Abstract

The objective of this study was to examine the relationships among three categories of measurements (rheological, sensory texture, and swallowing pressure) from fluids thickened to two different viscosities with 15 different hydrocolloids. Fluids at viscosities of 300 and 1500 cP (at 30 s−1) were targeted because these are the viscosities corresponding to the barium standards used in radiographic dysphagia diagnosis. Within the low viscosity (nectar) fluids (300 cP), the sensory properties thickness, stickiness, adhesiveness, mouth coating, and number of swallows were highly positively correlated with each other and highly positively correlated with the flow behavior index, n value (an indicator of shear-thinning behavior). Within the higher viscosity (thin honey) fluids (1500 cP), the sensory textures of adhesiveness, stickiness, mouth coating, and number of swallows correlated positively with rheological measures of n value. Swallowing pressures measured in the anterior oral cavity correlated negatively with the consistency coefficient k [shear stress/(shear rate)n]. Samples that were more shear thinning (lower n values, higher k values) were generally perceived as less thick, with less adhesive properties (stickiness, adhesiveness, mouthcoating, and number of swallows). This information can be useful for selecting thickeners for people with dysphagia. A desirable thickener for many dysphagic patients would be one that allowed for a safe swallow by being viscous enough to reduce airway penetration, yet pleasant to drink, having the minimal perceived thickness and mouthcoating associated with greater shear thinning.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The lifetime prevalence of a swallowing disorder is 38 % [1]. Without effective diagnosis and treatment, dysphagia can lead to dehydration, malnutrition, reduced rehabilitative potential after injury or illness, pulmonary complications related to chronic aspiration, associated reductions in quality of life [2–5], and even death.

Dysphagia can result in choking or aspiration when swallowing thin liquids, semi-solid, or solid foods. Because of the risk of aspiration, fluid intake may be curtailed, leading to inadequate hydration of patients with impaired swallowing [6, 7]. Modifications to the texture of liquids, such as increase in the viscosity, have been used to promote safe swallowing [8–10]. By thickening liquids, oropharyngeal transit time is increased, and a more cohesive bolus is created, thus compensating somewhat for the swallowing deficit [11, 12]. Commercial thickening agents are often used because of ease of preparation, convenience, reasonable cost, and the suspending ability of the thickened beverages [9, 10].

Rheology

The majority of thickened beverages are non-Newtonian [13], and thus exhibit both viscous and elastic properties. The rheological behavior of these fluids depends on the shear rate. The viscosity of non-Newtonian fluids is expressed as apparent viscosity (η a), defined as the ratio of shear rate to shear stress, specified for a given shear rate. However, the shear rate appropriate for swallowing is still the subject of debate.

In an effort to standardize thickened beverages used in the treatment and/or management of dysphagia, the National Dysphagia Diet Task Force set forth the following suggested categories to describe viscosities based on instrumental viscosity ranges as thin (1–50 cP), nectar-like/syrup-like (51–350 cP), thin honey-like (351–1750 cP), and pudding-like/spoon-thick (>1750 cP), measured at 50 s−1 and 25 °C. A shear rate of 50 s−1 was chosen by the task force, based on the average shear rate suggested by Wood [14] for the human swallow. This shear rate was intended as a starting point for the creation of national standards for dysphagic patients; the marker will undoubtedly be changed as more research is accumulated [15]. Disparities between the rheology of prethickened treatment fluids and diagnostic fluids are an ongoing concern in the treatment or management of dysphagia [16–18] (Ould Eleya and Gunasekaran [16]; Payne [17]; Brito-de la Fuente, 1[8]), with the standards being designed to target apparent viscosity at a shear rate of 30 s−1, rather than 50 s−1.

Shear-thinning fluids are those where η a decreases as shear rate increases. The power law model describes shear-thinning behavior:

where σ is the shear stress in Pa, K is the consistency coefficient at a shear rate of 1 s−1, \( \dot{\gamma }^{n} \) is shear rate (s−1), and the exponent n is the dimensionless flow behavior index which reflects closeness to Newtonian flow. The farther that n departs from one, the greater is the deviation from Newtonian flow. Fluids having flow index values less than 1.0 show shear-thinning properties, i.e., lower the value of n, the greater the shear-thinning behavior. The apparent viscosity of shear-thinning fluids will decrease as the shear rate increases, at constant shear stress. The consistency coefficient (K) is an indication of the relationship between the shear stress and shear rate. A higher consistency coefficient indicates that a greater shear stress must be applied to a fluid to effect the same change in shear rate [19].

The Herschel–Bulkley model is a modification of the power law model that includes yield stress

where σ o is the yield stress in Pa. Yield stress is the minimum shear stress that needs to be exerted on a fluid to initiate flow. Below the yield stress, a fluid exhibits solid-like behavior [20]. When yield stress is zero, the equation simplifies to the power law model. While the concept of yield stress is the subject of some debate, it may be a useful parameter in the development of thickened fluids for the treatment of dysphagia. Since fluids with a higher yield stress require a greater force to initiate flow, this may facilitate manipulation of the bolus, initiating the pharyngeal swallow, as well as impact sensory perception of thickness.

Sensory Evaluation of Liquids

Sensory evaluation of texture is a highly dynamic process because the physical properties of foods change continuously when they are manipulated in the mouth. Not even the most sophisticated piece of machinery, whether it be a texture analyzer or a viscometer, has been able to reproduce accurately and comprehensively all the events that take place in the mouth upon ingestion of a food or beverage [21].

Oral processing of a thickened beverage involves three different stages: initial introduction into the mouth, manipulation in the mouth, and swallowing. When a thickened beverage is introduced into the mouth, it is first positioned and pressed against the palate by the tongue. The filiform papillae, which coat the dorsal surface of the tongue but do not contain any taste buds, are responsible for keeping the food in place on the tongue. Foods are moistened by saliva and hence subjected to changes in texture. Saliva mixes with the thickened beverage (acting as a diluent and lubricant), and the tongue muscles move the food toward the throat. The bolus is monitored for its readiness for swallowing by evaluating its texture and finally swallowed, with the help of muscles in the pharynx and upper esophagus [22].

Matta et al. [5] used a modified texture profile method to describe the sensory characteristics of beverages prepared with commercial thickeners used for dysphagia diets. They found that starch-based thickeners imparted a grainy texture, gum-based thickeners imparted a higher “slickness”, and thickness generally was higher in beverages prepared with starch-based thickeners.

Although mouthcoating has received far less academic attention compared to thickness, Carvalho-da-Silva et al. [23] have shown that higher ratings of mouthcoating (from chocolate) were associated with longer in-mouth residence time and a greater number of swallows needed to clear the mouth. Thus, fluids that exhibit higher mouthcoating may increase the amount of time and effort needed for dysphagic patients to swallow them.

Relationships Among Rheological, Sensory, and Instrumental Measurements

The rheological properties are important determinants of the sensory assessment of fluid and semi-solid foods. Szczesniak [24] observed that sensory viscosity showed a curvilinear relation with the instrumental viscosity—the sensory viscosity increased more per unit of instrumental viscosity at high levels of instrumental viscosity than at low levels of instrumental viscosity. Adhesiveness increased linearly with an in increase in instrumental adhesiveness. Kokini et al. [25] found that sensory thickness was related to the viscous force between the tongue and the roof of the mouth and that sensory slipperiness was related to the reciprocal of the average of viscous and frictional forces. Aime et al. [26] found that mouthcoating was positively correlated with apparent viscosity and the consistency coefficient. Carvalho-da-Silva et al. [27] found that greater mouthcoating of chocolate was associated with a higher coefficient of friction in the range of sliding speeds occurring in the mouth.

Swallowing Biomechanics

Tongue activity plays a crucial role in both oral and pharyngeal phases of swallowing. This tongue activity has traditionally been quantified by recording swallowing pressures at three lingual sites (tip, blade, and dorsum) as the tongue hits the palate of the mouth during swallowing [28]. Increased bolus thickness has consistently increased lingual swallowing pressure [29–32]. However, the biomechanics of thickened beverage swallowing may be related to instrumental parameters other than apparent viscosity. Sensory textural attributes, such as thickness, adhesiveness, slipperiness, and mouthcoating may also contribute to the swallowing biomechanics.

Objective

The objective of this study was to examine the relationships among three categories of measurements (rheological, sensory texture, and swallowing pressure) from fluids thickened to two different viscosities. Fluids with apparent viscosities of 300 ± 30 cP (nectar) and 1500 ± 100 cP (thin honey) at 30 s−1 (Bracco Diagnostics, Inc.) were targeted because these are the viscosities corresponding to the bariums used most commonly in radiographic dysphagia diagnosis in the U.S. Fifteen different hydrocolloids were selected as thickeners, each used to produce nectar and thin honey consistencies. These thickeners were selected to represent a wide range of hydrocolloid categories, rheological properties, and sensory attributes.

Materials and Methods

Samples

The 15 thickeners listed in Table 1 were used to prepare 30 thickened beverages at nectar and thin honey viscosities. These beverages adhered to the apparent viscosities for nectar- and thin honey-like viscosities, i.e., η = 300 ± 30 cP for nectars and η = 1500 ± 100 cP for thin honeys at 22 °C, except that apparent viscosity was measured at a shear rate of 30 s−1 to match the diagnostic standards against which they were compared. (Additional information about these thickeners and fluid preparation is available in Supplemental Tables S1 and S2.)

All beverages were water based and made with a base liquid. The base liquid was sweetened with 3 % (w/w) sucrose, and pH was adjusted to approximately 4.45 ± 0.03 using citric acid (Tate & Lyle, Decatur, IL) and sodium citrate (Tate & Lyle), each added at approximately 0.1 %. Prepared samples were flavored using lemonade type flavor 645081 (Givaudan Flavors Corp., Cincinnati, OH).

Thickeners were mixed into the base liquid using a rotational mixer (Controller: Master Servodyne Controller, Cole Palmer Instrument Co., Chicago, IL; Rotational head: Model E650, 1/16–3/8 in CAP, 3/8–24 THD, Robbins Meyers Electro-craft, Hopkins, MN) equipped with a 12 × 5/16 in diameter stainless steel impeller shaft (Model A712, Caframo, Wiarton ON, Canada) and a 1.5 in stainless steel blade (Caframo).

The lemon flavor was added at 0.24 ± 0.01 % (v/w) of the final beverage to account for the differences in amount of thickener in each beverage. Some beverages had more complex manufacturing steps beyond thickener addition and mixing, such as extra ingredient addition or heating. For most beverages, the lemon flavor was added to the base liquid before the thickener, except the ones that were heated. A Corning stirrer-hot plate (Model PC-420, Corning Incorporated Life Sciences, Lowell, MA) was used for heating beverages. All beverages were stored in the refrigerator after they were made and for at least 24 h before testing the rheological properties. Prior to rheological profiling, densities of the fluids at 22 °C were measured using an 11.5 ml pycnometer (WU-38001-00, Cole-Parmer, Vernon Hills, IL).

Rheological Profiling

Apparent viscosities of the fluids manufactured for the sensory analysis were confirmed using Brookfield Ultra III HA and RV rheometers (Brookfield Engineering Labs, Middleboro, MA). Apparent viscosities of the fluids (30 s−1, 22 °C) fell within the prescribed parameters for nectars (300 ± 30 cP) or thin honey (1500 ± 100 cP) prior to sending the samples for sensory testing.

Full rheological testing was performed on the samples using a Discovery HR-3 rheometer (TA Instruments, New Castle, DE). Flow curves were determined using logarithmically stepped shear rates from 10,000 to 1 s−1. Apparent viscosity (30 s−1, 22 °C), flow index (n), consistency coefficient (K), and yield stress (σ o) were determined for all fluids by fitting to power law and Hershel–Bulkley models using TRIOS software. All samples were analyzed in triplicate.

Sensory Profiling

Subjects

Twenty-four subjects (6 males, 18 females) aged 19–58 with a median age of 26, were recruited from the University of Minnesota using an email screener. Subjects having a swallowing disorder or treatment thereof and/or any food allergies were excluded. Subjects were paid a cash incentive for their participation. The University of Minnesota Institutional Review Board approved this study.

Training Session

Individual beverage samples of 28 ml were removed from the refrigerator an hour before serving and served at room temperature in 60 ml Solo® cups labeled with random, 3-digit codes. New codes were generated for each test session.

Panelists attended one training session during the first week of the study. At the beginning of the session, they were provided with a lexicon that was based on the texture lexicon by Hootman [33]. This was modified with panelists input to describe relevant differences among the 30 products.

During the training session, each panelist was provided with a subset of ten different thickened beverages chosen as they best represented the entire set of 30 beverages in terms of thickness and mouthcoating, and included all chemical categories of thickeners. The different sensory attributes were illustrated by selecting samples from this set that varied perceivably in each sensory attribute. Panelists were asked to plug their nose using nose clips while rating tastes to avoid aromas. The remaining sensory attributes had to be rated without the nose clips. All flavors besides lemon flavor were to be considered together and rated on a scale for ‘Other Flavor.’ Panelists were also given instruction on how to rate the different textural attributes (i.e., thickness, adhesiveness, stickiness, slipperiness, and mouthcoating) (Table 2).

The panelists also learned a standardized sampling method to minimize variability in delivery as well as perception of the sensory attributes. The standardized sampling method ensured that each panelist evaluated the same amount of each sample. The standardized method required that they first gently stir the sample 30 times with a plastic spoon (Bakers and Chefs™ Plastic Spoons, Bentonville, Arkansas) in order to mimic the stirring done before instrumental measurements were taken. Panelists were prompted to do this for each beverage during the training and test sessions by computerized instructions. Panelists then filled the spoon full with the sample, leveled it off if necessary with a plastic coffee stirrer (Propak™ Coffee/Bar Stirrers), placed the nose clips on, put the spoonful of sample in their mouth, evaluated the sample for sweet, sour, and bitter tastes, removed the nose clips, and evaluated the sample for lemon and other flavor. (We had panelists rate these attributes to prevent them from ‘dumping’ these sensations into ratings of the texture attributes.) Panelists were permitted to expectorate this first spoonful of sample after evaluating it. Then, they consumed a second spoonful of the same sample and evaluated thickness, adhesiveness, stickiness, and slipperiness before swallowing. Mouthcoating and number of swallows required to cleanse the palate were evaluated after the second spoonful was swallowed.

Test Sessions

The 7 test sessions were divided into 4 sensory evaluation sessions, 1 lingual pressure measurement session, and 2 residual mouthcoating measurement sessions.

Sensory Evaluation Sessions

Panelists typically attended four sensory evaluation sessions during two consecutive weeks. The set of 30 thickened beverages was randomly divided into 2 groups of 15 beverages. The same 15 beverages were served to all panelists at each session. The position in which each of these 15 beverages was served at each session was determined by a design for 15 treatments in 2 blocks balanced for the effect of order of presentation and first-order carry-over effects [34]. Panelists sampled the complete set of 30 beverages in the first week (i.e., 15 beverages during session 1 and the remaining 15 during session 2). Similarly, all 30 beverages were sampled again through the second week.

The panelists tasted each beverage using the standardized sampling method described in the training session. At each session, the panelists rated each beverage for taste—sweet, sour, and bitter; flavor—lemon and other; and texture—thickness, adhesiveness, stickiness, slipperiness, mouthcoating, and the number of swallows required to clear the palate. Ratings for all these sensory attributes were collected on 15-point numerical category scale, with end-points of 0 and 15. The scale had tick marks labeled with numbers at regular intervals of 1 unit. Panelists could choose any point on the scale from 0 to 15, with end anchors “none” and “intense.” Panelists also recorded the number of swallows required to cleanse the palate after the thickened beverage was swallowed. The first swallow was not included in this rating. Twenty-two panelists completed all 4 sensory evaluation sessions.

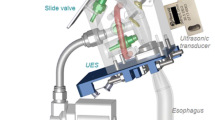

Lingual Pressure Measurement Session

Panelists attended one swallowing pressure measurement session. A 3-bulb array was inserted into their buccal cavity and bonded to their palate using Stomahesive™ (ConvaTec, USA) (Fig. 1). This bulb array was connected to a KayPentax Swallowing Workstation that recorded the pressure (mm Hg) exerted by the tongue on each pressure bulb as the panelist swallowed the sample. The panelists were fed a leveled spoonful of each of the complete set of 30 thickened beverages and asked to swallow the sample in a single swallow. The order in which each panelist was served these 30 beverages was determined by a 30 × 30 Latin square design balanced for order and carry-over effects, generated using DesignExpress® (Product Perceptions Ltd, Horley, Surrey, UK). Twenty-two panelists attended the swallowing pressure measurement session, but data collected from two panelists were not used due to discomfort caused by the lingual pressure array.

Residual Mouthcoating Measurement Session

Panelists attended two, hour-long residual mouthcoating measurement sessions during two consecutive weeks. One gl−1 of riboflavin (Sigma-Aldrich Co., St. Louis, MI) was incorporated into the base liquid of all the thickened beverages during preparation. The complete set of 30 thickened beverages was randomly divided into 2 groups of 15 beverages. At each session, all panelists were served the same set of 15 thickened beverages. The positions in which these 15 beverages were served was determined by a design for 15 treatments in 2 balanced blocks of 30 consumers each so as to balance the effect of order of presentation and first-order carry-over effects [34].

A rinse-and-expectorate protocol was developed that involved the following steps: panelists gently stirred the sample 30 times with a plastic spoon (Bakers and Chefs™ Plastic Spoons, Bentonville, Arkansas), filled the spoon full with the sample, leveled it off if necessary with a plastic coffee stirrer (Propak™ Coffee/Bar Stirrers), and swallowed this spoonful. Panelists then rinsed their mouth with 10 ml of water, swishing it three times inside the mouth, and spit this rinse water into a 16 oz. spit cup (Dart® Foam Cups, Mason, Michigan) labeled with the same code number as the sample. This rinse-and-expectorate protocol was repeated 5 times after swallowing each sample. (At the start of each session, panelists swallowed a spoonful of water instead of the thickened beverage sample, to familiarize them with the protocol as well as to remove food particles from their mouth.)

The riboflavin concentration in the rinse water from each judge for each sample was determined using a chemical analysis and fluorescent spectroscopy method [35]. The total riboflavin content in the rinse water was calculated by multiplying this riboflavin concentration by the volume of rinse water. The total riboflavin content was considered to be a measure of residual mouthcoating.

Data Analysis

The raw data from the tests above were compiled on Microsoft Excel sheets. Statistical analyses were carried out using SAS computer software (The SAS System for Windows™, Version 9.2, The SAS Institute Inc., Cary, NC) and XLSTAT ™ 2013 (Addinsoft SARL, New York, NY). Unless otherwise noted, statistical significance was set at 0.05. Although the taste and flavor measurements varied among the beverages, they were unrelated to any of the rheological, sensory texture, or swallowing pressure measurements and are not included in any data analyses reported here.

Linear regression (SAS PROC REG) was used to relate sensory and swallowing pressure measurements to the three rheological measurements (apparent viscosity, K value, and n value). Analyses were done separately for thin honey beverages and nectar beverages to visualize relationships within each of the two viscosity ranges.

Principal components analysis with Varimax rotation (XLSTAT®) was used to summarize the relationships among the three groups of measurements (sensory, rheological, and swallowing pressure) for the nectar and the thin honey beverages separately. The main data set for each principal components analysis contained the 15 beverages as observations and the rheological measurements as variables. Sensory texture measurements and swallowing pressures for each of the 15 beverages were added as supplementary variables.

The relationship between the sensory perception of mouthcoating and the instrumental measurement was examined for predicting mouthcoating using linear regression. The dependent variable was the sensory perception of mouthcoating; the instrumental measurement of residual riboflavin served as a predictor. Each judge was included in the model as a dummy variable.

Results

The relatively huge differences in viscosity between the two thickness levels (nectar and thin honey) overwhelmed comparisons among the thickeners, so the observations below have been separated into those for the nectar beverages and those for the thin honey beverages. The beverages within these subsets had very similar apparent viscosities, thus shifting the focus towards relationships of the other rheological properties with the sensory and swallowing measurements.

Supplemental Tables S3, S4, and S5 contain mean values of the rheological measurements, sensory measurements and swallowing pressure measurements, respectively.

Rheology and Density

The beverage samples exhibited a range of rheological behaviors at both thicknesses (Table S3). While all of the fluids met the target parameters for apparent viscosity at 30 s−1 when measured on the Brookfield rheometers, there were some variations among the apparent viscosities when the same samples were measured on the TA rheometer: some of the values fell outside of the target ranges, but most were not found to be significantly different (p < 0.05). Using the power law fit, flow indices (n values) for nectars varied from 0.24 to 0.86, whereas for thin honeys, n values varied from 0.24 to 0.77. Consistency (K) for nectars ranged from 280 cP to 4000 cP, whereas for thin honeys, K ranged from 2200 to 26,000 cP.

For many of the thickened solutions evaluated, Hershel–Bulkley predicted negative values for yield stress. Therefore, those parameters were not included in any further analysis. Further attempts were made to measure yield stress directly but the results were highly variable. Flow curves of the solutions showed no evidence of plateaus in stress values even when low shear rates (10−1–10−4 s−1) were used, so measurement of yield stress was not pursued for this work.

Densities of the fluids were not found to vary significantly among the samples, with both nectars and thin honeys in the range from 1.03 to 1.07 g ml−1. Therefore, density was not included in further analyses.

Nectar Beverages

The sensory properties thickness, stickiness, adhesiveness, mouthcoating, and number of swallows were highly negatively correlated with principal component 1, and highly positively correlated with the flow behavior index (n value) (Fig. 2; Table 3). Slipperiness was negatively correlated with n value and with all the other sensory texture attributes. Principal component 2 and apparent viscosity were not significantly correlated with any of the sensory or swallowing pressure measurements. This was not surprising because η a for either nectar or thin honey fluids was intended to be the same. Although bulb 1 and bulb 2 pressures were significantly correlated with each other, they were not significantly related to any of the principal components, or to any rheological measurements (Fig. 2; Table 3).

Principal components plot showing relationships among rheological, sensory, and swallowing pressure measurements for nectar beverages. The first component (horizontal axis) is highly positively correlated with K value (consistency coefficient) and highly negatively correlated with n value (flow behavior index). The second component is strongly positively correlated with apparent viscosity

Panelists rated high methoxyl pectin, methyl cellulose, calcium caseinate, and low methoxyl pectin relatively more intense than other thickeners for stickiness, adhesiveness, thickness, and mouthcoating. Flow indices for these fluids ranged from 0.77 to 0.86, so they tended to have more Newtonian flow than the other samples. Xanthan gum, extra stable waxy rice starch, agar, microcrystalline cellulose, and acetylated distarch phosphate were rated relatively lower on those thickness and adhesive–related attributes, and higher for slipperiness. These samples had the lowest n values (0.22–0.49) among the prepared nectar samples (Table S3; Fig. 3).

Principal components plot for nectar beverages showing the factor scores for the 15 thickeners. The first component (horizontal axis) is highly positively correlated with K value (consistency coefficient) and highly negatively correlated with n value (flow behavior index). The second component is strongly positively correlated with apparent viscosity

The sensory attributes thickness, adhesiveness, stickiness, mouthcoating, and number of swallows were highly correlated with each other (all r > 0.93; computed across means of the 15 nectar beverages). The n value was positively correlated (0.82 < r < 0.87) and the k value was negatively correlated with all these sensory attributes (−0.75 < r < −0.59). None of the rheological measurements were significantly related to the swallowing pressure measurements (−0.23 < r < 0.32).

Thin Honey Beverages

The sensory properties adhesiveness, stickiness, mouthcoating, and number of swallows were positively correlated (r > 0.54) with component 1 and with the n value (Fig. 4; Table 4). Slipperiness was negatively correlated with principal component 1, with the n value and with all the other sensory texture attributes. Bulb 1 and bulb 2 pressures were significantly correlated with each other and had correlations of 0.45 and 0.44, respectively, with principal component 1. Both bulb 1 and bulb 2 pressures were negatively correlated to K value, and were positively correlated to n value. Bulb 3 pressure was negatively correlated to slipperiness (r = −0.58).

Principal components plot showing relationships among rheological, sensory, and swallowing pressure measurements for thin honey beverages. The first component (horizontal axis) is highly positively correlated with n value (flow behavior index) and highly negatively correlated with K value (consistency coefficient) and yield stress. The second component is strongly positively correlated with apparent viscosity

The sensory attributes adhesiveness, stickiness, mouthcoating, and number of swallows were highly correlated with each other (all r > 0.94; computed across means of the 15 thin honey beverages). The n value was positively correlated with all these sensory attributes (0.68 < r < 0.75); the K value was negatively correlated with all these sensory attributes (−0.58 < r < −0.52). Bulb 2 pressure was negatively related to the K value (r = −0.40). Bulb 1 and 3 pressures were uniquely related, but not significantly correlated with any of the rheological measurements (Table 4).

Panelists rated calcium caseinate, low methoxyl pectin, methyl cellulose, and high methoxyl pectin (n values ranging from 0.67 to 0.77) relatively more intense for stickiness, adhesiveness, mouthcoating, and number of swallows. Those samples had the highest n values, i.e., they were the least shear thinning among the thin honey samples. Xanthan gum, iota carrageenan, microcrystalline cellulose, and agar (n values ranged from 0.23 to 0.40) were rated relatively lower on these attributes and relatively higher for slipperiness; those samples were the most shear thinning among the thin honeys. (Table S3; Fig. 5).

Principal components plot for thin honey beverages showing the factor scores for the 15 thickeners. The first component (horizontal axis) is highly positively correlated with n value (flow behavior index) and highly negatively correlated with K value (consistency coefficient) and yield stress. The second component is strongly positively correlated with apparent viscosity

Thickness was poorly correlated with either of the first two principal components—likely because all fluids were formulated to a similar apparent viscosity.

Sensory Attributes and Swallowing Pressures

Relationships among the swallowing pressures and the sensory attributes were generally weak, and even in the cases of significance, linear relationships had low R 2 values. Swallowing pressures for nectar beverages were negatively related to the number of swallows and positively related to thickness (Table 5). Swallowing pressures for thin honey beverages were not consistent among the three bulbs (Table 6).

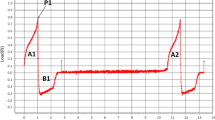

Residual Riboflavin as a Measure of Mouthcoating

The amount of riboflavin left in the mouth was positively correlated with the sensory mouthcoating scores. A 1 mg increase in riboflavin corresponded to a 4.1 unit increase in the sensory perception of mouthcoating (p < 0.001, Fig. 6). The amount of riboflavin left in the mouth plotted against the sensory mouthcoating scores showed a linear relationship (Fig. 6).

Discussion

Sensory evaluation of fluids does not occur at a constant shear rate. Instead people adjust the shear rates in the mouth to the consistency of the food they are consuming [36]. Shear rates in the mouth are generally lower for more viscous fluids and higher for less viscous fluids [37]. Likewise, successful prediction of sensory thickness from instrumental viscosity depends on the shear rate chosen for the instrumental measurement [25, 36, 38, 39]. Cutler et al. [38] predicted that the best correlation between sensory thickness and apparent viscosity of non-Newtonian fluid foods would be at a shear rate of 10 s−1. However, Wood [14] suggested an average shear rate of 50 s−1, which was adopted by the National Dysphagia Task Force for the standardization of treatment fluid viscosities even though η a of the diagnostic fluids commonly used for dysphagia were developed at an average shear rate of 30 s−1.

It is currently believed that there is large range of oral shear rates during swallowing, from 1 to 1000 s−1, based on observed flow characteristics of the bolus [17, 18]. At this point, no agreement on shear rate exists for perception of non-Newtonian foods [40]. Further, Nicosia [41] noted that the shear rates for a specific bolus during swallowing can vary across the duration of the swallow, and at a single time point, they can vary considerably from one region of that bolus to another. Houska et al. [42] showed that oral evaluation during swallowing of non-Newtonian fluids depended on viscosity, with a shear rate of approximately 12.7 s−1 at an equivalent instrumental viscosity of thin honey beverages [i.e., 1500 cP (mPa s)]. They also showed that oral evaluation during swallowing of non-Newtonian fluids with an equivalent instrumental viscosity of nectar beverages [i.e., 300 cP (mPa s)] occurred at a shear rate of approximately 70 s−1. Hasegawa, Otoguro et al. [43] reported a shear rate at swallowing of 10 s−1.

Based on the work of Houska et al. [42], one might expect that if rates closer to 10–12 s−1 for the thin honey beverages and closer to 70 s−1 for the nectar beverages had been used in this study, higher correlations may have been observed between the rheological properties of the beverages and their perceived thickness ratings. However, it also has been suggested in more recent work that great care is needed when using a single shear rate for the evaluation of non-Newtonian fluids: there may be dramatic differences among non-Newtonian fluids above and below the chosen shear rate, and that may have consequences beyond “thickness” perception [40]. These differences would likely be increasingly dramatic for very shear-thinning fluids.

Apparent viscosities of the nectar and thin honey fluids were achieved by way of thickener concentration; as concentrations increased, apparent viscosity and non-Newtonian behavior increased (n values decreased, K values increased). Formulating nectars and thin honeys to the shear rates suggested by Houska et al. [42] may have improved sensory correlations for more Newtonian fluids (higher n values), but there may be less distinction between very shear-thinning fluids. For example, in the case of thickened fluids with relatively high shear-thinning behavior (such as xanthan gum), thickener concentration for a fluid formulated to be 1500 cP at 12.7 s−1would begin to approach that of a fluid formulated to be 300 cP at 70 s−1.

Rao and Lopes da Silva [44] suggested that one reason shear-thinning non-Newtonian liquids are safer to swallow than thin Newtonian liquids is due to reduced fluid flow in the second half of the swallowing process. Reduced flow allows time for air passages (entry to the trachea and nasopharynx) to close completely, so a dysphagic patient is less likely to aspirate as they would with a Newtonian bolus. They also found that increased consistency coefficient (K value) of shear-thinning fluids significantly increased the time to swallow a critical volume of fluid (t cv), defined as the number of seconds to transport the first 1 ml of fluid into the esophagus. They assumed that the greater the value of t cv, the safer the swallow due to reduced risk of aspiration. O’Leary et al. [45] also noted that thickened liquids with greater shear thinning (low n value) may be more suitable for people with swallowing disorders because the high apparent viscosity at low shear rates prior to swallowing would prevent the fluid from rapidly running into the airway, and the shear thinning would make the fluid easy to swallow, requiring minimal muscular force. Thus, we would expect the fluids with relatively high shear thinning (fluids towards the right in Fig. 3 and towards the left in Fig. 5) to provide rheology more suitable for successful swallowing. Microcrystalline cellulose, agar, and xanthan gum exhibited these features at both nectar and thin honey consistencies (Figs. 3, 5). Acetylated distarch phosphate and extra stable waxy rice starch exhibited these features at a nectar consistency; iota carrageenan exhibited these features at a thin honey consistency. Nishinara et al. [13] provided some, but incomplete, evidence that more shear-thinning liquids (having relatively higher viscosities at low shear rates) were aspirated less than liquids with lower viscosities at lower shear rates. They suggested that these higher viscosities at lower shear rates might also alter the subjects’ perception of the bolus nearing the pharynx and airway (epiglottis).

Based on the rheological parameters measured, shear-thinning behavior (n value) and consistency coefficient (K) seemed to have the highest correlation with the sensory attributes studied. Samples that were more shear thinning (lower n values, higher K values) were generally perceived as less thick, with less adhesive properties (stickiness, adhesiveness, mouthcoating, and number of swallows) and greater slipperiness. Swallowing pressures did not appear to be significantly affected by the rheological parameters measured, or by sensory attributes.

Results of this study may be useful for selecting thickeners for people with dysphagia. A desirable thickener for many dysphagic patients would be one that allowed for a safe swallow (the fluid would have rheological properties that reduced airway penetration) yet be pleasant to drink (minimal perceived thickness, minimal mouth coating, and minimal off flavors). Additional research will be needed to select best combinations of thickeners that when mixed with beverages maximize desirable and minimize undesirable characteristics.

References

Roy N, Stemple J, Merrill RM, Thomas L. Dysphagia in the elderly: preliminary evidence of prevalence, risk factors, and socioemotional effects. Ann Otol, Rhinol Laryngol. 2007;116(11):858–65.

Adeleye B, Rachal C. Comparison of the rheological properties of ready-to-serve and powdered instant food-thickened beverages at different temperatures for dysphagic patients. J Am Diet Assoc. 2007;107:1176–82.

Lotong V, Chun S, Chambers E, Garcia J. Texture and flavor characteristics of beverages containing commercial thickening agents for dysphagia diets. J Food Sci. 2000;68(4):1537–41.

Macqueen CE, Taubert S, Cotter D, Stevens S, Frost GS. Which commercial thickening agent do patients prefer? Dysphagia. 2003;18(1):46–52.

Matta Z, Chambers E IV, Garcia JM, Helverson JMG. Sensory characteristics of beverages prepared with commercial thickeners used for dysphagia diets. J Am Diet Assoc. 2006;106(7):1049–54.

Pelletier CA, Lawless HT. Measuring taste acceptance in neurologically impaired adults. Food Qual Prefer. 2003;14(7):595–602.

Whelan K. Inadequate fluid intakes in dysphagic acute stroke. Clin Nutr. 2001;20(5):423–8.

Mills R. Rheology overview: control of liquid viscosities in dysphagia management. Nutr Clin Pract. 1999;14(5, suppl):S52–6.

Pelletier CA. A comparison of consistency and taste of five commercial thickeners. Dysphagia. 1997;12(2):74–8.

Stanek K, Hensley C, Van Riper C. Factors affecting use of food and commercial agents to thicken liquids for individuals with swallowing disorders. J Am Diet Assoc. 1992;92:488–90.

Crary MA, Groher ME. Introduction to adult swallowing disorders. St Louis: Butterworth-Heinemann; 2003.

Huckabee ML, Pelletier CA. Management of adult neurogenic dysphagia. San Diego: Singular Group Inc; 1999.

Nishinari K, Takemasa M, Su L, Michiwaki Y, Mizunuma H, Ogoshi H. Effect of shear thinning on aspiration—toward making solutions for judging the risk of aspiration. Food Hydrocoll. 2011;25(7):1737–43.

Wood FW. Psychophysical Studies on the consistency of liquid foods. Rheology and Texture of Foodstuffs, SCI Monograph, (1968). No. 27, p. 40.

National Dysphagia Diet Task Force. National dysphagia diet: standardization for optimal care. Chicago: American Dietetic Association; 2002.

OuldEleya MM, Gunasekaran S. Rheology of fluid foods for dysphagic patients. Appl Rheol. 2007;17:33137.

Payne C, Methven L, Bell A. Consistently inconsistent: commercially available starch-based dysphagia products. Dysphagia. 2009;26(1):27–33.

Brito-de la Fuente E, Ekberg O, Gallegos C. Rheological Aspects of Swallowing and Dysphagia. In: Eckberg O, editor. Dysphagia: diagnosis and treatment. New York: Springer; 2012. p. 493–506.

Rao MA. Rheology of liquid foods—a review. J Texture Stud. 1977;8(2):135–68.

Steffe JF. Rheological methods in Food Process Engineering. 2nd ed. East Lansing: Freeman Press; 1996.

Bourne MC. Food texture and viscosity concept and measurement. 2nd ed. San Diego: Academic Press; 2002. p. 257–80.

Szczesniak A. Psychorheology and texture as factors controlling the consumer acceptance of food. Cereal Foods World. 1990;35:1201–5.

Carvalho-da-Silva AM, Van Damme I, Wolf B, Hort J. Characterisation of chocolate eating behaviour. Physiol Behav. 2011;104:929–33. doi:10.1016/j.physbeh.2011.06.001.

Szczesniak AS. Classification of Textural Characteristics. J Food Sci. 1963;28(4):385–9.

Kokini J, Kadane J, Cussler E. Liquid texture perceived in the mouth. J Texture Stud. 1977;8(2):195–218.

Aime D, Arntfield S, Malcolmson L, Ryland D. Textural analysis of fat reduced vanilla ice cream products. Food Res Int. 2001;34:237–46.

Carvalho-da-Silva AM, Van Damme I, Taylor W, Hort J, Wolf B. Oral processing of two milk chocolate samples. Food Funct. 2013;4(3):461–9.

Hind JA, Nicosia MA, Gangnon R, Robbins JA. The effects of intraoral pressure sensors on normal young and old swallowing patterns. Dysphagia. 2005;20(4):249–53.

Miller JL, Watkin KL. The influence of bolus volume and viscosity on anterior lingual force during the oral stage of swallowing. Dysphagia. 1996;11(2):117–24.

Pouderoux P, Kahrilas PJ. Deglutitive tongue force modulation by volition, volume, and viscosity in humans. Gastroenterology. 1995;108(5):1418–26.

Shaker R, Cook IJS, Dodds WJ, Hogan WJ. Pressure-flow dynamics of the oral phase of swallowing. Dysphagia. 1988;3(2):79–84.

Nicosia MA, Hind JA, Roecker EB, Carnes M, Doyle J, Dengel GA, Robbins JA. Age effects on the temporal evolution of isometric and swallowing pressure. J Gerontol Ser A. 2000;55(11):M634–40.

Hootman RC. Manual on descriptive analysis testing for sensory evaluation. Philadelphia: ASTM International; 1992. p. 52.

MacFie HJ, Bratchell N, Greenhoff K, Vallis LV. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J Sens Stud. 1989;4(2):129–48.

Scott M, Hill F, Norris L, Heuser G. Chemical determination of riboflavin. J Biol Chem. 1946;165(1):65–71.

Shama F, Sherman P. Identification of stimuli controlling the sensory evaluation of viscosity II. Oral methods. J Texture Stud. 1973;4(1):111–8.

Engmann J, Burbidge AS. Fluid mechanics of eating, swallowing and digestion—overview and perspectives. Food Funct. 2013;4:443.

Cutler AN, Morris ER, Taylor LJ. Oral perception of viscosity in fluid foods and model systems. J Texture Stud. 1983;14:377–95.

Sherman P. Hydrocolloid solutions and gels. Sensory evaluation of some textural characteristics and their dependence on rheological properties. Prog Food Nutr Sci. 1982;6:266–84.

Stokes JR. Oral? rheology. Food oral processing. Oxford: Wiley-Blackwell; 2012. p. 225–63. doi:10.1002/9781444360943.ch11.

Nicosia MA. Theoretical estimation of shear rate during the oral phase of swallowing: effect of partial slip. J Texture Stud. 2013;. doi:10.1111/jtxs.12005.

Houska M, Valentova H, Novotna P, Strohalm J, Sestak J, Pokorny J. Shear rates during oral and nonoral perception of viscosity of fluid foods. J Texture Stud. 1998;29(6):603–15.

Hasegawa A, Otoguro A, Kumagai H, Nakazawa F. Velocity of swallowed gel food in the pharynx by ultrasonic method. J Jpn Soc Food Sci Technol. 2005;52:441–7.

Rao MA, Lopes da Silva JA. Role of rheological behavior in sensory assessment of foods and swallowing. In: Rao MA, editor. Rheology of fluid and semisolid foods: principals and applications. Second ed. New York: Springer; 2007. p. 403–17.

O’Leary M, Hanson B, Smith C. Viscosity and non-Newtonian features of thickened fluids used for dysphagia therapy. J Food Sci. 2010;75(6):E330–8.

Acknowledgments

This project was supported by National Research Initiative Grant 12143 from the USDA Cooperative state Research, Education and Extension Service, and the Wm. S. Middleton Memorial Veterans Hospital Geriatric Research, Education and Clinical Center (GRECC). This manuscript was partially prepared at the William S. Middleton Veteran Affairs Hospital in Madison, WI; GRECC manuscript #2015-015. The views and content expressed in this article are solely the responsibility of the authors and do not necessarily reflect the position, policy, or official views of the Department of Veteran Affairs or the U.S. government. This research was partly supported by the Minnesota Agricultural Experiment Station.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vickers, Z., Damodhar, H., Grummer, C. et al. Relationships Among Rheological, Sensory Texture, and Swallowing Pressure Measurements of Hydrocolloid-Thickened Fluids. Dysphagia 30, 702–713 (2015). https://doi.org/10.1007/s00455-015-9647-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00455-015-9647-9