Abstract

In this study, a high lipid-accumulating mutant strain of the microalgae Scenedesmus dimorphus was developed via radiation breeding. To induce mutant strain, S. dimorphus was gamma-irradiated at doses from 100 to 800 Gy, and then a mutant (Sd-Pm210) with 25 % increased lipid content was selected using Nile red staining methodology. Sd-Pm210 showed morphological changes and had higher growth rate compared to the wild type. From random amplified polymorphic DNA analysis, partial genetic modifications were also observed in Sd-Pm210. In comparisons of lipid content between wild type and Sd-Pm210 using thin-layer chromatography, the content of triacylglycerol was markedly higher in the Sd-Pm210 strain. The total peak area of fatty acid methyl ester was shown to have about 1.4-fold increase in Sd-Pm210, and major fatty acids were identified as palmitic acid, oleic acid, linoleic acid, and linolenic acid. To define the metabolic changes in the mutant strain, 2-dimensional electrophoresis was conducted. Several proteins related to lipid synthesis and energy metabolisms were overexpressed in the mutant strain. These results showed that radiation breeding can be utilized for the development of efficient microalgae strains for biofuel production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In 2008, fossil fuels supported most of the world’s energy needs and accounted for 88 % of primary energy consumption [5]. Considering rising costs and diminution of potential reserves, there is an increasing interest in developing new fuel supply sources to gradually replace fossil fuels. Due to these reasons and the need for recycling carbon dioxide increasingly emitted from the combustion of fossil fuels, research has begun to focus on alternative biomass-derived fuels [7, 14, 19, 24]. Currently, commercially produced biofuels are mainly derived from food and oil crops. Given the fact that the surface of agriculturally usable land tends to decrease, this has already led to a competition between biofuel and food and feed production.

One promising source of biomass for alternative fuel production is microalgae that have the ability to grow rapidly, synthesize, and accumulate large amounts (20–50 % of dry weight) of neutral lipid (mainly in the form of triacylglycerol) stored in cytosolic lipid bodies [10, 15, 18]. Algal-derived lipids do not compete with arable crops and have the advantage to be easily converted into biodiesel [13]. Moreover, oil production from microalgal biomass is higher than that of the best oilseed crops (rape oilseed), making microalgal biomass a valuable source of biodiesel [12].

Some species of diatoms (e.g., Chaetoceros muelleri) and green microalgae (e.g., Scenedesmus dimorphus, Chlorella vulgaris, Chlorococcum littorale, Botryococcus braunii, and Nannochloris) have been considered to be candidate strains for the production of neutral lipids for conversion to various types of biofuels (e.g., biodiesel, kerosene, and gasoline) [3, 18, 22, 23]. Among those, S. dimorphus was analyzed for its potential for production of biodiesel [17].

However, in contrast to biodiesel produced from higher plants, the microalgae process has not been commercialized due to high production costs. In order to solve this problem, it is essential to develop high lipid-producing strains. Development for superior strains via the introduction of genes has already been tried. But until now, applied ranges are limited in some species, and stable transgenic technologies for a variety of microalgal species are under development. Molecular biological methods in algae are not yet as developed as those for land plants are.

Mutations developed through irradiation of higher plants and microorganisms were already confirmed to be the safe and effective. Research and development of the mutation of microalgae has been performed recently [27]. Therefore, the goal of this study was to develop a high lipid-producing mutant microalgae via radiation breeding for the cost-effective production of biodiesel.

Materials and methods

Alga strain and culture conditions

The algal strain used in this work is Scenedesmus dimorphus supplied by The Culture Collection of Algae at University of Texas at Austin (Austin, TX, USA). The cells were grown at 20 °C, and with a 12:12 h light:dark cycle of exposure to white fluorescent light (>30 μmol photons m−2 s−1), either in liquid medium of Bold’s basal (BBM) in culture dish or on solid medium agar plates (1.5 % agar) [27].

The growth curves of the algal cells in liquid medium were determined via optical density (OD). OD values were measured using a spectrophotometer (UVIKON XL, BIO-TEK, Winooski, VT, USA) at 540 nm.

Cell size was calculated by PDQuest™ Basic 2D Gel Analysis software (Bio-Rad, Hercules, CA, USA). Before measurement, cells were captured with an Olympus BX-53 microscope (Olympus Optical Co. Ltd., Tokyo, Japan).

Mutation procedure

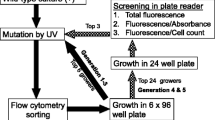

To induce mutations via gamma irradiation, cells must be prepared in a liquid medium. A 50-mL flask containing the microalgae was irradiated in a cobalt-60 gamma irradiator (point source, ACEL, IR-79; MDS Nordion International Co. Ltd., Ottawa, Ontario, Canada).

Mutant screening was performed with cells that survived after exposure at different irradiation doses (100, 200, 500, and 800 Gy). The variation of radiation intensity was conducted by different exposure time. When the cells were exposed for 50 min, the absorbed dose was 800 Gy. Original cell concentration before irradiation was about 0.1 OD540. After gamma irradiation, cells were inoculated in an agar plate. After few days, colonies that formed were inoculated in 2 mL of liquid medium placed in a 5-mL tube.

Screening of mutants with Nile red staining

Nile red staining was performed to screen for the high lipid-producing mutants. 100 μL samples with 1 μL Nile red (Sigma-Aldrich, St. Louis, MO, USA) solution (0.5 mg/mL in acetone) were put in a 96-well plate and incubated at 30 °C for 10 min. After algal cells were stained, fluorescence was measured. The excitation and emission wavelengths of 530 and 575 nm, respectively, were selected [8]. The high lipid-producing mutant was selected through comparison with the wild type.

Random amplified polymorphic DNA analysis

Random amplified polymorphic DNA (RAPD) analysis was used for the genetic mapping between the wild-type and mutant strain. The genomic DNA used for analysis was isolated via Accuprep genomic DNA extraction kit (Bioneer, Daejeon, South Korea). RAPD was performed using the OP A to Z RAPD primer (10mer Arbitary kit) [1]. PCR was performed at 95 °C denaturation for 5 min, then for 40 cycle at 94 °C (1 min), 35 °C (30 s), then 72 °C (1 min), and finally at 72 °C for 15 min. Amplification products were separated on 1.5 % agarose gel in 1 × TAE buffer and detected by ethidium bromide staining.

Total lipid and triacylglycerol (TAG) content

Total lipid was extracted using chloroform/methanol in the same manner as described by Bligh and Dyer [4]. Solvent was then evaporated, and the total lipid fraction was weighed and expressed as mg/g cell dry weight. TAG fraction was separated by thin-layer chromatography (TLC) on silica plates developed with hexane/diethyl ether/acetic acid (70:30:1 v/v/v) as described by [21].

Determination of total fatty acid composition

Fatty acid quantification was performed by trans-esterification [20]. Microalgae were cultured for 9 days, centrifuged at 4,000×g for 10 min, washed twice with distilled water, and then freeze-dried. The cells were subjected to trans-esterification [6] prior to gas chromatography (6890 series GC System, Agilent, Santa Clara, CA, USA). Supelco-FAME Mix RM3, Mix RM5, GLC50, GLC70, and heptadecanoic acid (Sigma-Aldrich) were used as a standard for fatty acid identifications and quantification.

Proteomic analysis

Protein preparation and 2-dimensional (2-D) electrophoresis were followed the method described by Yoon et al. [28]. Cultures of strains were washed twice with ice-cold phosphate-buffered saline (PBS; Invitrogen Co., Carlsbad, CA, USA), and the samples were ground directly in liquid nitrogen with a mortar and pestle. Sample lysis solution containing 8 M urea (GE Healthcare, Uppsala, Sweden), 2 M thiourea (GE Healthcare), 4 % (w/v) 3-[(3-cholamidopropyl) dimethyl-ammonio]-1-propanesulfonate (CHAPS; Sigma-Aldrich), 1 % (w/v) dithiothreitol (DTT; Sigma-Aldrich), and 1 mM phenylmethylsulfonyl fluoride (PMSF; Sigma-Aldrich) was mixed with ground samples. Trichloroacetic acid precipitation was performed to concentrate and purify the proteins in the lysis solution extract. Protein pellets were dissolved with rehydration solution [8 M urea, 2 % (w/v) CHAPS, and 0.002 % (w/v) bromophenol blue (Sigma-Aldrich)].

Focused, immobilized, 18-cm-long pH gradient (IPG) strips (GE Healthcare) with a pH range of 3–10 were used in this study. First-dimensional electrophoresis was performed on an IPG phore IEF system (GE Healthcare) using the manufacturer’s recommended protocols. After equilibration, the strip was placed on top of a 9–17 % gradient polyacrylamide gel and embedded in 0.5 % heated low-melting agarose in SDS electrophoresis running buffer [25 mM Tris, 192 mM glycine (GE Healthcare), and 0.1 % (w/v) SDS]. After SDS–PAGE, the gel was stained with Coomassie brilliant blue (CBB).

CBB-stained gels were scanned using a photo scanner (PERFECTION V700 PHOTO EPSON Co., Nagano, Japan). 2D gel imaging and analysis software PDQuest (version 8.0.1, Bio-Rad) was used for quantitative analysis of wild-type and mutant samples according to the protocols provided by the manufacturer.

In-gel digestion was performed on CBB-stained protein spots. Sequence-grade modified trypsin (12.5 ng/μL) (Promega, Madison, WI, USA) was added in a digestion buffer containing 50 mM ammonium bicarbonate and 5 mM CaCl2 to the dehydrated gel pieces and allowed to absorb for 45 min on ice. In-gel digestion of protein was performed overnight at 37 °C, followed by three extractions of peptides with 50 % (v/v) acetonitrile and 5 % (v/v) trifluoroacetic acid. The combined supernatants were dried and re-suspended in a small volume (3–5 mL) of 0.1 % (v/v) trifluoroacetic acid in 50 % (v/v) acetonitrile.

For protein identification, a 4,700 Proteomics Analyzer (Applied Biosystems, Foster City, CA, USA) was used for all MALDI-TOF MS (matrix-assisted laser desorption ionization time-of-flight mass spectrometry). The peptide mass profiles obtained were internally calibrated with MoverZ (http://www.genomicsolutionscanada.com). The proteins were identified by comparing peptide mass fingerprints to the NCBInr and Swiss-Prot protein databases using the Mascot software (http://www.matrixscience.com).

Results

Mutagenesis and screening of mutants

Cells of S. dimorphus were gamma-irradiated to induce mutagenesis, and the cells that survived were cultured in BBM agar plates. Mutant screening was performed with cells that survived after irradiation at doses from 100 to 800 Gy. At the absorbed doses of 200 and 500 Gy, the survival rates of S. dimosphus were 58 and 27 %, respectively. At 800 Gy, the survival rate was less than 10 %. At lower irradiation doses, the rate of survival cells was high, but the mutant with higher lipid content was little obtained. Therefore, the irradiation for the mutation was carried out at the absorbed dose of 800 Gy.

After 5–7 days of culture, culture broths that showed dark green were selected and neutral lipid levels were measured by Nile red fluorescence. Several mutants of S. dimorphus showing increased intensity in fluorescence were chosen for a more detailed characterization. For accurate analysis, the cells were cultured in 100 mL of liquid BBM medium to mid-log phase, and the relative neutral lipid content was determined on a cell dry weight basis. After this screening process, the mutant strain with high lipid content named Sd-Pm210 was finally selected.

Morphological and genetic comparison of wild type and mutant Sd-Pm210

Wild-type and mutant Sd-Pm210 S. dimorphus were compared for morphological changes using microscopy (Fig. 1). Sd-Pm210 mutant had a round form and a blunt end, but wild-type cells showed a long form and a sharp end. In analysis by microscopic images of 500 cells of wild-type and mutant strains, the average length and height of the mutant cells were found to be about 83 and 123 %, respectively, of those of the wild type.

To confirm the genetic changes in mutant Sd-Pm210, RAPD was performed with the use of 15 primers. Among the 15 primers screened, PCR products with five primer sets were shown to be different in wild-type and mutant strains (Fig. 2). Eight PCR products were only amplified in wild type, and five PCR products were only amplified in mutant. This result showed that there was some modification in the genome of mutant Sd-Pm210 S. dimorphus.

Growth rate and triacylglycerol (TAG) and total lipid content

The growth of the wild-type and mutant strains was measured for 16 days after inoculation (Fig. 3). The growth rate of mutant Sd-Pm210 was higher than that of the wild type. Optical density of Sd-Pm210 was approximately 1.45-fold higher compared to that of the wild type after 9 days of cultivation.

Isolated mutant Sd-Pm210 was analyzed to confirm the changes on TAG content levels via thin-layer chromatography (TLC) (Fig. 4). In TLC, the spots of TAG and fatty acids were larger in mutant compared to those in wild type.

For further analysis, the total lipid content was measured using dry cell weight. Lipid content increased about 1.25-fold in mutant, and lipid productivity was 32 % higher in the mutant strain compared to those in the wild type (Table 1).

FAME (fatty acid methyl ester) analysis by gas chromatography is shown in Table 2. The main fatty acids analyzed were palmitic acid (C16:0), stearic acid (C18:0), oleic acid (C18:1n9c), linoleic acid (C18:2n6c), and linolenic acid (C18:3n3). In FAME, the peak areas of mutant Sd-Pm210 were all larger than those of the wild type, and the total peak area of Sd-Pm210 was larger by a factor of 1.4 relative to that of wild type.

Comparison of protein expression patterns between wild-type and mutant Sd-Pm210

To understand the metabolism during high lipid accumulation and growth of the mutant Sd-Pm210, the protein expressions of wild-type and mutant Sd-Pm210 were compared by 2-D electrophoresis. Representative SDS–PAGE gels of the two different strains are presented in Fig. 5. More than 600 spots were detected in both strains. All spots were quantified using PDQuest software via gel-to-gel comparison. Among the detected spots, 17 protein spots showed at least twofold higher expression levels among those of wild-type and mutant Sd-Pm210. Five protein spots that showed higher expression levels in wild type and 12 spots that showed higher expression levels in mutant were analyzed for identification via MALDI-TOF MS. Only 11 proteins were reported to match proteins in the database with search scores above the minimum threshold for a significant match (p < 0.05), according to the individual search programs (Table 3). Those 11 spots were identified through searches of NCBInr and the Swiss-Prot protein database via MASCOT software. In results of MALDI-TOF MS, the MASCOT score (22–96) and sequence coverage (4–65 %) of each match were sufficiently high. The proteins were matched to the proteins of other algae, higher plants, etc. Among the 11 identified proteins, 8 were up-regulated in mutant while 3 were down-regulated.

Among the identified protein spots, four spots (SSP 2803, 2813, 3506, and 8419) represented lipid biosynthesis-related proteins, and other identified spots contributed to other metabolic activities such as energy (SSP 2807 and 2812), signaling (SSP 5726, 1818, and 1411), DNA metabolism (SSP 4418), and heat resistance (SSP 8707).

Discussion

Microalgae are already well known to produce the lipid that is the raw material for biodiesel. However, many studies have still been conducted to get an improved strain for the commercialization of biodiesel produced with microalgae. As a part of that effort, many strains have been developed via mutant breeding [26]. Li et al. [21] demonstrated that low starch and starchless C. reinhardtii mutants overproduced neutral lipid. There are many ways to induce mutation (chemical, physical, transgenic, etc.). In the previous study, Chlamydomonas reinhardtii mutant with 20 % higher lipid content was generated by restriction enzyme-mediated integration method [9]. Genetic mutation such as transgenic via foreign gene introduction has the limitation of producing unstable recombinant microalgae. Furthermore, lipid synthesis metabolism and function of specific genes of microalgae have not been defined well yet. Therefore, in this study, breeding via gamma irradiation has been used to develop a high lipid-producing S. dimorphus mutant. Radiation breeding had been successfully applied for the development of starch-over producing mutant Spirogyra [27].

After screening the induced mutant library via Nile red staining, the isolated mutant Sd-Pm210 was genetically analyzed. There are many experiments that find similarities and complete the classification of different strains via RAPD analysis [2, 11]. In this study, RAPD analysis was carried out to find genetic changes in mutant compared to wild type. PCR product profiles showed that there were some differences in the genome of the S. dimorphus mutant. However, any additional implications involving the genetic changes will need further experiments with genome sequencing.

The genetic mutation technologies such as transgenic via foreign gene induction have the limitation of producing unstable recombinant algae. In this respective, the gamma-irradiated microalga mutant from the present study was tested for the stability of high-lipid content. The stability was verified by making ten serial loopful to broth transfer. The terminal cultures were collected and analyzed for its lipid content and RAPD, and there was no difference from the initial mutant.

Lipid content is one of the most important parameters for the economical production of biodiesel. Lipid productivity as well as lipid content is also other important factor for cost-effective production of biodiesel [16]. Therefore, the growth rate and total lipid content of a mutant strain have been analyzed. According to the results of the experiment, it was confirmed higher lipid content and faster growth rate of mutant Sd-Pm210 relative to wild type. Additionally, changes in levels of free fatty acid, the main raw material of biodiesel, were confirmed by FAME analysis.

To understand the metabolic changes in mutant Sd-Pm210, 2-D electrophoresis was carried out to compare the protein expressions of wild type and mutant. Among the proteins identified, expression of lipid biosynthesis-related proteins, such as 3-methyl-2-oxobutanoate hydroxymethyltransferase (SSP 2803), was observed to be higher in the mutant. 3-Methyl-2-oxobutanoate hydroxymethyltransferase contributes to the pantothenate biosynthetic process. For many organisms, pantothenate is an essential nutrient to synthesize coenzyme-A as well as to synthesize and metabolize proteins and fats. In addition, acetyl-CoA carboxylase (SSP 2813) and acyl carrier protein (SSP 3506) are important factors that contribute to the fatty acid biosynthesis process in cytoplasm and chloroplast, respectively. These results suggest that increased expression of these proteins enables the mutant to maintain high levels of total lipid synthesis.

Among the up-regulated protein spots, various energy metabolism-related proteins were also identified in the mutant, including ATP synthase (SSP 2807). The ATP synthase subunit is also involved in the regulation of intracellular ATP levels [25], which suggest that increasing ATP synthase level could have caused an increase in the growth rate of the mutant.

In conclusion, a high lipid-accumulating mutant of S. dimorphus Sd-Pm210 was isolated and found to exhibit high rates of growth and lipid production. Through proteomic analysis, it was proposed that this radiation-induced mutant exhibits efficient energy metabolism and lipid synthesis and, therefore, could be utilized for the production of biofuel. Further efforts should be taken to increase the scale of production of biomass for this species, from laboratory-scale culture to pond-scale culture.

References

Al-Zahim MA, Ford-Lloyd BV, Newbury HJ (1999) Detection of somaclonal variation in garlic (Allium sativum L.) using RAPD and cytological analysis. Plant Cell Rep 18:473–477

Baillie BK, Belda-Baillie CA, Silvestre V, Sison M, Gomez AV, Gomez ED, Monje V (2000) Genetic variation in Symbiodinium isolates from giant clams based on random-amplified-polymorphic DNA (RAPD) patterns. Mar Biol 136:829–836

Berberoglu H, Gomez PS, Pilon L (2009) Radiation characteristics of Botryococcusbraunii, Chlorococcumlittorale, and Chlorella sp. used for CO2 fixation and biofuel production. J Quant Spectrosc Radiat Transf 110:1879–1893

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Biochem Physiol 37(8):911–917

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sustain Energy Rev 14:557–577

Browse J, McCourt PJ, Somerville CR (1986) Fatty acid composition of leaf lipids determined after combined digestion and fatty acid methyl ester formation from fresh tissue. Anal Biochem 152:141–145

Brune DE, Lundquist TJ, Benemann JR (2009) Microalgal biomass for greenhouse gas reductions: potential for replacement of fossil fuels and animal feeds. Environ Eng 135:1136–1144

Chen W, Zhang C, Song L, Sommerfeld M, Hu Q (2009) A high throughput Nile red method for quantitative measurement of neutral lipids in microalgae. Microbiol Methods 77:41–47

Choi YE, Hwang H, Kim HS, Ahn JW, Jeong WJ, Yang JW (2013) Comparative proteomics using lipid over-producing or less-producing mutants unravels lipid metabolisms in Chlamydomonads reinhardtii. Bioresour Technol 145:108–115

Day JG, Benson EE, Fleck RA (1999) In vitro culture and conservation of microalgae: applications for aquaculture, biotechnology and environmental research. In Vitro Cell Dev Biol Plant 35:127–136

de Morais MG, da Cruz Reichert C, Dalcanton F, Durante AJ, Marins LF, Costa JAV (2008) Isolation and characterization of a new Arthrospira strain. Z Naturforsch 63(11):144–150

Deng X, Li Y, Fei X (2009) Microalgae: a promising feedstock for biodiesel. Microbiol Res 3:1008–1014

Dismukes GC, Carrieri D, Bennette N, Ananyev GM, Posewitz MC (2008) Aquatic phototrophs: efficient alternatives to land-based crops for biofuels. Curr Opin Biotechnol 19:235–240

Duffy JE, Canuel EA, Adey W, Swaddle JP (2009) Biofuels: algae. Science 326:1345

Gouveia L, Oliveira AC (2009) Microalgae as a raw material for biofuels production. Ind Microbiol Biotechnol 36:269–274

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. Appl Phycol 21:493–507

Shah GC, Yadav M, Tiwari A (2012) Assessment for the higher production of biodiesel from Scenedesmus dimorphus algal species. Erud J of Biotechnol 1:1–9

Hu Q, Sommerfeld M, Jarvis E, Ghirardi M, Posewitz M, Seibert M, Darzins A (2008) Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances. Plant 54:621–639

Kosaric N, Velikonja J (1995) Liquid and gaseous fuels from biotechnology: challenge and opportunities. Microbiol Rev 16:111–142

Lepage G, Roy CC (1984) Improved recovery of fatty acid through direct transesterification without prior extraction or purification. Lipid Res 25:1391–1396

Li Y, Han D, Hu G, Dauvillee D, Sommerfeld M, Ball S, Hu Q (2010) Chlamydomonas starchless mutant defective in ADP-glucose pyrophosphorylase hyper-accumulates triacylglycerol. Metab Eng 12:387–391

Llman AM, Scragg AH, Shales SW (2000) Increase in Chlorella strains calorific values when grown in low nitrogen medium. Enzyme Microbial Technol 27:631–635

McGinnis KM, Dempster TA, Sommerfeld MR (1997) Characterization of the growth and lipid content of the diatom Chaetoceros muelleri. Appl Phycol 9:19–24

Scurlock JMO, Hall DO, House JI, Howes R (1993) Utilizing biomass crops as an energy source: a European perspective. Water Air Soil Pollut 70:499–518

Suda Y, Yoshikawa T, Okuda Y, Tsunemoto M, Tanaka S, Ikeda K, Miyasaka H, Watanabe M, Sasaki K, Harada K, Bamba T, Hirata K (2009) Isolation and characterization of a novel antistress gene from Chlamydomonas sp. W80. J Biosci Bioeng 107:352–354

Vigeolas H, Duby F, Kaymak E, Niessen G, Motte P, Franck F, Remacle C (2012) Isolation and partial characterization of mutants with elevated lipid content in Chlorella sorokiniana and Scenedesmu sobliquus. Biotechnology 162:3–12

Yoon MC, Choi JI, Kim GH, Kim DH, Park DH (2013) Proteomic analysis of Spirogyra varians mutant with high starch content and growth rate induced by gamma irradiation. Bioprocess Biosyst Eng 36(6):757–763

Yoon MC, Yang HY, Lee SS, Kim DH, Kim GH, Choi JI (2013) Characterization of gamma radiation inducible thioredoxin h from Spirogyra varians. Enzyme Microbial Technol 53(3):136–142

Acknowledgments

This research was supported by Golden Seed Project, Ministry of Agriculture, Food and Rural Affairs(MAFRA), Ministry of Oceans and Fisheries(MOF), Rural Development Administration(RDA), and Korea Forest Service(KFS), by the research supporting program by Chonnam National University 2013, and by the Antarctic organisms: Cold-Adaptation Mechanisms and its application grant (PE14070) funded by the Korea Polar Research Institute.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, Ji., Yoon, M., Joe, M. et al. Development of microalga Scenedesmus dimorphus mutant with higher lipid content by radiation breeding. Bioprocess Biosyst Eng 37, 2437–2444 (2014). https://doi.org/10.1007/s00449-014-1220-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1220-7