Abstract

Klebsiella is one of the genera that has shown unbeatable production performance of 2,3-butanediol (2,3-BD), when compared to other microorganisms. In this study, two Klebsiella strains, K. pneumoniae (DSM 2026) and K. oxytoca (ATCC 43863), were selected and evaluated for 2,3-BD production by batch and fed-batch fermentations using glucose as a carbon source. Those strains’ morphologies, particularly their capsular structures, were analyzed by scanning electron microscopy (SEM). The maximum titers of 2,3-BD by K. pneumoniae and K. oxytoca during 10 h batch fermentation were 17.6 and 10.9 g L−1, respectively; in fed-batch cultivation, the strains showed the maximum titers of 50.9 and 34.1 g L−1, respectively. Although K. pneumoniae showed higher productivity, SEM showed that it secreted large amounts of capsular polysaccharide, increasing pathogenicity and hindering the separation of cells from the fermentation broth during downstream processing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

2,3-Butanediol (2,3-BD), also known as 2,3-butylene glycol or dimethylene glycol, is a four-carbon diol synthesized as a product of mixed-acid fermentation. There is growing interest in the production of this industrially important chemical from renewable resources by microbial fermentation because 2,3-BD can be converted to a high-heating value (27,198 J g−1) liquid fuel additive, methyl ethyl ketone (MEK), and 1,3-butadiene, important in synthetic rubber production [1–4] the prices per kg of which have increased from US $ 1.67 to 2.32 and from US $ 2.20 to 3.99 per kg, respectively, during the first-half of 2011 mainly due to increasing prices of fossil raw materials.

Bacteria and yeasts have been studied for over 100 years with the aim of producing 2,3-BD by microbial fermentation [5–7]. Although many microorganisms inherently produce 2,3-BD via mixed-acid fermentation, K. pneumoniae, K. oxytoca, Enterobacter aerogenes, and Bacillus polymyxa can produce more 2,3-BD than other strains [8, 9]. Among them, Klebsiella species, K. pneumonia and K. oxytoca, have shown the best production of 2,3-BD by fermentation from a wide range of substrates, including pentoses (xylose and arabinose), hexoses (glucose, mannose, and galactose), and disaccharides (sucrose, lactose, cellobiose) [10–18]. Some Klebsiella species can also produce 2,3-BD from glycerol, one of the cheapest carbon sources in the recent days due to its surplus availability as a biodiesel byproduct [19, 20].

The production of 2,3-BD by various strains has been reported at high titer. The production of 2,3-BD using wild type and mutant strains of K. pneumoniae and K. oxytoca has been studied in various fermentation systems [21–23]. However, the merits and disadvantages of these two strains’ fermentation capabilities and usabilities have not been reported in detail.

This work reports a series of batch fermentations by wild type strains of K. pneumoniae (DSM 2026) and K. oxytoca (ATCC 43863) with initial glucose concentrations of 100–750 mmol L−1. Time course profiles of 2,3-BD and byproducts, including formic acid, acetic acid, ethanol, lactic acid, succinic acid, and acetoin, were recorded to investigate the selectivity of the strains. Fed-batch fermentations by both strains were conducted over an optimal range of glucose concentrations to assess in detail their fermentative characteristics. The morphology of the strains were analyzed by SEM and their industrial potential for 2,3-BD production was assessed.

Materials and methods

Microorganisms and media

Klebsiella pneumonia DSM 2026 and K. oxytoca ATCC 43863 were obtained from the German Collection of Microorganisms and the American Type Culture Collection, respectively. For seed preparation, cells from single colonies on Luria–Bertani (LB) agar (Difco Laboratories, Detroit, MI) plates were suspended in 20 mL test tubes with 5 mL complex medium and incubated at 37 °C for 5 h. 1 mL samples of culture medium were then transferred to 500 mL Erlenmeyer flasks containing 300 mL complex medium and grown to an optical density at 600 nm (OD600) of 2.0. Test tube and flask cultures were conducted in a rotary shaker at 150 rpm and 37 °C. The complex medium contained per liter: 5 g Bacto Difco yeast extract (Becton–Dickinson, Le Pont de Claix, France), 0.05 g FeSO4·7H2O, 0.001 g ZnSO4·7H2O, 0.001 g MnSO4·H2O, 0.001 g CaCl2·2H2O, 0.25 g MgSO4·7H2O, 6.6 g (NH4)2SO4, 8.7 g K2HPO4, and 6.8 g KH2PO4.

Fermentations

Batch fermentations were performed in a 5-l BIOFLO® & CELLIGEN® 310 bioreactor (New Brunswick. Scientific Co., Edison, NJ) containing 2.7 L complex medium plus 100, 200, 300, 400, 500, or 750 mmol L−1 glucose. The fermentor was continuously aerated through a 0.2-μm membrane filter at a flow rate of 3.0 L min−1. To minimize evaporation, the vent gas passed through a modified condenser mounted on the headplate of the fermentor. The agitation speed and temperature were maintained at 150 rpm and 37 °C, respectively, and pH was controlled at 6.5 ± 0.1 by the automatic addition of 5 N NaOH. Fed-batch fermentations were carried out by continuously feeding the fermentor with a concentrated solution containing 700 g L−1 glucose and 20 g L−1 MgSO4·7H2O at a predetermined flow rate using a peristaltic pump (Cole-Parmer, Vernon Hills, IL, USA). Unless otherwise noted, the conditions of fed-batch fermentation were similar to those of the batch fermentation.

Analytical procedures

The concentrations of glucose and metabolites, including 2,3-BD, formic acid, ethanol, acetic acid, lactic acid, succinic acid, and acetoin, were analyzed using a high-performance liquid chromatograph equipped with a refractive index detector (Agilent 1200 series, Agilent Technologies, Waldbronn, Germany). An Aminiex HPX-87H column (300 mm × 7.8 mm, Bio-Rad, Hercules, CA, USA) was isocratically eluted with 0.01 N H2SO4 at a flow rate of 0.6 mL min−1. The column oven temperature was 80 °C. Cell growth was monitored by measuring OD600 by UV–vis spectrophotometry (DR5000, Hach Company, CO). Cell concentration, dry cell weight (DCW), was determined from the standard curve relating OD600 to DCW per liter of culture broth (g L−1). DCW was measured by filtering the culture broth through a 0.45-μm membrane and washing it twice with equal volumes of deionized distilled water. The filtered cells were dried in an oven at 80 ± 5 °C overnight, cooled to room temperature in a desiccator and weighed.

For SEM, cells were fixed in a mixture of 2.5% glutaraldehyde and 2.0% paraformaldehyde solution buffered in 0.1 M sodium cacodylate (pH 7.2) at 4 °C for 2 h. They were then immobilized on a glass slide coated with poly-l-lysine. Secondary fixation was conducted in a mixture of 1.5% potassium ferricyanide and 1.0% osmium tetroxide. Prior to dehydration with hexamethyl disilizane, samples were pre-dehydrated using ethanol at 50, 60, 70, 80, 90, and 95% in series. All chemicals used in SEM preparation were of reagent grade and from Sigma-Aldrich. The dehydrated samples were sputter coated with gold at 30 mA plasma current under argon gas for 150 s. Microscopic examinations were carried out using a SEM (Quanta™ 250FEG, FEI Company, Hillsboro, OR) at an acceleration voltage of 10 kV.

Results and discussion

Batch fermentation

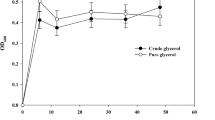

The efficiency of 2,3-BD production by K. pneumoniae and K. oxytoca was assessed by cultivating the strains under bioreactor conditions in a complex medium containing various initial glucose concentrations (100–750, 100 mmol L−1 glucose results not shown). Fermentation was continued until the glucose was completely exhausted (Table 1). For clarity, the time course profiles (Fig. 1) represent only a maximum of 10 h. The final 2,3-BD titer by K. pneumoniae (Fig. 1a–e) in all conditions was between 50 and 100% higher than the corresponding K. oxytoca equivalent (Fig. 1f–j). Since K. oxytoca showed a lower rate of glucose consumption, its fermentations took longer than those by K. pneumoniae (Table 1). 2,3-BD yield was highest with initial glucose concentrations of 300–400 mmol L−1 (Table 1). Glucose added at 500 mmol L−1 and above decreased the rates of cell growth, 2,3-BD production, and glucose consumption through substrate inhibition.

K. pneumoniae produced more 2,3-BD than K. oxytoca, mainly due to the nature of the mixed-acid fermentation. The anaerobic conversion of glucose to 2,3-BD occurs by the following equation: glucose → 2,3-BD + NADH2 + 2ATP + 2CO2 [24]. Production of 2,3-BD is likely to continue only if NAD+ is regenerated. During fermentation, the excess NADH2 is oxidized by producing reduced metabolites such as lactic acid and ethanol, with aeration reducing the demand for the production of excess metabolites [22]. The two strains showed differing metabolites profile (Figs. 1, 2). Lactic acid was the major byproduct from K. oxytoca, it was produced between two and four times more than by K. pneumoniae. Twice as much formic acid, the other acidic metabolite, was produced by K. pneumoniae than by K. oxytoca. The formic acid flux of K. pneumoniae indicates that most acetyl-CoA formed through pyruvate formate lyase (PFL), with K. oxytoca having used both PFL and pyruvate dehydrogenase complex (PDHc). K. pneumoniae produced twice as much ethanol, a reduced neutral metabolite, as K. oxytoca. This favoring of ethanol production over lactic acid contributed to the consumption of 2 mol of NADH, which was favorable to the redox balance for enhanced 2,3-BD production. Acetoin in the K. oxytoca culture was much higher than in the K. pneumoniae culture, which also suggests the large accumulation of NADH (Fig. 2). Acidic metabolites, potential inhibitors of cell function and 2,3-BD formation [25], were produced much more in the fermentation broth of K. oxytoca.

Metabolite distributions of K. pneumoniae and K. oxytoca in media with different initial glucose concentrations. a 200 mmol L−1, b 300 mmol L−1, c 400 mmol L−1, d 500 mmol L−1, e 750 mmol L−1. black ethanol, red succinic acid, green formic acid, yellow acetoin, blue lactic acid, and pink acetic acid

Fed-batch fermentation

Fed-batch fermentation by K. pneumoniae for 100 h produced a maximum titer of 51 g L−1 2,3-BD, about 30% higher than that from comparable fermentation by K. oxytoca (Table 2). In the initial 25 h of fermentation, glucose uptake and 2,3-BD production rates were comparable to those of batch fermentation. NAD+ regeneration by K. pneumoniae appeared to be through ethanol production pathway during the early period of fermentation, while K. oxytoca used lactic acid production pathway to regenerate NAD+. The selectivity of 2,3-BD production over other metabolites and the yield over glucose during initial K. oxytoca fermentation were much lower than during K. pneumoniae fermentation. Later during fermentation, the increased accumulation of metabolites in the fermentation broth would have limited glucose uptake, decreasing the rate of 2,3-BD production.

Each strain’s metabolite profile shows similar trends to their batch results. Both strains showed similar total molar concentrations of acidic metabolites, including formic, acetic, lactic, and succinic acids. However, K. oxytoca required twice as much base solution (5 N NaOH) to maintain pH 6.5 during the whole period of the fermentation. Similar to batch fermentation, acidification in the K. oxytoca culture broth was much higher than in the K. pneumoniae culture broth, mainly due to the higher production of 2,3-BD and ethanol by K. pneumoniae. The high pK a values of 2,3-BD (14.7 and 15.0) and ethanol (16.0) may have reduced the amount of the base solution needed for neutralization [26]. Furthermore, the pK a of lactic acid (3.86), the main byproduct by K. oxytoca fermentation, was much lower than those of the other acidic byproducts (acetic acid 4.75, succinic acid 4.16 and 5.61) except formic acid (formic acid 3.75). Less alkalinization and more acidification of K. oxytoca fermentation were the reason for requiring more NaOH, and the resulting high salt concentrations in fermentation broths normally inhibit cell growth and significantly adversely affect downstream processing and also wastewater treatment [27]. In particular, sodium from salt can degrade soil.

Microscopic analysis

Plate and broth cultures of both strains were examined. The high viscosity of K. pneumoniae in the broth and its stickiness on the agar plate indicated the presence of mucoid-like substances. When the culture broth was centrifuged at high speed (15,000×g), cell pellet was not formed (images not shown) at the bottom of the tube. Such behavior was not shown by K. oxytoca.

Cells’ morphological differences were observed by SEM. 50,000× and 100,000× magnification images clearly show the presence of CPS in K. pneumoniae but not in K. oxytoca (Fig. 3). A dense layer of CPS in K. pneumoniae has been reported to be pathogenic when tested in several animal models, causing pneumonia [28]. Capsulated K. pneumoniae cells were difficult to separate from the fermentation broth, which would hamper downstream processing. Such properties do not favor using K. pneumoniae in commercial 2,3-BD fermentation at large scale. However, given its superior 2,3-BD production, engineering K. pneumoniae for reducing CPS production is beneficial. Lin et al. [29] mutated certain genes responsible for CPS production to significantly reduce its production. Similarly, certain open reading frames responsible for CPS production in K. pneumoniae have been inactivated, allowing the viscosity of the fermentation broth to be reduced by up to 27% [30]. Therefore, K. pneumoniae with mutated genes responsible for CPS production remains potentially applicable industrially (Fig. 4).

Fed-batch fermentation profiles of K. pneumoniae (a) and K. oxytoca (b) during the production of 2,3-BD. Metabolites of K. pneumoniae (c) and K. oxytoca (d). Closed star lactic acid, closed circle ethanol, open circle succinic acid, closed triangle down formic acid, open triangle up acetoin, and closed square acetic acid

Conclusions

2,3-BD production by two Klebsiella strains and their cultural behaviors during fermentation were studied. K. pneumoniae showed a titer of 2,3-BD production 1.5-fold that of K. oxytoca. However, it also produced CPS that would hinder its industrial use. Therefore, disrupting the genes responsible for CPS synthesis to obtain non-pathogenic, non-CPS forming strain that would not obstruct downstream purification appears potentially beneficial. Engineering the metabolic pathways of K. oxytoca to reduce production of acidic metabolites could also lead to a strain suitable for 2,3-BD production.

References

Winfield ME (1945) The catalytic dehydration of 2,3-butanediol to 1,3-butadiene. J Council Sci Ind Res 18:412–423

Emerson RR, Flickinger MC, Tsao GT (1982) Kinetics of dehydration of aqueous 2,3-butanediol to methyl ethyl ketone. Ind Eng Chem Prod Res Dev 21:473–477

Yu EKC, Saddler JN (1982) Power solvent production by Klebsiella pneumoniae grown on sugars present in wood hemicelluloses. Biotechnol Lett 4:121–126

Garg SK, Jain A (1995) Fermentative production of 2,3-butanediol: a review. Bioresour Technol 51:103–109

Harden A, Walpole GS (1906) 2,3-Butylene glycol fermentation by Aerobacter aerogenes. Proc Roy Soc B 77:399–405

Syu MJ (2001) Biological production of 2,3-butanediol. Appl Microbiol Biotechnol 55:10–18

Ji XJ, Huang H, Ouyang PK (2011) Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol Adv 29:351–364

Celińska E, Grajek W (2009) Biotechnological production of 2,3-butanediol—current state and prospects. Biotechnol Adv 27:715–725

Ma C, Wang A, Qin J, Li L, Ai X, Jiang T, Tang H, Xu P (2009) Enhanced 2,3-butanediol production by Klebsiella pneumoniae SDM. Appl Microbiol Biotechnol 82:49–57

Barrett EL, Collins EB, Hall BJ, Matoi SH (1983) Production of 2,3-butylene glycol from whey by Klebsiella pneumonia and Enterobacter aerogenes. J Dairy Sci 66:2507–2514

Jansen NB, Tsao FT (1983) Bioconversion of pentoses to 2,3-butanediol by Klebsiella pneumoniae. Adv Biochem Eng Biotechnol 27:85–99

Jansen NB, Flickinger MC, Tsao FT (1984) Production of 2,3-butanediol from d-xylose by Klebsiella oxytoca ATCC 8724. Biotechnol Bioeng 26:362–369

Champluvier B, Decallonne J, Rouxhet PG (1989) Influence of sugar source (lactose, glucose, galactose) on 2,3-butanediol production by Klebsiella oxytoca NRRL-B199. Arch Microbiol 152:411–414

Grover BP, Garg SK, Verma J (1990) Production of 2,3-butanediol from wood hydrolysate by Klebsiella pneumoniae. World J Microbiol Biotechnol 6:328–332

Afschar AS, Bellgardt KH, Rossel CE, Czok A, Schaller K (1991) The production of 2,3-butanediol by fermentation of high test molasses. Appl Microbiol Biotechnol 34:582–585

Frazer FR, McCaskey TA (1991) Effect of components of acid-hydrolysed hardwood on conversion of d-xylose to 2,3-butanediol by Klebsiella pneumoniae. Enzyme Microb Technol 13:110–115

Cao N, Xia Y, Gong CS, Tsao GT (1997) Production of 2,3-butanediol from pretreated corn cob by Klebsiella oxytoca in the presence of fungal cellulose. Appl Biochem Biotechnol 63:129–139

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Li S, Nie ZK (2009) Development of an industrial medium for economical 2,3-butanediol production through co-fermentation of glucose and xylose by Klebsiella oxytoca. Bioresour Technol 100:5214–5218

Biebl H, Zeng AP, Menzel K, Deckwer WD (1998) Fermentation of glycerol to 1,3-propanediol and 2,3-butanediol by Klebsiella pneumonia. Appl Microbiol Biotechnol 50:24–29

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39

Zheng Y, Zhang HY, Zhao L, Wei LJ, Ma XY, Wei DZ (2008) One-step production of 2,3-butanediol from starch by secretory over-expression of amylase in Klebsiella pneumoniae. J Chem Technol Biotechnol 83:1409–1412

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Hu N, Li S (2009) Enhanced 2,3-butanediol production by Klebsiella oxytoca using a two-stage agitation speed control strategy. Bioresour Technol 100:3410–3414

Ji XJ, Huang H, Du J, Zhu JG, Ren LJ, Nie ZK, Du J, Li S (2010) Engineering Klebsiella oxytoca for efficient 2,3-butanediol production through insertional inactivation of acetaldehyde dehydrogenase gene. Appl Microbiol Biotechnol 85:1751–1758

Zhang L, Yang Y, Sun Jian, Shen Y, Wei D, Zhu J, Chu J (2010) Microbial production of 2,3-butanediol by mutagenized strain of Serratia marcescens H30. Bioresour Technol 101:1961–1967

Cheng KK, Liu HJ, Liu DH (2005) Multiple growth inhibition of Klebsiella pneumoniae in 1,3-propanediol fermentation. Biotechnol Lett 27:19–22

Woolley EM, George RM (1974) Ionization constants for water and for very weak organic acids in aqueous organic mixtures. J Sol Chem 3:119–126

Riffat R, Krongthamchat K (2006) Specific methanogenic activity of halophilic and mixed cultures in saline wastewater. Int J Environ Sci Technol 2:291–299

Simoons-Smit AM, Verweij-van Vught AM, MacLaren DM (1986) The role of K antigen as virulence factors in Klebsiella. J Med Microbiol 21:133–137

Lin MH, Hsu TL, Lin SY, Pan YJ, Jan JT, Wang JT, Khoo KH, Wu SH (2009) Phosphoproteomics of Klebsiella pneumoniae NTUH-K2044 reveals a tight link between tyrosine phosphorylation and virulence. Mol Cell Proteomics 8:2613–2623

Guo NN, Zheng ZM, Mai YL, Liu HJ, Liu DH (2010) Consequence of cps mutation of Klebsiella pneumoniae on 1,3-propanediol fermentation. Appl Microbiol Biotechnol 86:701–707

Acknowledgments

The authors thank Mi Yeon Cho and Duk-Ki Kim for their technical assistance on cell cultures and analytical procedures. This work was supported by the Industrial Strategic Technology Development Program (No. 10035241) funded by the Ministry of Knowledge Economy (MKE, Korea).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cho, JH., Rathnasingh, C., Song, H. et al. Fermentation and evaluation of Klebsiella pneumoniae and K. oxytoca on the production of 2,3-butanediol. Bioprocess Biosyst Eng 35, 1081–1088 (2012). https://doi.org/10.1007/s00449-012-0691-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0691-7