Abstract

When a dysphagic infant is prescribed thickened infant formula (TIF) as a treatment method, some clinicians determine their own addition rates of thickener to meet the specific needs of the infant rather than relying on the directions on the tin. In this study the rheological behaviour of a TIF at different addition levels of thickener was measured to determine whether there was a difference in full rheological response and in viscosity. In addition, the time taken for the TIF to reach a near-stable viscosity was also measured. One hundred grams of Karicare® infant formula was made up according to the manufacturer’s instructions and Karicare® feed thickener was added at levels of 2, 3, 4, 5, and 6 g, respectively. A strain-controlled rheometer (ARES) with Couette geometry was used to rheologically characterise the TIF at the different levels of thickener addition. There was a significant difference in viscosity between the low levels and the higher levels of addition thickener (p < 0.05). Also, the low levels of thickener addition showed Newtonian-like behaviour, whereas the higher levels of addition were shear-thinning. The time taken for the thickener to reach a near-stable viscosity was found to be 10 min. Guidelines for thickened infant formula need to take into account the different levels of thickener addition rates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dysphagia, which is a disturbance in the well-coordinated action of the swallowing mechanism [1], is on the rise amongst infants due to the increased survival rate of those born prematurely or with developmental disorders [2]. Infants rely solely on milk for all their nutritional needs for at least the first 6 months of their lives. One of the standard treatments for dysphagia is thickening the milk. Thickened liquids flow more slowly than regular liquids, with slower flow allowing for improved swallowing safety [3]. Rempel and Moussavi [4] demonstrated in a cerebral palsy population that thickened liquids improved the timing of swallow reflex initiation relative to the bolus arriving at the pharynx, resulting in improved airway protection compared with thin liquids.

Over the past decade, only a handful of research papers on thickened infant formula (TIF) for infants with dysphagia have been published. Two of these papers compared the variability in viscosity between the assessment fluids and the treatment fluids, i.e., barium and the TIF [5, 6]. In another study, de Almeida et al. [7] compared the viscosity of the TIF to that of thickened human milk and concluded that an alternative to commercial starch thickeners was needed for thickening human milk because of the presence of the enzyme amylase in human milk which degrades the starch and hence reduces the desired viscosity. In a recent commentary paper, the need was expressed for interdisciplinary professional guidelines for thickened milk: both human milk and infant formula [8].

Some clinicians determine their own addition rates of thickener to meet the specific needs of the infant with dysphagia rather than rely on the directions on the tin (personal communication, Speech Pathology Department, Mater Children’s Hospital, Brisbane) [9]. Currently, there are no international guidelines for recommended thickness level. The Australian standardised terminology and definitions for texture modified foods and fluids [10] recommends that thickened milk for dysphagic infants needs to be less than Level 150, mildly thick [11]. To meet this thickness level in practice, the starting point for thickener addition is generally about half the prescribed amount as given in the manufacturer’s instructions (personal communication, K. Jardine, speech pathologist, Mater Children’s Hospital, Brisbane). The amount of thickener is gradually increased until clinical signs suggestive of aspiration or feeding coordination difficulties are no longer evident (e.g., coughing, wet vocalisation, increased respiratory rate) [12]. Seminal dysphagia textbooks advise starting at the lowest level of thickener addition to prevent aspiration [12, 13]. If the viscosity of the thickened liquid is too high, it may be too hard for the infant to extract from the bottle, resulting in fatigue and insufficient consumption. In addition to safety considerations, starch adds to the nutrient density of the TIF and thus will influence the daily caloric intake of the infant and may also influence the infant’s hydration levels [14]; thus, a low level of addition is desired.

For this study we postulated that an increase in the amount of thickener will increase the viscosity of the TIF, but it may also change the rheological behaviour of the TIF. This work quantitatively measured the viscosity of the TIF at different levels of thickener addition. Furthermore, the following research questions were specifically addressed: (1) What is the viscosity of the TIF at the different levels of thickener addition? (2) How long does it take for the TIF to reach a stable viscosity with the starch thickener? (3) Are the rheological properties of the TIF the same at the different addition levels of thickener?

Methods

Materials

Karicare® infant formula (“infant formula”) and Karicare® food thickener (“thickener”) (Nutricia Ltd., Auckland, New Zealand) were purchased from a local pharmacy. The infant formula is predominantly whey-based, with the whey-to-casein ratio 3:2, and includes 12 basic ingredients plus added minerals, vitamins, and probiotics. The thickener is composed of maltodextrin, starch from maize, and carob bean gum.

Sample Preparation

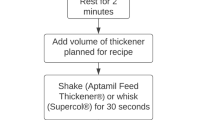

The thickened infant formula (TIF) was prepared following the manufacturer’s instructions for making 100 ml of formula but using accurately weighed amounts of infant formula (7.4 g = 1 scoop) and thickener (4 g = 1 scoop) rather than the suggested “scoops” to ensure reproducibility. Different weights of thickener, varying from 2 to 6 g, were used. The required amounts of infant formula and thickener were separately weighed out and added to 100 g of preweighed water (at 40 ± 2 °C) in a 260-ml Philips AVENT™ bottle. The bottle was shaken for 30 s to simultaneously mix the thickener and infant formula. This mixing time was found to be adequate to properly mix the powders and avoid lumps of undissolved powder. All samples were prepared and tested in triplicate. After mixing, 16 ml of the sample was withdrawn with a pipette and loaded into the cup of the rheometer for analysis.

Rheological Characterisation

All rheological measurements were performed in a strain-controlled rheometer [Advanced Rheometric Expansion System (ARES), TA Instruments Waters LLC, New Castle, DE, USA] with Couette geometry: cup diameter = 34 mm, bob diameter = 32 mm, and bob length = 34 mm. A water circulator kept the sample at 37 ± 1 °C. Both oscillatory and steady-shear tests were carried out.

For each thickener addition level, an oscillatory strain sweep was first performed at 10 rad/s to determine an appropriate strain (%) for further tests. The desired strain was one that gave an acceptable torque signal in the rheometer but still fell within the linear viscoelastic region (LVR) of the material, i.e., the measured viscosity in the rheometer was independent of the applied strain magnitude, indicating that the deformation was not altering the material structure. The chosen strains varied from 25 % for the lowest level of added thickener to 3 % for the highest, with thinner liquids requiring a higher strain and vice versa, as seen in Table 1.

Thickening Dynamics

Time sweeps were performed to establish the thickening profile of the different addition levels of TIF. Oscillatory time sweeps were run for 45 min to examine the time-dependent behaviour of the TIF at the different thickener addition levels. All measurements were performed at a strain rate of 10 rad/s and the strain as determined above (Table 1). This produced a measurable torque (converted to a stress value) from which the resulting dynamic viscosity (denoted as |η*|) was calculated. This dynamic viscosity is not the same as the steady-shear viscosity, η. However, measuring the dynamic viscosity is relevant as it allows us to observe the time-dependent thickening behaviour of the sample.

Viscosity Profile

The steady-shear viscosity was measured as a function of strain rate by means of a steady rate sweep. Steady rate sweeps were performed over a shear rate range of 1–100 s−1, 10 min after the sample had been prepared and loaded into the rheometer to ensure that the measurements were taken when the thickener had reached a near-stable state.

Statistical Analysis

All rheological tests were done in triplicate, and Minitab v16 statistical software was used to perform the statistical analysis by means of analysis of variance (ANOVA). A p value <0.05 is considered significantly different. Furthermore, t test comparisons were performed using the Fisher method to categorise the differences in viscosities between the different mean addition rates of thickener.

Results

Thickening Dynamics

Figure 1 shows the time sweep graphs of the different addition levels of thickener. These show the change in viscosity of the TIF as a function of time from when the samples were made. As expected, an increase in the amount of thickener leads to an increase in the viscosity. However, it is important to note that this is not a linear increase but a power law increase since the y axis is a logarithmic scale (Fig. 1). From Fig. 1 it can be seen that for the first 10 min there was a sharp, approximately threefold increase in viscosity for all levels of thickener addition. Subsequently, a dramatic reduction in the rate of increase in viscosity is seen. The 2- and 3-g addition levels of thickener showed a plateau viscosity being reached within the 45 min. On the other hand, the 4-, 5-, and 6-g addition levels of thickener show a continued increase in viscosity over the 45-min period, but at a much reduced rate. In fact, viscosity values increased only 1.5 times between 10 and 40 min, as opposed to the threefold increase in the first 10 min. Thus, we concluded in all cases that the viscosity of TIF reaches a near-stable value after 10 min.

The relationship between concentration and dynamic viscosity, as derived from the data of Fig. 1, is

where |η*| is the dynamic viscosity in Pa s and c is the concentration in g/100 g

Viscosity Profile

Figure 2 shows the steady-shear viscosity as a function of shear rate, 10 min after the sample had been mixed. As anticipated, the graph shows a direct correlation between the amount of thickener added and the viscosity. At the higher addition levels, the viscosity decreases as the shear rate increases. These are, therefore, shear-thinning fluids. The lower levels of thickener addition (2 and 3 g) exhibit Newtonian-like behaviour and these are not shear-thinning.

As stated above, an increase in the amount of added thickener leads to an increase in viscosity; this phenomenon is presented in Table 2. The mean steady-shear viscosity values at 50 s−1 are given in Table 2. A shear rate of 50 s−1 was chosen to be representative of the shear rate associated with swallowing, in accordance with the shear rate quoted in the literature [5, 6]. All levels of thickener addition differed significantly from each other (p < 0.001).

The relationship between concentration and steady-shear viscosity, as derived from the data of Fig. 2, is

where η is the steady-shear viscosity in Pa s and c is the concentration in g/100 g.

Discussion

We found that by increasing the addition rate of the thickener from 2–3 to 5–6 g/100 g, the behaviour of the thickened infant formula is very different, i.e., it changes from Newtonian-like behaviour to shear-thinning behaviour (non-Newtonian). This is important in clinical practice because as the flow rate is reduced, fluid becomes thicker and it may lead to reduced feeding due to the additional effort to extract the thicker material from the bottle.

Furthermore, the time required for the TIF to reach a near-stable viscosity was found to be 10 min. The nature of the starch thickener is such that it continues to thicken at a much reduced rate after the initial sharp increase in viscosity over the first 10 min. These findings may have significance in clinical practice and hence we recommend a minimum waiting period of 10 min.

Previous work done by Koperna et al. [15] incorporated a starch-based thickener (Milani Thick It) with fresh, cold cow’s milk, both 2 % fat and skim, and found that liquids thickened to a viscosity of between 51 and 350 mPa s [nectar-like consistency as per US National Dysphagia Diet (NDD)] did not continue to thicken over a 45-min period, whereas liquids thickened to a viscosity of between 351 and 1,750 mPa s (honey-like consistency) did continue to thicken over this time period.

Our work showed a similar trend in continued thickening over the given time period, with those samples with higher addition levels of thickener continuing to thicken whilst those with lower addition levels of thickener reaching a plateau viscosity. However, it is important to note that the viscosity results of our study were lower than those employed by Koperna et al. [15] and fell predominantly below the nectar-like consistency category for the 2- and 3-g additions and into the nectar-like consistency of the 4-, 5-, and 6-g additions. This difference in results between the two studies could possibly be attributed to different factors such as the method of testing and the preparation of the thickened fluids. Also, the composition of the infant formula is quite different to that of cow’s milk. The interaction of the thickener with the macro- and micronutrients in the infant formula and the cow’s milk may well be different. In the present study, all tests were done with the ARES rheometer, which is an accurate scientific machine used to obtain viscosity measurements. Tests were carried out at a controlled temperature of 37 ± 1 °C because the TIF is dispensed at body temperature. The viscosity values in Table 2 are associated with the viscosity of the fluid during swallowing because the fluid flows continuously. Furthermore, in our study, all components, i.e., water, infant formula, and thickener, were weighed on a laboratory balance that is accurate to three decimal places and all tests were done in triplicate. On the other hand, Koperna et al. [15] wanted to portray what happens in practice; therefore, the temperature was allowed to fall naturally. In addition, Koperna et al. [15] used the Safe Liquids measurement technique, which measures the flow time of a thickened fluid until the first break in flow as it goes through an 8-mm-diameter funnel. As stated by Koperna et al. [15], the method yielded variable results so they made adjustments to the experiment. Elements of the methodology of Koperna et al. [15] were also inconsistent with their water results, but not the milk studies completed in duplicate. Furthermore, Koperna et al. [15] commented on the variability of the thickener: “¼ teaspoon would cause a large change in flow time.” This observation is more likely a result of the inconsistency in the measurements of a spoonful, allowing greater chance for error, than measurements using weight, instead of a result of the variability of the product. This phenomenon highlights the importance of correct ratios of thickener to liquid to achieve the desired results. Thus, we propose that when making TIF for dysphagic infants, quantities be weighed in the same way that some medication is weighed. A weight-based measurement will allow better control over consistency levels so as to minimize variability and ensure reproducibility.

Some thickeners, such as the gum-based types, will thicken to their optimum consistency very rapidly after mixing. However, starch-based thickeners do not perform the same way as gums, i.e., starch-based thickeners take time to reach an optimal viscosity. In general, starch-based thickeners contain a form of modified starch which allows it to thicken without heating, i.e., the starch is pregelatinised, but due to the slow hydration capacity of the starch molecule, it typically takes time to thicken optimally because the original starch has a concentric compact structure and water needs time to go through the especially crystalline lamella [16]. A number of studies noted a standing/waiting period either as per the manufacturer’s instructions or as per clinical practice [5, 15, 17, 18]. However, no study was found that quantitatively tested the waiting period of the thickener to establish the optimal waiting period before administering the thickened liquid. In the current work we found that the starch-based thickener used took approximately 10 min to reach a nearly stable viscosity (Fig. 1). Although the nature of the starch-based thickener is such that it will continue to thicken, as mentioned earlier, this work shows that the rate of thickening after the initial 10-min high increase is much reduced over the rest of the period of 45 min, which resembles a typical feeding time for an infant.

Though only a few papers [5–7] that studied the rheology of TIF in some way or another were found, none of these works compared the nature of the TIF when different thickener additions or concentrations were used. As noted above, some seminal texts [8, 11–13] and clinical practice (personal communication, Speech Pathology Department, Mater Children’s Hospital, Brisbane) suggest that the minimum amount of thickener should be added to improve the signs and symptoms of feeding difficulties or clinical signs of aspiration. The findings from the current study are imperative to the practice of individualising thickness to need. The recommended ratio of thickener to infant formula according to the manufacturer’s instructions was 8 g of thickener in 200 ml of liquid, which translates to 4 g/100 g as in the current study. It is interesting to note from Fig. 2 that the levels of thickener addition below the manufacturer’s recommendation, i.e., 2 and 3 g, displayed a different rheological behaviour than that of the higher levels of thickener addition (≥4 g). The 2- and 3-g thickener addition levels showed Newtonian-like behaviour (no increase in viscosity with an increase in shear rate from 1 to 100 s−1), similar to that of unthickened milk, although their viscosity was 10 and 20 times higher, respectively. The higher levels of thickener addition showed Newtonian-like behaviour at the lower shear rates and shear-thinning behaviour at the higher shear rates. The latter would be of interest during bottle feeding, when the TIF is sheared through the teat, but further work in this area is necessary to establish the influences that would come into play.

Several different consistency terminologies are employed worldwide. The NDD has four distinct categories or levels of viscosity ranges: thin (1–50 mPa s), nectar-like (51–350 mPa s), honey-like (351–1,750 mPa s), and spoon-thick (>1,750 mPa s). Likewise, the Australian guidelines are divided into four categories: regular, Level 150 (mildly thick), Level 400 (moderately thick), and Level 900 (extremely thick). No viscosity ranges are associated with these categories in the published guidelines; however, studies in our laboratory have shown that the mean viscosity of Level 150 fluids is 150 mPa s at a shear rate of 50 s−1. It is important to keep in mind that these levels were developed with adults in mind and may not be applicable to infants and children. One could argue that only levels <350 mPa s would be applicable to infants, as levels thicker than this would not flow through an infant bottle teat. Judging from the results of the current study, one could debate that a new set of level standards for infants should be developed since the 5-g thickener addition level gave viscosity results of 160 mPa s at 50 s−1, which seems to be higher than the recommendation of the Australian guidelines of <Level 150 [10].

Limitations

A limitation of this study was that only one brand of infant formula and one brand of powdered thickener were investigated. Further inquiry is necessary with other brands of infant formula and thickening agents to improve the generalizability of these findings.

Conclusions

Little knowledge is currently available on thickened milk used in the management of dysphagia in infants. The aim of this study was to answer some practical questions about the rheological characteristics of thickened infant formula that would impact the feeding practice of a dysphagic infant. This study determined that it takes at least 10 min for the particular starch-based thickener used to reach an optimum viscosity after it is mixed with the infant formula. Another important result of this work is that there is certainly a difference in the rheological behaviour of the thickened infant formula at low and high addition levels of the thickener. The latter may lead to a change in the viscosity when sheared through the teat but further investigation is needed to ascertain this. Moreover, clinicians should be aware that thickener addition levels in excess of 4 g/100 g of formula (using the products tested) results in a TIF that would be classified a nectar-like fluid using the NDD guidelines but would have a higher viscosity than the Australian Level 150 (mildly thick).

References

Arvedson JC, Brodsky L. Pediatric swallowing and feeding: assessment and management. 2nd ed. Albany: Singular Publishing; 2002.

Saigal S, Doyle LW. Preterm birth 3- an overview of mortality and sequelae of preterm birth from infancy to adulthood. Lancet. 2008;371(9608):261–9.

Bisch EM, Logemann JA, Rademaker AW, Kahrilas PJ, Lazarus CL. Pharyngeal effects of bolus volume, viscosity, and temperature in patients with dysphagia resulting from neurologic impairment in normal subjects. J Speech Hear Res. 1994;37(5):1041–9.

Rempel G, Moussavi Z. The effect of viscosity on the breath-swallow pattern of young people with cerebral palsy. Dysphagia. 2005;20(2):108–12.

Cichero J, Nicholson T, Dodrill P. Liquid barium is not representative of infant formula: characterisation of rheological and material properties. Dysphagia. 2010;26(3):264–71.

Stuart S, Motz JM. Viscosity in infant dysphagia management: comparison of viscosity of thickened liquids used in assessment and thickened liquids used in treatment. Dysphagia. 2009;24(4):412–22.

de Almeida MB, de Almeida JA, Moreira ME, Novak FR. Adequacy of human milk viscosity to respond to infants with dysphagia: experimental study. J Appl Oral Sci. 2011;19(6):554–9.

Cichero JA, Nicholson TM, September C. Thickened milk for the management of feeding and swallowing issues in infants: a call for interdisciplinary professional guidelines. J Hum Lact. 2013;29(2):132–5.

Allen SS. Management of paediatric feeding problems. Chichester: Wiley; 2006.

Atheron M, Bellis-Smith N, Cichero JA, Suter M. Australian standardised terminology and definitions for texture modified foods and fluids. Nutr Diet. 2007;64(2):53–76.

Wolf L, Glass R. Clinical feeding evaluation. San Diego: Therapy Skill Builders; 1992.

Logemann J. Evaluation and treatment of swallowing disorders. 2nd ed. Austin: Pro-Ed; 1998.

Huckabee ML, Pelletier CA. Treatment of adult neurogenic dysphagia. 1st ed. San Diego: Singular Publishing Group; 1998.

McCallum S. Addressing nutrient density in the context of the use of thickened liquids in dysphagia treatment. Infant Child Adolescent Nutr. 2011;3(6):11.

Koperna C, Scarnecchia K, Pierce RS. The effects of time and temperature changes on liquids thickened to nectar and honey consistencies. Contemp Issues Commun Sci Disord. 2004;31:200–4.

Perez S, Bertoft E. The molecular structures of starch components and their contribution to the architecture of starch granules: a comprehensive review. Starch-Starke. 2010;62(8):389–420.

Payne C, Methven L, Fairfield C, Bell A. Consistently inconsistent: commercially available starch-based dysphagia products. Dysphagia. 2011;26(1):27–33.

O’Leary M, Hanson B, Smith C. Viscosity and non-Newtonian features of thickened fluids used for dysphagia therapy. J Food Sci. 2010;75(6):330–8.

Acknowledgments

The authors thank the input of the Paediatric Feeding Team at the Mater Children’s Hospital, Brisbane, Australia.

Conflict of interest

The authors have no conflicts of interest to disclose.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

September, C., Nicholson, T.M. & Cichero, J.A.Y. Implications of Changing the Amount of Thickener in Thickened Infant Formula for Infants with Dysphagia. Dysphagia 29, 432–437 (2014). https://doi.org/10.1007/s00455-014-9523-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00455-014-9523-z