Abstract

This paper proposes an efficient, hierarchical high-order enrichment approach for the finite cell method applied to problems of solid mechanics involving discontinuities and singularities. In contrast to the standard extended finite element method, where new degrees of freedom are introduced for all finite elements located in the enrichment zone, we define the enrichment on a so-called overlay mesh which is superimposed over the base mesh. The approximation on the base mesh is obtained by means of the finite cell method where the hp-d method is employed to introduce the hierarchical extension on the overlay mesh. We present two different strategies for defining the enrichment on the superimposed overlay mesh. In the first approach, the enrichment is based on a local h-, p- or hp-refinement utilizing the finite element method on the overlay mesh. Alternatively, the enrichment is constructed by means of the partition of unity method introducing carefully selected enrichment functions suitable for the problem at hand. Our results reveal that the proposed method improves the accuracy of the finite cell method significantly with only a minimum number of additional degrees of freedom. In this paper we will focus on examples with material interfaces although the method can also be applied to problems involving strong discontinuities and singularities. Accurate stress distribution and an exponential rate of convergence are the two striking characteristics of the proposed method. Due to the hierarchical approach it paves the way to using different approaches for the approximation on the base and the overlay mesh and accordingly allows multiscale problems to be addressed as well.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mesh generation can be one of the most difficult parts of a finite element (FE) computation, involving considerable computational input and expenditure, especially when the geometry is complex. Approximately 80 % of the overall time invested for a finite element analysis is devoted to geometrical modeling and mesh generation of the problem at hand [1]. Moreover, in cases of structures composed of highly heterogeneous materials, such as foams, composites or sandwich plates, the meshing can be very demanding or simply impossible. The situation becomes even more problematic in cases where there are special features such as discontinuities and singularities within the domain of interest. Capturing these phenomena with the standard FE methods requires a mesh aligned not only to the geometrical boundaries, but also to both weak and strong internal discontinuities as well as singularities. The partition of unity (PU) approaches such as, the extended finite element method (XFEM) and generalized finite element method (GFEM), are some of the most effective extensions of the finite element method, causing fewer mesh generation problems [2, 3]. These approaches dispense with the need for an aligned mesh by introducing extra non-smooth shape functions to the Ansatz. The enrichment function relies on taking advantage of prior knowledge of the solution [4], or by solving a local problem [5], and it is added to the approximation space by means of the PU concept. These methods have been widely used for the simulation of evolving discontinuities such as crack propagation [6–8], two-phase fluids [9, 10], or fluid-structure interactions [11, 12].

The fictitious domain approach is a more general category, which is used to simplify the mesh generation process or avoid it altogether [13, 14]. In this method the complex geometry is extended to a simpler, and easy-to-mesh domain. The consistency between the original domain and the extended one is preserved by penalizing the material properties on the extended domain. The extended domain can be discretized using different approaches, each one resulting in a different formulation. The finite cell method (FCM) is a fictitious domain method which employs high-order FEM for the discretization process [15–17]. Thanks to the high-order nature of the FCM, it has been demonstrated that the FCM can produce accurate structural analysis with a high rate of convergence by using a mesh independent of geometry. The reason for a mesh in the FCM is to provide a layout for defining the corresponding high-order shape functions. The voxel-based geometrical representation, which is common practice in biomechanical problems, or the implicit representation of geometry can be effectively combined with the FCM with hardly any outlay for mesh generation. The FCM has successfully been applied to various types of problems such as homogenization [18], topology optimization [19], biomechanics [20–24], geometrically nonlinear problems [25], elastoplasticity [26] and thin-walled structures [27]. However, the convergence rate of the standard FCM deteriorates in the case of heterogeneous materials since the displacement field exhibits a loss of regularity at the material interface, introducing a weak discontinuity. The weak discontinuity reduces the FCM convergence from exponential down to an algebraic rate. Moreover, the stress distribution near the weak discontinuity becomes excessively oscillatory, especially in large strain analysis [28, 29]. From an engineering point of view the accurate stress distribution can play a key role in the final design, for instance, in the case of shape and topology optimization, the fiber-matrix debonding or the evolution of dislocations.

The objective of this contribution is to improve the result of the FCM approximation for heterogeneous materials by combining the idea of the enrichment and FCM using a hierarchic domain decomposition concept. In this sense, the FCM space is enriched using additional, carefully selected shape functions defined on an overlay patch, where the patch is superimposed over the FCM approximation through the hp-d method. The overlay patch is local and only introduced in areas where the error is higher than a certain threshold. The enriched regions can be identified using error estimation or by prior knowledge of the error prone regions, for instance near material interfaces or singularities. The core idea of the presented approach follows the recent work on the hp-d-FCM [29]. In the mentioned work, the enrichment to the FCM approximation space has been defined by means of a quadtree using adaptive refinement. On each level of refinement, the approximation space has been enriched with some new degrees of freedom. The refinement has been made synergetically, thus taking advantage of the adaptive integration of the original FCM formulation [16]. The method presented in [29] is suitable for geometrically nonlinear problems. However, the main drawback of this type of enrichment is that many degrees of freedom have to be introduced in order to capture curved boundaries.

Our approach is also based on the hp-d method employing two different enrichment strategies. On the overlay mesh we either apply an h-, p- or hp-extension or we introduce carefully selected, high-order enrichment functions by means of the PUM. The high-order enrichment function is described with the aid of high-order Lagrange shape functions through the Chen–Babuška [30] points to decrease the interpolation error.

In either case of the aforementioned types of enrichment, the domain to be discretized is hierarchically decomposed and the enrichment is introduced on the overlay mesh, which is superimposed over the base mesh. The decomposition is carried out by taking advantage of the hp-d method. In contrast to standard enrichment methods, the proposed approach decouples the enrichment from the cells of the base mesh. In this way, it is possible to apply completely different mesh resolutions and shape functions for the discretization on the base and overlay mesh. On the base mesh we apply the FCM, which will be locally enriched by means of the hp-d method.

The paper is organized as follows: Sect. 2 provides a short introduction to the finite cell method and its solution characteristics while scrutinizing the main difficulties of the FCM in the numerical treatment of problems with material interfaces. Section 3 explains the enrichment procedure in the hp-d framework. Here we introduce the type of possible enrichments provided by mesh generation as well as the PUM, and we also describe the coupling procedure between the enrichment and the global approximation space. A high-order enrichment for the case of curved boundary material interfaces is also introduced in this section. Section 4 presents several 1D and 2D benchmarks. The paper concludes with a brief outline of the FCM’s potential with the proposed enrichment procedure.

2 The finite cell method

In this section we briefly review the FCM for problems in linear elasticity, including material interfaces in order to set the stage for the new refinement strategy which will be presented in Sect. 3. For a detailed description of the FCM we refer to [15, 16].

2.1 Mathematical formulation

Figure 1 outlines the basic idea of the FCM for a two-dimensional problem. The geometry may be complex with curved and straight boundaries including sharp corners. The material may also have pores and inclusions with different material properties from those of the matrix. Let us suppose that on the physical domain \(\varOmega \), a problem of linear elasticity is described by the weak form of equilibrium as

where the bilinear form and linear functional are defined as

respectively. In Eq. 2, \({\varvec{\varepsilon }}\) corresponds to the strains given in Voigt notation, C is the elasticity matrix, u is the displacement vector and v is the test function; f is the vector of volume loads, and \({\bar{\mathbf{t}}}\) is the vector of prescribed tractions on the Neumann boundary. The numerical solution of Eq. 1 using the standard FEM requires a mesh that is aligned to the geometry of the physical domain and to internal discontinuities and interfaces. In the FCM, however, the physical domain \(\varOmega \) is embedded into an extended domain \(\varOmega _e\) with a simple shape which is easily meshed with a structured Cartesian grid. In order to account for the geometry of the physical domain, we introduce an indicator function

The indicator function is equal to 1 if the corresponding point is located within the physical domain, otherwise it is 0. In order to avoid conditioning problems, we set \(\alpha =\alpha _0\) in the fictitious domain to very small values with \(q=4,\ldots ,15\). The elasticity matrix for the extended domain is defined as

where C(x) is the elasticity matrix corresponding to the physical domain and \(\mathbf{C}_m\) is the elasticity matrix of the matrix material. Inserting Eq. 4 into Eq. 2a and integrating over the extended domain results in

Equation 5 has the same structure as the bilinear form presented in Eq. 2a. In Eq. 5, however, the integration is carried out over the extended domain which is discretized by means of a structured mesh consisting of quadrilaterals in 2D or hexahedrals in 3D. Since the quadrilaterals and hexahedrals do not conform to the geometry of the physical domain, we call them cells in order to clearly distinguish them from finite elements. Cells that are located completely outside the physical domain are disregarded.

On the structured grid we apply hierarchic, high-order shape functions [31–33] in order to discretize the displacement field

where N is the matrix of shape functions. Following the Bubnov–Galerkin approach, the test function is also discretized with the same shape functions N as v = NV. Inserting the discretization of the displacement and the test function into the weak form leads to the final linear equation system

with stiffness matrix K and load vector F. Due to the similarity between the FCM and FEM, it is possible to take advantage of an existing high-order FEM code and adjust it to the FCM.

It should be noted that in the FCM the effort of the mesh generation of the classical FEM is shifted to the reliable and efficient quadrature of integrals with discontinuous integrands. This is a result of the fact that cells might be intersected by the boundary of the physical domain or might have different material properties due to inclusions. The integrand of the weak form on these cut cells is discontinuous and calls for a special numerical integration; see Eq. 5. However, the integration of a discontinuous function can be performed using various methods which are less troublesome than the mesh generation. A very simple and efficient way to this end is to adaptively increase the number of Gaussian points near the discontinuities on the cut cells. Here, local refinements are useful with the aim of capturing the discontinuity based on a recursive bisection of the cut cells. In 2D we apply a quadtree and in 3D an octree space partitioning scheme. The quadtree (octree) algorithm divides the cut cells into four (eight) smaller subcells. The subcells are only used for the integration purpose and do not add any additional degrees of freedom to the approximation. The partitioning procedure is continued on the cut subcells until a certain accuracy in the geometry representation is achieved. At the end of the partitioning, a standard Gauss quadrature rule is applied to the subcells. The quad/octree integration scheme is automatic and allows full control of the integration error [34].

Concerning the accurate integration on the cut cells, other approaches such as the estimation of the discontinuous integrands with the continuous functions [35–37], or local mesh generation are also applicable [38–40]. These approaches are usually used in the context of the XFEM and GFEM,

2.2 Solution characteristics of the FCM

To analyze the solution behavior of the FCM, we investigate a very simple, one-dimensional example given in Fig. 2a. The problem consists of a 1D bar which is clamped at the left-hand side with a traction \(f\) is acting upon it. The governing equation in this example is \(EAu^{\prime \prime }(x)+f(x)=0\). The exact solution reads

which is obviously discontinuous across the boundary of the geometry. For the FCM computation, the domain is discretized by using one p-version finite cell, with \(p=4\), which fails to resolve the geometry on the right-hand side. This cell is a cut cell, since one part of it resides in the physical region and the other part belongs to the fictitious domain. In order to minimize the error of the quadrature of the integrals with the discontinuous integrands, the cell is split into two subcells which are introduced for integration purposes only. The subcells are chosen such that their common interface coincides with \(x=L_1\), the point at which the integrand is discontinuous. A standard Gauss quadrature rule is performed on each of the two subcells with \(n_g=p+1\) Gaussian points. In the fictitious domain we set \(\alpha _0\) to \(10^{-12}\). In this manner, the fictitious domain is replaced by a very soft material which has the Young’s modulus \(E_{fict}=10^{-11}\).

Figure 2b, c compare the displacement and the strain obtained with the FCM to the analytical solution. It is evident from these figures that the FCM solution based on \(p=4\) is accurate in both the displacement as well as the strain in the physical region. The main reason for investigating this example is to emphasize the FCM behavior in the fictitious domain. In this region, the FCM solution is smoothly extended from the physical domain. Due to the indicator function, however, this part of the solution does not contribute to solving the problem and can simply be disregarded.

Owing to the high-order shape functions, the FCM is able to provide accurate results with an exponential rate of convergence even when there are void regions in the cells [16, 23, 24]. The high-order convergence can be guaranteed if the integration is performed accurately enough, provided that no singularities are introduced as a result of reentrant corners or cracks.

The simplicity and capabilities of the FCM lend this method to heterogeneous materials. Nevertheless, for this category of problems, the FCM runs into several difficulties such as a poor convergence rate and lack of accuracy in the stress field (i.e. derivatives). The problem is that in this case the solution exhibits a weak discontinuity at the material interface, which means the displacement field is continuous across the interface, whereas its derivative is discontinuous. If the cells are not aligned to the material interface, then there will be a cell in a domain which contains two different materials. The smooth high-order shape functions presented in the FCM are not able to approximate the kink of the displacement field in this cell. This can easily be demonstrated by studying a 1D example. We again consider the same problem as before, the fictitious domain having now been replaced by another material. The problem geometry and parameters are given in Fig. 3a. The exact solution for the displacement and the strain are as follows

Once again, the domain is discretized by one finite cell which does not resolve the material interface. The integration is likewise identical to the procedure described in the last example. Since the exact solution of the displacement is a function of \(x^4\), a finite cell with \(p=4\) is chosen for the approximation. Figure 3b, c depict the exact solution and the FCM one. Unsurprisingly, there is a considerable difference between the two solutions due to the material interface and the corresponding jump in the strain; see Eq. 9b. The problem arises from the fact that, in this case, the Ansatz has to resemble the solution in both material parts with different material coefficients. This is impossible to achieve since only one smooth polynomial is being used to discretize the displacement field. Increasing the polynomial order of the Ansatz will improve the approximation, but there will still be a deviation from the exact solution, particularly in the strain field. This situation can be observed from the FCM solution with \(p=8\), shown in Fig. 3b, c.

3 The enrichment in the hp-d framework

As observed in the previous section, the smooth high-order shape functions utilized in the FCM are not sufficient to accurately compute problems with (weak) discontinuities. The non-smooth behavior of the exact solution of the underlying problem to be solved might be due to material interfaces or singularities present in the physical domain. In order to overcome this problem, one possible remedy is to enrich the approximation space with some additional non-smooth functions to allow the non-smooth part of the solution to be accounted for correctly. There are various strategies for achieving this purpose, but here we focus on the extrinsic enrichment approach which extends the Ansatz with additional new degrees of freedom [41]. To this end, we modify the Ansatz for the displacement field as follows

where the first term on the right-hand side is related to the smooth hierarchic shape functions used in the standard FCM, and the second term corresponds to the enrichment functions. Irrespective of the definition of the enrichment, it can be superimposed over the FCM Ansatz by taking advantage of the hp-d method. In this manner, two domains are defined during the simulation, where one domain is responsible for discretizing the whole computational domain and the other one deals with the local features and the enrichment. Finally, the hp-d method, which is a domain decomposition approach [42–45], is used to couple the two domains. The principles of the hp-d method are briefly explained in the following section. Having described the hp-d method in Sect. 3.1, the construction of the enrichment function will be detailed in Sect. 3.2.

3.1 The hp-d method

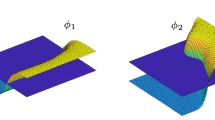

May we briefly recap the idea of the hp-d method [42, 45] since it is the underlying scheme used to introduce the local enrichment in the FCM. In the hp-d method the displacement field is composed of two parts

where \(\mathbf{u}_b\) is the standard \(h\)- or \(p\)-version of the finite element method defined on a coarse base mesh discretizing the whole computational domain. The second part, \(\mathbf{u}_o\) is the local enrichment function defined on a superimposed, so-called overlay mesh. The idea of the hp-d method in 1D is demonstrated in Fig. 4a. The global \(C^0\) continuity of the solution can either be provided by imposing homogeneous kinematic boundary conditions on the overlay mesh or by adjusting the enrichment function so that it automatically vanishes along the boundary of the overlay mesh. The overlay mesh can be superimposed over the base mesh at any point; see Fig. 4b. It is moreover also possible to have several overlay meshes overlapping each other [45].

Inserting Eq. 11 into the weak formulation, Eq. 1, and using corresponding admissible test functions, \(\mathbf{v}_b\) and \(\mathbf{v}_o\), the problem reads

where the indices “\(b\)” and “\(o\)” indicate the corresponding quantities defined on the base mesh and the overlay mesh, respectively. The displacement fields \(\mathbf{u}_b\) and \(\mathbf{u}_o\) are now discretized in the normal way

Following the Bubnov–Galerkin approach and discretizing the test functions in the same way as the displacement field and then inserting it into the weak formulation, Eq. 12, the resulting coupled linear equation system reads as

where \(\mathbf{K}_{bb}\) and \(\mathbf{K}_{oo}\) are the stiffness matrices on the base and overlay meshes, respectively. \(\mathbf{K}_{bo}\) and \(\mathbf{K}^T_{bo}\) are the coupling matrices. \(\mathbf{F}_{b}\) and \(\mathbf{F}_{o}\) are the vectors of corresponding forces. This coupled equation system can be solved in different ways. It can either be solved using a monolithic approach where the coupled matrices are computed explicitly and the resulting overall system is solved by any method, including direct as well as iterative solvers. Alternatively, it is possible to apply a block Gauss–Seidel iteration resulting in the following iterative procedure

In this form, the need for explicitly computing the coupling terms, \(\mathbf{K}_{bo}, \mathbf{K}^T_{bo}\), is replaced by computing \(\mathbf{K}_{bo}\mathbf{U}^{(i)}_o\) and \(\mathbf{K}^T_{bo}\mathbf{U}^{(i+1)}_b\) which can be interpreted as pseudo load vectors arising from the negative pre-strains in the last iteration step [45]. Using this interpretation, it is possible to utilize different software as a black box for performing the discretization on the base and overlay meshes, provided that the software is able to read and write the pre-strains at arbitrary points. The shortcoming of using this procedure is mainly the slow rate of convergence, which can be the case when introducing local enrichment functions increasing the condition number of the overall equation system. Applying acceleration schemes which are well-known from the partitioned solution approach for coupled problems [46], it is possible to significantly reduce the number of block Gauss–Seidel iterations. In order to readily test different types of local refinements via the hp-d method, we have chosen the solution based on the block Gauss–Seidel approach to be more flexible with the implementation. Applying this iteration approach, we never faced convergence problems, although an improved solution strategy will be considered in future work in order to solve the overall equation system more efficiently.

3.2 The enrichment space

In this section we present different refinement approaches which can be applied via the hp-d method in order to resolve local phenomena due to discontinuities or singularities in the exact solution of the underlying problem.

3.2.1 Mesh generation approach: hp-d-FCM

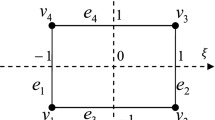

In this approach, the additional degrees of freedom related to the local enrichment are defined in terms of a finite element approach on an overlay mesh which resolves discontinuities and singularities by using a conforming mesh, which is superimposed over the base mesh. The overlay mesh covers only a small part of the global domain and the mesh density might be much higher than that of the base mesh. This approach is termed hp-d-FCM in order to avoid confusion with another refinement strategy which will be presented in the next section. The overlay mesh with its corresponding boundary can be located everywhere on the base mesh, also introducing hanging nodes. In order to preserve the \(C^0\) continuity of the overall displacement field \(\mathbf{u}_{hp\text{- }d}\), homogeneous Dirichlet boundary conditions

are described on the boundary \(\varGamma _o\) of the overlay mesh. As a result of this boundary conditions applied on the overlay mesh, a \(C^0\) continuous approach is guaranteed even in the case of hanging nodes, see Fig. 4b. Nonetheless, in order to facilitate the integration procedure of the weak form, the overlay mesh is chosen that will ensure its outer boundaries coincide with the elemental boundaries of the base mesh. It should be also noted that special care has to be taken with integrating the elements of the base mesh which are superimposed by the overlay mesh. Since the overlay mesh is usually finer than the base mesh, the integration of these elements has to be performed on the finer mesh, i.e. on the overlay mesh, to correctly account for the discontinuities in the elements of the overlay mesh. This is due to the fact that the approximation of the displacement field is defined as a \(C^0\) continuous Ansatz. Proper integration is vital if an optimal rate of convergence is to be achieved [34, 47].

It is worth mentioning that the hp-d-FCM approach is less problematic than the classical FEM in terms of mesh generation for problems involving complicated geometry or microstructured materials. The base mesh can be constructed by taking advantage of the FCM without any problem regarding the mesh generation. The overlay mesh is very local and can be constructed more or less independent of the base mesh. Furthermore, the overlay mesh can include hanging nodes and therefore the refinement on the overlay is very simple. This approach is very well suited for problems involving singularities in the exact solution of the underlying problem [45, 48].

3.2.2 High-order partition of unity approach: hp-d/PUM-FCM

In this concept, the non-smooth behavior is approximated locally with the aid of carefully selected functions \(F\) which are customized to capture discontinuities or singularities; the function is introduced to the approximation through the PU concept

where the functions \(N^*_j\) build a partition of unity. Here \(\mathbf{a}_j \) are the new degrees of freedom corresponding to the enrichment. The function \(F\) is the enrichment function and has the necessary characteristics regarding the non-smooth solution. This approach, which is well known in the context of the XFEM and GFEM, will be called hp-d/PUM-FCM below. We should mention that in the FCM this term is only required for the case of material interfaces, cracks and singularities. The case of pores and holes, which is taken care of by means of the Heaviside enrichment function [4] in the PU-based methods can be approximated without any enrichment term using the standard FCM. We accordingly describe the method for the case of material interfaces. In this type of enrichment, the discontinuity is normally represented by the iso-zero surface of the level set function. In addition to describing the location of the discontinuity, the level set function is also used to build up the enrichment function. For the case of weak discontinuity, the use of the absolute value of the level set function is a natural choice for the enrichment function since it has a discontinuous derivative along the material interface. It is desirable to have an enrichment function that vanishes at the boundaries of the enriched region [41]. To meet this requirement, we use the procedure suggested by Möes et al. [50] as follows

where \(M_j\) are the PU shape functions and \(\phi _j\) are the values of the level set function at the interpolation points. This procedure modifies the level set function so that it vanishes along the boundary of the enriched region. Thus the effect of the enrichment does not appear in the non-enriched area.

The application of the level set function, which was proposed in [4], is useful specifically for those cases where the location of the discontinuity changes over time, for instance, in the computation of crack propagation or fluid-structure interaction. The level set function usually interpolated in the domain of interest using finite element shape functions reads as follows

To achieve the optimal rate of convergence, an accurate description of the level set function and consequently an accurate description of the discontinuity in the domain is vital. For the case of discontinuities occurring at straight-sided lines, the interface position can be readily approximated by means of the standard linear Lagrange shape functions in Eq. 19. However, using linear shape functions for discontinuities along curved edges or interfaces can cause a significant error in stress distribution and hinder the optimal convergence. In order to accurately locate the interface, it is therefore necessary to use a sufficiently fine mesh, which will increase the computational effort. A possible approach for improving the accuracy of the discontinuity description without increasing the degrees of freedom has been suggested by Dréau et al. [49]. They proposed using a finer mesh, namely geometrical grid, for the level set function and a coarser mesh, namely computational grid, for the FEM approximation. In this way, the degrees of freedom remain unchanged, while the level set approximation becomes more accurate. A very fine mesh is necessary to reach the accepted error in the level set approximation, however. In addition, a correction term, corresponding to the different resolutions of the geometrical and computational grid, has to be defined to achieve the desired value for the enrichment function (zero) along the boundary of the enrichment region. Another possible remedy, which we use here, is the application of high-order shape functions for \(M_j\) in Eq. 19. The high-order polynomials, \(M_j\), can be represented by using different sets of shape functions. Nevertheless, the choice of interpolation points significantly influences the interpolation error. In this paper we use Lagrange shape functions that are either based on equidistant points or utilize the interpolation points proposed by Chen and Babuška [30]. In order to investigate the efficiency of high-order shape functions and to study the influence of the interpolation points we also compare the corresponding results with low-order shape functions. To this end we take a look at several examples.

The first example to be considered is a level set function which represents a circle over a quadratic domain. The exact description of the level set function reads

where \((x_c ,y_c)=(0,0)\) is the center, and \(r=\sqrt{0.5}\) is the radius of the circle. The level set value is negative (positive) if the point is located inside (outside) the circle and it is zero along the circle. The exact contour lines of the level set function, Eq. 20, are shown in Fig. 5. We consider two different discretizations. In one case, the domain of interest is discretized using 9 low-order, \(p=1\), elements. For the second case, we look at one element with quadratic Lagrange polynomials, \(p=2\). It should be noted that for the choice of \(p=2\) the equidistant and Chen–Babuška points are identical. In order to judge the quality of the interpolation, the difference between exact and interpolated values, \(\left| \phi _{ex}-\phi _{int}\right| \) is computed and shown in Fig. 6a, b.

In another accuracy assessment of the interpolation results we compute the relative error defined as follows

where \(\phi _{ex}\) and \(\phi _{int}\) denote the exact and interpolated version of the level set function, respectively. This error is plotted versus the number of interpolation points in Fig. 7. Since the level set function is quadratic, the high-order shape functions with \(p=2\) are able to represent the exact level set, whereas the low-order shape functions result in some approximation error.

The efficiency of using high-order approximation is even more pronounced when considering more complicated level set functions. This can be shown, for instance, by contemplating a level set function which is given as follows:

The zero level of this function for the case of \(n=6\), which is known as superellipse, is depicted in Fig. 8a where the interpolation domain is taken to be a square. The interpolation is accomplished with h- and p-refinement using the Lagrange shape functions. During the h-refinement, the polynomial degree is set to \(p=1\) and the number of divisions in x and y direction are simultaneously increased. In the case of the p-refinement the entire domain is discretized with one cell and the polynomial degree is varied as \(p=1,2,\ldots ,10\). We also take a look at the high-order Lagrange shape functions with both equidistant and Chen–Babuška points. In order to achieve an objective comparison between the results of different types of interpolation, the error, Eq. 21, is plotted over an equal number of interpolation points for each method in Fig. 8b. Both versions of the high-order shape functions result in an exponential convergence rate, whereas the convergence rate of the h-refinement is algebraic. In addition, Fig. 8b reveals that the Lagrange shape function with Chen–Babuška points produces slightly more accurate results than the equidistant points. It is worth mentioning that considering Lagrange shape functions with \(p=12\) results in the exact representation of the level set function. This is due to the fact that, in this case, the level set function itself is a polynomial degree of 12.

The next example to be contemplated falls in the category of non-polynomial level set functions. Interpolation of a non-polynomial function, which can frequently occur in realistic models, with a polynomial basis might prove to be a numerically challenging task. A non-polynomial function may be a superellipse, for instance, where \(n\) is chosen to be a non-integer value in Eq. 22. The zero level of such a function is depicted in Fig. 9a for the case of \(n=0.125\). To interpolate this function we apply an h-refinement where the entire domain of interest is discretized by a structured mesh with Lagrange elements of order \(p=1\). In another attempt, the domain is discretized with only a single high-order Lagrange element and the polynomial degree is varied as \(p=1,2,\ldots ,10\). Furthermore we study the influence of the interpolation points by comparing the equidistant set with the interpolation points proposed by Chen and Babuška.

Based on the error definition in Eq. 21, the error less than \(1\,\%\) in the interpolation results in a very accurate description of the level set function. As shown in Fig. 9b, all variations of the interpolation are able to fulfill this threshold. Both the h-refinement and the p-refinement with Chen–Babuška points converge with an algebraic rate, yet the convergence rate for the p-refinement is higher than the h-refinement. The high-order Lagrange shape functions with equally distributed points are less accurate than the same order Lagrange shape functions with Chen–Babuška points. This is clearly visible in Fig. 9b where the high-order interpolation with equally distributed points shows oscillatory results for a polynomial degree above 5.

The importance of a continuous interpolation suggests applying the high-order interpolation as a proper substitute for the low-order one. The continuity of the interpolation directly influences the task of integrating the weak form. That is to say that, when calculating the enrichment term in the weak form, as proposed in Eq. 17, not only the derivatives of the enrichment function \(F\) but also the level set function are involved. Accordingly, performing an h-refinement for an accurate level set interpolation yields a piecewise continuous representation on each finite element. In other words, in the h-refinement type of interpolation, discontinuities due to the essence of the interpolation arise along the boundaries of the interpolation elements. It is therefore essential to take these discontinuities into account when integrating the weak form. This may result in a computationally inefficient and expensive method. On the other hand, in the case of high-order interpolation, using one interpolation element for the level set function is normally sufficient. The interpolation of the level set function is accordingly continuous. This feature facilitates the integration part in the computation of the stiffness matrices. In cases where both the interface geometry and the level set function are very complicated, however some h-refinements are desired. This is depicted schematically in Fig. 10 for the interpolation of a function given as

This function, which is shaped like a starfish, is interpolated by means of the h- and p-refinement. Both cases of the interpolation have an equal number of interpolation points, so it is fair to claim the two cases are equivalent in terms of computational cost and memory usage. As is shown in Fig. 10, the interpolation curve is similar in each case, although the number of interpolation elements required to capture all the geometrical features of the starfish is different. In the case of high-order interpolation, the number of elements used for the domain discretization purpose is smaller than one in the low-order case. Therefore the number of edges at which discontinuities in the first derivative occur is much smaller, thus simplifying the integration of the underlying cell matrices. Another issue of importance when choosing a set of shape functions is the resulting condition number of the stiffness matrix arising in the equation system. The Lagrange shape functions with Chen–Babuška points have a smaller condition number than the equally distributed set of nodes; The condition number for a one-dimensional rod element using different sets of polynomial shape functions is shown in Fig. 11.

Finally it has to be mentioned that the enrichment function, Eq. 18, causes an undesired side effect, however. This is, in fact, due to the contribution of the first term on the right-hand side of Eq. 18. One welcome effect of this term is that it modifies the enrichment function along the boundary of the enrichment region. On the other hand, it also changes the value of the level set function along the material interface. The location of discontinuity can be computed accurately just using high-order shape functions for the level set function, for example, but following the modification based on Eq. 18 it becomes less accurate in terms of the location of the discontinuity. A graphical representation of an enrichment function \(F\) representing the boundary of a circle on a quadratic domain is given in Fig. 12, where \(p=3\) is chosen for \(M_j\).

The hp-d/PUM-FCM approach is mesh independent and suitable for problems such as time-dependent discontinuities or complicated multi-material structures where local mesh generation is still burdensome. With this method, the enrichment is carried out in patches rather than being applied to each individual element, so it produces fewer degrees of freedom than the XFEM or GEFM.

3.2.3 Selection of proper enrichment

The proposed approach employs the standard FCM for discretizing the global domain, with almost no cost in the sense of mesh generation, while the local features of the solution are captured on the overlay mesh. The selection of the type of discretization on the overlay mesh depends on the actual features of the underlying problem; see Fig. 13. We suggest the following classification for choosing the proper enrichment method on the overlay mesh:

-

(i)

Pores and voids: In this case no enrichment term is needed and the standard FCM is sufficient to capture all the available features of the underlying problem, provided that the integration of the weak form is performed accurately enough.

-

(ii)

Material interfaces and cracks: The structure of the exact solution in the vicinity of material interfaces and cracks is known a priori. Taking advantage of this knowledge, carefully selected enrichment functions are introduced to improve the quality of the finite cell approximation. These enrichment functions are, for example, the hat function for material interfaces, the Heaviside function for cracks, or asymptotic field available for crack tips. The enrichment functions are introduced via the PU concept and thus the use of the hp-d/PUM-FCM is a convenient choice. The enrichment functions defined on the overlay mesh can be of arbitrary order.

-

(iii)

Singularities: In cases where the structure of the solution in the vicinity of a singularity is not known a priori, the enrichment can be performed by applying the h-, p- or hp-version of the FEM to the superimposed overlay mesh. In this way, it is possible to enrich complicated 3D problems on a local level via the hp-d method, without the need for optimal enrichment functions.

4 Numerical examples

To demonstrate the performance of the proposed method, we will now proceed to present several numerical examples. All examples are in one or two dimensions. The 1D examples are solved using an in-house code based on Octave [51]. The 2D examples are computed with AdhoC, which is also an in-house, high-order FEM code customized for the FCM and extended for the local enrichment [52].

4.1 One-dimensional rod

Let us reconsider the second example described in Sect. 2.2, now applying the hp-d-FCM. Here a low-order, \(p=1\), overlay mesh with two elements is superimposed over one high-order base element. The material interface coincides with a node of two adjacent elements on the overlay mesh. All the other conditions remain unchanged. The overlay and base mesh are depicted in Fig. 14a. For the first test, a base mesh with one element of degree \(p=4\) is chosen. The exact and hp-d solution are illustrated in Fig. 14b, c. It can be observed that the displacement is computed accurately while there is a slight error in the strain. This difference is due to the insufficient discretization on the base mesh. If an Ansatz with a higher polynomial degree, \( p=8 \), is used, the accuracy improves significantly. In order to study the efficiency of the method presented here, let us substitute the traction by \(f=100x^{10}\) and examine the convergence of error in energy norm

Here \({\fancyscript{U}}\) is the strain energy defined as \({\fancyscript{U}}=\frac{1}{2}{\fancyscript{B}}(\mathbf{u},\mathbf{u})\). The exact value of the strain energy is computed analytically and is \(41.2324829320877\). \({\fancyscript{U}}_{hp\text{- }d}\) is obtained numerically with the subcell integration algorithm. Figure 15 shows the convergence behavior of the FCM scheme including the two different enrichment strategies: hp-d-FCM and hp-d/PUM-FCM. The polynomial degree on the base mesh is varied as \(p_b = 1,2,3,\ldots ,13\), while we chose \(p_o = 1\) for the overlay. Both type of enrichments converge exponentially likewise a standard p-FEM approach on a mesh consisting of two elements and resolving the material interface. This example shows that both enrichment types are equivalent for the case of a weak discontinuity and yield an exponential rate of convergence.

4.2 Bi-material plate

The second example to be considered consists of a two-dimensional, elastostatic, square bi-material plate in plane stress with Young’s moduli of \(E_1=2.1\)GPa, \(E_2=21\)GPa, and a Poisson’s ratio of \(\nu _1 =\nu _2 = 0\). The geometry and boundary conditions are sketched in Fig. 16. The plate is fixed at the top and the bottom in a vertical direction and on the left-hand side in a horizontal direction. A volume load, \(f = 100 sin(\pi x)\), is applied to the plate. For the computation, the origin of the coordinate system is placed at the center of the plate. The material interface is accordingly located at \(x=0\).

The entire domain is discretized by a structured, non-aligned mesh of \(3\times 3\) p-version finite cells; see Fig. 17. Considering this mesh, there are 3 cut cells with different materials. To minimize the integration error of the cells, an adaptive quadrature scheme based on the quadtree is applied, introducing subcells for integration purposes only. A Gauss quadrature with \(n_g=(p+1)^2\) Gaussian points is applied on all cells and subcells.

A first impression of the FCM solution can be obtained from the strain plot in Fig. 18 along the cut line \(AA^{\prime }\) which is shown in Fig. 16. The reference solution is related to an overkill discretization where the material interface is exactly resolved by the mesh. The FCM solution deviates from the reference solution near the material interface. Pursuing the idea of the hp-d/PUM-FCM approach, an overlay mesh with one element is superimposed over the base mesh. On the overlay mesh we define the enrichment with the help of Eq. 18 using low-order, \(p_o=1\), shape functions for \(M_j\); see Fig. 17. The hp-d/PUM-FCM converges to the reference solution and can capture the jump in the strain occurring at the material interface precisely. As regards the convergence of the proposed method, we investigate the error in the energy norm as shown in Fig. 19. The exact value of the strain energy computed from an overkill solution is \({\fancyscript{U}}_{ex}=1.0855806\). In the current example, the polynomial degree of the hierarchic shape functions on the base mesh is varied from \(p=1,2,3,\ldots ,15\), for the FCM without enrichment, and \(p_b=1,2,3,\ldots ,5\) for the hp-d/PUM-FCM with enrichment. The convergence rate in the case of the FCM is algebraic due to the material interface, which is not resolved by the mesh. An exponential rate of convergence is obtained with the hp-d/PUM-FCM. It should be noted that the enrichment only adds 8 degrees of freedom to the approximation, whereas the usual XFEM approach would introduce at least 16 degrees of freedom (4 for each cut cell).

4.3 Bi-material perforated plate with curved holes

By way of another example we assess a two-dimensional, elastostatic, bi-material plate perforated by six circular holes in plane stress with Young’s moduli of \(E_1=2.1\)GPa, \(E_2=21\)GPa, and a Poisson’s ratio of \(\nu _1 =\nu _2 = 0.3\). The dimension of the plate is \(L\times L\) with \(L=4\)mm and it is fixed in vertical and horizontal directions at the bottom and left-hand side, respectively. The geometry and boundary conditions are given in Fig. 20. The holes are implicitly represented by the inequality

where \((x^i_c,y^i_c)\) is the center of \(i\)-th hole and \(r=0.25\)mm is the radius of the holes. The origin of the coordinate system is placed at the center of the plate and the material interface is consequently located at \(y=0\). The plate is loaded by traction as depicted in Fig. 20. As in the previous example, results are obtained for two different methods: the standard FCM and the FCM with enrichment using hp-d-FCM.

For the FCM computation, the entire domain is discretized by a structured mesh of \(7\times 7\) p-version finite cells, as shown in Fig. 21. These cells conform neither to the holes nor to the material interface. In the void region \(\alpha _0=10^{-12}\) is chosen. In order to perform the quadrature of the cells, the adaptive quadtree-based integration algorithm is applied to the cells cut by the voids and material interface. The subcells generated by the quadtree algorithm are presented in Fig. 22. A Gauss quadrature rule with \(n_g = p+1\) integration points in each direction is performed on each cell and subcell.

In Fig. 23 the stress in \(x\)-direction along the cut line \(AA^{\prime }\) is compared to the reference solution. The reference solution is based on an overkill approach applying a p-FEM mesh, which resolves all features geometrically. The strain energy corresponding to this solution is \({\fancyscript{U}}_{ex}=2.5170654396\). Considering this result, the FCM accurately represents the stress distribution in the whole domain, even near the curved boundaries of all holes, without any need for the enrichment. However, there is significant deviation from the reference solution near the material interface. This deviation is due to the cells cut by the material interfaces. Therefore, an enrichment of the FCM is required in the vicinity of the material interfaces.

Let us now enrich the FCM solution using an overlay patch with two cells that resolve the material interface. The position of the overlay mesh is depicted in Fig. 21. For the sake of simplicity, the boundary of the overlay mesh coincides with elemental boundaries of the base mesh. The global \(C^0\) continuity is provided by applying homogeneous boundary conditions on the overlay mesh. The corresponding result from this solution can be seen in Fig. 23. The results near the material interface are considerably improved and the stress distribution is accurate everywhere in the domain. The hp-d enrichment also improves the FCM convergence rate significantly. The convergence in the energy norm for the standard \(p\)-FEM and FCM with and without enrichment is given in Fig. 24. The FCM convergence rate is algebraic, while the enriched version of the FCM converges exponentially like the standard p-FEM based on a mesh resolving all features of the problem.

4.4 Plate with circular inclusion

The proposed enrichment is also applied to a problem with a curved inclusion. Consider a composite square \(L \times L\) plate with length side of \(L = 2\) mm containing a circular inclusion with radius of \(r=\sqrt{0.125}\) mm at its center. The two materials are assumed to be linear elastic and plane stress conditions are taken into consideration. The matrix has a Young’s modulus of \(E_m=2.1\)GPa, and a Poisson’s ratio of \(\nu _m=0.3\). The inclusion is ten times stiffer with a Young’s modulus of \(E_i=21\)GPa, and a Poisson’s ratio of \(\nu _i = 0.3\). The displacements in normal direction are suppressed on the left-hand side as well as at the bottom of the plate. On the right-hand side, a uniform traction is applied to the plate; see Fig. 25. For computation purposes, the origin of the coordinate system is placed at the center of the plate. Thus, the geometry of the inclusion in the FCM is described implicitly by the inequality \(x^2+y^2 \le r^2\), where \(r\) is the radius of the inclusion.

We look at two different discretizations. In the first case, the domain is discretized by a non-aligned FCM mesh of \(3 \times 3\) \(p\)-version cells, while it is superimposed locally by a high-order overlay mesh resolving the circular inclusion. In this case, the superimposed region corresponds to the cell located at the center of the base mesh. During the computation process, the polynomial order on the base and overlay mesh is varied from 1 to 10. The corresponding base and overlay meshes are depicted in Fig. 26a.

Another approach looks at the hp-d-PUM/FCM. In this situation, the base mesh consists of \(4 \times 4\) p-version cells, where the overlay consists of a single cell which completely covers the inclusion. A high-order enrichment function is considered on the overlay mesh. To define the enrichment function, Eqs. 17 and 18 are used where the polynomial order of \(N^*_j\) is increased simultaneously with the polynomial order of the Ansatz on the base mesh. The polynomial order of the enrichment function \(M_j\) is chosen to represent the geometry of the material interface accurately. In our numerical experiment it turned out that \(p=5\) is sufficient for an accurate description of \(F\). The boundary of the overlay mesh also conforms to the boundary of the cells of the base mesh. The base and overlay meshes for this particular instance are sketched in Fig. 26b.

As a result of these computations, we consider the stress component \(\sigma _x\) along the cut line \(AA^{\prime }\), plotted in Fig. 25. The solutions of the FCM, hp-d-FCM, and hp-d/PUM-FCM are compared to the reference solution in Fig. 27a, b. The reference solution for this example is also obtained by an overkill p-FEM approach, where the strain energy corresponding to this solution is \({\fancyscript{U}}_{ex}=0.83853435\).

The standard FCM yields strong oscillatory results in the cells cut by the material interface. On the other hand, from Fig. 27a, b, it is evident that the solution of both types of enrichment corresponds very well to the reference solution.

It is important to mention that the computational effort for the two types of enrichment is different. In the case of the hp-d-FCM, in addition to the discontinuity at the material interface, the overlay elements also introduce some discontinuities in the strains, which are due to the \(C^0\) continuous approach applied on the overlay mesh; hence, the integration has to be carried out on the finer domain. The integration procedure in the hp-d/PUM-FCM is simpler than the hp-d-FCM and it also involves less computational cost. In this approach, the only discontinuity that exists appears at the material interface.

The result of the convergence study in terms of Eq. 24 for the p-FEM solution and FCM with and without enrichment is presented in Fig. 28. It is clear that the FCM scheme provides an algebraic rate only where the hp-d-FCM and the hp-d/PUM-FCM are both in a position to considerably improve the rate of convergence.

4.5 Interplay between the fictitious domain and the enrichment zone

The main advantage of the proposed approach is revealed in cases where there are pores and inclusions together in a single cell. In such cases, the enrichment term is only vital for the inclusions, whereas the fictitious nature of the approach is responsible for the holes. In order to study the performance of the approach in the said situation, we take a look at two examples, as follows.

The first example involves one quadrilateral cell containing a circular hole and a straight-sided material interface. The cell size is \(L \times L\) with a length side of \(L = 4\) mm. The two materials are taken to be linear elastic and plane stress conditions are assumed. The materials have a Young’s modulus of \(E_1=2.1\)GPa and \(E_2=21\)GPa, respectively. The Poisson’s ratio of both materials is taken to be \(\nu _1 = \nu _2= 0.3\). Symmetry boundary conditions are applied to the left-hand side, the bottom and the right-hand side. A constant volume load is applied to the cell. The corresponding cell is depicted in Fig. 29 along with some other dimensions.

The cell under consideration is neither aligned to the material interface nor to the boundary of the hole. Instead, the hole is considered using the fictitious domain approach with \(\alpha _0=10^{-12}\). In the first attempt, we contemplate the FCM without the enrichment term, where the polynomial degree of the Ansatz is chosen to be \(p=18\). With regard to the quadrature of the cell, we apply the quadtree-based integration, as described in Sect. 4.3.

In order to examine the accuracy of the result, the stress \(\sigma _x\) along the cut line \(AA^{\prime }\), which is shown in Fig. 29, is compared with the reference solution. The reference solution for this example is also given by an overkill p-FEM approach. As demonstrated in Fig. 30, the FCM obviously leads to an oscillatory stress distribution which is due to the presence of the kink in the displacement field at the material interface. In this context the FCM Ansatz is enriched using the hp-d/PUM-FCM method. Following this approach, one overlay cell is superimposed over the base cell. Due to the fact that the material interface is straight-sided, the low-order shape functions are sufficient for describing the enrichment function. \(F\) in Eq. 17 is consequently approximated using polynomials with \(p=1\). The outcome of this enrichment is given in Fig. 30 where the polynomial degree on the base cell and the overlay patch is determined to be \(p=8\). The solution shows considerable improvement and the oscillations have disappeared. There is a good agreement between the hp-d/PUM-FCM solution and the reference solution even in the vicinity of the critical regions i.e. the material interface and void region. The convergence is remarkably improved, too. The convergence of the error in energy norm in terms of Eq. 24 is shown in Fig. 31 where the polynomial order of the Ansatz of both base and overlay cell is simultaneously varied as \(p=1,2,\ldots ,10\).

One quadrilateral cell including a circular hole and a circular inclusion represents the second example in this section. The cell dimensions and properties are the same as in the last example, except for the geometry of the inclusion, where we have chosen a curved-sided material interface. The corresponding cell and dimensions are shown in Fig. 32. It is obvious that, due to the presence of the inclusion in this cell, the displacement field loses its regularity and exhibits a kink in the solution. Consequently, the FCM is unable to provide an accurate stress distribution in such a situation. This can be observed by examining the von Mises stresses along the cut line \(AA^{\prime }\) shown in Fig. 32, for instance. The reference solution for this example is provided by a conventional p-FEM approach where the geometry of the inclusion and hole are exactly resolved by taking high-order elements with blending functions into consideration [31, 33, 53]. As shown in Fig. 33, the FCM solution is oscillatory particularly in the vicinity of the inclusion. On the other hand, taking advantage of the PUM approach for this cell can significantly improve the FCM solution. For this reason, we define an enrichment procedure based on the hp-d/PUM-FCM where the overlay patch is a quadrilateral cell superimposed over the base cell. Since the geometry of the inclusion is a quarter-circle, the high-order shape functions based on the Chen–Babuška interpolation points with \(p=2\) should be sufficient to describe the geometry of the interface exactly. Following the modification of Eq. 18, however, and in order to eliminate the enrichment function along the non-cut boundaries of the overlay patch, we opt for a polynomial degree of \(p=5\) for the interpolation. At the same time, we choose \(p=8\) for the polynomial order of the Ansatz on the base and overlay cells. This enrichment process, which is illustrated in Fig. 33, results in a proper agreement with the reference solution. Fig. 34 shows the convergence study in terms of Eq. 24 for the FCM and hp-d/PUM-FCM. The polynomial degrees of \(N_i\) in Eq. 10 and \(N^*_j\) in Eq. 17 of the said convergence study are increased simultaneously by the same amount. It is clear that enriching the FCM not only influences the stress distribution but also considerably improves the convergence rate. These two interesting properties allow us to successfully employ the hp-d/PUM-FCM approach in cells containing both material interfaces and holes.

4.6 Heterogeneous material

The last example that we contemplate in this paper is a two-dimensional plate with a heterogeneous material, which is depicted in Fig. 35. The plate contains several inclusions as well as holes with circular and ellipsoidal geometries. The dimension of the plate under consideration is \(L \times L\) with \(L = 10\)mm and it is fixed in the vertical direction at the bottom and in the horizontal direction on the left- and right-hand sides. Moreover, a uniform normal traction is applied to the top of the plate, see Fig. 35. The material of the matrix is taken to be copper where its Young’s modulus is \(E_c=11.7\)GPa. The material of the inclusions is regarded as steel with a Young’s modulus of \(E_s=21\)GPa. The experiment is based on the assumption of plane stress conditions.

The domain of interest is discretized employing the hp-d/PUM-FCM approach. In this regard, a base mesh with \(8 \times 8\) FCM cells is chosen to discretize the entire domain. The cells on the base mesh may include a combination of holes and different materials. Following the proposed approach, those cells on the base mesh that exhibit inclusions are equipped with an overlay cell. Each of these cells is a high-order cell which may cover several cells of the base mesh. The enrichment term corresponding to the inclusions is defined on the overlay cells based on the PUM approach. That is to say, the enrichment function is described with the aid of Eq. 18 where \(M_j\) is described in terms of the high-order Lagrange shape functions with Chen–Babuška points based on a polynomial order of \(p=5\). The base mesh and the overlay cells are illustrated in Fig. 36. It is worth mentioning that there are both inclusions and holes on the overlay cells. However, the enrichment function is merely defined for the inclusion part, whereas the holes are treated in the fictitious sense.

The Ansatz space with \(p=8\) is considered on the base mesh. The polynomial order of the enrichment term on the overlay cells, cf. Eq. 17, is also taken to be \(p=8\). Concerning the quadrature of the cells of the base and overlay cells, we employ an adaptive integration algorithm based on the quadtree method. The subcells that are generated by this algorithm are depicted in Fig. 37.

In order to assess the accuracy of the solution, the von Mises stress along the cut line \(AA^{\prime }\) is compared to the reference solution. The reference solution is obtained from an overkill solution applying the commercial finite element simulation software Abaqus [54]. In the Abaqus computation the domain of interest is resolved by means of a sufficiently fine conforming low-order quadrilateral mesh. This simulation is based on the 4-node bilinear plane stress quadrilateral elements. As can be seen in Fig. 38, there is a good agreement between the hp-d/PUM-FCM solution and the reference solution obtained with Abaqus. The stresses are accurate in the vicinity of the holes and inclusions. The jump in the stresses, which is due to the presence of the inclusions, is likewise approximated precisely.

5 Conclusion

The FCM is an efficient discretization strategy allowing for high convergence rates without the burden of mesh generation. In the presence of discontinuities and singularities, however, the standard FCM, which is based on smooth hierarchic shape functions of high order, the convergence rate is much lower. In order to maintain the efficiency, we propose a refinement strategy employing the hp-d method. In this way, the FCM approximation can be improved on a local level in two different ways—either by superimposing a local h-, p- or hp-refinement or by taking advantage of the PUM in order to locally enrich the FCM approximation with carefully selected functions. Both strategies are based on an overlay mesh, which is superimposed over the base mesh to which the FCM is applied. The proposed strategy makes it possible to treat different types of discontinuities and singularities in a very general way. In this paper we have taken a look at weak discontinuities introduced by material interfaces. Whereas in the hp-d-FCM approach a mesh resolving the material interfaces is superimposed locally, the hp-d/PUM-FCM takes advantage of carefully selected enrichment functions of arbitrary order. We used several numerical examples to demonstrate that both approaches significantly improve the FCM approximation. In addition to high convergence rates, we have shown that the stresses, even those across the material interfaces, are very accurate. While the hp-d-FCM approach is a very accurate, general approach, the hp-d/PUM-FCM has turned out to be even more efficient, since the high-order PUM introduces only very few additional degrees of freedom while yielding the same accuracy as the hp-d-FCM. So far, only two-dimensional problems have been taken into consideration. Future work will focus on three-dimensional problems and nonlinearities, which are very important for engineering applications.

References

Cottrell JA, Hughes TJR, Bazilevs Y (2009) Isogeometric analysis: towards indegration of CAD and FEM. Wiley

Moës N, Dolbow J, Belytschko T (1999) A finite element method for crack growth without remeshing. Int J Numer Methods Eng 64:131–150

Duarte C, Babuška I, Oden J (2000) Generalized finite element method for three-dimensional structural mechanics problems. Comput Struct 77(2):215–232

Sukumar N, Chopp D, Moës N, Belytschko T (2001) Modeling holes and inclusions by level sets in the extended finite-element method. Comput Methods Appl Mech Eng 190:6183–6200

Kim DJ, Pereira JP, Duarte CA (2010) Analysis of three-dimensional fracture mechanics problems: a two-scale approach using coarse-generalized fem meshes. Int J Numer Methods Eng 81:335–365

Areias PMA, Belytschko T (2005) Analysis of three-dimensional crack initiation and propagation using the extended finite element method. Int J Numer Methods Eng 63:760–788

Guidault P, Allix O, Champaney L, Cornuault C (2008) A multiscale extended finite element method for crack propagation. Comput Methods Appl Mech Eng 197:381–399

Giner E, Sukumar N, Denia F, Fuenmayor F (2008) Extended finite element method for fretting fatigue crack propagation. Int J Solids Struct 45:5675–5687

Chessa J, Smolinski P, Belytschko T (2002) The extended finite element method (xfem) for solidification problems. Int J Numer Methods Eng 53:1959–1977

Groß S, Reusken A (2007) An extended pressure finite element space for two-phase incompressible flows with surface tension. J Comput Phys 224:40–58

Gerstenberger A, Wall W (2008) An extended finite element method/Lagrange multiplier based approach for fluid-structure interaction. Comput Methods Appl Mech Eng 197:1699–1714

Mayer UM, Gerstenberger A, Wall WA (2009) Interface handling for three-dimensional higher-order xfem-computations in fluidstructure interaction. Int J Numer Methods Eng 79: 846–869

Glowinski R, Kuznetsov Y (2007) Distributed Lagrange multipliers based on fictitious domain method for second order elliptic problems. Comput Methods Appl Mech Eng 196:1498–1506

Ramiàere I, Angot P, Belliard M (2007) A general fictitious domain method with immersed jumps and multilevel nested structured meshes. J Comput Phys 225:1347–1387

Parvizian J, Düster A, Rank E (2007) Finite cell method—h- and p-extension for embedded domain problems in solid mechanics. Comput Mech 41:121–133

Düster A, Parvizian J, Yang Z, Rank E (2008) The finite cell method for three-dimensional problems of solid mechanics. Comput Methods Appl Mech Eng 197:3768–3782

Rank E, Ruess M, Kollmannsberger S, Schillinger D, Düster A (2012) Geometric modeling, isogeometric analysis and the finite cell method. Comput Methods Appl Mech Eng 249–252: 104–115

Düster A, Sehlhorst HG, Rank E (2012) Numerical homogenization of heterogeneous and cellular materials utilizing the finite cell method. Comput Mech 50:413–431

Parvizian J, Düster A, Rank E (2011) Topology optimization using the finite cell method. Optimiz Eng 13:1–22

Düster A, Parvizian J, Yang Z, Rank E (2007) A high order fictitious domain method for patient specific surgery planning. In: Proceedings of APCOM’07 in conjunction with EPMESC XI. Kyoto, Japan

Ruess M, Tal D, Trabelsi N, Yosibash Z, Rank E (2012) The finite cell method for bone simulations: verification and validation. Biomech Model Mechanobiol 11:425–437

Ruess M, Schillinger D, Bazilevs Y, Rank E (2011) The B-spline version of the finite cell method for linear and nonlinear analysis of complex geometry. In: IGA conference. Austin, Texas

Yang Z, Kollmannsberger S, Düster A, Ruess M, Garcia E, Burgkart R, Rank E (2012) Non-standard bone simulation: interactive numerical analysis by computational steering. Comput Vis Sci 14:207–216

Yang Z, Ruess M, Kollmannsberger S, Düster A, Rank E (2012) An efficient integration technique for the voxel-based finite cell method. Int J Numer Methods Eng 91:457–471

Schillinger D, Ruess M, Zander N, Bazilevs Y, Düster A, Rank E (2012) Small and large deformation analysis with the p- and B-spline versions of the finite cell method. Comput Mech 50:445–478

Abedian A, Parvizian J, Düster A, Khademyzadeh H, Rank E (2010) The finite cell method for elasto-plastic problems. In: Proceedings of the tenth international conference on computational structures technology (Civil-Comp Press)

Rank E, Kollmannsberger S, Sorger C, Düster A (2011) Shell finite cell method: a high order fictitious domain approach for thin-walled structures. Comput Methods Appl Mech Eng 200:3200–3209

Schillinger D, Rank E (2011) An unfitted \(hp\) adaptive finite element method based on hierarchical B-splines for interface problems of complex geometry. Comput Methods Appl Mech Eng 200: 3358–3380

Schillinger D, Düster A, Rank E (2012) The \(hp\)-\(d\)-adaptive finite cell method for geometrically nonlinear problems of solid mechanics. Int J Numerl Methods Eng 89:1171–1202

Chen Q, Babuška I (1995) Approximate optimal points for polynomial interpolation of real functions in an interval and in a triangle. Comput Methods Appl Mech Eng 128:405–417

Szabó B, Babuška I (1991) Finite element analysis. Wiley

Szabó B, Düster A, Rank E (2004) The p-version of the Finite Element Method. In: Stein E, de Borst R, Hughes TJR (eds) Encyclopedia of computational mechanics, vol 1, Chap 5. Wiley, pp 119–139

Düster A, Bröker H, Rank E (2001) The p-version of the finite element method for three-dimensional curved thin walled structures. Int J Numer Methods Eng 52:673–703

Abedian A, Parvizian J, Düster A, Khademyzadeh H, Rank E (2012) Performance of different integration schemes in facing discontinuites in the Finite Cell Method. Int J Comput Methods 10:1350002

Ventura G (2006) On the elimination of quadrature subcells for discontinuous functions in the extended finite-element method. Int J Numer Methods Eng 66:761–795

Moumnassi M, Belouettar J, Béchet E, Bordas S, Potier-Ferry QDM (2011) Finite element analysis on implicitly defined domains: an accurate representation based on arbitrary parametric surfaces. Comput Method Appl Mech Eng 200:5–8

Mousavi SE, Sukumar N (2011) Numerical integration of polynomials and discontinuous functions on irregular convex polygons and polyhedrons. Computl Mech 47:535–554

Cheng K, Fries TP (2009) Higher-order XFEM for curved strong and weak discontinuities. Int J Numer Methods Eng 82:564–590

Abdelaziz Y, Hamouine A (2008) A survey of the extended finite element. Comput Struct 86:1141–1151

Belytschko T, Gracie R, Ventura G (2009) A review of extended/generalized finite element methods for material modeling. Model Simul Mater Sci Eng 17:043001

Fries TP, Belytschko T (2010) The extended/generalized finite element method: an overview of the method and its applications. Int J Numer Methods Eng 84:253–304

Rank E (1992) Adaptive remeshing and h-p domain decomposition. Comput Methods Appl Mech Eng 101:299–313

Rank E, Krause R (1997) A multiscale finite-element-method. Comput Struct 64:139–144

Krause R, Rank E (2003) Multiscale computations with a combination of the h- and p-versions of the finite-element method. Comput Methods Appl Mech Eng 192:3959–3983

Düster A, Niggl A, Rank E (2007) Applying the \(hp\)-\(d\) version of the FEM to locally enhance dimensionally reduced models. Comput Methods Appl Mech Eng 196:3524–3533

Erbts P, Düster A (2012) Accelerated staggered coupling schemes for problems of thermoelasticity at finite strains. Comput Math Appl 64:2408–2430

Krause R (1996) Multiscale computations with a combined h- and p-version of the finite-element method. Ph.D. thesis, Fach Numerische Methoden und Informationsverarbeitung, Universität Dortmund

Lee SH, Song JH, Yoon YC, Zi G, Belytschko T (2004) Combined extended and superimposed finite element method for cracks. Int J Numer Methods Eng 59:1119–1136

Dréau K, Chevaugeon N, Moës N (2010) Studied x-fem enrichment to handle material interfaces with higher order finite element. Comput Methods Appl Mech Eng 199:1922–1936

Moës N, Cloirec M, Cartraud P, Remacle JF (2003) A computational approach to handle complex microstructure geometries. Comput Methods Appl Mech Eng 192:3163–3177

Eaton JW (2002) GNU Octave Manual. Network Theory Limited

Düster A, Kollmannsberger S (2010) AdhoC\(^{4}\)—User’s Guide. Lehrstuhl für Computation in Engineering, TU München, Numerische Strukturanalyse mit Anwendungen in der Schiffstechnik, TU Hamburg-Harburg

Királyfalvi G, Szabó B (1997) Quasi-regional mapping for the p-version of the finite element method. Finite Elements Anal Des 27:85–97

Acknowledgments

The authors gratefully acknowledge the support provided by the Deutsche Forschungsgemeinschaft (DFG) under grant DU405/4-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joulaian, M., Düster, A. Local enrichment of the finite cell method for problems with material interfaces. Comput Mech 52, 741–762 (2013). https://doi.org/10.1007/s00466-013-0853-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-013-0853-8