuzzy set \( A \) regresses to a fuzzy set. Obviously, when \( 1 - \nu_{A} (x) = \mu_{A} (x) = 1 \) or \( 1 - \nu_{A} (x) = \mu_{A} (x) = 0 \), the intuitionistic fuzzy set \( A \) regresses to a crisp set. From the above results, crisp sets and fuzzy sets can be viewed as special cases of intuitionistic fuzzy sets. Therefore, using intuitionistic fuzzy set can describe vague objects in our daily life in more detail. Figure 2 shows an intuitionistic fuzzy set explanation of a real number R.

3.2 Arithmetic operations of intuitionistic fuzzy sets

We define the set operations of intuitionistic fuzzy sets based on definitions presented by Atanassov (1986). For every two intuitionistic fuzzy sets \( A \) and \( B \), the following operations and relations are valid:

-

(1)

\( A \subset B\,{\text{iff}}\,(\forall x \in E)(\mu_{A} (x) \le \mu_{B} (x)\& \nu_{A} (x) \ge \nu_{B} (x)); \)

-

(2)

\( A = B\,{\text{iff}}\,A \subset B\,\& \,B \subset A; \)

-

(3)

\( \overline{A} = \{ \langle x,\nu_{A} (x),\mu_{A} (x)\rangle \left| {x \in E} \right.\} ; \)

-

(4)

\( A \cap B = \{ \langle x,\min (\mu_{A} (x),\mu_{B} (x)),\max (\nu_{A} (x),\nu_{B} (x))\rangle \left| {x \in E} \right.\} ; \)

-

(5)

\( A \cup B = \{ \langle x,\max (\mu_{A} (x),\mu_{B} (x)),\min (\nu_{A} (x),\nu_{B} (x))\rangle \left| {x \in E} \right.\} ; \)

-

(6)

\( A + B = \{ \langle x,\mu_{A} (x) + \mu_{B} (x) - \mu_{A} (x) \cdot \mu_{B} (x),\nu_{A} (x) \cdot \nu_{B} (x)\rangle \left| {x \in E} \right.\} ; \)

-

(7)

\( A \cdot B = \{ \langle x,\mu_{A} (x) \cdot \mu_{B} (x),\nu_{A} (x) + \nu_{B} (x) - \nu_{A} (x) \cdot \nu_{B} (x)\rangle \left| {x \in E} \right.\} ; \)

From these equations, it follows directly that A + B is an intuitionistic fuzzy set.

4 Proposed approach

The traditional RPN method, as pointed out in Sect. 2.2, has four main shortcomings: (1) the RPN elements are not equally weighted with respect to one another in terms of risk; (2) the RPN scale itself has some nonintuitive statistical properties; (3) the RPN elements have many duplicate numbers; and (4) there is difficulty in judging evaluation criteria. Therefore, to overcome the aforementioned shortcomings, a new method using an IFS ranking technique to evaluate the orderings of risk for failure problems is proposed in this section.

4.1 The reason to use IFS

Conventional RPN calculation uses crisp values to represents the S, O, and D on a numerical scale from 1 to 10. These rankings are then multiplied to give the RPN. However, it often is hard to give a direct and correct numerical value of the S, O, and D by crisp values. In many real-life cases, the decision data of human judgments with preferences are vague, so that the traditional ways of using crisp values are inadequate. To deal with the vagueness of human thought and expression in making decisions, the fuzzy set theory is very helpful. Therefore, the parameter is being described as fuzzy variables, and this result is a more realistic and flexible reflection of the real situation.

4.2 Rank risk of failure operation using the IFS ranking technique

In terms of implementing arithmetic operations of the intuitionistic fuzzy set in FMECA, we use the vague fault-tree analysis definition proposed by Chang et al. (2006) to find degrees of influence of every unit as follows. Figure 3 shows a triangle intuitionistic fuzzy set explanation of a T unit fault.

Definition 4.1. Influence degrees for removing the \( i \)th unit

Let \( q_{{T_{i} }} \) represent that \( q_{T} \) is not included the \( i \)th unit of a failure interval (delete the \( i \)th unit). \( V \) denotes the difference between \( q_{T} \) and \( q_{{T_{i} }} \) The larger value of \( V \) represents the \( i \)th unit has a greater influence on; then

where \( q_{T} = (a_{T} ,a_{T}^{'} ,b_{T} ,c_{T}^{'} ,c_{T} ) \) and \( q_{{T_{i} }} = (a_{{T_{i} }} ,a_{{T_{i} }}^{'} ,b_{{T_{i} }} ,c_{{T_{i} }}^{'} ,c_{{T_{i} }} ) \).

When a product’s safety standard is high, the prediction’s result should be relied on. However, if the result does not match the standard, the designer should improve its design by using redundant place analysis. Redundant place analysis can assist the designer in making correct decisions to make a more reliable product design with better safety. For example, suppose that the jth unit has the lowest reliability, as shown in Fig. 4; adding a redundant jth unit could improve the system’s reliability.

Definition 4.2. Influence degree for adding the \( j \)th unit

Let \( R_{{T_{j} }} \) represent that \( R_{T} \) adds the redundant \( j \) th unit of reliability. \( U \) denotes the difference between \( R_{T} \) and \( R_{{T_{j} }} \) . The larger of \( U \) represents adding the redundant \( j \) th unit, which can increase the reliability on \( R_{T} \) ; then

where \( R_{T} = (a_{T} ,a_{T}^{'} ,b_{T} ,c_{T}^{'} ,c_{T} ) \) and \( R_{{T_{j} }} = (a_{{T_{j} }} ,a_{{T_{j} }}^{'} ,b_{{T_{j} }} ,c_{{T_{j} }}^{'} ,c_{{T_{j} }} ).\)

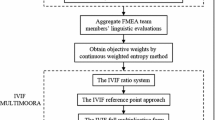

4.3 The procedure of the proposed approach

According to the definitions in Sect. 3, we propose a model, consisting of nine steps, for risk priority analysis. In Sect. 5, an example that is drawn from a silane supply system is used for illustrative purposes to demonstrate our proposed approach. The nine steps are described as follows.

Step 1

Verify the system’s compound and working purpose

-

Conduct the first step of FMECA, which should allow us to understand the contents, system compound, and the product’s working purpose.

Step 2

Determine analysis level

-

The normal analysis is distinguished by five layers: system, detail system, model, module, and unit.

Step 3

Establish system of reliability block diagram

-

A reliability block diagram can explain units’ relationships in parallel and series.

Step 4

List potential failure modes

-

Based on historical data and past experiences, list the failure modes of each FMECA member.

Step 5

Establish the FMECA table

-

Arrange failure mode content in an FMECA table. List the reasons of failure mode occurrence.

Step 6

Define system unit fault interval

-

Unit fault can cause the breakdown of the whole system. Define the triangle intuitionistic fuzzy set for each unit fault according to the experts’ experiences.

Step 7

The priority for assessing fault risk

-

By Definition 4.1, we delete the \( i \)th unit from the reliability block diagram and calculate \( V(q_{T} ,q_{{T_{i} }} ) \), \( \forall i \). Use V to rank the influential power of each unit for the system.

Step 8

Assessing redundant systems

-

By Definition 4.2, we add the redundant \( j \)th unit to the reliability block diagram and calculate \( U(R_{T} ,R_{{T_{j} }} ) \), \( \forall j \). Use U to rank the increasable reliability for the whole system.

Step 9

Analyze the results and provide suggestions.

5 An illustrative example

In this section, an illustrative example of a silane supply system in a TFT-LCD process is presented in order to demonstrate the procedure that is proposed in this paper. The TFT-LCD process uses various kinds of highly responsive and dangerous materials with a high risk of ignition, explosion, and toxicity. Silane is a chemical compound, which has the chemical formula SiH4 that is required in the TFT-LCD process. The silane supply system has no color, reacts with air, has a suffocating effect, is readily combustible in the presence of air, and releases uncrystallized SiO2 smoke. Under high temperature or fire, if the pressure regulator of the steel bottle contains silane malfunctions, it can cause an explosion.

The FMECA of a silane supply system is shown in Table 6. The data is from a midsized manufacturing factory located in Hsinchu Science Park in Taiwan (Wang 2006). The reliability block diagram of a silane supply system accident is shown in Fig. 5.

5.1 Conventional RPN method

The conventional RPN method consists of rating the potential failures from 1 to 10 with respect to their severity, probability of occurrence, and detection and multiplying the three numbers together. The RPN value is used to prioritize the actions. The RPN of the silane supply system shown in Table 7.

5.2 Fuzzy RPN method

Bowles et al. (Bowles and Pelaez 1995) were the first to propose the fuzzy RPN method. This approach uses fuzzy logic for directly working with linguistic terms in making criticality assessments. In fuzzy rule base analysis, the linguistic variable is determined to be the probability of occurrence (\( O \)), the severity (\( S \)), and the detection (\( D \)). Each of the three linguistic variables is described by five linguistic terms: Remote, Low, Moderate, High, and Very High. The interpretations of these linguistic terms are given in Table 8 (Pillay and Wang 2003). Using Table 8 as a guide, users can rank the severity, occurrence, and detection for the failure mode on a scale, such as those in Figs. 6, 7, and 8.

The support value for each of these linguistic terms is determined by taking the weighted average of the support values given by each expert. Hence, the support values for the linguistic terms describing the risk can be summarized as: Low (0.5), Fairly Low (1.5), Moderate (2.5), Fairly High (6.5), and High (8.5). These results are then defuzzified using the weighted mean of maximum (WMoM) method (Bowles and Pelaez 1995) to obtain a ranking, as shown in Table 9. For the detailed WMoM method, please refer to Bowles and Pelaez’s paper (Bowles and Pelaez 1995).

5.3 Proposed method

The triangle intuitionistic fuzzy set of each unit fault in silane supply system failure is obtained from a domain expert based on his experience, as shown in Table 10.

Ranking risk according to the relative importance of each unit fault allows the users to assign limited resources to the most serious risk items. We calculated the difference in intuitionistic fuzzy failure between the overall “silane supply system accident” and deleted the nodes in the second level (denoted as \( V(q_{T} ,q_{{T_{i} }} ) \), \( i = A1,\,A2,\,A3,\, \ldots ,\,C06 \)), based on Definition 4.1, and the results are shown in Table 11.

In order to examine the silane supply system failure’s redundancy place, we use Definition 4.2 to calculate the increase of system reliability by each unit’s redundancy place. The results are organized in Table 11.

According to the results shown in Table 11, if B02’s redundancy increases, the silane supply system’s reliability can rise from\( \langle [(0.999094484,0.999431880,0.999737564);0.7],[(0.998986982,0.999431880,0.999857941);0.8]\rangle \) to \( \langle [(0.999182004,0.999497543,0.999780053);0.7],[(0.998998955,0.999497543,0.999870240);0.8]\rangle \).

5.4 Comparisons and discussion

The results obtained for the FMECA using the proposed approach are collated with the results obtained from the conventional RPN method and are presented in Table 12. From Table 12, we can see that the RPN values of units A04 and B04 are both 210. From Table 7, the values of \( S \), \( O \), and \( D \) are 7, 5, and 6 for unit A04 and 5, 6, and 7 for unit B04; hence an RPN of 210 is obtained. Although the RPN values for both units are the same, the risk levels are different. This difference can be obviously identified when the intuitionistic fuzzy set ranking technique is applied. The results of our proposed method show that unit B04 has a higher priority compared with unit A04. However, the conventional RPN method puts these two units at the same priority.

On the other hand, the ranking that is produced by the fuzzy RPN method does not differentiate the units with the same linguistic terms that describe the factor that is considered. For example, \( S \), \( O \), and \( D \) for units A01, A15, and B01 are assigned as Moderate High, Low Moderate, and Low Moderate, respectively, and the defuzzified ranking is 2.241 for all three units (Table 9). Although the RPN for all three units are the same, the risk levels are different. This difference can be obviously identified when the intuitionistic fuzzy set ranking technique is applied. The results of the proposed method show that unit B01 has a higher priority compared with units A01 and A15. However, the fuzzy RPN method puts these three units at the same priority. The reprioritization that is obtained from the intuitionistic fuzzy set ranking technique in terms of criteria is:

-

B02 > A03 > B04 > A04 > A05 > A02 > A14 > A19 > B03 > B01 > A01 > A10 > A06 > A15 > ··· > C06,

which is different from the conventional RPN prioritization—i.e.,

-

B02 > A03 > A04, B04 > A05 > A02 > A14 > A19 > B03 > A01, A06, A10, B01 > A15, A17 > ··· > C06,

and also is different from the fuzzy RPN prioritization—i.e.,

-

B02 > A03 > A04 > A19 > A14 > A02 > A05 > B03 > B04 > A01, A15, B01 > ··· > C02, C04, C05, C06.

The results shown in Table 12 indicate that the conventional RPN method yields 11 unique RPN values among 31 items when the risk of failure in a silane supply system is ranked. These elements are formed by a single combination of \( S \), \( O \), and \( D \). We then find that the fuzzy RPN method results in 18 unique RPN values. This paper focuses on system reliability combined with the intuitionistic fuzzy set ranking technique applied to FMECA. The proposed intuitionistic fuzzy set ranking RPN method is compared with both the conventional RPN and the fuzzy RPN methods. The intuitionistic fuzzy set ranking RPN method yields 27 unique RPN values among 31 items. This shows that a more accurate ranking can be achieved by applying our proposed intuitionistic fuzzy set ranking RPN technique to FMECA.

6 Conclusion

This paper has proposed a novel technique for the reprioritization of failure modes in FMECA. It is useful when conducting FMECA using available information and an expert’s expertise, which is often uncertain or vague in the design phase. In particular, a highly technical system usually has no crisp inputs or outputs, and the relationships between the associated failure modes and effects are very complex, both subjectively and qualitatively. This paper focuses on system reliability and proposes an intuitionistic fuzzy set ranking technique specifically to reduce the occurrence of duplicate RPN numbers. The proposed method can resolve some inherent shortcomings of the conventional RPN method. It provides the designer with a systematic approach to identify high-risk areas and attain explicit levels of safety by identifying and implementing ways to reduce the hazard frequency of occurrence and the extent of the respective consequences.

Moreover, a silane supply system is employed as an illustrative example to compare the results obtained from using the conventional RPN method, the fuzzy RPN method proposed by Bowles and Pelaez (1995), and the proposed method. We find that our proposed approach is very effective in RPN prioritization. The proposed method provides the analyst with the flexibility to decide which factor is more important to the analysis, and the outcome of the analysis will provide valuable information for the decision-making process. The proposed approach also provides an evaluation of redundancy place, which can assist the designer in making correct decisions to make a safer and more reliable product design.

The advantages of the proposed intuitionistic fuzzy set ranking technique are as follows:

-

(1)

The proposed method can reduce the occurrence of duplicate RPN numbers.

-

(2)

The failure information in FMECA is described as intuitionistic fuzzy variables, which are more realistic and flexible in reflecting real situations.

-

(3)

The results of the analysis provide more accurate and effective information for the decision-making process.

-

(4)

The proposed approach also provides an evaluation of redundancy place, which can assist the designer in making correct decisions to make a safer and more reliable product design.

References

Atanassov KT (1983) Intuitionistic fuzzy sets. Central Tech Library, Bulgarian Academy Science, Sofia. Report no. 1697(84)

Atanassov KT (1986) Intuitionistic fuzzy sets. Fuzzy Sets Syst 20:87–96. doi:10.1016/S0165-0114(86)80034-3

Bowles JB (2003) An assessment of RPN prioritization in a failure modes effects and criticality analysis. In: Processing annual reliability and maintainability symposium, pp 380–386

Bowles JB, Pelaez CE (1995) Fuzzy logic prioritization of failures in a system failure modes, effects and criticality analysis. Reliab Eng Syst Saf 50:203–213. doi:10.1016/0951-8320(95)00068-D

Chang JR, Chang KH, Liao SH, Cheng CH (2006) The reliability of general vague fault-tree analysis on weapon systems fault diagnosis. Soft Comput 10:531–542. doi:10.1007/s00500-005-0483-y

Ford Motor Company (1988) Potential failure mode and effects analysis (FMEA) reference manual

Pillay A, Wang J (2003) Modified failure mode and effects analysis using approximate reasoning. Reliab Eng Syst Saf 79:69–85. doi:10.1016/S0951-8320(02)00179-5

Sankar NR, Prabhu BS (2001) Modified approach for prioritization of failures in a system failure mode and effects analysis. Int J Qual Reliab Manage 18:324–335. doi:10.1108/02656710110383737

Seyed-Hosseini SM, Safaei N, Asgharpour MJ (2006) Reprioritization of failures in a system failure mode and effects analysis by decision making trial and evaluation laboratory technique. Reliab Eng Syst Saf 91:872–881. doi:10.1016/j.ress.2005.09.005

US Department of Defense Washington, DC (1980) Procedures for performing a failure mode effects and criticality analysis, US MIL-STD-1629A

Wang CL (2006) Use FMEA to assess the safety of silane supply system-take TFT-LCD factory as an example. National Chiao Tung University, Taiwan

Wang J, Ruxton T, Labrie CR (1995) Design for safety of engineering systems with multiple failure state variables. Reliab Eng Syst Saf 50:271–284. doi:10.1016/0951-8320(95)00094-1

Xu K, Tang LC, Xie M, Ho SL, Zhu ML (2002) Fuzzy assessment of FMEA for engine systems. Reliab Eng Syst Saf 75:17–29. doi:10.1016/S0951-8320(01)00101-6

Zadeh LA (1965) Fuzzy sets. Inf Contr 8:338–353. doi:10.1016/S0019-9958(65)90241-X

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, KH., Cheng, CH. & Chang, YC. Reprioritization of failures in a silane supply system using an intuitionistic fuzzy set ranking technique. Soft Comput 14, 285–298 (2010). https://doi.org/10.1007/s00500-009-0403-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-009-0403-7