Abstract

The physicochemical properties (capacity, kinetics and selectivity) of the ion exchange resins Amberlite IRA900, IRA400, IRA96 and IRA67 were determined to evaluate their comparative suitability for lactic acid recovery. Both the kinetics of lactic acid sorption from aqueous solutions and the equilibrium were assessed using mathematical models, which provided a close interpretation of the experimental results. The best resins (Amberlite IRA96 and IRA67) were employed in further fixed-bed operation using aqueous lactic acid solutions as feed. In this set of experiments, parameters such as capacity, regenerant consumption, percentage of lactic acid recovery and product concentration were measured. Amberlite IRA67, a weak base resin, was selected for lactic acid recovery from SSF (simultaneous saccharification and fermentation) broths. Owing to the presence of nutrients and ions other than lactate, a slightly decreased capacity was determined when using SSF media instead aqueous lactic acid solutions, but quantitative lactic acid recoveries at constant capacities were obtained in four sequential load/regeneration cycles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Lactic acid is a commodity chemical with a wide range of applications, mainly in the food industry (which utilizes about 80% of the total production, especially as a microbial preservative or as an agent for acidification or buffering), but also in the production of pharmaceuticals and cosmetics as well as in the polymer industry, where it is used for making biodegradable plastics [1, 2]. The industrial production of lactic acid can be carried out by two alternative technologies: chemical synthesis from fossil fuels and biotechnological technologies—the latter being based on the utilization of biomass as raw materials. Nowadays, the fermentative production of lactic acid is the world's leading technology.

In lactic acid fermentations which are carried out without addition of neutralizing or buffering agents, the pH decreases during bioconversion because of the dissociation of the acid, thus slowing the fermentation kinetics or even preventing the microbial metabolism. In industrial processes, pH is controlled either by adding a soluble alkali (such as NaOH, KOH, Ca(OH)2 or NH4OH) or by reaction with an excess of calcium carbonate, leading to a salt as the final product [2, 3]. A variety of applications have been described for the sodium, potassium, ammonium or calcium lactates [4]. When the objective is the production of lactic acid and the neutralization is carried out with calcium carbonate, the calcium lactate has to be recovered by filtration and reacted with sulphuric acid to give calcium sulphate, adding both new costs in chemicals and additional waste management to the overall process [2, 5]. Economic estimates show that the costs of recovery and purification account for about 50% of the overall production costs [5, 6], their reduction being one of the most important challenges in the production of lactic acid [7].

Several approaches have been considered in literature for lactic acid recovery, including solvent extraction [6] and electrodialysis [8]. However, comparatively high amounts of solvents are needed for extraction, and toxic effects are provoked by solvents [6, 9]. In the electrodialysis units, cells adhered to membranes during the process, leading to decreased efficiency in the overall recovery system [8].

In this field, ion exchange separation provides an interesting alternative for lactic acid recovery from solutions having low concentration and complex composition [7], as in the case of fermentation media. A variety of commercial ion exchange resins are available, with different structures, polymers and functional groups. These differences result in a wide variation in physicochemical properties (basicity, kinetics and capacity of exchange, susceptibility towards regeneration and so on), which control their suitability for a given problem.

The sorption in ion exchange resins can be ascribed to two different phenomena, adsorption and ionic exchange, which can happen simultaneously. At low pH, the weak base resins in free base form adsorb mainly the undissociated form of the lactic acid, which can be recovered by elution with methanol, ethanol or water at mild temperatures [1]. However, the pH of lactic fermentation media is usually in the range 5–7, lactate being the predominant form under these conditions. In this case, the sorption capacity of a given weak base resin could be increased by acidification of the fermentation media to switch the equilibrium towards the molecular form of the acid, but this operational procedure raises the operational costs, particularly if the fermentation media has to be recycled (for example, when lactic acid is recovered during fermentation by intermittent contact with resins). Contrarily, the strong base resins in OH− form have high affinity for lactic acid and maintain their capacity in a wide range of pH, but strong regenerating agents are required for product recovery [7].

This work deals with the comparative evaluation of four resins for lactic acid recovery at pH=4.85, usually employed in SSF (simultaneous saccharification and fermentation) processes [10]. Under these conditions, the dissociated form of the lactic acid was predominant. From experiments carried out with synthetic solutions of lactic acid, the determination of physicochemical and kinetic parameters allowed the selection of the best resin to be employed for lactic acid recovery from SSF broths in which pretreated Eucalyptus wood was converted into lactic acid by the simultaneous action of fungal enzymes and bacteria (Lactobacillus delbrueckii NRRL B-445).

2 Materials and methods

2.1 Resin preparation

The anion exchange resins Amberlite IRA 900, IRA 400, IRA 96 and IRA 67 were selected for this study. Their main characteristics are presented in Table 1. Before utilization, the resins were washed and converted into their OH− or Cl− forms. Resins in OH− form were obtained by washing the resins sequentially with 1 N NaOH solution, distilled water, 1 N HCl solution, distilled water, 1 N NaOH solution and distilled water (until pH=7). Because of their own nature, Amberlite IRA67 and IRA96 could not be obtained in OH− form (both resins remained in free base form at pH higher than 9). Resins in Cl− form were obtained by washing the resins sequentially with 1 N HCl solution, distilled water, 1 N NaOH solution, distilled water, 1 N HCl solution and distilled water (until pH=7). Aliquots of resins in OH− or free base and Cl− forms were air dried and assayed for moisture by oven drying at 105 °C for 24 h.

2.2 Preparation of synthetic solutions of lactic acid to be used for resin selection

Samples of preset concentrations were prepared from a commercial solution containing 88% lactic acid and heated near the boiling point in order to hydrolyse the lactic anhydride present. Then, pH was adjusted to 4.85 by adding 5 N NaOH and the samples were stored at 4 °C until use. Before utilization, lactic acid was determined by high performance liquid chromatography (HPLC) (see below).

2.3 Manufacture of SSF media

Simultaneous saccharification and fermentation of processed Eucalyptus wood was carried out in a 2-l bioreactor with 1.0 l of working volume. A medium (containing water and processed wood at a liquor to solid ratio=30:1, 5 g yeast extract/l, 10 g peptone/l, 5 g sodium acetate/l, 2 g sodium citrate/l, 2 g K2HPO4/l, 1 ml Tween 80/l, 0.58 g MgSO4 .7H2O/l, 0.12 g MnSO4.H2O/l and 0.05 g FeSO4.7H2O/l) was sterilized in an autoclave. After temperature regulation, an inoculum of Lactobacillus delbrueckii NRRL-B445 and the volume of Trichoderma reseei cellulases needed to achieve an enzyme/substrate ratio of 28 UPF/g solid were added to the medium. The temperature was kept at 45°C and pH was controlled at 4.85 by automatic addition of 4.0 N NaOH. A new addition of substrate (in the same amount employed initially) was carried out after 10 h [10]. After 60 h, the liquors were separated from the solid residues by filtration and stored at 4°C in a refrigerator. A sample of the broth was used for HPLC analysis of lactic acid and sugars (see below).

2.4 Study of batch operation: kinetics and equilibrium

In the study of equilibrium, 2 g of dry resin and 20 ml of either aqueous lactic acid solutions or SSF media were contacted in 50 ml flasks at 25°C. The initial pH of all samples was fixed in 4.85, the optimum value for SSF. After contacting phases with magnetic stirring until the equilibrium was reached, samples of the supernatants were withdrawn and analysed for lactic acid by HPLC (see below). In kinetic studies, 2 g of dry resin and 20 ml of lactic acid solution (concentration around 60 g/l) were contacted in 50 ml flasks. Temperature and pH were the same as in equilibrium studies. At preset contact times, samples of supernatants were withdrawn and analysed for lactic acid (see below).

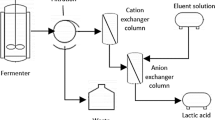

2.5 Fixed-bed operation

A column (length, 6 cm; i.d., 1.2 cm) was charged with 2.77 g of resin, filled with water, vacuum drained to determine the interstitial volume and refilled with distilled water. Then, a solution containing 42 g lactic acid/l was pumped at a flow rate of 3.5 ml/min. Fractions of the effluent were collected and analysed for lactic acid. The resin was considered to be saturated when the lactic acid concentration in the effluent reached the value corresponding to the feed. The interstitial solution was removed by pumping distilled water until the lactic acid concentration of the effluent was below 0.1 g/l. Lactic acid recovery was achieved by pumping 1 N HCl through the column. Samples of the effluent were collected and analysed for lactic acid until an outlet concentration below 0.1 g/l was reached. Finally, a washing step was carried out as above to remove the HCl contained in the interstitial space, and the column became ready for a new cycle. Experiments with SSF media were carried out in a different column (length, 9 cm; i.d., 1.2 cm) containing 4.1 g of resin, with the rest of the operational conditions being the same as above.

2.6 Analytical methods

Lactic acid and sugars were determined by HPLC using a Hewlett Packard chromatograph fitted with an RI (refraction index) detector (detector temperature, 40°C). Other analysis conditions were: column, ION-300; mobile phase, 0.003 M H2SO4; elution flow, 0.5 ml/min.

2.7 Fitting of parameter values

The experimental data were fitted to the proposed models using commercial software (TableCurve from Jaendel Scientific, USA).

3 Results and discussion

The suitability of a given ion exchange resin for lactic acid recovery from SSF media depends on its physicochemical features (including capacity, selectivity and sorption kinetics), but also on its susceptibility and stability towards load/regeneration cycles.

The capacity of the resins in their different forms were evaluated in the first part of this study. As the final objective is to obtain a lactic acid solution from a fermentation medium where the lactate ion is predominant, the regeneration has to be accomplished by means of an acid (in our case, HCl). When a strong base resin is used in Cl− form, the load/regeneration cycle can be summarized in the following steps:

-

1.

\( {\rm{ }}\overline {R^ + {\rm{Cl}}^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + L^ - _{{\rm{aq}}} \leftrightarrow \overline {R^ + L^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{Cl}}^ - _{{\rm{aq}}} \)

-

2.

Washing with distilled water

-

3.

\( {\rm{ }}\overline {R^ + L^ - } + {\rm{H}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{Cl}}^{\rm{ - }} _{{\rm{aq}}} \leftrightarrow \overline {R^ + {\rm{Cl}}^{\rm{ - }} } + {\rm{H}}^{\rm{ + }} _{{\rm{aq}}} + L^ - _{{\rm{aq}}} \)

-

4.

Washing with distilled water

where L − denotes the lactate ion, R + denotes the overall complex matrix functional group, and the upper bar accounts for the charged resin. In this simplified approach, it is assumed that both lactic acid and HCl are completely dissociated.

If the resin is initially loaded with OH− ions, the overall cycle for lactic acid recovery can be described by the following stages:

-

1.

\( \;\overline {R^ + {\rm{OH}}^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + L^ - _{{\rm{aq}}} \leftrightarrow \overline {R^ + L^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{OH}}^ - _{{\rm{aq}}} \)

-

2.

Washing with distilled water

-

3.

\( \;\overline {R^ + L^ - } + {\rm{H}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{Cl}}^ - _{{\rm{aq}}} \leftrightarrow \overline {R^ + {\rm{Cl}}^ - } + {\rm{H}}^{\rm{ + }} _{{\rm{aq}}} + L^ - _{{\rm{aq}}} \)

-

4.

Washing with distilled water

-

5.

\( \;\overline {R^ + {\rm{Cl}}^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{OH}}^ - _{{\rm{aq}}} \leftrightarrow \overline {R^ + {\rm{OH}}^ - } + {\rm{Na}}^{\rm{ + }} _{{\rm{aq}}} + {\rm{Cl}}^ - _{{\rm{aq}}} \)

-

6.

Washing with distilled water

This second possibility involves a higher number of stages, and so increased costs in terms of chemicals and waste management. It can be noted that strong base resins in OH− form exchange ions, but also can interact with the undissociated form of the acid through neutralization reactions (which are not included in the above scheme for simplification).

Resins were contacted with an aqueous solution containing 60 g lactic acid/l with initial pH adjusted to 4.85 by NaOH addition. When equilibrium was reached, samples of supernatants were withdrawn and the capacities of the resins (denoted q, g lactic acid/g dry resin) were calculated by the equation:

where LAC0 and LACE are the initial and equilibrium concentrations of lactic acid (g/l), V is the volume of solution (l) and w is the amount of dry resin employed (g).

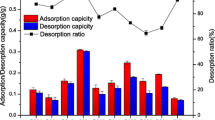

Figure 1 shows the capacities of the resins in their different forms. In Cl− form, the weak base resins presented the highest capacities. However, the strong base resins in OH− form presented higher capacities than the weak base ones (in free base form). This last finding can be explained on the basis that the strong base resins present usually low affinities for the OH− ion [11, 12]; this fact allowing them to exchange it easily. Additionally, as was said before, strong base resins in OH− form can interact with both dissociated and undissociated forms of lactic acid, but the weak base resins in free base form interact only with the undissociated form (which is in the minority at pH=4.85) [7]. On the other hand, it can be noted that the capacities of resins with a macroreticular structure (Amberlite IRA 900 and IRA 96) are slightly higher than the ones of the respective gel-matrix resins.

Considering the results obtained with the sequences studied, and on the basis of the above discussion, it can be concluded that the resins in Cl− form present advantages for further operation. Furthermore, the separation of the HCl contained in the final solution of lactic acid can be easily achieved owing to the relative volatility of this compound.

3.1 Ion exchange isotherms

The equilibrium conditions are of major interest in the selection of an ion exchange resin for a defined purpose. Even though preliminary conclusions on this subject can be drawn from Fig. 1, a more detailed experimentation was undertaken in order to obtain the equilibrium isotherms in a wide range of concentrations. As mentioned in the Methods section, experiments were carried out at 25°C in media having an initial pH of 4.85. This pH was selected because it would be compatible with intermittent lactic acid recovery from fermentation media. The exchange of L − ions caused a slight decrease in pH (up to 4.6 in the worst case), but this variation had little effect on the balance between the dissociated and undissociated forms of lactic acid, which was always clearly favourable to the dissociated form. Owing to this, ion exchange (and not adsorption) is expected to be the predominant phenomena in experiments. Figure 2, which shows the isotherms for the resins considered, confirmed this. In agreement with previous findings (see Fig. 1), the weak base resins presented higher capacities than the strong base ones in all the range of concentrations explored.

The adsorption of lactic acid can be described by a model similar to the one proposed by Barboza et al. [13] for clavulanic acid recovery using Amberlite IRA 400. According to the chemical reaction:

the net adsorption rate, r q, can be written as:

where k 1 and k 2 are the kinetic parameters defining the adsorption and desorption steps, respectively, LAC i is the lactic acid concentration in liquid phase at the considered time, q m is the maximum resin capacity and q i is the resin charge at the considered time (expressed as g lactic acid/g dry resin). When equilibrium is reached, r q=0, LAC i =LACE and q i =q. With these assumptions:

where q and LACE are as above, and K (l/g) is the equilibrium constant calculated as k 1/k 2. This equation (Langmuir's isotherm) was used to fit the experimental series of data q/LACE. Table 2 shows the results obtained for the regression coefficients, as well as the statistical parameters measuring the correlation and significance of models. These results show that the major differences among resins are caused by their different maximum capacities (measured by the parameter q m), whereas K showed similar values in all the cases considered. Furthermore, it can be noted that the maximal capacities were lower than indicated by the suppliers (see Table 1), which is possibly related to the fact that some functional groups were not accessible to lactate ions. A similar finding was reported by Evangelista et al. [7].

3.2 Kinetics of lactic acid sorption

A set of assays was carried out to assess both the kinetic pattern of lactic acid recovery from aqueous solutions and the contact time necessary for reaching equilibrium. Figure 3 shows the time courses of lactic acid concentration for the four resins considered. All of them exhibited a common kinetic pattern characterized by an initial stage of fast exchange, followed by a slower stage. This behaviour is in agreement with the findings of Kaufman et al. [2] for weak base resins. The overall process is made up of sequential stages, including: (1) solute mass transfer through the liquid film surrounding the resin particles; (2) intraparticle diffusion of solute and (3) solute adsorption. If the mass transfer through the film is the rate-controlling step, the kinetics of the process is defined by the following equation:

where LAC is the lactic acid concentration (g/l) in the liquid phase at the considered time t (min), LACE is the final concentration in the liquid phase (defined by the equilibrium conditions) and K c (min−1) is an overall mass transfer coefficient.

By integration of Eq. (4), the interrelationship between LAC and time is given by the equation:

where LAC0 is the initial lactic acid concentration in the medium. When the operational variables w, V and LAC0 are fixed, combining both Eqs. (1) and (3) (measuring the operation and equilibrium conditions, respectively), the parameter LACE, can be calculated for each resin. From these results, the experimental data LAC versus t were fitted according to Eq. (5) to obtain the corresponding values of the overall mass transfer coefficient K c.

Table 3 lists the results calculated for K c, as well as the statistical parameters measuring the correlation and significance of models. Figure 3 shows the agreement between experimental results and the corresponding values calculated using the proposed model. This model has been used in literature to fit related results [12].

When resins having the same kind of matrix are considered, K c reached higher values for weak base resins; whereas for resins with the same type of basicity, K c reached higher values for macroreticular-type resins (IRA 900 and IRA 96), this fact being in relation with the known slower difusion characteristic of gel-type resins. The results determined for K c are of the same order as those reported for experiments carried out under related conditions [12]. The findings of the kinetic assays confirmed the comparative advantages of weak base resins for lactic acid recovery.

3.3 Processing of SSF media: batch and column operation

Batch experiments were carried out in order to assess the ability of the resins for lactic acid recovery from SSF media. For comparative purposes, similar experiments were carried out with aqueous lactic acid solutions having the same concentration as the SSF media (see Fig. 4). As expected, and in agreement with data reported for related experiments [1], the resin capacities determined for fermentation media decreased by 27–35% with respect to those obtained with aqueous solutions, owing to both the exchange of ions other than lactate (for example, sulphate, phosphate, citrate and acetate) and to the adsorption of extraneous components (nutrients, enzymes, etc.) to the polymer.

The above data on kinetics and capacities proved that weak base resins were the most favourable ones for lactic acid recovery from aqueous solutions and from fermentation media. So, the two weak base resins considered in this study (Amberlite IRA 96 and Amberlite IRA 67) were assayed for column operation (the usual procedure at an industrial scale). In this part of the study, variables such as the degree of lactic acid recovery, the consumption of regenerant and the stability towards load/regeneration cycles were considered.

A first set of four load/regeneration cycles was carried out with aqueous solutions containing 42 g lactic acid/l (the same concentration obtained in SSF media). Figure 5 shows the time course of lactic acid concentration in the effluent determined in this part of the experimentation. The capacity of the resin in column operation (q FB, g/g o.d. resin) was calculated by numerical integration of the elution profiles, according to the expression:

where LACout is the lactic acid concentration of the effluent (g/l), LACfeed (g/l) is the lactic acid concentration of the feed, V is the volume of solution collected (l), and w is the mass of resin contained in the system (g). The integration started in the breakthrough point (limit V 1 corresponds to the conditions when the elution volume reached the value corresponding to the interstitial volume), and finished when the concentration of the effluent reached its maximum value (limit V 2).

The percentage of lactic acid recovery (PR) was calculated by numerical integration of the expression:

where the variables have the same meaning as before. In this case, the integration was carried out from the initial to the final points of the recovery stages (corresponding to elution volumes V 1 and V 2, respectively). Table 4 summarizes the results obtained and confirms that both resins showed constant capacities, which were higher than those determined in batch experiments. This finding is in agreement with literature data [7] and can be justified on the basis of the different nature of both kinds of experiments: in batch assays, the Cl− ions remained in the media affecting both pH and equilibrium conditions, whereas the same ions were washed out in column operation. Quantitative regeneration was achieved with both resins, but the requirements of regenerant are slightly lower in the case of Amberlite IRA67. Because of this, the average concentration of lactic acid in the effluent was higher in this case (13.3 g/l in comparison with 11.7 g/l for Amberlite IRA 96).

Considering the above findings, the resin Amberlite IRA67 was selected for assessing the recovery of lactic acid from SSF in column operation. Figure 6, which shows the results obtained in four sequential cycles of load/regeneration, proved that the average capacity decreased with respect to the previous experiment with aqueous lactic acid solutions (from 0.373 g/g to 0.273 g/g), a similar behaviour to that observed in batch experiments, which can be ascribed to the same reasons explained before. However, it must be noted that a constant capacity was determined in the various cycles, the recovery of lactic acid being quantitative in all the cases. In the assay leading to almost quantitative lactic acid recovery, the average concentration of lactic acid reached 16 g/l (see Table 5).

In conclusion, Amberlite IRA67 in chloride form presents a favourable behaviour for lactic acid recovery from SSF media, in terms of kinetics, affinity, capacity and susceptibility to regeneration.

References

Evangelista RL, Nikolov ZL (1996) Recovery and purification of lactic acid from fermentation broth by adsorption. Appl Biochem Biotechnol 57–58:471–480

Kaufman EN, Cooper SP, Davison BH (1994) Screening of resins for use in a biparticle fluidized-bed bioreactor for the continuous fermentation and separation of lactic acid. Appl Biochem Biotechnol 45–46:545–554

Zheng Y, Ding X, Cen P, Yang CW, Tsao GT (1996) Lactic acid fermentation and adsorption on PVP. Appl Biochem Biotechnol 57–58:627–632

Hughes CH (1994) Guía de aditivos. Acribia, Zaragoza, Spain

Kaufman EN, Cooper SP, Clement SL, Little MH (1995) Use of a biparticle fluidized-bed bioreactor for continuous and simultaneous fermentation and purification of lactic acid. Appl Biochem Biotechnol 45–46:605–620

Zihao W, Kefeng Z (1995) Kinetics and mass transfer for lactic acid recovery with anion exchange method in fermentation solution. Biotechnol Bioeng 47:1–7

Evangelista RL, Mangold AJ, Nikolov ZL (1994) Recovery of lactic acid by sorption: resin evaluation. Appl Biochem Biotechnol 45–46:131–144

Nomura Y, Iwahara M, Hongo M (1987) Lactic acid production by electrodialysis fermentation using immobilized growing cells. Biotechnol Bioeng 30:788–793

Davison BH, Scott CD (1992) A proposed biparticle fluidised-bed for lactic acid fermentation and simultaneous adsorption. Biotecnol Bioeng 39:365–368

Moldes AB, Alonso JL, Parajó JC (2000) Multi-step feeding systems for lactic acid production by simultaneous saccharification and fermentation of processed wood. Bioproc Eng 22:175–180

Mafart P, Béliard E (1994) Ingeniería industrial alimentaria—II. Técnicas de separación. Acribia, Zaragoza

Harland CE (1994) Ion exchange: theory and practice. Royal Society of Chemistry, Cambridge

Barboza M, Almeida RMRG, Hokka CO (2002) Kinetic studies of clavulanic acid recovery by ion exchange chromatography. Bioseparation 10:221–227

Acknowledgements

The authors are grateful to "Xunta de Galicia" for the financial support of this work in the scope of the Research Project reference PGIDT00PXI38301PR.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moldes, A.B., Alonso, J.L. & Parajó, J.C. Recovery of lactic acid from simultaneous saccharification and fermentation media using anion exchange resins. Bioprocess Biosyst Eng 25, 357–363 (2003). https://doi.org/10.1007/s00449-002-0316-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-002-0316-7