Abstract

A polymethylmethacrylate (PMMA) conico-cylindrical flask (CCF) with an inner arrangement consisting of eight equidistantly spaced rectangular strips mounted radially on a circular disk to provide additional surface area for fungal attachment was employed for production of cellulase by Chaetomium crispatum and xylanase by Gliocladium viride. The design allowed comparison of production between CCFs with hydrophobic surface (PMMA-CCF), hydrophilic glass surface (GS-CCF) and 500-ml Erlenmeyer flask (EF). Compared with the EF, endo-β-1,4-glucanase and FPase (filter paper degradation) activities increased from 0.044 to 0.156 and from 0.008 to 0.021 IU/ml, respectively, in the PMMA-CCF, while growth of C. crispatum was higher by at most 1.38-fold compared with the other vessels. Xylanase production in the EF was at most 5.08-fold higher and growth of G. viride was at most 1.52-fold higher compared with the other vessels. Temporal pattern of biofilm development based on two-channel fluorescence detection of extracellular polymeric substances (EPSs) and whole cells in a confocal laser scanning microscope demonstrated increase by 100% in biovolume, 25% in thickness and 62.5% both in substratum coverage and total spreading of C. crispatum biofilm in PMMA-CCF over 6 days. Biovolume of G. viride biofilm in GS-CCF increased by 150% over 4 days while that in PMMA-CCF enhanced by 200% over 2 days. Biofilm thickness in PMMA-CCF was 44% higher compared with GS-CCF and increased by 175% over 2 days. Substratum coverage was 38% higher in GS-CCF compared with PMMA-CCF. Thus, reactor surface area and property, shear forces and biofilm formation influenced enzyme production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The intertidal zone, which occupies the upper edge of the world’s coasts extending over 1,600,000 km, is probably the most important coastal habitat given its biological productivity and economic value. It comprises rocky platforms, sandy beaches, mudflats, estuaries, salt marshes, mangrove forests, certain coral reefs and human-made infrastructures. Intertidal microbial communities often occur as biofilms which are high-density attached communities embedded in extracellular biopolymer matrices [1]. The microbial biofilm is a common adaptation of natural bacteria and other microorganisms. In the fluctuating environments of intertidal systems, biofilms form protective microenvironments and may structure a range of microbial processes [2].

Marine surface-associated microorganisms may require conditions that resemble their native environment in order to produce the maximum amount of bioactives; for example, several studies have shown an increased production of antimicrobial compounds when the surface-associated bacteria were grown in vitro to form surface attached biofilms [3]. Filamentous fungi from intertidal estuarine regions have been proven to be of biotechnological significance, some examples being as producer of enzymes [4] and oxidizer of polyaromatic hydrocarbons [5]. Gutierrez-Correa and Villena [6] proposed that both solid-state fermentation and fungal biofilm fermentation depended on surface adhesion and a new fermentation category named surface-adhesion fermentation (SAF) was suggested. However, no investigations have been done to demonstrate the effect of surface attachment of intertidal fungi on the production of bioactive metabolites, and it may be hypothesized that surface attachment of intertidal fungi can enhance bioactive metabolite production.

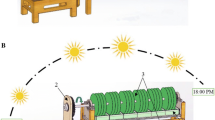

Currently, there are no small-scale vessels that provide substantially enhanced surface area as well as property for attachment of biofilm-forming microbes. It would therefore be advantageous to have a suitable device that would enable researchers to verify if surface attachment and biofilm formation would enhance production of bioactive substances by intertidal fungi on a small scale. A novel shaking flask, the CCF, the inner arrangement of which promotes biofilm formation was designed. Compared with corresponding Erlenmeyer flask of similar volume the CCF provided more than 80% additional surface for uniform biofilm attachment and growth. The device has a diameter close to that of a 500-ml Erlenmeyer flask so that it can be easily placed in a rotary shaker for routine small-scale studies. The diameter of the flask neck will not allow the insertion of the inner arrangement inside the standard shaking flask. To overcome this difficulty, the CCF has been designed. The CCF’s design enables the researcher to vary the internal surface properties (hydrophobic/hydrophilic) of the vessel. Previous successful studies in the CCF allowed comparison of protease activity of an intertidal gamma-proteobacterium [7], melanin production by intrinsically surface-adhering Shewanella colwelliana as well as antimicrobial activity of surface-colonizing Pseudoalteromonas rubra [8]. In the present investigation it was endeavored to compare cellulase and xylanase production by two identified estuarine filamentous fungi cultivated in the CCF with the activity obtained in the traditional Erlenmeyer flask. Thus, the aims of the present investigation were, first, to examine the application of the novel reaction vessel in filamentous fungal cultivations and second, to test the proposed hypothesis by demonstrating the effect of surface attachment of intertidal fungi on the production of enzymes.

In this study C. crispatum isolated from the estuarine sediments of the river Weser, Germany was used. The fungus produces a cellulolytic enzyme complex consisting of exo-1,4-β-glucosidase, endo-1,4-β-glucanase and beta-glucosidase or cellobiase. Insoluble crude cellulosics such as newsprint, recycled paper, rice and flax straw were substantially solubilized at 28 °C within 3–5 days of fermentation of C. crispatum [9]. The second fungus, G. viride was isolated from Santos estuary, Sao Paulo, Brazil. The fungus produces high yields of cellulase-free xylanase on oat spelts xylan and removes 7% of hemicellulose from pulp [10].

Materials and methods

Microorganisms and media composition

Chaetomium crispatum (CBS 149.58) and G. viride (CBS 109832) were used in this study. The first microorganism was maintained on oat meal agar and the second on potato dextrose agar, sub-cultured every month and stored at 4 °C. Cellulase production was studied by cultivating C. crispatum on Vogel’s complete medium [11], pH 6.0 containing 1% (w/v) carboxy methyl cellulose (CMC). For xylanase production, G. viride was grown in the basal medium containing (g/l) citric acid 0.25; (NH4)2SO4 5; K2HPO4 5; MgSO4·7H2O 0.5; CaCl2·2H2O 0.02; yeast extract 10; trace elements solution 1 ml supplemented with oat spelts xylan (1%, w/v), pH 6.0 [12, 13]. Disks cut from 72-h-old cultures actively growing on their respective maintenance medium plates were placed in 1.5 ml of sterile medium, vortexed and 1.0 ml of supernatant containing 10 9 spores/ml used to inoculate the vessels.

Flask configurations and operating conditions

The CCF made of polymethylmethacrylate (PMMA-CCF) was designed along with engineers from M/s Plastic Abhiyanta, Kolkata, India [7, 8]. The PMMA-CCF contained three parts, namely a lower cylindrical portion, an upper funnel portion and an inner arrangement. The dimensions were (a) lower cylindrical portion: height 150 mm, outer diameter 80 mm, thickness 5 mm; (b) upper funnel portion: diameter of the funnel base 90 mm, diameter of funnel top 40 mm. The two parts were joined by screwing the upper part into the lower part. The inner arrangement consisted of eight equally spaced rectangular strips mounted radially on a circular disk (height of the strip 150 mm, thickness 5 mm, diameter of the disk 70 mm, thickness 5 mm). In the second configuration (GS-CCF), 16 autoclaved borosilicate microscope glass slides (75 mm × 25 mm × 1.35 mm) were aseptically attached to both sides of the eight-strip inner arrangement of the PMMA-CCF with a strong non-toxic adhesive (Fevi Kwik, Pidilite Industries Ltd., Mumbai, India). This provided a hydrophilic surface to the inner arrangement of the GS-CCF, while the PMMA-CCF had hydrophobic surface characteristics. One hundred milliliters of medium was added to each vessel. The surface area of the inner arrangement was 706.4 cm2. The surfaces of the inner arrangement, of both PMMA-CCF and GS-CCF were roughened with Grade 50 sandpaper [7]. Quantitative measurement of roughness was obtained for roughened PMMA surfaces of 15 rectangular strips of the inner arrangement and the same number of roughened microscope glass slides. The roughness average value (R a) was determined on a stylus-type profilometer (Surtronic 3+, Taylor Hobson Ltd., England). The traverse length was 4.0 and the cut-off length was 0.8 mm. A traverse speed of 1 mm/s and a Gaussian filter were applied. Talyprofile (Taylor Hobson, England) software was employed for data analysis. For sterilization, the PMMA-CCF and GS-CCF were disassembled, the components washed thoroughly in tap water and immersed in 3% (v/v) sodium hypochlorite for 5 h. The parts were then surface-sterilized under UV light (TUV15W/G15T8, Philips, The Netherlands) in a laminar airflow bench for 30 min. The production of cellulase by C. crispatum and xylanase by G. viride in these two novel configurations were compared with that in a standard 500-ml Erlenmeyer flask made of borosilicate glass (EF), the third flask configuration. Ports on the top lid of the CCF were available for air inlet and exhaust. Three modes of aeration were examined in each of the three reactor configurations with the two fungi: shaking at 140 rpm in an orbital shaker (with cotton plugs), orbital shaking with external aeration of 0.75 l/min of air (through ports on top of the CCF) and external aeration without shaking. The radius of orbital shaking was 20 mm. Cultivation temperatures of C. crispatum and G. viride were previously optimized at 28 °C [9] and 30 °C [12], respectively. All cultivations were done thrice in duplicate sets for each vessel configuration. Samples (5 ml) were aseptically withdrawn alternately every 24 h for 7 days from each of the two flasks of the duplicate set.

Analytical methods

Measurement of culture pH

The pH of the culture broth was recorded every 24 h with a short-range (5.0–7.5) pH paper (Merck, India).

Assay of enzymatic activity

Generally, for all enzyme assays, the culture samples were filtered through Whatman No. 1 filter paper and the filtrates were centrifuged at 10,000g for 15 min at 4 °C (Eppendorf model 5810R, rotor F-34-6-38). The clear supernatant was assayed for enzymatic activity. Cellulase activity of C. crispatum was measured with d-glucose as standard, as described [14]. The filter paper degradation (FPase) and endo-β-1,4-glucanase activities were determined spectrophotometrically at 540 nm by the dinitrosalicylic acid (DNS) method based on the release of reducing sugars from Whatman No. 1 filter paper strip (1.0 cm × 6.0 cm) and 2% CMC, respectively [15]. One unit of FPase or endo-β-1,4-glucanase activity is defined as the amount of enzyme that liberates 1 μmol of glucose equivalents per minute under the assay conditions. Xylanase activity of G. viride was determined using the aforementioned DNS assay method with oat spelts xylan as substrate [10] and d-xylose as the standard. One unit of xylanase activity is defined as that amount of enzyme which catalyzes the release of 1 μmol of xylose equivalents per minute of reaction under the assay conditions.

Measurement of planktonic cell growth

Free mycelial growth was ascertained by recording the cell dry weight of samples withdrawn from the suspension and not from the biofilm. Culture samples (5 ml) were filtered through pre-weighed filter paper (Whatman No. 1) under suction; the filter paper was dried at 80 °C to constant weight determined on a Sartorius AG, Germany model GD103 balance as described [16, 17].

Measurement of biofilm formation

Biofilm formation was quantified by scraping off approximately 45 cm2 of the total biofilm surface with a sharp scalpel at the end of the experiment and drying at 80 °C. The dry weight was measured on an electronic digital balance (Sartorius AG, Germany model GD103) as described [16, 17].

Estimation of EPSs

The EPS was extracted from the cell-free culture supernatant and biofilm. The EPS in cell-free culture supernatant was estimated as described [18]. Samples (1 ml) collected at various intervals were centrifuged at 9,000g (Eppendorf model 5810R, rotor F-34-6-38) for 20 min and the resulting supernatant was filtered through a 0.45 μm membrane filter. The supernatant was mixed with four volumes of absolute ethanol, stirred vigorously and left overnight at 4 °C. The precipitated EPSs were obtained by centrifugation at 9,000g for 10 min. The precipitate was air dried for 4 h and dissolved in 2 ml of distilled water. The polysaccharide content of EPS samples was estimated by the phenol sulfuric acid method [19] using glucose as standard and the protein content of EPS samples was estimated by Lowry method [20] with BSA as standard. Polysaccharide and protein contents of biofilm EPS were determined following Paramonova et al. [21]. Biofilm was scraped from PMMA and glass slides into 1 ml PBS. The suspension was mixed with 0.5 ml 1 M NaOH, vortexed and incubated with mild shaking at room temperature for 15 min. The suspension was then centrifuged at 10,000g for 5 min. The supernatant was collected and mixed with 100% ice-cold ethanol (0.5 ml supernatant:1.5 ml ethanol) and placed in the freezer for 30 min. The polysaccharide content of 1 ml of the mixture was measured following Dubois et al. [19]. Protein content of the samples was estimated by the Lowry method [20] with BSA as standard.

Determination of residual cellulose and xylan

In a set of experiments separate from the ones described, residual cellulose of culture samples of C. crispatum was determined using cellulose as standard [22]. Ten-milliliter cultures were centrifuged (3,000g for 20 min) and the supernatants were carefully discarded. The pellets were suspended in 3 ml acetic acid–nitric acid reagent (150 ml of 80% acetic acid with 15 ml of pure nitric acid) and boiled for 30 min in a water bath. After cooling and centrifuging (10,000g for 10 min), the supernatants were discarded and the pellets were washed with 10 ml distilled water. The pellets were then suspended in 10 ml of 67% (v/v) H2SO4, kept to stand for 1 h, properly diluted with distilled water and cooled in an ice bath. Ten milliliters cold anthrone reagent (0.2% anthrone in concentrated H2SO4) was added to each sample and the tubes were boiled for 16 min in a water bath. The tubes were cooled at room temperature and absorbance recorded at 620 nm against a reagent blank.

In a set of experiments separate from the ones described, residual xylan of G. viride cultures was determined by the orcinol-based assay method [23]. Water-soluble and insoluble forms of residual xylan were precipitated by the addition of 1 M perchloric acid to culture samples [24], centrifuged at 10,000g for 15 min and the xylan content measured using xylose as standard. Three milliliters of the test solution was mixed with equal volume of orcinol reagent and the solutions were boiled for 20 min in a water bath. The tubes were cooled at room temperature and absorbance recorded at 660 nm against a reagent blank. Residual substrate of the culture samples was expressed as percentage (%) of initial substrate present.

Determination of spore surface hydrophobicity

Spore surface hydrophobicity was determined by the microbial adhesion to hydrocarbons (MATH) assay as described by Smith et al. [25]. Spores were harvested by addition of two aliquots (3.0 ml) of 1.0 M PUM buffer containing (g/l) K2HPO4 22.2; KH2PO4 7.26; urea 1.8; MgSO4·7H2O 0.2; pH 7.1 to three replicate agar plates of the two fungi followed by gentle scraping of the colony surface with a sterile, bent glass rod. Spore suspensions were transferred to sterile glass bottles. Optical density of each replicate spore suspension was adjusted to 0.4 at 470 nm and dispensed (3.0 ml) into glass tubes. Hexadecane (300 μl) was added to each tube and the tubes vortexed three times for 30 s. The vortexed tubes were allowed to stand at room temperature for 15 min before the hexadecane phase was carefully removed and discarded. Tubes were then cooled to 5 °C and any residual solidified hexadecane removed. The tubes were then returned to room temperature and the A470 of the resultant spore suspensions were determined. The hydrophobic index (HI) was calculated using the following equation:

In this assay, spore suspensions with HI > 0.7 were considered hydrophobic. All measurements otherwise described in “Analytical methods” were performed thrice in duplicate sets.

Microscopy

Morphology of the fungal cell mass growing in suspension was observed at 100× magnification in a compound microscope (model MLX-100; Olympus Corporation, Japan) attached with a digital camera (Coolpix P90; Nikon Corporation, Japan).

Biofilm architecture was determined by confocal laser scanning microscopy (CLSM). For this study, sterilized PMMA slides and borosilicate microscope glass slides (75 mm × 25 mm × 1.35 mm, in the case of G. viride) were aseptically attached to both sides of the eight-strip inner arrangement of the PMMA-CCF with Fevi Kwik® (Pidilite Industries Ltd., Mumbai, India). A set of four flasks was utilized during cultivation of G. viride on PMMA surface and two slides were taken out at each time interval by applying a minimal amount of sterile warm water to debond the adhesive (following the manufacturer’s instruction). Slides were aseptically taken out (two each) after 0.5, 1, 1.5 and 2 days of cultivation. Similarly, a set of three flasks was used for the cultivation of G. viride on glass surface and two slides were taken out from each flask at second, third and fourth day of culture. Likewise, a set of four flasks was used for the cultivation of C. crispatum on PMMA surface and two slides were taken out from each flask at third, fourth, fifth and sixth day of culture. The slides were washed twice with 1 ml of 1× PBS buffer and excess fluid was removed by using Whatman filter paper. For EPS staining, the slides were incubated in the dark for 20 min with 200 μl of 100 μg/ml (in PBS) fluorescein isothiocyanate-concanavalin A (FITC-conA, Sigma, USA). Excess FITC-conA was removed by two rinses of 1 ml PBS and one rinse with 1 ml TRIS (all units in g/l; EDTA 18.6; TRIS 0.158; NaC1 20; KC1 0.4). Thereafter, slides were incubated for 2 min using 200 μl of 10 μM SYTO 64 (Molecular Probes, USA) dissolved in TRIS-buffer to stain the fungal cells. Excess SYTO 64 was removed by two rinses of 1 ml TRIS and one rinse of 1 ml PBS. Biofilm development was visualized using a confocal laser scanning microscope (Leica TCS SP2, Germany) equipped with an argon laser and helium–neon laser. HCX PL APO CS 40× 1.25 oil-immersion lens was used as the objective. The parameters for the CLSM were set once and applied evenly as much as possible for the rest of the experiments in order to ensure that there could be quantitative comparison of the results. Image stacks were collected under identical conditions (i.e. similar area and vertical resolution) at 1-μm z-intervals. For visualization of FITC-conA, excitation was set at 488 nm and emission at 520 nm, whereas for visualization of SYTO 64, excitation was fixed at 543 nm and emission at 620 nm. Experiments were performed thrice in duplicate sets and therefore values of 12 replicate determinations are reported.

Image analysis

PHLIP software (http://phlip.sourceforge.net), an open-source software specifically designed for three-dimensional biofilm analysis [26] was applied. PHLIP automatically sets the threshold value using the Otsu algorithm and calculates the architectural parameters. PHLIP runs on the Matlab platform and requires an additional definitions file, which was automatically produced by Auto-PHLIP-ML software (http://sourceforge.net/projects/auto-phlip-ml). Auto-PHLIP-ML also removes bias from biologically insignificant pixels by removing extraneous images. In this work PHLIP calculations were used to determine the biovolume, mean thickness, substratum coverage, total spreading, roughness coefficient and surface area-to-biovolume ratio. PHLIP was run in the “no connected volume filtration” (CVF) mode. Data were exported in an HTML format and were statistically analyzed using Origin®. ImageJ (http://rsb.info.nih.gov/ij/) was used for processing the image stacks using the Volume Viewer 1.31 plugin (http://rsb.info.nih.gov/ij/plugins/volume-viewer) [26, 27]. Three-dimensional surface plot of the biofilm was constructed out of the intensity of the fluorescence signals for each biofilm segment using the interactive 3D surface plot plugin 2.32 of ImageJ.

Results

Effect of flask configuration, aeration and surface property on enzyme production, growth and biofilm formation by C. crispatum

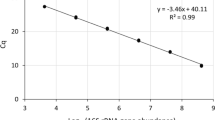

The roughness average R a (PMMA) was estimated as 2.51 ± 0.05 μm (standard deviation, n = 15) while R a (glass) was determined to be 2.43 ± 0.02 μm (standard deviation, n = 15). Thus, the two materials were almost of equal roughness. External aeration with or without shaking did not significantly affect enzyme production, growth and biofilm formation in comparison with orbital shaking at 140 rpm. Therefore, in further experiments the top part of the upper funnel was plugged with sterile cotton like standard shaken Erlenmeyer flasks. The PMMA-CCF proved to be a much better reaction vessel for the production of endo-β-1,4-glucanase as well as filter paper degradation activity (Fig. 1). The PMMA-CCF allowed steady increase in planktonic cell mass till 4 days (Fig. 1). Biofilm formation, as recorded by dry weights, was observed only on the PMMA-CCF (1.16 ± 0.04 g at the end of the cultivation). The specific attachment of C. crispatum on PMMA surface was estimated as 0.80 ± 0.03 g biofilm biomass/g total biomass. EPS obtained from the biofilm formed in the PMMA-CCF contained much higher proportion of polysaccharides (4.46 ± 0.02 mg/ml) than proteins (1.67 ± 0.01 mg/ml). Cell suspension EPS-polysaccharides peaked (5.97 ± 0.32 mg/ml) on the fourth day and then decreased to 3.78 ± 0.29 mg/ml at the end of the cultivation in the PMMA-CCF, while the EPS-polysaccharide concentration reached a maximum value of 3.19 ± 0.22 and 3.72 ± 0.32 mg/ml in the EF and GS-CCF, respectively (Suppl. Fig. 1). A reverse trend was obtained in case of cell suspension EPS-protein where the concentration in the PMMA-CCF ranged from 0.02 ± 0.01 to 0.05 ± 0.01 mg/ml from the third to the fifth days, whereas the level obtained in the other two vessels was 0.04 ± 0.01 to 0.08 ± 0.01 mg/ml in the EF and 0.02 ± 0.01 to 0.07 ± 0.01 mg/ml in the GS-CCF (Suppl. Fig. 1). The HI value of C. crispatum spores was estimated as 0.93, indicating them to be hydrophobic and possessing affinity only for the hydrophobic PMMA surface. These results clearly point toward a strong correlation between the hydrophobic reactor surface, endo-β-1,4-glucanase production, filter paper degradation activity of C. crispatum, growth of the fungus, biofilm formation and EPS-polysaccharide concentration. It was observed that the medium pH of C. crispatum cultivation varied from 6.0 ± 0.2 to 6.7 ± 0.2 in all the three flask configurations, indicating that pH influenced the results uniformly. Utilization of cellulose by C. crispatum was faster in the vessel that allowed quicker growth; 36.3 ± 4.5% cellulose remained in the PMMA-CCF after 2 days in comparison with 69.9 ± 4% and 68.4 ± 4.5% in the EF and GS-CCF, respectively (Suppl. Fig. 2). In the EF and GS-CCF, C. crispatum grew as scattered filamentous mycelia, while in the PMMA-CCF, the fungus formed a distinct biofilm structure (Fig. 2).

Confocal laser scanning microscopy of C. crispatum biofilm

Although the determinations described in the previous section were recorded for 7 days, the thickness of the biofilm after 6 days did not allow penetration of the laser beam. To allow the development of a stable biofilm, slides were initially taken out of the PMMA-CCF after 3 days of cultivation. Thus, data from the third to the sixth days are presented. Biofilm architectural parameters were generated from FITC-conA fluorescence (green channel) and SYTO 64 fluorescence values (red channel). As shown in Fig. 3, for C. crispatum biofilms grown on PMMA surface, biovolume represented the overall volume of the biofilm and it also provided an estimate of its biomass. EPS biovolume increased faster than the volume contributed by the cells and 100% increase was noted. Biofilm thickness provided a measurement of the spatial size of the biofilm. Average thickness provided information about the upper extent of the biofilm. Thickness increased by 25% till 5 days and the cells played a greater role than the EPS. Substratum coverage increased by 62.5% over time; the area covered by EPS was higher than that by the cells. Total spreading increased by 62.5% over time and that promoted by EPS was higher than that contributed by the cells. The biofilm roughness coefficient provided a measure of how much the thickness of the biofilm varied and was an indicator of its heterogeneity. Decrease of roughness coefficient in the green channel indicated EPS assumed an ordered structure while cells remained more or less non-heterogenous. The surface area/biovolume ratio reflected the fraction of the biofilm that was exposed to the nutrient flow and thus may indicate how the biofilm adapted to the environment. Initially exposed to the nutrient, the biofilm slowly became stable and adapted over time. As evident from Fig. 4a, at an early stage of development (when the biofilm was 3 days old), appearance of strong green fluorescence indicated intense secretion of EPS. Thereafter, emergence of red fluorescence on the fourth day (Fig. 4b) signified formation of mature ascospores. Finally, the image (Fig. 4c) obtained on the fifth day suggested development of the mature biofilm showing the ascospores of C. crispatum embedded in a matrix of EPS. Three-dimensional surface plots showed that with the progression of the C. crispatum biofilm, the surface became very heterogeneous with irregular thickness and interstitial voids (Suppl. Fig. 3).

Biofilm architectural parameters during C. crispatum biofilm development on PMMA surface a biovolume, b mean thickness, c substratum coverage, d total spreading, e roughness coefficient and f surface area (SA) to biovolume (BV) ratio. Filled square red channel, filled circle green channel. Error bars represent one standard deviation from the mean

Effect of flask configuration, aeration and surface property on enzyme production, growth and biofilm formation by G. viride

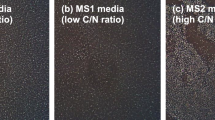

External aeration with or without shaking did not enhance enzyme production, growth and biofilm formation in contrast to orbital shaking at 140 rpm. Therefore, in further experiments the top part of the upper funnel was plugged with sterile cotton like standard shaken Erlenmeyer flasks. High enzyme activities as well as planktonic growth were recorded in the EF in comparison with the PMMA-CCF and the GS-CCF (Fig. 5). Biofilm formation was highest in the PMMA-CCF (1.6996 ± 0.2300 g) compared with the GS-CCF (0.7926 ± 0.0910 g) and EF (0.1998 ± 0.0610 g). Higher biofilm formation and lower planktonic growth was observed in the PMMA-CCF and in the GS-CCF in comparison to higher planktonic growth and lower biofilm formation noticed in the EF (Fig. 5). The specific attachment of G. viride was calculated as 0.08 ± 0.02 g biofilm biomass/g total biomass in the EF, 0.54 ± 0.01 g biofilm biomass/g total biomass on the PMMA surface and 0.33 ± 0.02 g biofilm biomass/g total biomass on the glass surface. The polysaccharide content of the biofilms formed in the PMMA-CCF (10.14 ± 1.40 mg/ml) was higher in comparison with the polysaccharide content measured in the EF (5.08 ± 0.98 mg/ml) and the GS-CCF (4.70 ± 0.88 mg/ml). Similarly, biofilm protein concentrations were much higher in the PMMA-CCF (2.12 ± 0.99 mg/ml) compared with the EF (0.45 ± 0.20) and the GS-CCF (1.40 ± 0.75 mg/ml). Cell suspension EPS-polysaccharide was found to be higher in the PMMA-CCF during the third to the fifth days (2.05 ± 0.19 to 2.05 ± 0.17 mg/ml) in contrast to the EF (1.41 ± 0.23 to 1.28 ± 0.21 mg/ml) and the GS-CCF (1.14 ± 0.23 to 0.92 ± 0.14 mg/ml). Protein concentration, similarly, was highest in the PMMA-CCF on the second day (0.26 ± 0.01 mg/ml) compared with the EF (0.16 ± 0.01) and the GS-CCF (0.22 ± 0.01) and then remained comparable to the other vessels till the seventh day (Suppl. Fig. 4). Although biofilm formation by G. viride was correlated with the hydrophobic reactor surface and EPS synthesis, results indicated association between xylanase production and planktonic growth of the fungi. Enzyme production was higher in the vessel with a hydrophilic surface that allowed lowest biofilm formation. It was observed that the medium pH of G. viride cultivation varied from 6.0 ± 0.2 to 7.2 ± 0.2 in all the three flask configurations, indicating that pH influenced the results uniformly. Utilization of xylan by G. viride was faster in the vessel that allowed faster growth; 38.5 ± 4.5% xylan remained in the EF in contrast to 48.5 ± 5.2 and 55.9 ± 5% in the PMMA-CCF and GS-CCF, respectively, at the end of the cultivation (Suppl. Fig. 5). G. viride spores partitioned to a slightly greater extent into the organic phase rather than the aqueous phase (HI = 0.76), with spore surface characteristics apparently on the borderline between hydrophobic and hydrophilic. This explains the higher affinity of the G. viride spores for the PMMA surface than the glass surface. In the EF, G. viride grew as aggregated filaments in planktonic cultures that were not observed in the CCF. Figure 6 shows the extent of biofilm formation in the three vessels: highest in the PMMA-CCF followed the GS-CCF and least in the EF.

Confocal laser scanning microscopy of G. viride biofilm

The thickness of the biofilm after 2 days of growth on the PMMA surface and 4 days of growth on the glass surface did not allow penetration of the laser beam. Allowing the development of a stable biofilm, slides were taken out of the PMMA-CCF after 12 h of cultivation and out of the GS-CCF after 2 days of culturing. Thus, the data from 12 to 48 h of the PMMA surface-grown biofilm and the data from the second to the fourth day of the glass surface-grown biofilm are presented, although the determinations described in the previous section were recorded for 7 days. Figure 7 compares the biofilm architectural parameters of G. viride biofilms grown on PMMA and glass surfaces. It is evident that the biovolume of the biofilm on glass surface that increased by 150% attained the comparable biovolume as the film on PMMA surface that also enhanced by 200%, in double the time. Mean thickness on PMMA surface was higher by 44% compared with that recorded for the film on glass surface and increased by 175% over time. Substratum coverage was higher by 38% on the glass surface in contrast to the PMMA, though a longer time was required to cover the area. EPS contributed more to coat the surface than the cells. Total spreading on glass surface continued over 4 days (enhancement by 21%), while it became steady on the PMMA surface (increase by only 10%), the contribution of EPS being higher than the cells in spreading the fungus. Comparison of the roughness coefficients showed that glass surface biofilm was more heterogeneous compared with the PMMA surface biofilm. Evaluation of the surface area/biovolume ratios showed that the biofilm on the PMMA surface got adapted over a shorter time compared with the glass surface. Figure 8a depicts the image of the 2-day grown film of G. viride on the glass surface. Though in its initial phase, low extent of green fluorescence indicated feeble production of EPS. The image of the following day (3rd day, Fig. 8b) showed a greater amount of red fluorescence compared with the green while the final image obtained on the fourth day (Fig. 8c) showed the appearance of EPS secreting filaments interspersed with mature cells. As apparent from Fig. 8d, at an early stage of development of G. viride on the PMMA surface (when the biofilm was 0.5 day old), appearance of predominant green fluorescence indicated secretion of EPS. Thereafter, emergence of red fluorescence at 1.0 day (Fig. 8e) and 1.5 days (Fig. 8f) signified formation of cellular structures. Finally, the image (Fig. 8g) obtained on the second day suggested development of the mature biofilm showing the filaments of G. viride embedded in a matrix of EPS. Supplementary Fig. 6 shows that patchy biofilms developed when G. viride grew on the glass surface. When the fungus was grown on the PMMA surface, the projected 3D biofilm surface was spread wider along the section with more fibril-like protuberances interspersed with channels (Suppl. Fig. 6). Thus, the ImageJ analysis in conjunction with the biofilm architectural parameters demonstrated satisfactory development of G. viride biofilm on the PMMA surface, but not on the glass surface.

Biofilm architectural parameters during G. viride biofilm development a biovolume, b mean thickness, c substratum coverage, d total spreading, e roughness coefficient and f surface area (SA) to biovolume (BV) ratio. Filled square red channel on PMMA surface; filled circle green channel on PMMA surface; open square red channel on glass surface; open circle green channel on glass surface. Error bars represent one standard deviation from the mean

Discussion

In this study the effect of flask configuration on enzyme production by C. crispatum and G. viride was enquired. There were strong geometric differences between the CCF and the EF and it may be argued that the CCF without the inner arrangement would have made a logical comparison. One of the purposes of this study was to test the applicability of the CCF for fungal biofilm cultivations as an alternative to the commonly used laboratory Erlenmeyer flask. The CCF’s design enables the researcher to vary the internal surface properties (hydrophobic/hydrophilic) of the vessel that, till date, has not been achieved in the Erlenmeyer flask. Removal of the inner arrangement would drastically reduce the surface available for biofilm formation and thus the objective of the study would not be realized. Therefore, use the CCF without the inner arrangement was not preferred. While endo-β-1,4-glucanase and filter paper-degrading activity of the former were correlated with biofilm formation, xylanase activity of the latter was not related to biofilm formation. Highest endo-β-1,4-glucanase production was attained before highest growth was achieved, similar to the pattern observed for cellulolytic activity of C. crispatum growing on soluble cellulose by Geeraerts and Vandamme [9]. The reported cellulolytic activities may appear to be rather low, although the lower limit of detection of reducing sugars by the DNS method is 20 μg [28] and lowest reducing sugar content in the samples under investigation in this study was 30 μg. Furthermore, utilization of cellulose confirms elaboration of cellulolytic enzymes. Highest xylanase and growth occurred at the same time (4th day) in case of G. viride. In the PMMA-CCF, where a thick biofilm formed, showed higher planktonic growth of C. crispatum compared with the lower planktonic growth in the EF and GS-CCF where no biofilm developed. It appeared that the initial high numbers of planktonic cells allowed surface attachment and that the planktonic cells may also have contributed toward the high enzyme activity in the PMMA-CCF. It may be questioned that planktonic growth can mask any real effect of biofilm on enzyme production, and therefore, to suppress the initial planktonic biomass unattached spores should have been replaced with fresh production medium. However, it may be emphasized that the experiments have been designed to study the intrinsic natural mode of growth of the fungi and not forcefully inducing them to form biofilms. It was examined if the vessel that promoted higher cell attachment was more conducive for cell growth (including both planktonic and biofilm) and enzyme production or not. Some authors found that growth of freely suspended mycelium of Aspergillus sp. produced either similar or lesser amount of biomass than when grown on surfaces of several supports [29–31]. However, Villena and Gutiérrez-Correa [16] reported that free mycelium cultures produced more biomass than biofilm cultures both in shaken flasks as well as in a specially designed microbioreactor. This observation was opposite to the previous three reports [29–31] but was in concurrence with the authors’ earlier findings [32] and with Papagianni and Mattey [33].

Enhanced levels of supernatant polysaccharides in comparison with protein (by 120-fold for C. crispatum and by 8-fold for G. viride) were associated with biofilm formation on PMMA surfaces by the filamentous fungi of this study, indicating that polysaccharides played an important role than proteins in the formation of the biofilm. Two stages of biofilm formation by filamentous fungi involve secretion of polysaccharides. The stage of active attachment to a surface often includes secretion of adhesive substances by germinating spores and active germlings. In the next phase of microcolony formation that involves apical elongation and hyphal branching, hyphae explore the substratum, ramify across surfaces as a monolayer and/or become invasive. This stage involves the production of a polymeric extracellular matrix that allows the growing colony to adhere tenaciously to the substrate [34]. It should be considered that EPS that remain tightly bound to the cell surface by covalent linkages and cannot be easily removed from the cell surface are called the “attached” fraction. Those EPS that are more loosely bound in the form of slime and can be easily shed into the medium, as well as those in free planktonic state are called the “non-attached” fraction. Only a few studies have explicitly explored the differences between two EPS fractions [35]. The “non-attached” fraction of the EPS was determined in this study.

Villena and Gutierrez-Correa [16] noted that increased FPase production by A. niger may be due to better environmental conditions obtained in microbioreactors; particularly, oxygen transfer could be enhanced by the turbulence created by oxygen bubbling. It may be argued that the strips of the inner arrangement of the CCF presumably acted as baffles to enhance mixing, thus allowing better oxygen and nutrient uptake. However, low enzyme production by C. crispatum in the GS-CCF and high xylanase activity of G. viride in the EF indicated the role of surface hydrophobicity/hydrophilicity of the cultivation vessels and not better mass transfer in the determination of enzyme concentrations. Higher biofilm was formed by G. viride in the GS-CCF compared with that in the EF. So, xylanase production analogous to that in the EF did not occur in the GS-CCF although this vessel had a hydrophilic surface. Low shear stress was likely to have enhanced xylanase production in the EF as the aggregated filamentous structure of G. viride was not seen in the planktonic cultures in the CCF, where the strips of the inner arrangement generated high shear forces that disrupted the agglomerated structure. Cell morphology played a pivotal role in the elaboration of xylanase activity of G. viride and the results are in agreement with Villena and Gutiérrez-Correa [17] who correlated differences in lignocellulolytic enzyme volumetric and specific productivities with morphological differences between pelletous and biofilm morphology of cultures.

Results showed that external aeration with or without shaking did not significantly affect enzyme production, growth and biofilm formation in comparison with orbital shaking at 140 rpm for both C. crispatum and G. viride. If additional oxygen had an effect on enzyme production, then the flask with external aeration would have yielded higher enzyme levels. Forced aeration provided higher dissolved oxygen (DO) levels, but this higher DO level did not enhance growth and enzyme production in the two fungi. In the earlier study [8] the same design of the CCF in conjunction with the standard Erlenmeyer flask was used previously to compare melanin production by S. colwelliana and antibiotic production by P. rubra in different flask configurations and to determine the effect of external aeration on the bioactivities. Whereas melanin production was not sensitive to the means of aeration, antimicrobial production was strongly dependent upon it. Thus, the CCF and the present experimental design can identify the role of external aeration in the variation of bioactivities.

Fungi can be regarded as regular biofilm-forming organisms with two inherent and fundamental processes: adhesion and subsequent differential gene expression to develop new and distinct phenotypes diverse from those of free living conditions [6, 36]. It was demonstrated that A. niger biofilms developed on polyester cloth produced 50–70% more cellulase activity than freely suspended mycelial cultures [6, 32]. It appeared that physical interactions between fungal and support surfaces were responsible for the better performance of biofilm cultures [37]. It has also been reported that Aspergillus fumigatus formed biofilms showing a differential gene expression and this condition may be responsible for its increased pathogenicity [38, 39]. Harding et al. [34] discussed compelling evidence in support of the hypothesis that filamentous fungi are capable of forming biofilms. A set of criteria for characterizing filamentous fungal biofilms was proposed along with a preliminary model that described the different stages of biofilm development in these microorganisms. Through this investigation, successful satisfaction of three criteria as recommended [34] for biofilm formation by filamentous fungi was demonstrated: first surface-associated growth of cells, second, cells embedded in a self-produced and secreted extracellular polymeric matrix and third, altered gene expression resulting in enhanced or lowered enzyme production.

Chandra et al. [40] reported different surface modifications influenced the ability of Candida albicans to form biofilm to various extents. Authors noted that the mechanisms underlying the ability or inability of C. albicans to form biofilms on test surfaces are unknown. The role of different surface chemistries in microbial adhesion and biofilm formation has been proposed to be a complex interplay between different microbial and host factors, including thermal cycling, protein coating, hydrophobicity and nonspecific physiochemical forces or specific ligand–receptor interactions. Martinez and Casadevall [41] carried out experiments with Cryptococcus neoformans strain B3501 on microtiter plates composed of polystyrene, polyvinyl, polycarbonate and glass. The yeast cells formed biofilms on support material in the following order of strength: polyvinyl > glass > polystyrene > polycarbonate. Cultivations in the novel CCF that allowed convenient interchange of growth surfaces, in combination with the standard Erlenmeyer flask established that vessel surface characteristics crucially influenced productivity. The present study is the first report on the effect of the nature of the surface (hydrophobic or hydrophilic) on the growth, biofilm formation and metabolite production by filamentous fungi and it may be inferred that the hydrophobicity/hydrophilicity of the surface should be given serious consideration while developing models for biofilm formation by filamentous fungi.

CLSM has been applied in the research on biofilm formation by filamentous fungi. Villena et al. [42] studied the biomass organization of A. niger biofilms and pellets that were stained with fluorescein isothiocyanate and analyzed by means of CLSM and detectable differences between both types of growth were found. In previous studies, COMSTAT mathematical modeling [43] has been successfully used for CLSM image analyses of volumetric parameters of C. albicans biofilm architecture, such as biovolume, average thickness, roughness coefficient and surface area/volume ratio [44]. The present study is the first report on the temporal pattern of biofilm development by monitoring volumetric parameters of filamentous fungi based on two-channel fluorescence detection through the application of the PHLIP image analysis software. Results demonstrated that amongst different genera as well as within a species of filamentous fungi, the progression of biofilm formation varied depending on the surfaces on which the fungus was grown. This was possible through the skilful design of the CCF that allowed easy attachment removal of standard size slides and subsequent successful CLSM analyses. Such an attachment is not possible in shake flasks; hence this new design was necessary. The removal of slides would alter the fluid movement, so different sets of flasks were utilized. Multi-channel analysis, in comparison with single-channel analysis (e.g. COMSTAT) can distinguish various biofilm components and thus investigations of microbial biofilms can be approached comprehensively [26].

Incomplete utilization of cellulose and xylan and the cessation of growth in the presence of residual substrates were observed. An exponential increase in cell concentration with time is reasonable to expect only if the rate of increase of the cell concentration is proportional to the cell concentration, which requires that substrate be in excess and that substrate reactivity be constant through most of the batch growth curve. Although both of these conditions are met during the exponential phase of growth on a soluble substrate, it is unusual for either of them to be satisfied for growth on cellulosic substrates, while both of the conditions are impossible. Thus, there is little basis to expect exponential growth in batch cultures of microorganisms growing on cellulose over any significant range of conversion values. For enzymatic hydrolysis of natural celluloses, several determinants of hydrolysis rate have been proposed, including crystallinity, degree of polymerization, particle size, pore volume, accessible surface area and products of hydrolysis [45]. Growth on xylans by Butyrivibrio fibrisolvens, Bacteroides species and many other bacteria often resulted in utilization of only 60–75% of the xylan, even when the xylan was in a soluble form. This incomplete hydrolysis did not seem to be due to the loss of enzyme activities [46]. Xylan degradation by Ruminococcus albus was incomplete, suggesting that the carbohydrate composition of the residual xylan may be recalcitrant to further hydrolysis and that growth by R. albus terminated as a result. The cessation of xylan degradation and growth was not attributable to alterations in xylan composition but was perhaps due to xylose accumulation [24].

Conclusions

Through the application of the newly designed device, it was shown that diverse enzyme levels, variable extents of cell adhesion and biofilm formation occur when C. crispatum and G. viride were cultivated in differently constructed shaking vessels. Highest enzyme activities of G. viride occurred in the vessel with hydrophilic surface, whereas the number of attached cells was greater on hydrophobic surface. Considering the proposed hypothesis, it may be concluded that first, varying levels of enzyme activities may indicate differential gene expression, although higher biofilm formation did not mean consequential high enzyme production and second, the association of high enzyme levels with the biofilm mode of growth varied within the genera of intertidal filamentous fungi. Considering the CCF as an example of small-scale parallel bioreactor systems which are used to speed up many areas of bioprocessing [47], the knowledge of the parameters (aeration, vessel surface characteristics, growth and biofilm formation) in the initial stages of process development will aid the researcher to take informed decisions at the later phases. Given the limited data on the cultivation of estuarine fungi and the tools to assess their special conditions for metabolite production, the results of this study would be of significance to this area of research. Future work will concentrate upon comparisons of oxygen mass transfer and power consumption between the CCF and EF as well as filamentous fungal biofilm formation in greater depth and detail.

References

Ortega-Morales BO, Chan-Bacab MJ, De la Rosa-García SDC, Camacho-Chab JC (2010) Valuable processes and products from marine intertidal microbial communities. Curr Opin Biotechnol 21:346–352

Decho AW (2000) Microbial biofilms in intertidal systems: an overview. Cont Shelf Res 20:1257–1273

Penesyan A, Kjelleberg S, Egan S (2010) Development of novel drugs from marine surface associated microorganisms. Mar Drugs 8:438–459

Niture SK, Pant A (2007) Production of cell wall-degrading enzymes by a pH tolerant estuarine fungal isolate Fusarium moniliforme NCIM1276 in different culture conditions. World J Microbiol Biotechnol 23:1169–1177

Da Silva M, Cerniglia CE, Pothuluri JV, Canhos VP, Esposito E (2003) Screening filamentous fungi isolated from estuarine sediments for the ability to oxidize polycyclic aromatic hydrocarbons. World J Microbiol Biotechnol 19:399–405

Gutiérrez-Correa M, Villena GK (2003) Surface adhesion fermentation: a new fermentation category. Rev Peru Biol 10:113–124

Sarkar S, Roy D, Mukherjee J (2011) Enhanced protease production in a polymethylmethacrylate conico-cylindrical flask by two biofilm-forming bacteria. Bioresour Technol 102:1849–1855

Mitra S, Sarkar S, Gachhui R, Mukherjee J (2011) A novel conico-cylindrical flask aids easy identification of critical process parameters for cultivation of marine bacteria. Appl Microbiol Biotechnol 90:321–330

Geeraerts HAM, Vandamme EJ (1983) Cellulolytic properties of Chaetomium crispatum. J Chem Technol Biotechnol 2:107–113

Christov LP, Szakacs G, Balakrishnan H (1999) Production, partial characterization and use of fungal cellulase-free xylanases in pulp bleaching. Process Biochem 34:511–517

Vogel HJ (1956) A convenient growth medium for Neurospora (medium N). Microb Genet Bull 13:42–43

Chipeta ZA, Du Preez JC, Szakacs G, Christopher L (2005) Xylanase production by fungal strains on spent sulphite liquor. Appl Microbiol Biotechnol 69:71–78

Du Preez JC, Van der Walt JP (1983) Fermentation of d-xylose to ethanol by a strain of Candida shehatae. Biotechnol Lett 5:357–362

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Villena GK, Gutiérrez-Correa M (2006) Production of cellulase by Aspergillus niger biofilms developed on polyester cloth. Lett Appl Microbiol 43:262–268

Villena GK, Gutiérrez-Correa M (2007) Morphological patterns of Aspergillus niger biofilms and pellets related to lignocellulolytic enzyme productivities. Lett Appl Microbiol 45:231–237

Kim HO, Yun JW (2005) A comparative study on the production of exopolysaccharides between two entomopathogenic fungi Cordyceps militaris and Cordyceps sinensis in submerged mycelial cultures. J Appl Microbiol 99:728–738

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Raunkjær K, Hvitved-Jacobsen T, Nielsen PH (1994) Measurement of pools of protein, carbohydrate and lipid in domestic wastewater. Water Res 28:251–262

Paramonova E, Krom BP, van der Mei HC, Busscher HJ, Sharma PK (2009) Hyphal content determines the compression strength of Candida albicans biofilms. Microbiology 155:1997–2003

Updegraff DM (1969) Semi micro determination of cellulose in biological materials. Anal Biochem 32:420–424

Schneider WC (1957) Determination of nucleic acids in tissues by pentose analysis. Methods Enzymol 3:680–684

Reveneau C, Adams SE, Cotta MA, Morrison M (2003) Phenylacetic and phenylpropionic acids do not affect xylan degradation by Ruminococcus albus. Appl Environ Microbiol 69:6954–6958

Smith SN, Chohan R, Armstrong RA, Whipps JM (1998) Hydrophobicity and surface electrostatic charge of conidia of the mycoparasite Coniothyrium minitans. Mycol Res 102:243–249

Mueller LN, De Brouwer JFC, Almeida JS, Stal LJ, Xavier JB (2006) Analysis of a marine phototrophic biofilm by confocal laser scanning microscopy using the new image quantification software PHLIP. BMC Ecol 6:1–15

Eshed L, Yaron S, Dosoretz CG (2008) Effect of permeate drag force on the development of a biofouling layer in a pressure-driven membrane separation system. Appl Environ Microbiol 74:7338–7347

Percival Zhang Y-H, Himmel ME, Mielenz JR (2006) Outlook for cellulase improvement: screening and selection strategies. Biotechnol Adv 24:452–481

Liu F, Li W, Ridgway D, Gu T, Moo-Young M (1998) Inhibition of extracellular protease secretion by Aspergillus niger using cell immobilization. Biotechnol Lett 20:539–542

Papagianni M, Joshi N, Moo-Young M (2002) Comparative studies on extracellular protease secretion and glucoamylase production by free and immobilized Aspergillus niger cultures. J Ind Microbiol Biotechnol 29:259–263

Iqbal M, Saeed A (2005) Novel method for cell immobilization and its application for production of organic acid. Lett Appl Microbiol 40:178–182

Villena GK, Moreno P, Gutiérrez-Correa M (2001) Cellulase production by fungal biofilms on polyester cloth. Agro Food Ind Hi Tech 12:32–35

Papagianni M, Mattey M (2004) Physiological aspects of free and immobilized Aspergillus niger cultures producing citric acid under various glucose concentrations. Process Biochem 39:1963–1970

Harding MW, Marques LLR, Howard RJ, Olson ME (2009) Can filamentous fungi form biofilms? Trends Microbiol 17:475–480

Xu C, Santschi PH, Schwehr KA, Hung C-C (2009) Optimized isolation procedure for obtaining strongly actinide binding exopolymeric substances (EPS) from two bacteria (Sagittula stellata and Pseudomonas fluorescens Biovar II). Bioresour Technol 100:6010–6021

Wimpenny J, Manz W, Szewzyk U (2000) Heterogeneity in biofilms. FEMS Microbiol Rev 24:661–671

Gamarra NN, Villena GK, Gutiérrez-Correa M (2010) Cellulase production by Aspergillus niger in biofilm, solid-state, and submerged fermentations. Appl Microbiol Biotechnol 87:545–551

Mowat E, Williams C, Jones B, McChlery S, Ramage G (2009) The characteristics of Aspergillus fumigatus mycetoma development: is this a biofilm? Med Mycol 47(Suppl.1):S120–S126

Seidler MJ, Salvenmoser S, Müller FMC (2008) Aspergillus fumigatus forms biofilms with reduced antifungal drug susceptibility on bronchial epithelial cells. Antimicrob Agents Chemother 52:4130–4136

Chandra J, Patel JD, Li J, Zhou G, Mukherjee PK, McCormick TS, Anderson JM, Ghannoum MA (2005) Modification of surface properties of biomaterials influences the ability of Candida albicans to form biofilms. Appl Environ Microbiol 71:8795–8801

Martinez LR, Casadevall A (2007) Cryptococcus neoformans biofilm formation depends on surface support and carbon source and reduces fungal cell susceptibility to heat, cold, and UV Light. Appl Environ Microbiol 73:4592–4601

Villena GK, Fujikawa T, Tsuyumu S, Gutiérrez-Correa M (2010) Structural analysis of biofilms and pellets of Aspergillus niger by confocal laser scanning microscopy and cryo scanning electron microscopy. Bioresour Technol 101:1920–1926

Heydorn A, Nielsen AT, Hentzer M, Sternberg C, Givskov M, Ersbøll BK, Molin S (2000) Quantification of biofilm structures by the novel computer program COMSTAT. Microbiology 146:2395–2407

Da Silva WJ, Seneviratne J, Samaranayake LP, Del Bel Cury AA (2010) Bioactivity and architecture of Candida albicans biofilms developed on poly(methyl methacrylate) resin surface. J Biomed Mater Res B Appl Biomater 94:149–156

Lynd LR, Weimer PJ, Van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: Fundamentals and biotechnology. Microbiol Mol Biol Rev 66:506–577

Hespell RB, Whitehead TR (1990) Physiology and genetics of xylan degradation by gastrointestinal tract bacteria. J Dairy Sci 73:3013–3022

Weuster-Botz D (2005) Parallel reactor systems for bioprocess development. In: Scheper T (ed) Advances in biochem engineering/biotechnology, vol 92. Springer, Berlin, pp 125–144

Acknowledgments

Financial support to JM, RG (DBT Sanction No. BT/PR11479/AAQ/03/423/2008) and DST-PURSE, 2009-10) is thankfully acknowledged. Authors wish to thank Dr. Arun Bandyopadhyay and Mrs. Banasri Das for their help during confocal microscopy.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Fig. 1

Effect of flask configuration on (a) cell suspension EPS-polysaccharides and (b) cell suspension EPS-proteins of C. crispatum. Symbols represent: ■ EF; ● PMMA-CCF; ▲ GS-CCF. Error bars represent one standard deviation from the mean. (DOC 35 kb)

Supplementary Fig. 2

Effect of flask configuration on utilization of cellulose by C. crispatum. Symbols represent: ■ EF; ● PMMA-CCF; ▲ GS-CCF. Error bars represent one standard deviation from the mean. (DOC 23 kb)

Supplementary Fig. 3

Estimated 3D surface plots of C. crispatum biofilm on PMMA surface following analysis by ImageJ using the interactive 3D surface plot 2.32 plugin after (a) 3, (b) 4 and (c) 5 days. (TIFF 979 kb)

Supplementary Fig. 4

Effect of flask configuration on (a) cell suspension EPS-polysaccharides and (b) cell suspension EPS-proteins of G. viride. Symbols represent: ■ EF; ● PMMA-CCF; ▲ GS-CCF. Error bars represent one standard deviation from the mean. (DOC 35 kb)

Supplementary Fig. 5

Effect of flask configuration on utilization of xylan by G. viride. Symbols represent: ■ EF; ● PMMA-CCF; ▲ GS-CCF. Error bars represent one standard deviation from the mean. (DOC 23 kb)

Supplementary Fig. 6

Estimated 3D surface plots of G. viride biofilm following analysis by ImageJ using the interactive 3D surface plot plugin 2.32 after (a) 2, (b) 3 and (c) 4 days on glass surface and after (d) 0.5, (e) 1, (f) 1.5 and (g) 2 days on the PMMA surface. (TIFF 2534 kb)

Rights and permissions

About this article

Cite this article

Mitra, S., Banerjee, P., Gachhui, R. et al. Cellulase and xylanase activity in relation to biofilm formation by two intertidal filamentous fungi in a novel polymethylmethacrylate conico-cylindrical flask. Bioprocess Biosyst Eng 34, 1087–1101 (2011). https://doi.org/10.1007/s00449-011-0559-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0559-2