Abstract

Cultivation of microalgae in wastewater is a promising and cost-effective approach for both CO2 biofixation and wastewater remediation. In this study, a new strain of Coelastrum sp. was isolated from cattle manure leachate. The isolated microalgae were then cultivated in wastewater. Effects of different sCOD concentrations (600, 750, 900, 1050 mg L−1) and light intensities (1000, 2300, 4600, 6900 and 10000 Lux) on biomass production, CO2 consumption rate and nutrient removal from wastewater were investigated. The results showed that maximum cell growth and CO2 consumption rate were 2.71 g L−1 and 53.12 mg L−1 day−1, respectively, which were obtained in the wastewater with 750 mg L−1 sCOD and under the light intensity of 6900 Lux. The microalgae were able to completely consume all CO2 after incubation period of 4 days. The highest sCOD, total Kjeldahl nitrogen (TKN), nitrate and total phosphorous (TP) removal at such conditions were 53.45, 91.18, 87.51 and 100%, respectively. The lipid content of microalgal biomass was also measured under different light intensities; maximum amount of lipid was determined to be 50.77% under illumination of 2300 Lux. Finally, the CO2 consumption rate and biomass productivity of microalgae in semi-batch culture with continuous gas flow (CO2 6%:N2 94%) were investigated. The rate of CO2 consumption and biomass productivity were 0.528 and 0.281 g L−1 day−1, respectively. The TKN, nitrate, TP and sCOD removal rate of microalgae were 83.51, 80.91, 100, 41.4%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, global warming is the most discussed and debated environmental concern in every academic and scientific community. The major cause of global warming, climate change, and biological extinctions is the increasing trend of CO2 concentration in the atmosphere [1]. The atmospheric CO2 concentration has increased from 1% in 1990s to 4% in recent years [2]. There are several routes to reduce carbon dioxide concentration. The most popular methods are based on chemical reactions and reduction of carbon dioxide concentration through bioprocesses [1, 3]. Among the available alternatives, the biological methods sound promising because of the possibility of direct carbon dioxide capturing from flue gas streams [4]. In this context, microalgae have gained great attention due to their high CO2 biofixation efficiency and fast growing nature [5].

Massive cultivation of microalgae is only economically viable when wastewater is used as nutrient. Microalgae have displayed great potential for biological nutrient removal and have been successfully used in wastewater treatment processes [6,7,8]. Nutrient removal from wastewater using microalgae offers many benefits where reduction of carbon dioxide takes place via photosynthetic process; it is not a necessity to add organic carbon for nitrification/denitrification and the process has low capital and operating costs [9, 10].

In cases where production of valuable pure products such as carotenoid [11], protein [12, 13], and phycocyanin [14] is in demand, synthetic media is used for microalgae cultivation. Otherwise, when microalgae are cultivated in wastewater, the biomass can only be used for production of fertilizer [15] or biodiesel [16, 17]. However, coupling the cultivation of microalgae in effluent waste streams with CO2 fixation processes would be a solution to address part of the issues concerning environmental health protection and sustainable development. Although several studies have focused on the biological sewage treatment [18,19,20] and reduction of carbon dioxide emission [21,22,23] via microalgae cultivation, in recent years limited works have investigated the growth of microalgae in wastewater for both nutrient removal and CO2 fixation [16, 24]. Shen et al. [25] cultivated Scenedesmus obliquus with 5% CO2 aeration in municipal wastewater. They reported maximum total nitrogen and phosphorus removal efficiencies of 97.8 and 95.6%, respectively. In addition, the CO2 fixation rate was 256.56 mg L−1 day−1. In another investigation, Nayak et al. [16] studied the nutrient removal efficiency of Scenedesmus sp. with 2.5% CO2 aeration. The highest CO2 fixation rate and removal efficiencies for NH4, NO3 and PO4 were 368 mg L−1 day−1, 98, 70.2 and 78.9%, respectively.

Isolation and selection of suitable microalgae species are necessary for efficient wastewater treatment and at the same time CO2 capturing. Furthermore, to achieve high performance and efficiency, bioreactors must be operated at optimal culture conditions. To these ends, in the present study a new strain of Coelastrum sp. was isolated from cattle manure leachate. In the second step, the growth characteristics, CO2 fixation efficiency and nutrient removal properties of the isolated species cultivated in wastewater were investigated.

Since the process is photosynthetic, the light supply is an essential factor for the growth of autotrophic microalgae. However, high light intensities can cause reduction in CO2 fixation and biomass productivity [24]. In this context, the potential of the isolated microalgae for CO2 fixation, nutrient removal and lipid accumulation at different light intensities was evaluated. Finally, in a batch system with continuous gas flow, the CO2 fixation rate of microalgae was determined.

Materials and methods

Characteristics of wastewater

The wastewater used in this study was collected from a local dairy cattle farm (Babolsar, Iran). The cattle manure leachate was collected from the effluent of a press separator, after separation of solids and used as wastewater for algal cultivation. The wastewater was autoclaved (121 °C for 15 min) and then stored at 4 °C to avoid any variation of composition. The autoclaved wastewater was used for the growth medium in the experiment. It was necessary to autoclave the wastewater before use as high population of fermentative microorganism and anaerobic bacteria originating from the bovine rumen was present in the raw wastewater which competed with the microalgae cells on the available nutrients. Before each experiment, the solid particles in the wastewater were removed by centrifugation at 12,000 rpm for 15 min. The characteristics of the autoclaved wastewater are summarized in Table 1.

Algal isolation and growth condition

In this study, a new strain of Coelastrum sp. was isolated from the cattle manure leachate. Pure culture was obtained by serial transfers on solid BG11 media [26]. The cells were inoculated in 150 mL of BG11 medium and incubated at 30 °C for 14 days. During the incubation time, external illumination was provided using warm white LED lamps at light intensity of 2300 Lux with 12:12-h light:dark cycle.

Identification of strain

The microalga was identified using the phylogenetic analysis based on 18S rDNA gene sequence. Genome DNA of pure strain was extracted using modified method based on SDS-shock and freeze–thaw [27]. The amplification of partial 18S rDNA gene was performed with a universal eukaryotic primer SSU1 (5-AACCTGGTTGATCCTGCCAGT-3) and ITS1DR (3-CCTTGTTACGACTTGACCTTCC-5). PCR product was sequenced with SSU1 and SSU850 (5-GGGACAGTTGGGGGTATTCGTA-3) primers [28]. The nucleotide sequences of certain known microalgae were compared to the defined 18S rDNA gene sequence and aligned using basic local alignment tool (BLAST) in Gene Bank database of the National Center for Biotechnology Information (NCBI). The evolutionary history was inferred by the Maximum Likelihood method based on Tamura-Nei model [29]. The phylogenetic study was conducted using MEGA software version 7 [30].

Batch and semi-batch cultivation of microalgae in wastewater

The growth rate, nutrient removal and CO2 consumption potential of Coelastrum sp. at different levels of sCOD and various light intensities were investigated in several batch experiments for incubation period of 10 days. Batch experiments were performed in 116-mL serum bottles sealed with a rubber closure and an aluminum cap, containing 40 mL of diluted wastewater. Dilution of the wastewater (solid-free cattle manure leachate) was essential as the high sCOD of the wastewater inhibited the growth of the Coelastrum sp. cells. To remove the air in the headspace of the bottles, all serum bottles were purged with a mixed gas containing 5% CO2 and 95% N2 for several minutes. Then the bottles were inoculated with the Coelastrum sp. cells harvested from the exponential growth phase of a growing culture via centrifugation at 6000 rpm for 3 min; the cells were re-suspended in the wastewater.

To investigate the effect of sCOD concentration on the performance of the algal culture, the sterilized wastewater was diluted with sterile distilled water to obtain four different levels of sCOD, namely 600, 750, 900 and 1050 mg L−1. This experiment was conducted under a constant light intensity of 2300 Lux. The effect of light was also studied at different light intensities of 1000, 2300, 4600, 6800 and 10,000 Lux; the light intensity was measured by a digital light meter (Mastech MS6610, USA). All experiments were performed in triplicate and the results were reported as mean value ± SD.

Finally, semi-batch experiment with continuous gas flow (6% CO2:94% N2) at a flow rate of 100 mL min−1 was performed in 500-mL Erlenmeyer flask with a working volume of 400 mL. The biomass production, nutrient and CO2 removal under optimum condition for 14 days were stigated.

Monitoring growth and CO2 fixation rates

Samples were collected in every 48 h and biomass concentration was determined by measurements of optical density at 680 nm, in a visible spectrophotometer (Jenway 6320D, UK). After drying the algal cells in an oven at 70 °C for 24 h, the cell dry weight was determined. The relationship between OD680 and cell dry weight (X, g L−1) of the microalgae was obtained by the following linear relation [31]:

The specific growth rate (μ, day−1), cell doubling time (TD, day) and biomass productivity (PB, g L−1 day−1) are calculated by Eqs. (2–4) [16]:

where Wf and W0 are the final and initial biomass concentrations (g L−1), respectively. In addition, tf and t0 correspond to the final and initial time (day) of the growth phase.

The gas sample was collected from the serum bottle headspace; the CO2 concentration was determined by gas chromatography analysis. A GC (Agilent 7220A, USA) equipped with a thermal conductivity detector (TCD) and a packed column (Carboxene 1000, Supelco, USA) was used for the analysis. The injector and detector temperatures were set at 150 and 220 °C, respectively. The oven temperature was increased from 40 to 150 °C at a heating rate of 20 °C min−1. The CO2 fixation rate (mg L−1 day−1) was calculated according to the mass (moles) of mixed gas contained in the serum bottles, using the following relations:

where P is the cylinder pressure (Pa), V represents the volume of headspace of serum bottles (L), T is the ambient temperature (K), n denotes the amount of mixed gas substance (mol), R is the universal gas constant, M is the molecular weight of CO2 (mg mol−1), y0 represents the volume fraction of CO2 in the headspace of serum bottles at day t0 (%) and y i is the volume fraction of CO2 in the headspace of serum bottles at day t i (%).

In addition, the rate of CO2 fixation (mg L−1 day−1) for the semi-batch experiment conducted in the Erlenmeyer flask with continuous gas flow was defined by Eq. (7) [26]:

where PB is the biomass productivity (mg L−1 day−1).

Water quality analysis and nutrient removal

The total Kjeldahl nitrogen (TKN: ammonia, organic and reduced nitrogen), total phosphorous (TP) and nitrate removal were measured every 48 h, starting from the point of inoculation. At this interval, specific amount of microalgae suspension was withdrawn from the culture to determine the mentioned parameters based on standard methods for examination of water and wastewater [32].

The nutrient removal percentage (%) and removal rates (mg L−1 day−1) were calculated according to Eqs. (8) and (9), respectively:

where C0 and Cf are the nutrient concentrations at initial (t0) and final (tf) times, respectively, and Δt (day) expresses the time of cultivation [16].

Lipid content

The lipid content of the microalgae biomass was determined by the following method [33]. The total lipid content was extracted by organic solvent and its mass was determined. After growing the algae for 8 days, an aliquot of 1 mL microalgal solution was initially centrifuged at 6000 rpm for 10 min. After that, the supernatant was withdrawn and a mixture of 0.5 mL phosphate buffer solution (PBS: 8 mM Na2HPO4, 2 mM NaH2PO4, 140 mMNaCl, pH 7.4) and 1 mL glass beads was added to the test tube. Then, the mixture was agitated using a vortex mixer at 3000 rpm for 4 min; every 1 min tap water was added for cooling the glass tubes. A 3 mL of the extraction solution, which was a 2:1 (v/v) chloroform–methanol mixture, was added and mixed. The sample was incubated overnight at 27 °C to extract the lipid. On the following day, for the phase separation, 1 mL of distilled water was added and the sample was centrifuged at 5000 rpm for 10 min. Then, the lower organic phase was discarded and the extraction procedure was redone by addition of 2 mL of the extraction solution to the test tube for an extraction period of 2 h. The organic phases were then collected and the chloroform was evaporated in an oven at 50 °C. Finally, the extracted lipids were weighed and the lipid content of the microalgae was expressed as percent of dry weight.

Chlorophyll a concentration

The concentration of chlorophyll a (Chl a ) and chlorophyll b (Chl b ) was determined using the methanol extraction and optical absorption correlation as described in the literature [26]. At the end of each batch, 2 mL of the microalgae suspension was centrifuged at 4400 rpm for 6 min and then the supernatant was discarded. A 5 mL of methanol was added to the test tube. The sample was mixed by vortex agitator and gently sonicated in ultrasonic batch for 5 min to disperse the cell pellet. The extract was heated in a hot water bath at 60 °C for 40 min. After repeating the centrifugation step and cooling the sample to 0 °C for 15 min, the absorbance of the supernatant was measured at 652 and 665 nm. Modified Arnon’s equations were used to calculate the Chla+b (mg L−1) concentration in the extracts [26]:

Results and discussion

Identification of microalgae

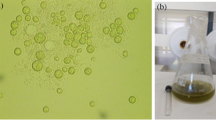

According to morphological character of microalgae and phylogenetic tree, the isolated microalga closely belonged to the genus Coelastrum. The microalga is green and spherical in shape roughly in size of about 3–8 μm, and non-motile (without flagella). Table 2 shows the morphological and physiological properties of identified algae. Results showed that this strain has low similarity to known taxa, strain belonged to Chlorophyta and located between two orders, Sphaeropleales and Chlorellales. Phylogenetic tree (Fig. 1) showed this strain was more near to Scenedesmaceae family in the order Chlorellales (Chlorellaceae and Oocystaceae). With these results this strain can be presented as a new taxon in Scenedesmaceae family. The submitted sequence data to Gen Bank having accession number of (MG456602) is shown as Coelastrum sp. strain SM in the phylogenetic tree.

Effect of sCOD concentrations on microalgae cultivation

Cell growth and CO2 biofixation

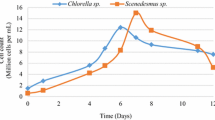

The capability of Coelastrum sp. for biomass production and CO2 biofixation was examined at different initial sCOD concentrations of wastewater. The variations of biomass concentration and CO2 consumption throughout the cultivation period are illustrated in Fig. 2a, b, respectively. As shown in Fig. 2a, in all growth media, an initial lag phase was observed which lasted for about 2 days. It was the period of adaptation of Coelastrum sp. to the growth environment. After second day, microalgae entered the exponential growth phase. The biomass concentration exponentially increased for 6 days and reached 1.92, 2.21, 1.76 and 1.45 g L−1 for 600, 750, 900 and 1050 mg L−1 sCOD, respectively. The growth of microalgae reduced due to reduction of one or more essential nutrients after 8 days of cultivation. Results showed that the medium with initial sCOD of 750 mg L−1 was the most suitable culture for the microalgae. In this medium, the maximum productivity and growth rate and minimum doubling time were obtained (Table 3), whereas the lowest biomass concentration was found in BG11 medium which is among the common media for algae cultivation. The cells stopped dividing when biomass concentration reached 1.28 g L−1 after 10 days of cultivation in BG11 medium.

Figure 2b represents the variations of CO2 concentration in the headspace of serum bottles as well as CO2 utilization rate by the Coelastrum sp. cells in growth media with different initial sCOD concentrations. The highest CO2 consumption rate (30.36 mg L−1 day−1) was obtained in the wastewater medium with initial sCOD concentration of 750 mg L−1 where at this condition the highest cell growth was attained. This confirms the direct proportionality of the CO2 biofixationability of microalgae with the cell density. The CO2 concentration was 5% in the headspace of the serum bottles and completely consumed after 8, 7, 9, 10 and 11 days of cultivation for media containing 600, 750, 900, 1050 mg L−1 of sCOD and BG11 medium, respectively.

Nutrient removal

Taking into account the European legislation on discharge of effluents, the defined values for the concentration of nutrients have been recommended to be 10 or 15 mg L−1 for total nitrogen and 1 or 2 mg L−1 for total phosphorus based on population equivalent [24].

Nitrogen and phosphorous are the main nutrient components required for the photosynthetic microalgae. Use of wastewater to support the growth of microalgae has the remarkable advantage that microalgae utilize the nutrients for their growth and simultaneously the COD loading of the wastewater is reduced. In this study, Coelastrum sp. was capable to remove nutrients from the wastewater under specific conditions. The changes in TKN, TP and nitrate concentrations of wastewater with respect to time are exhibited in Fig. 3a–c, respectively.

The TKN and nitrate continuously decreased during the cultivation period as illustrated in Fig. 3a, b. For all media with different sCOD concentrations, high removal rate of TKN and nitrate was observed at first 6 and 4 days, respectively. Afterwards, the removal rate reduced and that was attributed to the reduction of the microalgae growth rate. The nutrient removal rate by Coelastrum sp. is summarized in Table 4. In the medium with 750 mg L−1 sCOD, Coelastrum sp. showed great potential to remove TKN and nitrate (84–85%). Concentrations of TKN and nitrate approximately reached 9.2 and 3.68 mg L−1, at the end of cultivation.

Figure 3c presents the variation of TP with respect to cultivation time. TP showed high removal rate (Table 4) and reached zero within the first 4 or 5 days in different batch bioreactors although in the medium with 750 mg L−1 sCOD the TP was utilized within only 3 day.

According to the previous studies [25, 34], there are two defined methods for phosphorus removal from wastewater. The first method is the use of microalgae for uptake of biotic phosphorus and the second one is the removal of abiotic phosphate by precipitation which only occurs at high medium pH (9–11). In this work, in the first 6 days of cultivation the pH value never reached 9 (see Fig. 3d). Therefore, the main phosphorus removal mechanism was taken up by the microalgae.

The results obtained for nitrogen and phosphorous removal efficiencies complied with the microalgae growth results; this shows that the Coelastrum sp. could effectively utilize the nutrients from the wastewater to maintain their growth.

The growth of Coelastrum sp. in the media with 600, 750, 900 and 1050 mg L−1 sCOD decreased after 8 days and changes in pH values of the culture was monitored every 48 h during logarithmic phase (Fig. 3d). The initial pH of all media was set at 7 and after a gradual decline due to solubility of CO2, the pH increased to 9.76, 10.08, 10.21 and 10.71 for 600, 750, 900 and 1050 mg L−1 sCOD, respectively. In the course of microalgae cultivation, the pH has increased that was due to CO2 and nitrate utilization of algae [35, 36]. In a batch culture without aeration, pH may rise. In fact, pH values above 10 are common when CO2 is limited and wastewater carbon source such as bicarbonate is used by the microalgae [37].

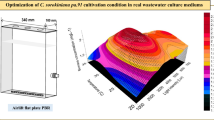

Effect of light intensity on microalgae cultivation

As results showed, the best medium for microalgae growth and nutrient removal was the wastewater with 750 mg L−1 sCOD. In the following section, the effect of light intensity on the growth and productivity of microalgae in the medium with 750 mg L−1 sCOD was examined.

Cell growth and CO2 biofixation

Coelastrum sp. was grown under warm white LED lamps at different light intensities. Figure 4a shows the effects of light intensities on microalgae cell dry weight. The biomass concentration reached 1.43, 2.21, 2.47, 2.71 and 1.84 g L−1 at light intensities of 1000, 2300, 4600, 6900 and 10,000 Lux, respectively. The maximum cell density of 2.71 g L−1 was obtained at 6900 Lux and there was no lag phase at this light intensity. Also, the maximum specific growth rate and biomass productivity for the light intensities of 1000, 2300, 4600, 6900 and 10,000 Lux were 0.35, 0.41, 0.42, 0.43 and 0.36 day−1 and 0.16, 0.26, 0.29, 0.32 and 0.22 g L−1 day−1, respectively (see Fig. 4b). Generally, the effect of light intensity on microalgae growth could be classified into four regions. The first region is lag phase where growth is constant with increase of light intensity. The next phase is light limitation in which growth rate is directly proportional to the light intensity and as the light intensity increases from low to high light, the growth is enhanced. The third phase is light saturation in which growth rate is independent of light intensity. The last phase is light inhibition where the growth rate decreases with an increase in light intensity [38]. The microalgae biomass production significantly improved with increase in the light intensity. The desired light intensity for the algal cell growth was 6900 Lux; however, the growth efficiency decreased as the light intensity was increased to 10,000 Lux which could occur because of two reasons. At high light intensities, the growth may decrease due to bleaching of chlorophyll (light inhibition region) or it is plausible that at high light intensities, due to the heavy cell population, a shadow is created on the cells by the layer close to the surface. The shadow prevents the penetration of light into depth of culture and the limited light transported to the cells caused by self-shading phenomenon restricts the growth [39].

Figure 4c illustrates the effects of different light intensities on CO2 removal. Higher CO2 removal rate was obtained while more biomass was generated. Maximum CO2 consumption rates were 26.56, 30.35, 42.5, 53.12 and 26.56 mg L−1 day−1 at light intensities of 1000, 2300, 4600, 6900 and 10,000 Lux, respectively. Therefore, the most desired light intensity to obtain the highest CO2 consumption was 6900 Lux at which the maximum cell growth was also attained. A comparison between Fig. 4a, c indicates that although CO2 was fully consumed in batch bioreactors within first days of cultivation, for example within 4 days at light intensity of 6900 Lux, the cells survived and continued their growth up to 8 days. This indicates that the microalgae could uptake the required carbon and nutrients from the wastewater; this resulted in 53.45% sCOD removal at light intensity of 6900 Lux (data not shown). In fact the mixotrophic growth of microalgae changed to heterotrophic growth.

Nutrient removal

Figure 5a and b show the effect of light intensity onTKN and nitrate removal using microalgae, respectively. The TKN and nitrate removal improved with the increase of light intensity up to 6900 Lux which was along with the increase of biomass production as shown in Fig. 4a. This shows that the cells utilized the nutrients for their growth and reproduction. Through the microalgae cultivation process at 6900 Lux, 91.18% of TKN and 87.51% of nitrate were removed from the wastewater. As data are illustrated in Fig. 5c, the TP concentration reached zero after 5, 3, 3, 2 and 4 days of cultivation under light intensities of 1000, 2300, 4600, 6900 and 10,000 Lux, respectively. A high TP removal rate was obtained under the light intensity of 6900 Lux (see Table 5). Effect of light intensity on nutrient removal corresponds to biomass production. In fact, the same trend has been observed in a previous study by Li et al. [38].

Lipid content

Lipid content of microalgae may increase due to changes in the environmental conditions such as a shock or stress. Increase in the growth of microalgae does not necessarily mean that the lipid content of microalgae enhanced. The desired condition for maximum lipid content should be determined for each species of microalgae through detailed investigation [38].

Light intensity is one of the main factors affecting the growth and the lipid accumulation in microalgae. Figure 6 presents the variations of lipid content, lipid productivity and Chla+b concentration at the end of the batch cultivation, under different light intensities. The lipid content (percentage of cell dry weight) increased from 18.43% at 1000 Lux to 50.77% when the light intensity was increased to 2300 Lux. Then, the lipid content decreased as the light intensity was increased from 2300 to 10,000 Lux. As results show, Coelastrum sp. was able to store lipid favorably at 2300 Lux with high lipid productivity (11.08 mg L−1 day−1), while the suitable light intensity for the maximum microalgae growth was 6900 Lux (see Fig. 4a). The highest Chla+b concentration of 9.1 mg L−1 was also produced at the light intensity of 2300 Lux. It has been reported in the literature [40, 41] that high light intensities may reduce the chlorophyll and lipid contents of the microalgae cells. Two reasons may be responsible for the reduction of chlorophyll content. First, when the light is not limited, there is no need of high chloroplast activity and the cell need not produce too much chlorophyll to absorb light. As a result, with increasing light intensity, chlorophyll production is reduced. Second, exposing a cell to a high light intensity may lead to the degradation of chlorophyll and conclude to its reduction. As a result of chlorophyll reduction, production of ATP and NADPH in photosynthetic process, which are consumed in lipid biosynthesis, was reduced [42]. Therefore, the cause of lipid reduction at high light intensity can be justified by the reduction of chlorophyll.

Semi-batch cultivation with continuous gas flow

To demonstrate the potential of the microalgae for CO2 removal under optimal condition, a semi-batch experiment with continuous gas flow (6% CO2:94% N2) was performed. Figure 7 shows the variations of biomass concentration, CO2 removal efficiency and pH throughout the cultivation period. Coelastrum sp. showed high CO2 biofixation potential and maximum CO2 removal efficiency (34.33%) at the end of the logarithmic phase. The microalgae growth and nutrient removal in the Erlenmeyer flask gradually decreased compared to the serum bottle experiments. This could be due to the change of cultivation conditions. After consumption of CO2 in batch bottles, the microalgae grew heterotrophically. But due to continuous gas flow in semi-batch cultivation, the microalgae grew under mixotrophic condition and preferred to use CO2 more than wastewater as carbon source. As a result, the sCOD removal in semi-batch system was lower than batch system, whereas CO2 fixation rate increased. The microalgae efficiently removed organic nutrient from the wastewater. The average removal of TKN, nitrate, TP and sCOD was 83.51, 80.91, 100 and 41.4%, respectively. The pH of culture was set at 7; it decreased constantly because of solubility of CO2 till the stationary phase of cell growth and reached about 6.3 in the last days of cultivation period. The difference in pH variation in the semi-batch system with the batch system is due to continuous supply of CO2. The biomass productivity and CO2 fixation rate of Coelastrum sp. as compared to other species are summarized in Table 6. The obtained results in this study were comparable to those available in the literature.

Conclusion

This research showed that Coelastrum sp. has great potential to produce high biomass concentration and also to remove nutrients from wastewater. The effect of different sCOD concentrations and light intensity on the TKN, nitrate and TP removals, microalgae growth and CO2 consumption rate was investigated. The suitable medium was the wastewater with 750 mg L−1 initial sCOD and the optimum light intensity was determined to be 6900 Lux. When Coelastrum sp. was cultivated under optimum conditions, the average sCOD, TKN, nitrate and TP removal efficiency was 53.45, 91.18, 87.51 and 100%, respectively. In addition, the microalgae showed high cell growth (2.71 g L−1). The light intensity of 2300 Lux was found to be beneficial for high accumulation of lipid in algal cells (50.77%). This shows the great potential of the isolated microalgae strain for biodiesel production. In addition, when Coelastrum sp. was cultivated under semi-batch conditions with continuous gas flow, the biomass productivity and CO2 removal rate were 0.281 and 0.528 g L−1 day−1, respectively. At this condition, the average removal rate of TKN, nitrate, TP and sCOD were 83.51, 80.91, 100 and 41.4%, respectively. These results suggest that Coelastrum sp. is a suitable microalgae for carbon dioxide biofixation, lipid production and wastewater bioremediation.

References

da Rosa GM, Moraes L, Cardias BB, Costa JAV (2015) Chemical absorption and CO2 biofixation via the cultivation of Spirulina in semicontinuous mode with nutrient recycle. Bioresour Technol 192:321–327

Beerling DJ, Royer DL (2011) Convergent cenozoic CO2 history. Nat Geosci 4(7):418–420

Raeesossadati M, Ahmadzadeh H, McHenry M, Moheimani N (2014) CO2 bioremediation by microalgae in photobioreactors: impacts of biomass and CO2 concentrations, light, and temperature. Algal Res 6:78–85

Jin H-F, Lim B-R, Lee K (2006) Influence of nitrate feeding on carbon dioxide fixation by microalgae. J Environ Sci Health A 41(12):2813–2824

Wang B, Li Y, Wu N, Lan CQ (2008) CO2 bio-mitigation using microalgae. Appl Microbiol Biotechnol 79(5):707–718

Mennaa FZ, Arbib Z, Perales JA (2015) Urban wastewater treatment by seven species of microalgae and an algal bloom: biomass production, N and P removal kinetics and harvestability. Water Res 83:42–51

Ouyang Y, Zhao Y, Sun S, Hu C, Ping L (2015) Effect of light intensity on the capability of different microalgae species for simultaneous biogas upgrading and biogas slurry nutrient reduction. Int Biodeterior Biodegrad 104:157–163

Maity JP, Bundschuh J, Chen C-Y, Bhattacharya P (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives—a mini review. Energy 78:104–113

Ruiz-Martinez A, Garcia NM, Romero I, Seco A, Ferrer J (2012) Microalgae cultivation in wastewater: nutrient removal from anaerobic membrane bioreactor effluent. Bioresour Technol 126:247–253

Wang M, Kuo-Dahab WC, Dolan S, Park C (2014) Kinetics of nutrient removal and expression of extracellular polymeric substances of the microalgae, Chlorella sp. and Micractinium sp., in wastewater treatment. Bioresour Technol 154:131–137

Moussa ID-B, Chtourou H, Karray F, Sayadi S, Dhouib A (2017) Nitrogen or phosphorus repletion strategies for enhancing lipid or carotenoid production from Tetraselmis marina. Bioresour Technol 238:325–332

Chen C-Y, Chang Y-H, Chang H-Y (2016) Outdoor cultivation of Chlorella vulgaris FSP-E in vertical tubular-type photobioreactors for microalgal protein production. Algal Res 13:264–270

Eldalatony MM, Kabra AN, Hwang J-H, Govindwar SP, Kim K-H, Kim H, Jeon B-H (2016) Pretreatment of microalgal biomass for enhanced recovery/extraction of reducing sugars and proteins. Bioprocess Biosyst Eng 39(1):95–103

Zeng X, Danquah MK, Zhang S, Zhang X, Wu M, Chen XD, Ng I-S, Jing K, Lu Y (2012) Autotrophic cultivation of Spirulina platensis for CO2 fixation and phycocyanin production. Chem Eng J 183:192–197

Wuang SC, Khin MC, Chua PQD, Luo YD (2016) Use of Spirulina biomass produced from treatment of aquaculture wastewater as agricultural fertilizers. Algal Res 15:59–64

Nayak M, Karemore A, Sen R (2016) Performance evaluation of microalgae for concomitant wastewater bioremediation, CO2 biofixation and lipid biosynthesis for biodiesel application. Algal Res 16:216–223

Soydemir G, Keris-Sen UD, Sen U, Gurol MD (2016) Biodiesel production potential of mixed microalgal culture grown in domestic wastewater. Bioprocess Biosyst Eng 39(1):45–51

Guldhe A, Ansari FA, Singh P, Bux F (2017) Heterotrophic cultivation of microalgae using aquaculture wastewater: a biorefinery concept for biomass production and nutrient remediation. Ecol Eng 99:47–53

Choi HJ, Lee SM (2015) Effect of the N/P ratio on biomass productivity and nutrient removal from municipal wastewater. Bioprocess Biosyst Eng 38(4):761–766

Heo S-W, Ryu B-G, Nam K, Kim W, Yang J-W (2015) Simultaneous treatment of food-waste recycling wastewater and cultivation of Tetraselmis suecica for biodiesel production. Bioprocess Biosyst Eng 38(7):1393–1398

Moraes L, da Rosa GM, Cardias BB, dos Santos LO, Costa JAV (2016) Microalgal biotechnology for greenhouse gas control: carbon dioxide fixation by Spirulina sp. at different diffusers. Ecol Eng 91:426–431

Tebbani S, Lopes F, Filali R, Dumur D, Pareau D (2014) Nonlinear predictive control for maximization of CO2 bio-fixation by microalgae in a photobioreactor. Bioprocess Biosyst Eng 37(1):83–97

Razzak SA, Ali SAM, Hossain MM, Mouanda AN (2016) Biological CO2 fixation using Chlorella vulgaris and its thermal characteristics through thermogravimetric analysis. Bioprocess Biosyst Eng 39(11):1651–1658

Gonçalves A, Simões M, Pires J (2014) The effect of light supply on microalgal growth, CO2 uptake and nutrient removal from wastewater. Energy Convers Manage 85:530–536

Shen Q-H, Jiang J-W, Chen L-P, Cheng L-H, Xu X-H, Chen H-L (2015) Effect of carbon source on biomass growth and nutrients removal of Scenedesmus obliquus for wastewater advanced treatment and lipid production. Bioresour Technol 190:257–263

Basu S, Roy AS, Mohanty K, Ghoshal AK (2013) Enhanced CO2 sequestration by a novel microalga: Scenedesmus obliquus SA1 isolated from bio-diversity hotspot region of Assam, India. Bioresour Technol 143:369–377

Saba F, Papizadeh M, Khansha J, Sedghi M, Rasooli M, Amoozegar MA, Soudi MR, Fazeli SAS (2017) A rapid and reproducible genomic DNA extraction protocol for sequence-based identification of archaea, bacteria, cyanobacteria, diatoms, fungi, and green algae. J Med Bacteriol 5(3–4):22–28

Olmos J, Paniagua J, Contreras R (2000) Molecular identification of Dunaliella sp. utilizing the 18S rDNA gene. Lett Appl Microbiol 30(1):80–84

Tamura K, Nei M (1993) Estimation of the number of nucleotide substitutions in the control region of mitochondrial DNA in humans and chimpanzees. Mol Biol Evol 10(3):512–526

Kumar S, Stecher G, Tamura K (2016) MEGA7: molecular evolutionary genetics analysis version 7.0 for bigger datasets. Mol Biol Evol 33(7):1870–1874

Arbib Z, Ruiz J, Álvarez-Díaz P, Garrido-Perez C, Perales JA (2014) Capability of different microalgae species for phytoremediation processes: wastewater tertiary treatment, CO2 bio-fixation and low cost biofuels production. Water Res 49:465–474

APHA, AWWA, WEF (2012) Standard methods for the examination of water and wastewater, 22nd edn. American Public Health Association, Washington, DC

Ge S, Champagne P (2016) Nutrient removal, microalgal biomass growth, harvesting and lipid yield in response to centrate wastewater loadings. Water Res 88:604–612

Ma X, Zhou W, Fu Z, Cheng Y, Min M, Liu Y, Zhang Y, Chen P, Ruan R (2014) Effect of wastewater-borne bacteria on algal growth and nutrients removal in wastewater-based algae cultivation system. Bioresour Technol 167:8–13

Kao C-Y, Chen T-Y, Chang Y-B, Chiu T-W, Lin H-Y, Chen C-D, Chang J-S, Lin C-S (2014) Utilization of carbon dioxide in industrial flue gases for the cultivation of microalga Chlorella sp.. Bioresour Technol 166:485–493

Hulatt CJ, Thomas DN (2011) Productivity, carbon dioxide uptake and net energy return of microalgal bubble column photobioreactors. Bioresour Technol 102(10):5775–5787

Larsdotter K (2006) Wastewater treatment with microalgae—a literature review. Vatten 62(1):31

Li Y, Zhou W, Hu B, Min M, Chen P, Ruan RR (2012) Effect of light intensity on algal biomass accumulation and biodiesel production for mixotrophic strains Chlorella kessleri and Chlorella protothecoides cultivated in highly concentrated municipal wastewater. Biotechnol Bioeng 109(9):2222–2229

Abdel-Raouf N, Al-Homaidan A, Ibraheem I (2012) Microalgae and wastewater treatment. Saudi J Biol Sci19(3):257–275

Guedes AC, Meireles LA, Amaro HM, Malcata FX (2010) Changes in lipid class and fatty acid composition of cultures of Pavlova lutheri, in response to light intensity. J Am Oil Chem Soc 87(7):791–801

Cheirsilp B, Torpee S (2012) Enhanced growth and lipid production of microalgae under mixotrophic culture condition: effect of light intensity, glucose concentration and fed-batch cultivation. Bioresour Technol 110:510–516

Rosenberg JN, Oyler GA, Wilkinson L, Betenbaugh MJ (2008) A green light for engineered algae: redirecting metabolism to fuel a biotechnology revolution. Curr Opin Biotechnol 19(5):430–436

Tang D, Han W, Li P, Miao X, Zhong J (2011) CO2 biofixation and fatty acid composition of Scenedesmus obliquus and Chlorella pyrenoidosa in response to different CO2 levels. Bioresour Technol 102(3):3071–3076

Zhao B, Su Y, Zhang Y, Cui G (2015) Carbon dioxide fixation and biomass production from combustion flue gas using energy microalgae. Energy 89:347–357

Acknowledgements

The authors gratefully acknowledge Biotechnology Research Lab., Babol Noshirvani University of Technology for the facilities provided to conduct present research. Also, special thanks are extended to Mazandaran Gas Company, Sari, Iran, for the financial support for the present research through research Grant # 11226.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mousavi, S., Najafpour, G.D., Mohammadi, M. et al. Cultivation of newly isolated microalgae Coelastrum sp. in wastewater for simultaneous CO2 fixation, lipid production and wastewater treatment. Bioprocess Biosyst Eng 41, 519–530 (2018). https://doi.org/10.1007/s00449-017-1887-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-017-1887-7