Abstract

Low-energy ion implantation was employed to breed laccase producing strain Paecilomyces sp. WSH-L07 and a mutant S152 that exhibited an activity of more than three times over the wild strain was obtained. The optimum substrate of both the wild and mutant laccases was 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonate), and followed by guaiacol with optimal pH at 3.4 and 5.0, respectively, while the mutant laccase exhibited a broader active pH range. The mutant laccase had a higher optimal catalytic temperature (60–65 °C) than the wild one (55 °C), and the wild laccase deactivated rapidly when temperature increased above 55 °C. Furthermore, the mutant laccase was more stable under neutral and alkaline conditions. A thermostability experiment revealed that the mutant laccase was superior to the wild laccase. Both laccases were stable in the presence of metal ions, mildly inhibited by SDS (0.5 mM), EDTA (1 mM) and 1,4-dithiothreitol (0.5 mM), and almost completely inhibited by 0.1 mM NaN3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Laccases (benzenediol: oxygen oxidoreductase; EC 1.10.3.2) belong to the multicopper oxidase family, which catalyze one-electron transfer from a wide variety of organic and inorganic substrates, including the substituted phenols, aromatic amines, lignin, some inorganic ions, and several other substrates [1, 2]. Their wide substrates spectrum allows laccases to be extensively used in various areas such as pulp delignification, dye decoloration, environmental pollutant detoxification, biopolymer modification, biotransformation, and food dechlorination [1, 3–7]. However, industrial applications of laccases are usually hindered by their long fermentation period, low laccase yield, as well as poor enzyme stability. In this case, this study focuses on the mutation breeding and the mutant strains with higher laccase productivity and better enzyme properties.

Low-energy ions exist widely in nature and are generated in the laboratory through acceleration, mass selection, transfer of energetic ions to a reaction chamber, and interaction with ion-target [8]. Besides modifying semiconductor surfaces, low-energy ions modify the genes of plants and microorganisms and represent a novel and effective method for genetic modification in recent decades [8, 9]. Although there is no consensus on the lethality rate of different low-energy ions (N+, Ar+, H+ and He+) in breeding plants and microbes, it is clear that N+ induces higher mutation rate and has been applied to breeding. Several remarkable mutants have been obtained by nitrogen ions implantation, and some of them have been used in industrial applications [8, 10–12]. Low-energy ion irradiation of recombinant laccase-producer Pichia pastoris yielded mutants with higher laccase production (7.7 mg/L, a 92.5% increase), slightly improved catalytic ability and superior thermal stability compared with non-irradiated control [13].

Compared to other genetic modification methods, such as site-directed mutagenesis, which requires both extended knowledge derived from crystallographic studies of the active site and sensitive assay systems that ideally combine phenotypic and genotypic characterization in vitro and in vivo, low-energy ion implantation is particularly suited for an enzyme when the understanding about its structure and active site is lacking [14]. Low-energy ion implantation presents a novel and nonpolluting approach for genetic modification that is as effective as site-directed mutagenesis.

The microorganism used in this work was isolated from soil and identified as Paecilomyces sp., which exhibited a much higher level of laccase synthesis with an average activity of 820 U/L on the eighth day, compared with other strains of Paecilomyces species [15–17]. As a thermophilic microorganism [15, 18], Paecilomyces sp. is a potential laccase-producer with better enzyme stability. However, the low laccase productivity of the wild strain was unsuitable for large scale application. A suitable process of laccase synthesis by Paecilomyces sp. needs to be developed, and the enzyme properties need to be elucidated and improved. The objective of this study was to breed a Paecilomyces sp. WSH-L07 mutant with improved laccase production and superior enzyme properties by low-energy ion implantation.

Materials and methods

Microorganism, media, and culture conditions

The wild strain Paecilomyces sp. WSH-L07 was isolated from crop soil and deposited in Lab of Biosystem and Bioprocess Engineering, School of Biotechnology, Jiangnan University, China [17]. Both the wild strain and laccase active mutants were grown at 30 °C on potato dextrose agar (PDA) slants for preservation, or cultivated for 7 days in 250 mL flasks containing 100 mL modified yeast extract peptone dextrose (YPD–Cu) medium at 30 °C and 150 r/min. The PDA medium contained potato extract 200 g/L, glucose 20 g/L, and agar 20 g/L. The selective plates (PDA–ABTS) used for preliminary screening were supplemented with 0.5 g/L 2,2′-azino-bis(3-ethylbenzothiazoline-6- sulfonate) (ABTS) (Sigma Chemical Co., USA) in PDA medium before autoclaving [17]. The YPD–Cu medium containing glucose 20 g/L, peptone 5 g/L, yeast extract 2 g/L, and CuSO4 100 μM (initial pH 6.5) was used for laccase production [17].

Spore suspensions (1 × 106–107 spores/mL) were prepared from PDA slants cultured at 30 °C for 6 days and 2 mL of prepared suspensions were inoculated into 250 mL Erlenmeyer flasks containing 100 mL YPD–Cu medium to test laccase production in submerged cultivation.

Low-energy ion implantation

Low-energy ion implantation was carried out with the heavy ion implantation facility at the Institute of Plasma Physics, Chinese Academy of Sciences (Hefei, Anhui, China).

After incubated on PDA slants for 6 days, spores were washed with sterilized physiological sodium chloride solution and diluted to a suspension with 1 × 106–107 spores/mL. Prepared spore suspension (0.1 mL) was spread over sterilized dishes as single-cell layer and air-dried in an asepsis room. Then, the dishes were implanted by nitrogen ions with energy of 10 keV. Every two dishes were placed sequentially in the target chamber. The upper one was exposed to ion beam bombardment, while the lower one was unexposed as a control. After implantation, the treated and control plates were washed with 1 mL sterilized physiological sodium chloride solution, and 100 μL samples were spread onto PDA–ABTS plates and incubated at 30 °C. The number of colonies was counted to determine the survival rate [10]. Experiments were done in triplicate.

Screening procedure

Laccase producing mutants could secrete laccase into agar medium and oxidized ABTS to a green-colored compound. Primary screening of laccase active mutants was visually carried out based on the intensity of the dark-green dye [17]. The mutants with obvious dark-green dye were inoculated on PDA slants and incubated at 30 °C until sporulation. Secondary screening was then developed by incubating above selected strains into YPD–Cu media in duplicate and the supernatants of YPD–Cu medium cultured for 7 days were assayed for laccase activity. Mutants with laccase activity increased by more than 5% over that of the wild strain were classified as positive mutants, while mutants with laccase activity decreased by more than 5% were classified as negative mutants. The mutation rate was calculated as the number of positive or negative mutants divided by the total number of surviving colonies.

To investigate the stability of laccase production during passage cultivations, mutants with obvious increment of laccase production were continuous inoculated onto fresh PDA slants and incubated at 30 °C for 6 days. Laccase activity was assayed by each passage after incubating the mutants into YPD–Cu medium.

Enzyme properties of laccases from the wild and mutated strains

The substrate specificity of laccases from the wild and mutated strains was carried out by testing the oxidation of ABTS, guaiacol, catechol, p-anisidine, dimethylaniline, orcinol, and dimethyl phthalate. ABTS was purchased from Sigma Chemical Co., USA, and the others were analytical grade obtained from Sinopharm Chemical Reagent (Shanghai, China).

The pH dependence of laccase activity was measured in 0.1 M citrate buffer (pH 2.6–7.2) at 30 °C, and the temperature dependence of laccase activity was determined in 0.1 M citrate buffer (pH 3.4) in the range from 25 to 70 °C.

The pH stability of laccase was studied by incubating enzyme solutions in 0.1 M citrate buffer (pH 2.6–6.0), 0.1 M phosphate buffer (pH 6.0–8.0) and 0.1 M Tris–HCl buffer (pH 7.2–8.8) at room temperature. For determination of enzyme thermostability, enzyme solutions were incubated in 0.1 M citrate buffer (pH 3.4 or pH 5.0) at 45 and 55 °C for 10–90 min.

The effects of metal ions (Al3+, Mn2+, Cu2+, Co2+, Ca2+, Mg2+, Ni2+, Zn2+ and Hg2+) and several potential inhibitors (SDS, EDTA, 1,4-dithiothreitol, NaN3 and β-mercaptoethanol) on laccase activity were tested. The assay mixture of a total volume of 1 mL contained 0.1 mL enzyme solutions, 0.1 mL above-mentioned agents at various concentrations and 1 mM ABTS in 100 mM citrate buffer (pH 3.4). The reaction mixture with the absence of ions and inhibitors was used as control.

The assayed solutions of the wild strain and mutant S152 were concentrated to a similar activity level in a vacuum drying oven at 4 °C. All the values are the means of duplicate experiments and the deviation was below 5%.

Enzyme assay

Laccase activity was assayed spectrophotometrically by measuring the oxidation of ABTS at 420 nm described by Rajan with some modifications [7]. The assay mixture in a total volume of 1 mL contained 0.1 mL cell-free supernatants at various dilutions and 1 mM ABTS in 100 mM citrate buffer (pH 3.4). One unit of enzyme activity was defined as the amount of enzyme required to oxidize 1 μmol ABTS per minute at 30 °C. Laccase activity on other substrates was measured similarly at their wavelength of maximum absorbance. Enzyme activity was measured using ABTS as a substrate unless otherwise stated.

Native PAGE and active staining

The methods of native PAGE and active staining were similar to Palmieri [19]. Native PAGE was carried out under non-denaturating conditions where separating and stacking gels were 10 and 5% polyacrylamide, respectively, and buffer solutions were 1 M Tris buffer (pH 8.8) for separating gel, 1 M Tris buffer (pH 6.8) for stacking gel and 25 mM Tris buffer (pH 8.8) with 190 mM glycine as the electrode reservoir solution. The loading volume of enzyme solutions from the wild and mutated strains was adjusted to the same laccase activity level. After native PAGE, proteins were actively stained in 0.2 mM ABTS in 0.1 M citrate buffer (pH 3.4) or in 0.2 mM guaiacol in 0.1 M citrate buffer (pH 5.0).

Results and discussion

Determination of dosage in N+ implantation

Spores of wild Paecilomyces sp. WSH-L07 strain were exposed to various doses of N+ with fixed energy at 10 keV. As shown in Fig. 1, the survival rate exhibited a characteristic “saddle shape” with increasing doses of nitrogen ions. At first, the survival rate decreased, then increased at 60 × 1014 ions/cm2 and reached a maximum at 100 × 1014 ions/cm2. When the dose of N+ exceeded 100 × 1014 ions/cm2, the survival rate decreased again. Such saddle shape of survival rate was quite different from the results of other traditional irradiation, such as UV, X-ray or γ-ray. This phenomenon could be explained by a reasonable mechanism based on the energy and momentum deposition effect at lower doses and by the charge stimulating effect at higher doses [20].

The positive and negative mutation appeared to correlate with the doses of low-energy ions (Fig. 2). The highest positive rate and the lowest negative rate were obtained when the dose of nitrogen ions was kept at 40 × 1014 and 60 × 1014 ions/cm2. Both positive and negative rate were above 30% at a dose of 40 × 1014 and 60 × 1014 ions/cm2, respectively, which indicated a broad mutation spectrum and would thus be favorable for breeding mutants with novel genetic characters.

Screening for high laccase secreting mutant

More than 200 mutants with obvious oxidized dye were isolated from PDA–ABTS plates and inoculated into YPD–Cu medium. Among all the mutants tested, six strains exhibited more than 30% increase in laccase activity compared to that of the wild strain. Specifically, the mutant S151 and S152 exhibited about 3–4-fold increase in secreted laccase (Table 1).

The genetic stability of laccase producing strains was determined by continuous passage experiment (Fig. 3). All of the above six mutants were stable during five continuous passages. The mutant S152 exhibited better passage stability and the highest laccase activity of 3,300 U/L after 7 days of incubation, which is 4.6 times of that of the wild strain. Thus, the mutant S152 was selected as a preferable laccase-producer for further studies.

Enzyme properties of laccases from wild and mutant strains

Effect of pH and temperature on laccase activity

Higher catalytic performance was detected by ABTS and guaiacol as the substrates (data not shown), and the pH dependence of laccase in oxidizing ABTS and guaiacol was shown in Fig. 4. With ABTS as the substrate, laccases from both the wild strain and mutant S152 were the most active at pH 3.4, and inactivated rapidly at extreme acid conditions (pH < 3.0). Different active pH ranges between laccases from the wild strain and mutant S152 was observed. The activity of laccase from the wild strain decreased when pH above 4.6, dropping to 48% of its maximum value at pH 6.0, whereas the activity of laccase from mutant S152 remained more than 83% of its maximum value at pH 3.0–6.0. Similarly, laccases from both the wild strain and mutant S152 were the most active on guaiacol at pH 5.0, while the activity of mutant S152 laccase declined more slowly than that of the wild strain with the increasing of pH, retaining 70% of its maximum value at pH 6.8. In general, fungi laccases exhibited a narrow active pH range with optimal catalytic performance at the range of pH from 3.0 to 6.0 depending on the type of substrate [3, 21–24]. The optimal pH of laccase from Trichoderma harzianum WL1 was observed at pH 4.5 using ABTS as a substrate and inactivated at higher pH, with about 50% residual activity at pH 6.0 [22]. Moreover, free and immobilized Trametes versicolor laccases were detected different optimal pH at pH 5.5 and 5.0, respectively, with syringaldazine as the substrate, and free enzyme lose its activity rapidly when pH value above 5.5 while the immobilized laccase displayed improved pH stability [3]. A wider active pH range of laccase from mutant S152 was obtained in this study by the ions implantation, which would be more applicable for industrial application.

Temperature dependence of laccase from the wild strain and mutant S152 was shown in Fig. 5. With ABTS as the substrate, laccase activity of the wild strain increased with increasing temperature from 25 to 55 °C, and decreased sharply when temperature rose above 55 °C, while laccase from the mutant S152 had an optimal temperature range at 60–65 °C and retained 74% of its maximum activity at 70 °C. Most laccases kept their activities in the range of 30–50 °C [3, 22, 23]. The laccase from T. harzianum was found to be active in a temperature range from 30 to 50 °C, with the maximum activity at 35 °C [22]. The optimal temperature for the Trametes sp. laccase to catalyze the oxidation of guaiacol was 50 °C [23]. Compared with other reported laccases [3, 22, 23], laccase from Paecilomyces sp. in this study was found to be more active at higher temperature, especially for the mutant laccase, although it was lower than laccase from Trametes hirsute [24].

Effect of pH and temperature on enzyme stability

Enzyme inactivation during catalysis is a great obstacle that limits industrial application, but could be resolved by exploiting enzymes with better pH and thermal stability through genetic modification.

Laccases from the wild strain and mutant S152 showed similar pH stability when kept in different buffers for 30 min; both of them were stable over the pH range 3.4–8.8, but inactivated drastically at a lower pH (Fig. 6). After incubating for 12 h in 0.1 M phosphate buffer, laccase activity of the wild strain decreased sharply in acid conditions, but relatively stable under neutral and alkaline conditions which retained 83% of its maximum at pH 6.6, while laccase from the mutant S152 retained more than 93% of its maximum activity over the pH range 6.0–8.8 (Fig. 6) even after incubation for 24 h (data not shown).

pH stability of laccase produced by wild Paecilomyces sp. WSH-L07 (closed) and mutant S152 (open) in 0.1 M citrate buffer (squares), 0.1 M phosphate buffer (triangles) and 0.1 M Tris–HCl buffer (circulars) for 30 min (solid lines) and 12 h (dot lines). All these assays were performed with ABTS as the substrate in 0.1 M citrate buffer (pH 3.4) and measured at 30 °C

As described above, the half-time of laccase from the mutant S152 was as long as 12 h at room temperature over the pH range 3.0–4.2, but decreased rapidly at 45 and 55 °C after incubation in 0.1 M citrate buffer (pH 3.4). Although laccases from the wild and mutant strains were unstable at pH 3.4 and high temperature, improved thermal stability for both enzymes at pH 5.0 was detected. As temperature rose to 55 °C, the laccase activity of mutant S152 decreased more slowly, retaining 70% of enzyme activity after heat treatment for 90 min, whereas laccase activity of the wild strain remained only 58% (Fig. 7).

Temperature stability of laccase produced by wild Paecilomyces sp. WSH-L07 (closed) and mutant S152 (open) incubated at 45 °C (squares) and 55 °C (triangles) in 0.1 M citrate buffer at pH 3.4 (solid lines) and pH 5.0 (dot lines). All assays were performed with ABTS as the substrate in 0.1 M citrate buffer (pH 3.4) and measured at 30 °C

With improved pH stability and thermal stability, laccase from the mutant S152 would be more suitable for biotechnological and environmental applications, such as decoloration of waste water from textile (under neutral or alkaline pH conditions), pulp delignification, and biotransformation [3, 5].

Effect of metal ions and inhibitors on laccase activity

The activities of laccases from the wild and mutant strains were tested in the presence of several metal ions including Al3+, Mn2+, Cu2+, Co2+, Ca2+, Mg2+, Ni2+, Zn2+ and Hg2+, and the results were summarized in Table 2. Laccases from the wild and mutant strains exhibited similar resistance to metal ions, which remained stable in the presence of 1 mM metal ions tested, even at 10 mM (<20% inhibition).

Besides, the sensitivity of laccases from the wild and mutant strains to several potential inhibitors was also tested (Table 2). Both enzymes were almost completely inhibited by NaN3 at a concentration of 0.1 mM, which may be due to the binding of NaN3 to the types 2 and 3 copper sites affecting internal electron transfer, and inhibiting enzymes activities [25]. Other agents exhibited obvious inhibition at higher concentrations. The activities were strongly inhibited by DTT and β-mercaptoethanol at a concentration of 1 mM, whereas enzyme activities were mildly inhibited by SDS, with 33% and 48% residual activities at a concentration of 1 mM for laccases from the wild and mutant strains, respectively, and slightly inhibited by 1 mM EDTA (<20 inhibition). A strong inhibition of laccase activities by addition of 5 mM SDS or EDTA was observed.

Industrial waste effluents usually contain various metal ions, and chelators such as EDTA, in the textile industry during dyeing process. The resistance of laccase from mutant S152 to various metal ions and low concentration of EDTA indicated the potential of the enzyme in the treatment of industrial waster effluents, particularly in the dyeing degradation.

Zymogram analysis of laccases from the wild strain and mutant S152

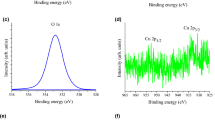

Native PAGE and active staining are commonly used to identify and distinguish laccase isoenzymes from other proteins. The zymogram analysis (Fig. 8) of laccase from the mutant S152 indicates that the activity profiles obtained were similar to that from the wild strain with at least three ABTS-active bands (Lac 1, Lac 2 and Lac 3) but only two guaiacol-active bands (Lac 1 and Lac 3). The prominent ABTS-active bands Lac 1 and Lac 3 were more intense than the obvious guaiacol-active band Lac 3 which was agreed with the results of substrate specificity.

There is no discernable difference in the intensity of the prominent active bands between the wild strain and mutant S152. This indicated that, at the same laccase activity level, the amount of laccase proteins in the concentrated enzyme solutions from the wild strain was basically equal to that from the mutant S152. In other words, the catalytic activities per enzyme molecule from the both strains were at equal level, irrespective of laccase’s source strain.

Although the mechanisms by which ion implantation manifest its radiobiological effects remain unclear, several researchers have suggested that it may involve not only energy absorption, but also mass deposition and charge exchange that are more complex than those caused by other traditional irradiation, such as UV, X-ray, and γ-ray. Some ions reach within microbes and interact with critical intracellular molecules resulting in fragmentation of biological building blocks, disruption of DNA, and induction of mutation effects [9, 11, 26]. Liu et al. [27] analyzed the types of transglutaminase gene mutation and found that nitrogen ion implantation could induce in all of the four nucleotides mutations, including transition, transversion, and deletion of DNA base. The same reasoning may offer a reasonable explanation of its broad mutation spectrum and remarkable mutation effect such as enhanced enzyme production and improved enzyme properties.

Conclusions

Low-energy ion implantation was used to mutate and breed a newly isolated laccase producing strain Paecilomyces sp. WSH-L07, and a genetically stable mutant S152 was obtained with four times laccase activity compared with that of the wild strain. The properties of laccases from the wild and mutant strains were investigated. The mutant laccase was active over a wider pH range, a wider temperature range, and more stable under neural and alkaline conditions than that from the wild strain, although their thermal stability was similar. Both the wild and mutant laccases were almost not affected by the tested metal ions, and mildly inhibited by SDS (0.5 mM), EDTA (1 mM) and DTT (0.5 mM). The activities were almost completely inhibited by 0.1 mM NaN3. The laccase from the mutant S152 with improved production and enzyme properties has the potential for biotechnology and industrial application.

References

Yaropolov AI, Skorobogatko OV, Vartanov SS, Varfolomeyev SD (1994) Laccase: properties, catalytic mechanism, and applicability. Appl Biochem Biotechnol 49:257–280

Couto SR, Toca-Herrera JL (2007) Laccase production at reactor scale by filamentous fungi. Biotechnol Adv 25:558–569

Bayramoglu G, Yilmaz M, Arica MY (2009) Preparation and characterization of epoxy-functionalized magnetic chitosan beads: laccase immobilized for degradation of reactive dyes. Bioprocess Biosyst Eng. doi:10.1007/s00449-009-0345-6

Marjasvaara A, Torvinen M, Vainiotalo P (2004) Laccase-catalyzed mediated oxidation of benzyl alcohol: the role of TEMPO and formation of products including benzonitrile studied by nanoelectrospray ionization Fourier transform ion cyclotron resonance mass spectrometry. J Mass Spectrom 39:1139–1146

Xavier A, Tavares APM, Agapito MSM, Evtuguin DV (2008) Sequential batch reactor for eucalypt kraft pulp effluent treatment with Trametes versicolor. J Chem Technol Biotechnol 83:1602–1608

Tanaka T, Tonosaki T, Nose M, Tomidokoro N, Kadomura N, Fujii T, Taniguchi M (2001) Treatment of model soils contaminated with phenolic endocrine-disrupting chemicals with laccase from Trametes sp in a rotating reactor. J Biosci Bioeng 92:312–316

Rajan A, Senan RC, Pavithran C, Abraham TE (2005) Biosoftening of coir fiber using selected microorganisms. Bioprocess Biosyst Eng 28:165–173

Gu SB, Li SC, Feng HY, Wu Y, Yu ZL (2008) A novel approach to microbial breeding: low-energy ion implantation. Appl Microbiol Biotechnol 78:201–209

Feng HY, Yu ZL, Chu PK (2006) Ion implantation of organisms. Mater Sci Eng R 54:49–120

Su CX, Zhou W, Fan YH, Wang L, Zhao SG, Yu ZL (2006) Mutation breeding of chitosanase-producing strain Bacillus sp. S65 by low-energy ion implantation. J Ind Microbiol Biotechnol 33:1037–1042

Chen Y, Lin ZX, Zou ZY, Zhang F, Liu D, Liu XH, Tang JZ, Zhu WM, Huang B (1998) High yield antibiotic producing mutants of mutants of Streptomyces erythreus induced by low energy ion implantation. Nucl Instrum Methods Phys Res Sect B 140:341–348

Liu ZQ, Zhang JF, Zheng YG, Shen YC (2008) Improvement of astasanthin production by a newly isolated Phaffia rhodozyma mutant with low-energy ion beam implantation. J Appl Microbiol 104:861–872

Hong YZ, Xiao YZ, Zhou HM, Fang W, Zhang M, Wang J, Wu LJ, Yu ZL (2006) Expression of a laccase cDNA from Trametes sp. AH28-2 in Pichia pastoris and mutagenesis of transformants by nitrogen ion implantation. FEMS Microbiol Lett 258:96–101

Andreas FK, Craig JC, Joseph MK, James BS, Andrew DM, David JS (2005) Site-directed genome modification: nucleic acid and protein modules for targeted integration and gene correction. Trends Biotechnol 23:399–406

Liang ZQ, Han YF, Chu HL (2007) A new thermotolerant Paecilomyces species which produces laccase and a biform sporogenous structure. Fungal Divers 27:95–102

Kluczek-Turpeinen B, Tuomela M, Hatakka A (2003) Lignin degradation in a compost environment by the deuteromycete Paecilomyces inflatus. Appl Microbiol Biotechnol 61:374–379

Liu ZY, Zhang DX, Hua ZZ, Li JH, Du GC, Chen J (2009) A newly isolated Paecilomyces sp. WSH-L07 for laccase production: isolation, identification, and production enhancement by complex inducement. J Ind Microbiol Biotechnol 36:1315–1321

Liang ZQ, Han YF, Chu HL (2005) Studies on the genus Paecilomyces in China. Fungal Divers 20:83–101

Palmieri G, Giardina P, Bianco C, Fontanella B, Sannia G (2000) Copper induction of laccase isoenzymes in the ligninolytic fungus Pleurotus ostreatus. Appl Environ Microbiol 66:920–924

Song DJ, Yao JM, Shao CL, Yu ZL (1999) A possible mechanism of dose related survival of microorganism implanted by N+ ions (in Chinese). Nucl Technol 22:129–132

Younes SB, Mechichi T, Sayadi S (2007) Purification and characterization of the laccase secreted by the white rot fungus Perenniporia tephropora and its role in the decolourization of synthetic dyes. J Appl Microbiol 102:1033–1042

Sadhasivam S, Savitha S, Swaminathan K, Lin FH (2008) Production, purification and characterization of mid-redox potential laccase from a newly isolated Trichoderma harzianum WL1. Process Biochem 43:736–742

Tong PG, Hong YZ, Xiao YZ, Zhang M, Tu XM, Cui TJ (2007) High production of laccase by a new basidiomycete, Trametes sp. Biotechnol Lett 29:295–301

Zhang H, Zhang Y, Huang F, Gao P, Chen J (2009) Purification and characterization of a thermostable laccase with unique oxidative characteristics from Trametes hirsuta. Biotechnol Lett 31:837–843

Ryan S, Schnitzhofer W, Tzanov T, Cavaco-Paulo A, Gubitz GM (2003) An acid-stable laccase from Sclerotium rolfsii with potential for wool dye decolourization. Enzyme Microb Technol 33:766–774

Yu ZL (2007) Study on the interaction of low-energy ions with organisms. Surf Coat Technol 201:8006–8013

Liu XQ, Zhang GQ, Qian SJ (2007) Mutation spectrum analysis of transglutaminas gene in Streptomyce fradiae after irradiation by N+ ion (in Chinese). Acta Microbiol Sin 47:265–269

Acknowledgments

We thank Mr. Yuan Hang in the key laboratory of Ion Beam Bioengineering of Chinese Academy of Science and Dr. Huang He in Nanjing University of Technology for their kindly helps in performing the ion implantation. This work was supported by the National Outstanding Youth Foundation of China (No. 20625619), the Major State Basic Research Development Program of China (973 Program) (No. 2007CB714306), the Program for Changjiang Scholars and Innovative Research Team in University (No. IRT0532), New Century Excellent Talents in University (NCET-07-0378).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Z., Zhang, D., Hua, Z. et al. Improvement of laccase production and its properties by low-energy ion implantation. Bioprocess Biosyst Eng 33, 639–646 (2010). https://doi.org/10.1007/s00449-009-0389-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-009-0389-7