Abstract

Dextran synthesis has been studied since the Second World War, when it was used as blood plasma expander. This polysaccharide composed of glucose units is linked by an α-1,6-glucosidic bond. Dextransucrase is a bacterial extra cellular enzyme, which promotes the dextran synthesis from sucrose. When, besides sucrose, another substrate (acceptor) is also present in the reactor, oligosaccharides are produced and part of the glucosyl moieties from glucose is consumed to form these acceptor products, decreasing the dextran yield. Although dextran enzymatic synthesis has been extensively studied, there are few published studies regarding its molecular weight distribution. In this work, the effect of maltose on yield and dextran molecular weight synthesized using dextransucrase from Leuconostoc mesenteroides B512F, was investigated. According to the obtained results, maltose is not able to control and reduce dextran molecular weight distribution and synthesis carried out with or without maltose presented the same molecular weight distribution profile.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dextran is a polysaccharide obtained from dextransucrase and sucrose. When, besides sucrose, another substrate (acceptor) is also used, side products (acceptor products) are formed. The presence of maltose in the digest leads to the synthesis of oligosaccharides as presented in Fig. 1[1].

Dextransucrase acceptor reaction with maltose [1]

Based primarily on a consideration of the most logical interpretation of the action of acceptors molecules the insertion mechanism for dextran biosynthesis was proposed [2]. After a study using labelling pattern of the biosynthesis of intracellular glycogen from sucrose by Niseria perflava amylosucrase another theory, where all carbohydrases act by transglucosylation, argued against the insertion mechanism supporting that synthesis at the reducing end could not occur. Another study, based on labelled acceptors proposed a mechanism for dextran synthesis where the insertion mechanism was taken into account and the acceptors were responsible for the chain termination [3].

According to the insertion mechanism with acceptors, dextran is biosynthesised by dextransucrase from Leuconostoc mesenteroides B512F by the addition of glucose units to the reducing ends of the growing chain. The enzyme forms a covalent complex with the reducing end of the dextran chain and the glucosyl unit forms a covalent intermediate with the enzyme and is inserted between the enzyme and the dextran growing chain. The chain elongation is terminated when acceptors, as fructose or glucose, reach a sufficient concentration that they interact at the active site in such a way that one of their hydroxyl groups makes a nucleophilic attack onto C1 of the dextran. According to this mechanism, oligosaccharides (acceptor products) synthesis is also attributed to the acceptor nucleophilic attack. The mechanism is presented in Fig. 2.

In the scheme presented in Fig. 2, the acceptor can be a natural side product of dextran synthesis as fructose released from sucrose when the enzyme biocatalysts the synthesis, or an added carbohydrate such as maltose.

Considering acceptors as chain terminators, high amounts of them in the reactor would increase the chain termination rate and, according to this mechanism, the addition of an acceptor to the reactor would yield low molecular weight dextran. The proper amount of acceptor should, in theses, control the dextran molecular weight providing a way of obtaining clinical dextran.

Dextran has been studied since the Second Word War, when it was used as blood plasma expander, but few works regarding its molecular weight distribution have been published, especially when acceptors are added to the reactor. In this work, the maltose (acceptor) effect on dextran molecular weight was investigated. Several dextran enzymatic syntheses were carried out using dextransucrase from Leuconostoc mesenteroides B512F. Maltose was chosen because it is the best-known acceptor for this synthesis [1].

Materials and methods

Enzyme preparation

A strain obtained from ARS Culture Bacterial Collection (NRRL Culture collection, United States Department of Agriculture, Peoria, IL, USA) was used. The conventional fermentation medium used for dextransucrase and dextran synthesis is composed of sucrose, a nitrogen source and minerals. In this work a fermentation medium containing sucrose 50 g/L (food grade); yeast extract, 20 g/L (Merck); MgSO4·7H2O, 0.20 g/L; MnSO4·2H2O 0.01 g/L; FeSO4·7H2O, 0.01 g/L; CaCl2·2H2O, 0.02 g/L; NaCl0, 0.01 g/L; and K2HPO4 (anhydrous), 20 g/L [4] was employed.

Enzyme was produced by feed batch fermentation using a mixed solution composed by NaOH (120 g/L) and sucrose (300 g/L) to control the pH level and keep high sucrose concentration in the culture medium. Fermentation was done in a BioFlo III (New Brunswick Scientific Co.) at 27°C and pH controlled at 6.7 (±0.1) during 6 h with mechanical agitation of 150 rpm and aeration of 0.5 L/min. After this period, the feed flow rate was interrupted and the pH was allowed do drop to 5.2, when the process was considered finished. The cells were harvested by centrifugation at 4°C (10,000 rpm for 10 min). The enzyme was recovered from the culture broth by precipitation with polyethylene glycol (PEG 1500). The partially purified enzyme was then diluted in a pH 5.2 sodium acetate buffer (20 mM) containing 0.05 g/L of CaCl2.

Enzyme activity assay

Enzyme activity was determined by quantifying the released fructose by the DNS method [5]. The enzymatic preparation (55 μL) was mixed with a 455 μL of a 10% (w/v) sucrose solution in an acetate buffer pH 5.2 (20 mM containing 0.05 g/L of CaCl2) and then incubated for 1 h at 30°C. Enzyme activity was determined by linear regression. Dextransucrase activity is expressed in DSU/mL (dextransucrase unit/mL). One dextransucrase unit is the amount of enzyme that converts 1 mg of sucrose into dextran in 1 h under ideal reaction conditions (30°C; pH 5.2) [6].

Dextran enzymatic synthesis

Syntheses were carried out at 30°C and pH 5.2 in a glass batch reactor, with temperature control, containing enzyme, maltose and sucrose in different proportions. Samples were taken at regular time intervals until the sucrose was totally consumed, confirmed by thin layer chromatography analysis (TLC). Immediately after sampling, the samples were heated by 5 min at 100°C (enzyme inactivation). After cooling to room temperature, dextran was precipitated adding three volumes of ethanol 96%. The samples were dried until constant weight at 60°C and the final mass obtained was used to calculate the dextran yield. The dextran molecular weight was characterised by gel permeation chromatography (GPC) and the supernatant was used to visualise the acceptor products formation by thin layer chromatography (TLC).

Thin layer chromatography

The acceptor products, sucrose and fructose were separated and qualitatively analysed by TLC, using silica gel plates. The multiple ascent technique was used. The solvent system used for the acceptor products separation was acetonitrile/ethyl acetate/1-propanol/water (85:20:50:90 v/v/v/v) and two ascents, while for the sucrose, maltose and fructose the solvent system used was acetonitrile/water (85:15 v/v) with three ascents. At the end of each ascent, the plate was dried in a hood by solvent evaporation.

The detection system used was a solution of 0.3% (w/v) of 1-naphtyletienediamine and 5% (v/v) of H2SO4 concentrated in methanol. After finishing the last ascent the plates were immersed into the detection reagent and then dried by solvent evaporation. The dried plates were put into an oven at 120°C for 10 min. The carbohydrate identification was done by visual identification directly on the plate.

Molecular weight characterisation

Dextran molecular weight characterisation was done by gel permeation chromatography analysis (GPC) using five dextran standards purchased from American Polymer Standard Corporation. The standards covered the range of molecular weight from 11 kDa to 530 kDa \((\overline{{M{\rm w}}})\). These standards are considered good for GPC analysis because they provide three molecular weights \((\overline{{M{\rm w}}}, \overline{{M{\rm n}}} \hbox{ and } \overline{{M{\rm p}}})\) that allow broad calibration and the polymer can be properly characterized.

Chromatographic analysis were performed in a system composed by two pumps model 515, auto sampler model 715 and refraction index detector model 410, all of them from Waters. The data were acquired and handled through the software Millenium 32. The column set was composed by two hydroxyl-polymetilmetacrilate columns (Ultrahydrogel 1,000 and Ultrahydrogel 500) also from Waters, with exclusion limit of 1×106 and permeation limit of 4×105, respectively. The columns were connected in series. Samples and standards solutions (1 mg/mL) were prepared diluting dextran into sodium azide water solution (0.02% w/v) allowing 24 h to rest the polymer. Analyses were done in duplicate injecting 150 μL of each sample. A solution of water/NaN3 0.02% (Sigma Co.) was used as eluent. The temperature of the column set and the detector was 40°C and eluent flow rate was 0.8 mL/min.

Results

Dextran syntheses were carried out with enzymatic activity of 40 DSU/ mL. Sucrose concentration was chosen in such a way that no substrate inhibition could occur (lower than 200 mM) [1]. A total of eight syntheses were done using sucrose and maltose concentrations presented in Table 1.

During the experiments the viscosity of the medium strongly decreased when maltose was used as a second substrate (the higher the maltose, the lower the viscosity). Thin layer chromatography was used to track the acceptor products formation and sucrose consumption. No leucrose formation was observed when maltose was used as acceptor. Dextran and panose formation were quickly observed at the beginning of the reaction. Higher oligosaccharides (homologous series with degree of polymerisation higher than panose) were not obtained at the beginning of the reaction and maltose was not totally consumed at the end of the reaction (when sucrose was totally consumed). Dextran yield was calculated based on initial sucrose molar concentration.

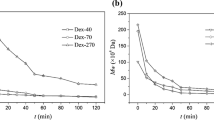

Dextran is a polysaccharide composed by glucose units linked to each other by α-1,6-glycosidic bond. Dextran yields profile obtained for the syntheses are presented in Table 1, are presented in Fig. 3.

According to Fig. 3, high dextran yields were obtained when just sucrose was loaded in the reactor. High maltose concentrations lead to lower dextran yields (the higher the maltose in the digest, the lower the dextran yield). Comparing Fig. 3a and b, it is clear that not only the maltose/sucrose ratio affects dextran yield, but also initial concentration of the substrates. In Fig. 3a, higher sucrose and maltose concentrations were used and dextran yields were lower than the obtained when lower substrates concentrations were used (Fig. 3b) for the same maltose/sucrose ratio. This observation is pertinent since the ratio cannot be considered a good parameter and the actual substrate concentration should be considered.

According to the presented results, high amounts of glucosyl moieties are deviated from dextran synthesis to produce side products (isomaltooligosaccharides) even when low maltose is present in the reaction medium since it is observed that dextran yield decreases more than 40% by adding 25% of maltose in the reactor.

Glucose units from sucrose, not polymerised onto dextran, were consumed to form acceptor products, since no significant free glucose was found in the reaction medium at 270 min (TLC analysis).

The dextran obtained according to the synthesis conditions presented in Table 1 was characterised by GPC. Dextran narrow standards from American Polymer Standard Corporation were employed in the GPC analysis. The molecular weights of the standards (provided by the manufacturer) are presented in Table 2.

Glucose and high molecular weight commercial dextran (Sigma Co.) were used to find the time required to reach the permeation and exclusion limits of the column set. These times are presented in Fig. 4.

According to Fig. 4, all the samples with molecular weight below 2,000 kDa should present retention time higher than 12 min. As glucose has the lowest molecular weight, there is no sample with retention time higher than 30 min. Figures 5 and 6 present the chromatograms obtained for runs 1 and 4 (Table 1).

Gel permeation chromatogram for run 1 (Table 1) at reaction times: 10, 30, 60, 90 and 270 min

Gel permeation chromatogram for run 4 (Table 1) at reaction times: 10, 30, 60, 90 and 270 min

Discussion

According to the results presented in Figs. 5 and 6, maltose has no significant effect on dextran molecular weight, and acts only deviating the glucosyl moieties from the dextran formation to the acceptor, yielding acceptor products. The presence of oligosaccharides contamination in dextran samples were tested using TLC analysis and no trace of oligosaccharides with degree of polymerisation lower than 20 (20 glucose units) were found.

The syntheses yielded a product with a bimodal distribution composed by high molecular weight dextran (Mw>1,000 kDa) and oligodextran (Mw<10 kDa), even when just sucrose is present in the reactor, what indicates that this oligodextran is naturally formed during the synthesis. Chromatograms obtained for the other runs (not shown) presented similar results [7].

According to the results, the acceptor reaction is parallel to the dextran synthesis and does not constitute a way of controlling dextran molecular weight by chain grow termination, since dextran and panose formation occurs at the same time. This observation was only possible tracking the dextran and acceptor products formation with the time, instead of analysing the results only at the end of the synthesis (as done in several published works).

Even when high maltose/sucrose ratio is used in the digest (Fig. 6), dextran molecular weight distribution is similar to the one obtained when only sucrose is presented in the digest and maltose only decreases the dextran yield, deviating the D-glucosyl units from dextran to the acceptor. Based on the obtained results, a mechanism able to explain the difficulty on controlling the dextran molecular weight, regarding to produce clinical dextran ( \(\overline{{Mw}}\) 40 and 70 kDa) using acceptors, and the chain elongation of the acceptor products by sucrose addition [8] is proposed in Fig. 7.

According to the scheme proposed in Fig. 7, the acceptor (maltose) binds on its intermediate site, where the oligosaccharide synthesis occurs. The acceptor products are formed deviating the glucosyl moieties from the dextran formation decreasing dextran yield. Acceptor products synthesis and dextran synthesis are parallel reactions and acceptors do not decrease the dextran molecular weight or affect its molecular weight distribution.

Even though acceptors cannot be employed to control dextran molecular weight, they can be applied to oligosaccharides synthesis. These processes can be designed considering mainly the acceptor chain elongation and the desired degree of polymerisation of the acceptor product. For isomlatooligosaccharides, the presented results showed that employing high concentrations of maltose and low concentrations of sucrose is an operating condition that favours oligosaccharide synthesis and decreases dextran yield. Low dextran yields are interesting not only because the glycosil moieties are used to increase oligosaccharide yields, but also because low dextran at the end of synthesis facilitates the purification step since the viscosity is strongly reduced (purification steps sometimes are the most expensive ones in an industrial process).

As higher oligosaccharides are not formed at the beginning of the reaction, stopping the reaction at the time when the desired acceptor product reaches a good concentration avoiding its chain elongation can control the degree of polymerisation. Substrates (maltose and sucrose) can be also fed into the reactor in order to keep the initial proportions and to avoid the chain elongation, as well as, to increase the yield. As dextran does not effectively take part in the oligosaccharide synthesis, and according to the presented results can be considered a by product in oligosaccharides synthesis, mechanistic pathways and mathematical models considering only the oligosaccharides synthesis and substrates consumption [1] can be used to optimise the system and to find the operating conditions that result in high productivity and high yield of the desired acceptor product. This simplification is very useful for process modelling and simulation since mathematical models for polymer systems, like dextran synthesis, are very complex and requires complex mathematical algorithms.

Conclusions

The mechanism of dextransucrase action, a glucansucrase that can be obtained from several strains of Leuconostoc mesenteroides, is still not totally understood. Some recent studies based on cloning of glucansucrases encoding gene in addition to the structure–function relationship studies showed two functional domains: a core region involved in sucrose binding and a C-terminal domain involved in glucan-binding [9]. These recent works confirm that glucan-biding site is separated from sucrose biding site as previously suggested [10–12].

The mechanism proposed in this work argues against the theory that acceptors are chain terminators and the acceptor products are formed by dextran chain displacement from its active site. The mechanism is in agreement with the fact that no acceptors were found at the dextran reducing end [9] and is also able to explain the non-competitive inhibition of dextran synthesis observed for several acceptors [2, 8, 13–15]. The mechanism also explains the possibility of the acceptor chain elongation by the non-reducing end (as can be seen in Fig. 1) and the glucan elongation by the reducing end as previously proposed [2].

The observation that acceptor reaction does not affect the glucan molecular size distribution strongly suggests that acceptor reaction can occur at a unique and separated site. The comprehension of the acceptor reaction mechanism is important to increase the yield of acceptor products and to develop industrial process to synthesise them. These carbohydrates are called prebiotic since they are not metabolised by human digestive enzymes and promote the development of bidifidobacteria in human intestines [9, 16, 17].

Abbreviations

- D :

-

Dextran mass (moles of polymerised glucose)

- DXT:

-

Dextran

- \(\overline{{M{\rm w}}}\) :

-

Weight average molecular weight (g/mol)

- \(\overline{{M{\rm n}}}\) :

-

Weight average molecular weight (g/mol)

- \(\overline{{M{\rm p}}}\) :

-

Peak average molecular weight (g/mol)

- S 0 :

-

Initial sucrose concentration (mM)

- PDI:

-

Polydispersity index

References

Heincke C, Demuth B, Jördenin HJ, Buchholz K (1999) Kinetics of the dextransucrase acceptor with maltose—experimental results and modeling. Enzyme Microb Technol 24:523–534

Ebert KH, Schenk G (1968) Mechanism of biopolymer growth: the formation of dextrans and levan. Adv Enzymol 30:179–221

Robyt JF, Walseth TF (1978) The mechanism of acceptor reactions of Leuconostoc mesenteroides B- 512F dextransucrase. Carbohydr Res 61:433–445

Guimaraes DRB, Costa FAA, Rodrigues MF (1999) Optimization of dextran synthesis and acidic hidrolisys by surface response analysis. Braz J Chem Eng 16:129–139

Miller GL (1959) Use of dinitrosalicilic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Tsuchiya HM, Koepsel HJ, Corman J, Bryant MO, Feger VH, Jackson RW (1952) The effect of certain cultural factors on production of dextransucrase by Leuconostoc mesenteroides. J Bac 64:521–526

Rodrigues S (2003) Estudo da síntese enzimática de dextrana na presença de maltose como acceptor. Universidade Estadual de Campinas, Faculdade de Engenharia Química, Campinas—SP-Brazil, p 250, PhD Thesis

Paul F, Oriol E, Auriol D, Monsan P (1986) Acceptor reaction of a highly purified dextransucrase with maltose and oligosaccharides—application to the synthesis of controlled-molecular-weight dextrans. Carbohydr Res 149:433–441

Monchois V, Willemot RM, Monsan P (1999) Glucansucrase: mechanism of action and struture–fuction relantioships. FEMS Microbiol Rev 23:131–151

Kobayashi M, Mihara M, Matsuda K (1986). Dextransucrase form Leuconostoc mesenteroides NRRL B512F: characterization of the enzyme bound to sephadex gel. Agric Biol Chem 49:3189–3195

Kobayashi M, Yokoyama I, Matsuda K (1986) Substrate binding sites of Leuconostoc dextransucrase evaluated by inhibition kinetics. Agric Biol Chem 50:2585–2590

Yokayama I, Kobayashi M, Matsuda K (1985) Comparison of multiplicity of dextransucrase from six strains from of Leuconostoc mesenteroides. Agric Biol Chem 49:501–507

Böker M, Jördening HJ, Buchholz K (1994) Kinetics of leucrose formation from sucrose by dextransucrase. Biotechnol Bioeng 43:856–864

Stringer CS, Tsuchiya HM (1958) A kinetic study of dextransucrase. J Am Chem Soc 80:6620–6625

Mayer RM, Mattheus MM, Futerman CL, Parnaik VK, Jung SM (1981) Dexatransucrase: acceptor substrate reactions. Arch Biochem Biophys 208:278–287

Chung CH, Day DF (2002) Glucooligosaccharide from Leuconostoc mesenteroides B-742 (ATCC 13146): a potential prebiotic. J Ind Microbiol Biotechnol 29:196–199

Machida Y, Fukui F, Komoto T (1986) Use of oligosaccharides for promoting the proliferation of bidifidobacteria. European Patent 0242459

Acknowledgements

The authors acknowledge the Brazilian funding agencies CNPq, CAPES and FAEP for the financial support and to ARS Culture Bacterial Collection for the Leuconostoc mesenteroides strain used in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodrigues, S., Lona, L.M.F. & Franco, T.T. The effect of maltose on dextran yield and molecular weight distribution. Bioprocess Biosyst Eng 28, 9–14 (2005). https://doi.org/10.1007/s00449-005-0002-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-005-0002-7