Abstract

Main conclusions

Eukaryotic microalgae hold incredible metabolic potential for the sustainable production of heterologous isoprenoid products. Recent advances in algal engineering have enabled the demonstration of prominent examples of heterologous isoprenoid production.

Isoprenoids, also known as terpenes or terpenoids, are the largest class of natural chemicals, with a vast diversity of structures and biological roles. Some have high-value in human-use applications, although may be found in their native contexts in low abundance or be difficult to extract and purify. Heterologous production of isoprenoid compounds in heterotrophic microbial hosts such as bacteria or yeasts has been an active area of research for some time and is now a mature technology. Eukaryotic microalgae represent sustainable alternatives to these hosts for biotechnological production processes as their cultivation can be driven by light and freely available CO2 as a carbon source. Their photosynthetic lifestyles require metabolic architectures structured towards the generation of associated isoprenoids (carotenoids, phytol) which participate in photon capture, energy dissipation, and electron transfer. Eukaryotic microalgae should, therefore, contain inherently high capacities for the generation of heterologous isoprenoid products. Although engineering strategies in eukaryotic microalgae have lagged behind the more genetically tractable bacteria and yeasts, recent advances in algal engineering concepts have demonstrated prominent examples of light-driven heterologous isoprenoid production from these photosynthetic hosts. This work seeks to provide practical insights into the choice of eukaryotic microalgae as biotechnological chassis. Recent reports of advances in algal engineering for heterologous isoprenoid production are highlighted as encouraging examples that promote their expanded use as sustainable green-cell factories. Current state of the art, limitations, and future challenges are also discussed.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microalgae are fascinating organisms that aid in our understanding of fundamental aspects of the natural world, photosynthesis, the environment, and primary production. More recently, these organisms have been touted for their biotechnological potential as containable, unicellular green-cell factories for generating sustainable bio-production processes from photosynthesis (Wijffels et al. 2013). As carbon dioxide (CO2) is currently in abundance in the global environment, the capacity of microalgae, like higher plants, for photosynthetic growth using CO2 as a carbon source and (sun)light for energy is a powerful prospect for the development of sustainable biotechnological processes with these organisms (Melis 2012). In contained microbial-style cultivation concepts, microalgae are able to capture a freely available feedstock (CO2) and convert it into higher value bio-based products from light energy (Melis 2012; Larkum et al. 2012; Jakob et al. 2013; Fresewinkel et al. 2014). These products include the algal biomass itself or the array of natural products generated by different algal species. In addition to native products generated from microalgae, biotechnological processes are now aimed at increasing the product range produced by these organisms through genetic and metabolic engineering (Rosenberg et al. 2008). Expanding the native product portfolio of microalgal strains holds incredible potential for the development of customized, sustainable, light-driven bio-production concepts from these hosts (Specht et al. 2016).

Although promises of genetic engineering of microalgal strains have existed for three decades, mature engineering concepts have only recently been successfully demonstrated (Rasala et al. 2013; Karas et al. 2015; Lauersen et al. 2015b, 2016, 2018; Wichmann et al. 2018; D’Adamo et al. 2018). Practical examples of high-level algal genetic engineering have lagged behind other biotechnological hosts due to their seemingly recalcitrant genetic natures, which is especially true in members of the Chlorophyta like the model green microalga Chlamydomonas reinhardtii (Fuhrmann et al. 1999; Schroda et al. 2000; Shao and Bock 2008) and many Chlorella sp. (Yang et al. 2016). Increasing developments in genetic engineering tools and design concepts have led to maturing of algal engineering technologies (Scaife and Smith 2016). New trends are emerging in the genetic engineering of not only green microalgae (Crozet et al. 2018), but Bacillarophyceae (diatoms) as well to produce completely non-native chemical products (D’Adamo et al. 2018; Lauersen et al. 2018).

Eukaryotic microalgae are especially interesting hosts for engineering concepts aimed at the use of native isoprenoid metabolism to produce heterologous isoprenoid products. Isoprenoids, sometimes also called terpenoids or terpenes, are a class of structurally and functionally diverse natural hydrocarbons which have a wide range of human-use applications such as pigments, perfumes and cosmetics, medicines, as well as chemical signals and pest control agents (Bohlmann and Keeling 2008; Leavell et al. 2016). Many high-value isoprenoid products are plant secondary metabolites (Buckingham et al. 1994). They are generated from universal carbon precursors, isopentenyl pyrophosphate (IPP) and its isomer dimethylallyl pyrophosphate (DMAPP), which are found in all organisms (Lange et al. 2000; Kirby and Keasling 2009). Starting from IPP and DMAPP, the diversity of known isoprenoid chemical structures are created from modular enzymatic pathways composed of terpene synthases (TPSs) and cytochrome P450s (CYPs) (Kirby and Keasling 2009; Zerbe et al. 2013; Pateraki et al. 2014, 2015; Luo et al. 2016; Andersen-Ranberg et al. 2016). Pathways towards specialized isoprenoid chemicals are modular can be transferred from a native organism into a heterologous host to produce identical isoprenoid products from the universal prenylated precursors found within (Kirby and Keasling 2009; Leavell et al. 2016). Examples of isoprenoid products from natural as well as heterologous sources which are currently available and their relative market prices are presented in Table 1.

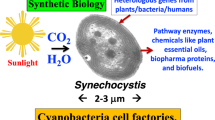

The photosynthetic lifestyles of eukaryotic microalgae require effective pathways for the generation of isoprenoid pigments and electron carriers which play key roles in photosynthesis (Lohr et al. 2012). Therefore, the flux towards isoprenoids within algal strains may be higher than organisms traditionally used for heterologous fermentative microbial production like bacteria and yeasts. Additionally, algae share evolutionary ancestry with land plants, it may be that these cells contain cellular environments more favorable for plant TPSs than bacteria or yeast hosts. As mature engineering concepts with eukaryotic microalgae are only now starting to be demonstrated, these hosts currently represent an untapped biotechnological resource for heterologous isoprenoid production (Scaife and Smith 2016). This report seeks to discuss the practical aspects of genetic engineering strategies with eukaryotic microalgal hosts and the most recent developments of efforts towards the generation of heterologous isoprenoid products (Fig. 1). In addition, the value of algal hosts as green-cell bio-factories, the native isoprenoid metabolism of microalgae, challenges to mature genetic engineering of eukaryotic algae, as well as current limitations and future challenges in algal production processes are discussed.

Engineering eukaryotic microalgae for heterologous isoprenoid production. Many high-value isoprenoids are plant secondary metabolites. Plant pathways must be adapted to eukaryotic algal genetic contexts via strategies which may include codon-optimization, intron addition, and cloning into organism-specific expression vectors. Once suitable engineering has been performed and expression of isoprenoid pathways confirmed in eukaryotic algal hosts, heterologous isoprenoids can be produced in containable liquid microalgal cultures with light energy and CO2 as a carbon source at scale. Authorized photos of outdoor algal cultivation taken by author at Necton’s facilities in Olhão, Portugal (2016)

The value of algal hosts for sustainable biotechnology and containable, light-driven bio-processes

Unicellular photosynthetic microalgae are complete carbon capture and bioconversion cell factories (Melis 2013). Through the concerted efforts of carbon concentrating mechanisms, the generation of reducing equivalent energy by the action of photosynthesis, and the reactions of the Calvin-Benson-Bassham cycle, microalgal cells are able to capture CO2 from their environment and convert it into chemical building blocks for cellular growth (Kruse et al. 2005; Melis 2013). This capacity, like in higher plants, allows microalgae to generate their biomass and a range of native products using the minimal inputs of water, (sun)light, nitrogen, phosphorous, trace elements, and CO2 as a carbon source. The main differences between the application of higher plant systems and unicellular microalgae for biotechnological concepts lay in the capacities for contained and scalable microbial style cultivation in photo-bioreactors (Ugwu et al. 2008; Morweiser et al. 2010) (Fig. 2). Unlike higher plant cultivation in traditional agricultural concepts, photo-bioreactors for microalgal cultivation can be constructed on any land-type, even coupled directly to industrial sites, greatly expanding the potential cultivation locations for microalgae (Lehr and Posten 2009; Morweiser et al. 2010; Singh and Sharma 2012). Therefore, algal cultivation does not have to compete with agricultural land resources, a factor which promoted their use as next-generation biomass feedstocks for biofuels (Kruse et al. 2005; Schenk et al. 2008; Fairley 2011; Melis 2012). Cultivation in photobioreactors allows controllable environmental regulation and can help ensure reliable yields over traditional crops as they are not as sensitive to weather anomalies and abiotic stressors (Posten 2009; Morweiser et al. 2010; Hallmann 2016). Some algae are also amenable to cultivation in wastewater, which can have the dual benefits of inexpensive nutrient sources for growth (nitrogen, phosphorous) coupled to resulting water decontamination (Jiang et al. 2011). Photobioreactors can mitigate some risks of gene or strain escape into the environment which can be important if isolates are proprietary or under specific local regulations (Wijffels et al. 2013). Although many benefits are notable for algal photobioreactor concepts, they also require significant financial investment in their construction and may have large energy or maintenance requirements (Morweiser et al. 2010; Wolf et al. 2016). Continued investment and technological advances are still required to bring algal cultivation technologies to a mature status.

Large-scale light-driven cultivation concepts with eukaryotic microalgae. Shown here are model microalgal strains grown outdoors at scales from 0.1 to 90 m3 volume. a, bP. tricornutum grown in a 0.5 m3 flat panel and 1.5 m3 multilayer tubular photobioreactors. cNannochloropsis sp. grown in a 90 m3 cascade raceway. dC. reinhardtii cultivated in a 0.13 m3 glass green wall airlift reactor. e Light microscopy of P. tricornutum, courtesy of Julian Wichmann. fN. gaditana, photo by author. gC. reinhardtii, courtesy of Dr. Viktor Klassen. Scale bars represent 10 µm. Photobioreactor photos courtesy of Tiago Guerra, A4F – Algae for Future (http://www.a4f.pt, Portugal)

Microalgal biomass is rich in many interesting products, for example, the capacity for some algae to accumulate a large percentage of their biomass as triacylglycerols (TAGs), similar to those found in plant oils, further spurred interest in their use for the generation of liquid biofuels (Hu et al. 2008). Algal biofuel technologies are still steadily developing; however, fuels represent bulk chemicals, which are sold at large volumes with low prices per unit. Algae are also natively able to produce products of mid- or high value and are already sources of natural isoprenoid pigments (Table 1). Economically relevant examples of this include beta-carotene produced from Dunaliela salina and astaxanthin produced from the microalga Haematococcus pluvialis (Lorenz and Cysewski 2000; Raja et al. 2007). The diatom Phaeodactylum tricornutum is rich in omega poly-unsaturated fatty acids (PUFAs) and the anti-oxidant carotenoid fucoxanthin, which are both valuable for human nutrition and aquaculture (Danielewicz et al. 2011; Eilers et al. 2016).

Isoprenoid metabolism and its structure in eukaryotic microalgae

Microalgae in nature must cope with diurnal light changes and rapidly fluctuating light intensities caused by weather patterns as well as seasonal variations (Schierenbeck et al. 2015). To survive these situations, microalgae natively contain capacities for turnover of photosynthetically associated carotenoids that quench excess excitational energy (Lohr et al. 2012). In algal (and plant) cells, the phytol-tail of chlorophyll molecules, carotenoids, and plastoquinone are all derived from isoprenoid metabolism or contain portions of their structures containing isoprenoids. There are two pathways known to generate isoprenoid products, the 2-c-methyl-d-erythritol 4-phosphate/1-deoxy-d-xylulose 5-phosphate (MEP/DOXP) pathway and the mevalonate pathway (MVA) (Schwender et al. 1996; Rohmer 1999; Lange et al. 2000; Lohr et al. 2012). The MEP pathway is generally associated with prokaryotes as well as plant plastids owing to their endosymbiotic cyanobacterial ancestry (Rohmer et al. 1993; Lohr et al. 2012). The MVA pathway is the sole isoprenoid pathway in archaea, animals, as well as fungi (Rohmer 1999). It is also found in the cytoplasm of higher plants and some algae, which contain both the plastidial MEP and cytosolic MVA pathways (Lichtenthaler et al. 1997; Lohr et al. 2012). Both pathways generate the same 5-carbon isoprenoid precursors isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP) from either glyceraldehyde-3 phosphate (G3P) and pyruvate (MEP), or acetyl-CoA (MVA). The MEP pathway is encoded entirely in the nuclear genome, yet its protein products are localized in the algal chloroplast (Lohr et al. 2012). The MVA pathway has been lost through evolution in the Chlorophyta (C. reinhardtii, Chlorella sp., etc.) and Eustigmatophyceae like Nannochloropsis sp (Lohr et al. 2012). In diatoms, Glaucophytes, and some Rhodophyta, the MVA pathway is also maintained within the cytoplasm. For a thorough analysis and overview of isoprenoid metabolism present across different microalgae, the reader is directed to the analysis conducted by Lohr et al. (2012). Here, the isoprenoid metabolism of green algae and diatoms are discussed as relevant examples of isoprenoid engineering have been demonstrated with these hosts (Fig. 3).

Isoprenoid metabolism in eukaryotic microalgal cells. Left cell diagram: isoprenoids are produced in Chlorophyta and Eustigmatophyceae exclusively from the 2-c-methyl-d-erythritol 4-phosphate (MEP) pathway which is encoded in the nuclear genome (N) and localized in the chloroplast. Right cell diagram, isoprenoid production in diatoms, higher plants, and some Rhodophyta (red algae) is mediated by the MEP pathway in the chloroplast (shown in brown for diatoms) as well as the mevalonate (MVA) pathway in the cytoplasm. ER endoplasmic reticulum, DXS 1-deoxy-d-xylulose-5-phosphate synthase, G3P glyceraldehyde 3-phosphate, Pyr pyruvate, IPP isopentenyl pyrophosphate, DMAPP dimethylallyl pyrophosphate, IDI isopentenyl diphosphate isomerase. FPPS farnesyl pyrophosphate synthase, GGPPS geranylgeranyl pyrophosphate synthase, FPP farnesyl pyrophosphate (15 carbon), GGPP geranylgeranyl pyrophosphate (20 carbon), UQ ubiquinone (45-carbon), SQS squalene synthase, squalene (30-carbon sterol precursor), phytol tail of chlorophyll (20-carbon), PQ plastoquinone (45 carbon). Of note, in P. tricornutum, IDI and SQS are found as a fusion protein and it is not yet known what role an FPP synthase might play in this cellular structure

From the C5 base compounds IPP and DMAPP, prenyl transferases build higher-carbon number containing molecules by serial condensation of these C5 units. The prenylated compounds are named in increasing order of size: geranyl pyrophosphate (GPP, C10), farnesyl pyrophosphate (FPP, C15), and geranylgeranyl pyrophosphate (GGPP, C20). GPP is a precursor for monoterpenes (C10), FPP is a precursor for sesquiterpenes (C15) and is also the main precursor of squalene (C30) which forms the basis of cellular sterols as well as triterpenes (C30). GGPP is the precursor for photosynthetically associated isoprenoid products like the phytol tail of chlorophyll molecules (C20), carotenoids (C40), and plastoquinone (PQ, C45) (Fig. 4) (Lange et al. 2000; Kirby and Keasling 2009; Lohr et al. 2012).

Grenoid secondary metabolites. IPP and DMAPP are 5-carbon prenylated carbon backbones which can be condensed by the action of pyrophosphate synthases into higher-order chemical backbones. Geranyl, farnesyl and geranylgeranyl pyrophosphate synthases (GPPS, FPPS, and GGPPS, respectively) create the products geranyl pyrophosphate, farnesyl pyrophosphate, and geranylgeranyl pyrophosphate (GPP, FPP, and GGPP, respectively). Each product contains an increasing number of carbon atoms which form the basis for isoprenoid products mediated by the activity terpene synthases. Monoterpene synthases (mTPS) catalyze GPP into 10-carbon monoterpene products, sesquiterpene synthases (sTPS) catalyze FPP into 15-carbon sesquiterpenoid products, triterpene synthases (tTPS) catalyse the 30-carbon squalene into triterpenoid products (squalene is created from two FPP molecules via the squalene synthase), and diterpene synthases (diTPS) catalyze the 20-carbon GGPP into diterpenoid products. GGPP is also the basis of numerous isoprenoids involved in photosynthesis: carotenoids (i.e. β-carotene) are created from the 40-carbon phytoene which is made from two molecules of GGPP via the phytoene synthase (PSY). Example products from each class of terpene synthase are depicted

The wide variety of chemical structures observed from isoprenoid secondary metabolites in nature are formed by the concerted efforts of terpene synthases (TPSs) which cleave the prenyl groups from isoprenoid carbon skeletons and participate in chemical reactions which guide these molecules to their functional forms (Fig. 4) (Buckingham et al. 1994; Kirby and Keasling 2009). Further functionalization of isoprenoid skeletons can be mediated by membrane bound cytochrome P450 enzymes (CYPs) which catalyze the addition of functional groups to isoprenoid backbones (Pateraki et al. 2015). Many medicines or fragrances of high value which come from plants are diterpenoids (C20) which have been extensively chemically decorated by concerted efforts of CYPs (Lin et al. 1996; Andersen-Ranberg et al. 2016; Pateraki et al. 2017).

Eukaryotic microalgae which have lost the MVA pathway through evolution rely solely on the MEP pathway for the generation of all cellular isoprenoids, including those used outside of the chloroplast for the production of isoprenoid products like electron transporters (ubiquinone) and sterols (Lohr et al. 2012). The MEP pathway is considered more stoichiometrically efficient than the MVA pathway (Gruchattka et al. 2013) and seems to be sufficient for enabling independence from the cytosolic MVA pathway in many microalgae. Carbon flux towards isoprenoids has been estimated to account for ~ 5% of carbon fixed via photosynthesis in microalgal cells (Melis 2012, 2013). An exception to this, however, is the green colonial microalga Botryococcus braunii var. Showa, which has been found to natively secrete up to 35% of its carbon fixed from photosynthesis as long-chain botryococcene polyterpenes entirely produced from precursors generated by the plastidial algal MEP pathway (Eroglu and Melis 2010) (Fig. 5). These isoprenoids are found as an oil-like substance outside of the algal colonies and indicate that carbon flux through the MEP pathway towards isoprenoids can be highly flexible. However, this strain exhibits a characteristically slow growth rate, which makes it impractical for most biotechnological applications (Cabanelas et al. 2015). Nevertheless, B. braunii var. Showa is an interesting example and may indicate that the MEP pathway of algal cells has an innate capacity to channel high flux of carbon towards heterologous isoprenoid products, encouraging further biotechnological investigation in these hosts.

A natural example of high titers of isoprenoid production from a eukaryotic alga. Botryococcus braunii var. Showa (a), is a member of the Chlorophyta and contains only the MEP pathway for isoprenoid generation it its chloroplast. Nevertheless, this strain has been shown to excrete up to 35% of its photosynthetically fixed carbon as long-chain Botryococcene polyterpenoids, exemplary chemical structure depicted (b).

General considerations for genetic engineering of eukaryotic microalgae

All plastids evolved from a single endosymbiotic event and the diversification of algal types observed today is the result of this primary, as well as secondary and tertiary endosymbiotic events following the uptake of plastids and consequent natural selection (McFadden 2001; McFadden and Van Dooren 2004; Keeling 2010; Archibald 2012). Eukaryotic microalgae are not a consistent phylogenetic group; rather this is an umbrella term for many different microorganisms that are the product of divergent evolutionary histories, endosymbiotic events and, with few exceptions, are capable of photosynthesis (McFadden 2001; Archibald 2012; Hallmann 2016). Therefore, to generalize engineering strategies across all microalgae is difficult as their genetic contexts are highly specific, variable, and often poorly understood. Chlorophyta, such as the model microalga C. reinhardtii, are highly divergent to the oleaginous model microalgae Nannochloropsis sp. (Eustigmatophyceae) or the model diatoms (Bacillarophyceae) Thalassiosira pseudonana, Fitsulifera solaris, or Phaeodactylum tricornutum. Eustigmatophyceae and Bacillarophyceae have evolved from secondary endosymbiosis; therefore, their nuclear context is completely different and unrelated to Chlorophyta (McFadden 2001). This has the practical consequence for the biotechnologist that every target algal strain requires customized genetic tools to enable reliable genetic engineering strategies.

Eukaryotic microalgae generally maintain nuclear, mitochondrial, and plastid genomes (Scala et al. 2002; Merchant et al. 2007; Radakovits et al. 2012). In C. reinhardtii, all three have been sequenced and demonstrated to be transformable (Kindle et al. 1989; Goldschmidt-Clermont 1991; Remacle et al. 2006; Merchant et al. 2007). Complete genomic resources are also available for the model diatom P. tricornutum (Scala et al. 2002) and several Nannochloropsis species (Radakovits et al. 2012; Vieler et al. 2012; Corteggiani Carpinelli et al. 2014). With the advent of low-cost sequencing technologies, more algal strains with fully sequenced genomes are regularly becoming available (Bogen et al. 2013; Jaeger et al. 2017). When combined with transcriptomic data, promoters from highly expressed genes can be combined with appropriate codon optimization to match the target genome (Jaeger et al. 2017). This information can be used to construct appropriate genetic tools for each respective host, which can now be readily generated through customized DNA synthesis services.

Challenges in genetic engineering of eukaryotic microalgae

Conducting reliable engineering in a microalgal host depends on several factors: are there promoters that can drive high rates of transcription for gene expression? What is known of the codon usage bias of the genome and is it flexible? How do DNA regulatory mechanisms like epigenetic silencing and intron densities hinder or support transgene expression? Finally, can the strain be reliably grown in the lab and selected for with antibiotic (or other) selection agents?

Although numerous reports exist of genetic transformation of microalgae (Yang et al. 2016; Hallmann 2016), the common adoption of eukaryotic microalgal engineering as a biotechnological platform and fundamental research topic has not met the focused energy and input at the scales seen for plant biotechnology. At the time of writing, a Google Scholar search of the keywords “plant transformation” gave 3,380,000 results while “algal transformation” gave only 378,000. There is also a very large difference in the levels of maturity of algal transformation in comparison to efforts in higher plants: although many reports exist describing transformation of an algal strain with a selectable marker, concentrated and reliable over-expression of target genes and pathways in mature engineering concepts are a rarity. In this work, only mature engineering strategies are discussed, as other reports summarize claimed transformation success in eukaryotic microalgal strains (Hallmann 2007, 2016).

Much work has already been done on recombinant protein over-expression in the chloroplast of C. reinhardtii (Specht et al. 2010; Purton et al. 2013; Carrera Pacheco et al. 2018; Dyo and Purton 2018), while algal metabolic engineering strategies involving multiple expression cassettes and novel product generation have focused on nuclear engineering (Lauersen et al. 2016, 2018; Wichmann et al. 2018; D’Adamo et al. 2018). In addition, mature chloroplast engineering of other model microalgae like the diatom P. tricornutum has not yet been reported; therefore, the discussion here will focus on nuclear engineering in C. reinhardtii and P. tricornutum.

Algal promoters and codon optimization

In higher plants and other eukaryotic systems, reliable viral promoters are well characterized and drive efficient transgene expression (Streatfield 2007; Black et al. 2017). Perhaps the only common feature across eukaryotic microalgae is that viral promoters have not been found to drive robust expression of transgenes [a comparative study of promoter expression rates was performed in C. reinhardtii by (Kumar et al. 2013)]. There is also a large practical difference for many gene targets between basal expression levels and true overexpression depending on their catalytic activity. Lack of strong heterologous promoters has led to the use of inherent promoters and corresponding 3′ untranslated regions (UTRs) from a target alga to mediate transgene expression (Mussgnug 2015). These elements are often identified via transcriptomic studies and used alone, or as synthetic fusions of their elements to drive reliable transgene expression. The tools available for C. reinhardtii nuclear engineering have been extensively reviewed previously and are now being developed into standardized parts (Mussgnug 2015; Scaife and Smith 2016; Crozet et al. 2018). Key examples of algal-originating promoters are the hybrid HSP70A-RBCS2-i1 (Lumbreras et al. 1998), native photosystem I reaction center subunit II [PsaD, (Neupert et al. 2009)], or newly developed synthetic promoters (Scranton et al. 2016) used for C. reinhardtii and the fucoxanthin chlorophyll a/c-binding protein B (FcpBp) promoter used for P. tricornutum (Siaut et al. 2007).

In addition to the need of specific algal promoter use, the nuclear genome of C. reinhardtii exhibits a relatively high native GC content (~ 64%, 68% in coding regions) and specific codon bias (Merchant et al. 2007). This has led to transgene design strategies where a coding sequence (CDS) must first be synthetically redesigned with optimal codon usage prior to transformation for expression from the nuclear genome of this host (Potvin and Zhang 2010). Codon optimization is an enabling technology which promoted the expression of antibiotic resistance cassettes and small fluorescent or bioluminescent reporters in C. reinhardtii (Fuhrmann et al. 1999; Shao and Bock 2008; Rasala et al. 2013; Lauersen et al. 2015b).

Foreign DNA integration and transgene expression limitations

Integration of foreign DNA in eukaryotic algal nuclear genomes largely occurs by non-homologous end joining (NHEJ) (Gumpel et al. 1994), with the exception of one report of homologous recombination (HR) in Nannochloropsis sp. (strain W2J3B) (Kilian et al. 2011). Although HR does occur in the nuclear genome of C. reinhardtii, its frequency is too low to be of practical use (Gumpel et al. 1994). NHEJ is a random DNA integration process of vector DNA into the algal genome which results in position effects on transgene expression. In addition, the action of inherent nucleases can cause digestion of vector DNA during transformation or physical forces can result in shearing. Consequently, colonies obtained through antibiotic selection screening can be false positives with no or low target gene of interest (GOI) expression (Lumbreras et al. 1998; Barahimipour et al. 2016; Weiner et al. 2018). In order to overcome screening limitations, GOI are often fused to a fluorescent or bioluminescent reporter, allowing detection of positive transformants at the agar plate level (Fuhrmann et al. 1999; Shao and Bock 2008; Rasala et al. 2013; Lauersen et al. 2013b, 2015b, 2016). Other strategies have used linkage of a GOI to a selection marker by a viral 2A peptide, which causes a skip in ribosome linkage of amino acids at a known position, resulting in two separate proteins being formed from a single mRNA (Rasala et al. 2012). Using this strategy, quantitative increases in selection pressure can correlate with increased selection of strains exhibiting higher GOI expression (Rasala et al. 2012, 2013). This mechanism is, however, not completely efficient, with a mixture of full-fusion and separate proteins detectible in Western blots (Rasala et al. 2013).

Screening of large numbers of transformants is usually required to find appropriate individuals exhibiting high-level GOI expression (Lauersen et al. 2013a, 2015b). It is not clear whether integration efficiency into the genome, nuclease digest, or position effects in the genome are the major cause of low efficiencies of positive transformants in C. reinhardtii. Nevertheless, the variability of false positive transformants in this host is highly dependent on transformation vector construct length. Indeed, identification of positive GOI expression can range from ~ 50 to ~ 2% efficiency depending on the construct (Baier et al. 2018). In the diatom P. tricornutum, single or multiple constructs can be more reliably integrated into the genome in a single transformation event; however, variability of target transgene expression is also observed, requiring screening of a number of transformants to identify those with robust GOI expression (D’Adamo et al. 2018) (Fig. 6).

Behaviors of nuclear transgene expression constructs in different organisms. When a YFP expression cassette (yellow) with selection marker (gray) is transformed into C. reinhardtii (a) DNA is integrated into the genome through non-homologous end joining (NHEJ), resulting in up to ~ 50% of selected transformants exhibiting no target gene expression (white arrow). b A comparable construct transformed into P. tricornutum also integrates into the nuclear genome via NHEJ; however, some level of expression is detectible in almost all of the transformants selected by antibiotic resistance; however, there is also variability in expression level across the population: fluorescence comparison of 72 transformants relative to 24 colonies of parental strain (WT). c Identifying positive transformants in C. reinhardtii becomes more challenging as larger expression constructs are used. A 7-kb expression vector for a target protein fused to YFP is shown. In only a few transformants can fluorescence be detected (construct and efficiencies reported in Baier et al. 2018); consequently, large numbers of colonies must be screened to find a transformant with robust expression of larger target transgenes in C. reinhardtii (d). Fluorescence images were captured by Dr. Thomas Baier and Julian Wichmann on the NightShade LB 985 In vivo Plant Imaging System (Berthold Technologies) using filters appropriate for YFP as previously described (Wichmann et al. 2018)

C. reinhardtii strains have also been generated which are less susceptible to repression of foreign transgene expression. The UVM4 and 11 strains (ultraviolet light mutagenized strains 4 and 11) generated by Juliane Neupert and Ralph Bock, have contributed greatly to the advancement of green-algal biotechnology over the past decade (Neupert et al. 2009). These strains are well-domesticated work-horses for C. reinhardtii nuclear engineering concepts which, through random mutagenesis, now exhibit more reliable transgene expression rates than other parental strains. This domestication is similar in concept to that conducted with Escherichia coli which has led to the use of only a few standardized strains for common laboratory practices. The mutagenesis steps which were used to generate UVM4/11 have been described as knocking out factors which repress nuclear transgene expression by an as of yet unknown mechanism. In our hands, UVM4 has been a reliable chassis for the investigation of gene expression and applied biotechnology from the nuclear genome of C. reinhardtii since 2011 (Lauersen et al. 2013a, b, 2015a, b, 2016, 2018; Wichmann et al. 2018; Baier et al. 2018).

Intron mediated enhancement is necessary to enable robust nuclear transgene expression in C. reinhardtii

Although integration of foreign DNA into the nuclear genome of C. reinhardtii was demonstrated almost 30 years ago (Kindle et al. 1989; Kindle 1990), the reliable overexpression of foreign transgenes has been slow to develop compared to other biotechnologically relevant hosts. Only recently has reliable expression of large transgenes been shown to be possible from the nuclear genome of C. reinhardtii, which enabled the first demonstrations of heterologous isoprenoid production from this host (Lauersen et al. 2016, 2018; Wichmann et al. 2018; Baier et al. 2018). C. reinhardtii has a natively high average intron density of ~ 6.4 introns per gene, and the average intron length is 336 bp, which is greater than the average exon length of 240 bp (Merchant et al. 2007). This means that introns occupy more genetic space in the coding regions of C. reinhardtii nuclear DNA than the coding sequences themselves. The mechanisms which control gene expression from the nuclear genome in green microalgae are not well understood, however, it is clear that intron sequences play a key role in influencing transcription rates through enhancer elements and mRNA processing. It has been previously reported that the insertion of introns into heterologous transgenes can have a positive effect on gene expression in microalgae and other organisms like fruit fly and mammalian cell lines (Palmiter et al. 1991; Duncker et al. 1997; Lumbreras et al. 1998; Hallmann and Rappel 1999; Eichler-Stahlberg et al. 2009; Dong et al. 2017; Tikhonov et al. 2017). Very recently, we determined that large transgenes could be reliably expressed from the nuclear genome of C. reinhardtii if repetitive spreading of the first intron of C. reinhardtii ribulose-1,5-bisphosphate carboxylase/oxygenase (RuBisCO) small subunit 2 (rbcS2i1) was used to minimize exon lengths in synthetic codon optimized transgenes (Baier et al. 2018). The strategy was determined to benefit gene expression in two ways: quantitative effect of intron addition on transcript abundance due to the presence of enhancer elements within the intron and an increase of transcript abundance mediated by reduced average exon lengths (Fig. 7).

Designing nuclear transgene expression constructs for C. reinhardtii requires intron addition to ensure reliable expression. Due to an inherently high GC content (64%) and narrow codon usage bias, genes of interest must be codon-optimized to enable proper expression from the nuclear genome of C. reinhardtii. Recently, we determined that insertion of the rbcS2i1 (intron) sequence throughout target transgenes to minimize exon lengths generated synthetic genes which could work with algal transcriptional machinery to allow reliable expression from the nuclear genome. Compared to constructs without intron spreading, transgene expression has been shown to be up to 100-fold greater when this gene design strategy was employed (Baier et al. 2018)

The intron spreading transgene design strategy adds a further level of complexity to heterologous sequence design for expression from this algal host. However, it has been found to be necessary to facilitate robust and reliable expression of larger transgenes (greater than 1 kb) from its nuclear genome to levels detectible by Western blotting, if the protein is tolerated by the eukaryotic cell (Baier et al. 2018). Although currently only demonstrated in C. reinhardtii, this strategy will likely aid engineering efforts in other green microalgae as well, especially those which share evolutionary lineage with the Chlorophyta. Elucidating the regulatory mechanisms which introns contribute to controlling gene expression is a pressing topic for continued fundamental research initiatives with green microalgae and may be of interest to understanding the general mechanisms of gene expression in other eukaryotes as well (Gallegos and Rose 2015).

Other biotechnologically relevant model microalgae like the Bacillariophyceae (diatoms) or Eustigmatophyceae maintain lower genetic complexity than the green microalgae (Scala et al. 2002; Radakovits et al. 2012; Vieler et al. 2012). The model diatom P. tricornutum and members of the Nannochlorospis sp. have been found to have nuclear genomes with medium to low GC contents, 54% and ~ 33%, respectively, as well as average intron densities of 0.8 and 1.7 introns/gene, respectively (Scala et al. 2002; Corteggiani Carpinelli et al. 2014). Expression of transgenes in these hosts, therefore, is less likely to be dependent on complex codon and transgene optimization as has been demonstrated for C. reinhardtii (Siaut et al. 2007; Poliner et al. 2018a, b). Nevertheless, organism specific promoters are commonly used for engineering these hosts.

It is yet unclear how intron addition may affect transgene expression levels in these two organisms; however, this is certainly an interesting factor to be tested. An added benefit of intron addition into target transgenes may be to minimize risks of transgene escape from cultivation of engineered algal strains. Indeed, codon-optimised intron-containing transgenes, including those for antibiotic resistance, would not be expressed by prokaryotes in the environment if DNA transfer were to occur. Intron addition into synthetic transgenes can also be used to stabilize genetic constructs in bacteria during cloning when basal promoter activity cannot be avoided in the bacterial strain. Coding sequence disruption mediated by the presence of introns can allow the cloning of expression constructs for proteins toxic to bacteria, or those which would disrupt plasmid stability (Verruto et al. 2018).

Heterologous production of isoprenoids and algal cells as hosts

Many high-value isoprenoids come from plants and are found in their native context in small quantities or are difficult to separate and purify (Leavell et al. 2016). In order to overcome these limitations and generate isoprenoid products in a reliable manner, their production in heterologous microbial hosts has been developed into a mature technology (Kirby and Keasling 2009; Leavell et al. 2016). This is enabled by the modularity of isoprenoid metabolic pathways (Andersen-Ranberg et al. 2016). Once characterised, the specific TPSs and CYPs required to generate a target isoprenoid product from prenyl precursors can be expressed in biotechnologically relevant hosts and identical chemical products created from them (Chandran et al. 2011). This kind of heterologous isoprenoid bio-production has been extensively developed in heterotrophic bacteria and yeasts owing to their genetic tractability and capacities for growth in current fermentation infrastructures (Kirby and Keasling 2009). Significant advances have also been made in the genetically tractable photosynthetic cyanobacteria which have been recently reviewed elsewhere (Davies et al. 2015; Chaves and Melis 2018). In this report, focus is placed on eukaryotic algal engineering as relative newcomers in the field of green genetic engineering.

As heterologous host systems for plant TPS expression, eukaryotic green algae share distant evolutionary ancestry with land plants and may have favorable cellular environments for these enzymes compared to bacteria or yeasts. Microbial style cultivation of algal cells is conducted at temperatures similar to those used for plant growth, although usually with elevated CO2, which further encourages their use as hosts for expression of heterologous plant TPSs (Lohr et al. 2012). Their metabolism is structured towards production of precursors for photosynthetic associated isoprenoids and plastids contain ample reducing equivalents during light-driven growth (Melis 2012). Therefore, algal cells may be ideal hosts for the expression and production of heterologous plant metabolic pathways. Members of the Bacillarophyceae (diatoms) may also be ideal hosts for the production of isoprenoids derived from FPP and squalene. These organisms are spread throughout global oceans, maintain the cytosolic MVA pathway, and are rich in sterols which contribute to membrane fluidity in cold environments (Lohr et al. 2012). Sterols and triterpenes share the same C30 squalene precursor, making a strong case for the use of diatoms for triterpenoid production.

The focus of this report is on engineering non-native isoprenoid production from eukaryotic microalgal hosts. At the time of writing, four prominent examples of heterologous isoprenoid production from eukaryotic microalgal hosts exist in literature. One example of heterologous triterpenoid production has been shown in the model diatom P. tricornutum (D’Adamo et al. 2018), two examples of heterologous sesquiterpenoid production have been shown in the model green microalga C. reinhardtii (Lauersen et al. 2016; Wichmann et al. 2018), and a very recent report describes the use of this host also for the production of heterologous diterpenoids (Lauersen et al. 2018). Each one is discussed in detail in the following sections.

Heterologous triterpenoid production in the model diatom P. tricornutum

P. tricornutum stands out as an interesting candidate for the generation of triterpenes and sterol derivatives as it contains both the MEP pathway in its chloroplast and MVA pathway within its cytosol (Lohr et al. 2012). P. tricornutum, therefore, naturally has a capacity to channel acetyl-CoA towards isoprenoid products via the C30 intermediate squalene. A peculiar feature of the MVA pathway of P. tricornutum is a fusion between its isopentenyl diphosphate isomerase (IDI) and squalene synthase (SQS) (Scala et al. 2002; Bowler et al. 2008). IDI is responsible for balancing pools of the C5 isoprenoid building block isomers IPP and DMAPP, while SQS should generate C30 squalene from two molecules of C15 FPP. It is not yet known how these enzymes work together in the diatom to generate squalene; however, it may be that this enzymatic orientation supports efficient channeling towards squalene as a product. Squalene can be catalyzed into triterpenoids via triterpenoid synthases (tTPSs). This capacity was recently used to create the non-native triterpenoid lupeol in P. tricornutum (D’Adamo et al. 2018). Lupeol has many pharmacological activities and has numerous potential medicinal applications (Table 1; Siddique and Saleem 2011). In this report, two different lupeol synthases (LUS) from Arabidopsis thaliana and Lotus japonicus (AtLUS and LjLUS, respectively) were expressed from the nuclear genome and allowed to accumulate in the cytoplasm of the diatom, both of which resulted in lupeol production (Fig. 8). It was determined that expression of these genes modified the transcriptional levels of genes involved in the MVA and later sterol biosynthesis pathways. No systematic study was conducted on improving LUS titers within the cytosol and it is not yet known if the maximal flux towards the triterpenoids has already been reached. At lab scale, the best performance of lupeol production was 110 ± 1 µg lupeol/g dry weight in a single LjLUS expression strain. It is likely that significant improvements in titers can be made with further engineering efforts as other triterpenoid products could be produced up to ~ 0.4% of leaf biomass in agro-infiltrated tobacco leaves by combined MVA pathway engineering and tTPS overexpression (Reed et al. 2017).

g heterologous triterpenoid production in P. tricornutum. (D’Adamo et al. 2018). a Diatoms contain the cytosolic MVA pathway in addition to the MEP pathway in the chloroplast. Heterologous expression of two separate lupeol synthases (AtLUS or LjLUS) was shown to convert squalene into the heterologous triterpenoid lupeol in P. tricornutum. Co-expression of the MtCYP716A12 cytochrome P450 either separately or in fusion to its corresponding reductase, MtCPR, resulted in specific hydroxylation of the heterologous lupeol to betulin, the first step in its conversion towards betulinic acid. b 550 L fence-style horizontal tubular photobioreactor (Bouygues Energies and Services, UK) used to cultivate genetically modified P. tricornutum at 550 L scale. Photo courtesy of Mike Allen from Plymouth Marine Laboratory and Exeter University. Three strains were cultivated in this reactor and their relative triterpenoid productivities investigated

Lupeol is a base triterpenoid which can be further functionalized, first to the betulin intermediate, then to the pharmaceutical agent betulinic acid by concentrated activity of CYP enzymes (D’Adamo et al. 2018). CYPs require electron donors to provide the reducing power for their chemical reactions, a role which is naturally performed by cytochrome P450 oxidoreductases (CPRs) (Pateraki et al. 2015). In this work, the Medicago truncatula CYP716A12 and its corresponding reductase (MtCPR) were co-expressed in P. tricornutum in order to determine the capacity for functionalization of heterologous lupeol to the intermediate betulin. Two different approaches were investigated: (1) simultaneous co-transformation of the LjLUS with a zeocin resistance cassette, and the MtCYP716A12, as well as MtCPR coding sequences. (2) Serial transformation of a synthetic fusion of MtCY716A12 and MtCPR into an LjLUS expression strain and selection for both original LjLUS zeocin resistance and the CYP cassette nourseothricin (nat) resistance.

Both approaches were found to enable expression of the CYP and CPR enzymes as well as LjLUS, indicating the DNA uptake and construct expression in P. tricornutum is robust. Transforming multiple vectors in a single event saves time and logistical complexity of multiple rounds of selection, a feature which promotes the use of P. tricornutum for complex metabolic engineering strategies. Several strains could be isolated which converted small amounts of lupeol into the betulin intermediate, thus confirming activity of the CYP within the diatom. No aberrant growth performance was observed for any strain generated in this work, indicating that although the native metabolic flux towards sterols had been altered by the novel metabolite, no impact on cellular fitness could be observed in lab-scale.

Of note in this publication, was the attempt to demonstrate scalability of P. tricornutum cultivation to 550 L working volume in indoor tubular fence style photo-bioreactor cultivations (Fig. 8b). The strains exhibited growth behaviors as expected for P. tricornutum in this system. During scale-up, large variations were obtained due to the amount of culture which could be harvested. However, from 430 L of harvested culture, 98 g of an AtLUS expression strain could be collected which contained a total of 1.27 mg lupeol (at 13 µg/g dry biomass). Although yields were low, this work is an excellent first example of heterologous triterpenoid production from a diatom. Undoubtedly, future work will be able to increase yields from this host and, given the ease of its large-scale cultivation, production of high-value triterpenoids could be readily conducted with diatoms once titers are improved.

Heterologous isoprenoids from the model green microalga C. reinhardtii

C. reinhardtii has a metabolic architecture typical for Chlorophyta wherein the MEP pathway located in the chloroplast is responsible for the production of IPP, DMAPP, and all subsequent isoprenoid molecules in the cell (Lohr et al. 2012). To date, three reports of heterologous isoprenoid production have been demonstrated in C. reinhardtii, all of which were conducted by our working group (Lauersen et al. 2016, 2018; Wichmann et al. 2018). The following sections describe in detail two examples of sesquiterpenoid production and several examples of diterpenoid production from this host.

Patchoulol production from C. reinhardtii

The FPP synthase of C. reinhardtii (Uniprot ID: A8IX41) does not contain a plastid transit peptide and in vivo localization indicated that this enzyme forms a halo around the algal nucleus (Lauersen et al. 2016). The CrFPPS likely interacts with the squalene synthase that has been previously localized in the endoplasmic reticulum when expressed in onion cells (Kajikawa et al. 2015). The localization of CrFPPS indicated that FPP may be available in the cytosol; therefore, the first attempts at heterologous sesquiterpenoid production were conducted with enzymes expressed and localized there. The first demonstration of heterologous sesquiterpenoid production from C. reinhardtii was also the first transgene construct to be designed which contained repetitive spreading of the rbcS2 intron 1 (rbcS2i1) (Lauersen et al. 2016). The reasons for attempting this design strategy were two-fold; our previous trials of transgene expression using the pOptimized vector (Lauersen et al. 2015b) routinely resulted in low expression levels when using codon optimized cDNA over ~1 kb and terpene synthases (TPSs) are known to be catalytically slow enzymes (Kirby and Keasling 2009; Vickers et al. 2017). Therefore, failing to achieve robust TPS over-expression would result in heterologous isoprenoid production limitations.

The ~ 1662 bp patchoulol synthase [PcPs, (Deguerry et al. 2006)] was codon optimised for expression from the nuclear genome of C. reinhardtii and three copies of the rbcs2i1 were inserted throughout the sequence. The resultant intron containing optimized gene was 2097 bp. This strategy was employed in order to minimize exon lengths and, potentially, encourage robust transgene expression. PcPs catalyzes the conversion of FPP into patchoulol, a fragrant C15 alcohol which is the major component found in the oil of the patchouli plant Pogostemon cablin (Deguerry et al. 2006). The gene was cloned in fusion to a bright yellow fluorescent reporter (mVenus, hereafter YFP) in the pOptimized vector backbone as it was already known the PcPs could function as a fusion protein without affecting its activity (Albertsen et al. 2011) and to enable rapid as well as robust transformant identification at the agar plate level (discussed above, Fig. 6). After transformation and regeneration on selective plates, bright yellow fluorescent colonies could be detected on the primary transformant plate and a strong odor of patchouli fragrance was noted (Lauersen et al. 2016).

It was determined that the expression of the PcPs alone was rate-limiting towards production of the patchoulol product. To overcome this, gene-fusions were designed and constructed in order to enable expression of large fusion proteins containing multiple PcPs active sites (Fig. 9). Surprisingly, the introns spread throughout the PcPs sequence enabled the expression of long mRNA towards the production of the fusion proteins, with the largest, a 3X repeat of PcPs fused to YFP, having a molecular mass of ~ 227 kDa. This strategy resulted in strains which produced ~ 1 mg patchoulol/g dry biomass in 6 days when grown photomixotrophically with acetate and air and served as a foundation study for our future efforts in heterologous isoprenoid engineering with this host.

Engineering heterologous patchoulol production in C. reinhardtii. a Overexpression of the P. cablin patchoulol synthase PcPs was possible from the nuclear genome of C. reinhardtii using the intron spreading optimization strategy described above. Transformants expressing this construct produced the heterologous sesquiterpenoid patchoulol (chemical structure depicted). Screening was facilitated by fusion of the enzyme to mVenus (YFP) or mCerulean3 (CFP) reporters (b). In order to boost levels of the PcPs protein in the cell, first double transformation and selection with a second antibiotic was performed (ii-CFP control and iii, P-paromomycin, H-hygromycin). Additionally, constructs were built containing multiple copies of the PcPs in synthetic fusion proteins (iv and v). Although large, these proteins were able to express from the nuclear genome and resulted in improved titers of patchoulol over single PcPs_YFP expressing transformants. Data originally reported in Lauersen et al. (2016) and modified for this representation, abbreviations for cellular metabolites are described in Fig. 3

Successful expression of the PcPs in C. reinhardtii was significant for several reasons: the first was the successful use of introns to encourage large transgene expression, which spurred a systematic investigation in their use in numerous other transgenes (Baier et al. 2018). We have since used rbcS2i1 intron spreading as a basic tool for gene design for all transgene expression constructs from the C. reinhardtii nuclear genome. The second was that the cell had freely available FPP in the cytoplasm which could be converted into a non-native isoprenoid product via heterologous sTPS over-expression. During this work, it was determined that the non-native isoprenoid product could be produced to much higher titers if strains were cultivated with a biocompatible organic solvent overlay, the C12 alkane dodecane, as a second phase on top of the algal culture. Dodecane allowed culture growth and simultaneous capture of the heterologous isoprenoid products. It is not yet clear how excretion from the cells occurs, whether by passive diffusion or active transport. Nevertheless, patchoulol partitions more favorably into dodecane than into the algal cells or culture medium, a finding similar to production of this product in the yeast Saccharomyces cerevisiae (Gruchattka and Kayser 2015). Dodecane overlay allows straightforward capture and analysis of heterologous isoprenoid products, as the polar phase can be removed from cultures simply by centrifugation and injected directly into gas chromatography mass spectroscopy (GC–MS).

Bisabolene production from C. reinhardtii

Our second target for sesquiterpenoid production from C. reinhardtii was (E)-α-bisabolene (hereafter, bisabolene) (Wichmann et al. 2018). Our goal was to engineer bisabolene production from C. reinhardtii as this compound has been shown to have favorable properties as a drop-in diesel replacement after hydrogenation. Bisabolene synthase (AgBs) is a sTPS found in the grand fir tree Abies grandis (Bohlmann et al. 1998). RbcS2i1 intron spreading was used to enable expression of the AgBs from the nuclear genome of C. reinhardtii. At 2448 bp, the AgBs was a larger gene than the PcPs and required 6 copies of the rbcS2i1 throughout its CDS to minimize exon lengths. The AgBs protein could be expressed reliably in fusion with fluorescent reporters to its full-length from this gene design strategy and mediate the production of bisabolene from the inherent cytosolic FPP pool. The catalytic efficiency of AgBs was determined be too slow to mediate effective production by expression of a single construct. Repetitive AgBs fusions, similar to the repetitive PcPs constructs, did not express to high amounts and resulted in poor bisabolene yields. Therefore, the original pOptimized (pOpt) vectors (Lauersen et al. 2015b) were expanded with increasing selection cassettes and the AgBs was systematically overexpressed by serial transformations of this gene fused to different reporters with different selection markers (Fig. 10). Through subsequent rounds of transformation and selection, strains were generated containing increased amounts of the AgBs protein and bisabolene titers could be increased up to 4.5 mg/g dry biomass. Fluorescent reporter fusion allowed selection of strains each round which did not lose expression of the original AgBs-linked constructs during successive transformation. The AgBs-reporter fusion proteins generated from each construct were highly similar in amino acid sequence, differing only in fluorescent reporter fusion. In addition, all constructs, including selection markers were expressed from with the HSP70-RBCS2-i1 hybrid promoter. Nevertheless, the cell tolerated continued increases in their abundance through the multiple transformation and selection rounds, suggesting the transcriptional and translational limit for transgenes expressed from the nuclear genome in C. reinhardtii has not yet been reached.

Engineering heterologous (E)-α-bisabolene production in C. reinhardtii. a Over-expression of the A. grandis bisabolene synthase (AgBs) could be combined with knockdown of either the geranylgeranyl pyrophosphate synthase (GGPPS) or squalene synthase (SQS) in C. reinhardtii.b Strains expressing an AgBS_YFP fusion construct produced modest amounts of bisabolene, which could be improved by serial transformation and selection for expression constructs with separate reporters (AgBs fused to CFP and RFP) and antibiotic selection markers. A fourth transformation with a luciferase-linked artificial micro RNA construct (amiRNA) mediated downregulation (k.d.) of the direct competitor for the FPP precursor, SQS, and resulted in more than doubling of bisabolene productivities (P color photograph, Y YFP, C CFP, R RFP, and L luciferase signals). Colored bars represent the respective estimated productivity contribution each AgBs-reporter construct contributed to the total yield of bisabolene observed. Data originally reported in Wichmann et al. (2018), panel B was modified from Fig. 6 of this publication, abbreviations for cellular metabolites are described in Fig. 3

In addition to protein overexpression, the main bottlenecks for isoprenoid flux towards farnesyl pyrophosphate (FPP), the precursor of sesquiterpenoids, were targeted for down-regulation by artificial micro RNA (amiRNA) in bisabolene producing strains. It was determined that knockdown of GGPP synthase (GGPPS) and squalene synthase (SQS) both resulted in increased production of bisabolene. GGPPS knock-down may result in increased IPP and DMAPP pools in the chloroplast; it is possible that export to the cytoplasm, where these would be converted to FPP by the FPP synthase, acts as a balance mechanism to prevent perturbed homeostasis in the chloroplast. SQS knock-down should result in a pooling of FPP. Under both scenarios, more FPP should be available for the AgBs to convert to bisabolene which was confirmed when the SQS was knocked down in a triple AgBs overexpression line (Fig. 10). SQS knockdown resulted in more than doubling of bisabolene productivity in this strain, up to 10.3 ± 0.7 mg bisabolene/g dry biomass. The results indicated that C. reinhardtii could convert up to 1% of its total biomass into a completely novel product without affecting cellular fitness or growth.

In both patchoulol and bisabolene production examples, major engineering hurdles were overcome in the green alga C. reinhardtii; the first and most important was the development of an effective transgene design strategy to enable robust expression from the nuclear genome (Baier et al. 2018), and the second was that C. reinhardtii could handle significant modifications in terms of recombinant construct expression as well as metabolic channeling to non-native products. In both cases, patchoulol and bisabolene, C. reinhardtii produced more when the cells were grown mixotrophically with light and acetate, than with CO2 as a sole carbon source. As the cytosolic FPP is a precursor also for isoprenoids which participate in respiratory metabolism in the mitochondria (ubiquinone), it is likely that flux towards FPP in the cytoplasm is higher under mixotrophic conditions. Given the levels of engineering achieved with these two projects, the capacity for reliable transgene design and expression, and a desire to access the metabolic flux of the MEP pathway towards isoprenoids in the algal chloroplast, the next metabolic engineering strategy conducted with C. reinhardtii was towards the production of C20 diterpenoids from the algal chloroplast.

Diterpenoid production from C. reinhardtii

Many plant-based medicines and fragrances are diterpenoids; therefore, this class of compounds is of potentially high commercial value and heterologous production is of great interest (see Table 1). Some examples of high-value medicinal diterpenoids are taxol, ingenol-3-angelate, and forskolin (Lin et al. 1996; Andersen-Ranberg et al. 2016; Pateraki et al. 2017). These three products are highly chemically functionalized derivatives of the C20 backbone diterpenoids taxadiene, casbene, and 13R(+) manoyl oxide, respectively (pictured in Fig. 11a). Taxadiene is produced by the Taxus brevifola taxadiene synthase (Uniprot: Q41594), casbene from the Ricinus communis casbene synthase (P59287), and 13R(+) manoyl oxide from the concerted efforts of two Coleus forskohlii monofunctional synthases (CfTPS2 and CfTPS3, X4ZWN5 and X5A2Z7, respectively). CfTPS2 first makes the precursor (5s,9r,10r)-copalyl diphosphate ((+)-CPP) from GGPP which is subsequently converted to 13R(+) manoyl oxide by CfTPS3 (Pateraki et al. 2014). These enzymes are all diterpene synthases (diTPSs), which make diterpenoid backbones from the prenylated intermediate GGPP.

Engineering heterologous diterpenoid production and a CYP mediated hydroxy-functionalized derivative from C. reinhardtii. a Multiple diterpene synthases (diTPSs) could be reliably expressed from the nuclear genome of C. reinhardtii and targeted to the algal chloroplast mediated by a targeting peptide. In addition, co-expression of a soluble CYP was found to specifically hydroxylate heterologous 13R(+) manoyl oxide at the C9-position; abbreviations for cellular metabolites are described in Fig. 3. b Each diTPS was found to mediate production of its previously characterized diterpenoid product from the precursor GGPP. Shown here are representative gas chromatography mass spectroscopy chromatograms (GC–MS) of dodecane overlay samples from transformants expressing different plant diTPSs. The internal standard (IS) was used for normalization of peak area, and in internal dodecane peak (d) is visible in all samples. Novel peaks for 13R(+) manoyl oxide (24.5 min), casbene (major peak at 23.8 min), and taxadiene (24.9 min) can be seen. c It was found that some diTPSs could be fused to an engineered yeast GGPP synthase (GGPPS) to channel C5 isoprenoid precursors IPP and DMAPP more efficiently into diterpenoid products resulting in significant improvements of diterpenoid yields without affecting native cellular pigmentation levels. d When cultivated with different carbon sources, more heterologous diterpenoid (13R(+) manoyl oxide) was produced when CO2 alone was used as a carbon source in day:night illumination cycles. The strain produced up to 80 mg manoyl oxide/g cell dry mass in 7 days of cultivation. The data presented in this figure were originally reported in Lauersen et al. (2018)

We chose expression of heterologous constructs from the nuclear genome and consequent targeting to the algal chloroplast to mediate heterologous diterpenoid production in C. reinhardtii (Lauersen et al. 2018) as our recent gene design strategy enabled reliable expression of large transgenes from the nuclear genome and multiple transgene expression (Lauersen et al. 2016; Wichmann et al. 2018). Although algal chloroplast transformation could be used for expression of a single diTPS, a previous report found no diterpenoid product when the cis-abienol (diterpene) synthase was overexpressed from the chloroplast genome of C. reinhardtii (Zedler et al. 2014).

Heterologous expression and chloroplast targeting of taxadiene and casbene synthases as well as co-expression of both CfTPS2 and 3 could be successfully shown, all of which led to the production of the desired diterpenoid products for each respective enzyme (Lauersen et al. 2018) (Fig. 11b). Several insights were determined early in this work: very large heterologous fusion proteins could be reliably expressed from the nuclear genome of C. reinhardtii and targeted to the algal chloroplast mediated by the 36 amino acid photosystem I reaction center subunit II (PsaD) chloroplast target peptide (CTP). This CTP could be used to target multiple heterologous proteins in a single strain simultaneously to the algal chloroplast. Additionally, it was determined that diterpenoid products were not only produced in the algal chloroplast but were also found to excrete from the cells into dodecane overlays.

It was determined that although some native GGPP could be diverted to diterpenoid products by diTPSs, native mechanisms outcompeted GGPP channeling to heterologous products, limiting their productivity. Diterpenoid titers were subsequently improved by co-overexpression of MEP pathway enzymes, thereby generating more freely available GGPP for the diTPSs (Lauersen et al. 2018). The first committed step of the MEP pathway is the 1-deoxy-d-xylulose 5-phosphate synthase (DXS) (Lichtenthaler 1999); this enzyme has been found to be rate-limiting for the flux towards IPP and DMAPP as it is feedback inhibited by these compounds (Lohr et al. 2012). GGPP synthase converts these compounds into GGPP, the precursor of diterpenoids. Heterologous expression of DXS from Salvia pomifera (Trikka et al. 2015) or an engineered yeast GGPP synthase (Ignea et al. 2015) in a CfTPS2 and CfTPS3 expressing strain was found to increase 13R(+) manoyl oxide titers (Lauersen et al. 2018). The most significant increase in manoyl oxide production was observed when CfTPS2, the rate limiting enzyme for GGPP conversion to manoyl oxide, was fused to the yeast GGPPS (Fig. 11c). In this scenario, a metabolic pull was directly created on the C5 precursors IPP and DMAPP which could be converted by the heterologous GGPPS to GGPP in the vicinity of the CfTPS2, potentially increasing channeling to its active site. This step led to a strain which produced ~ 40 mg manoyl oxide/L culture in 5 days.

When cultivated in 400 mL bioreactor concepts with different carbon sources, this strain produced manoyl oxide at higher titers when CO2 was used as a sole carbon source. This is in direct contrast to observations of productivity of sesquiterpenoids produced from the cytoplasm and may indicate dynamic regulation of isoprenoid flux compartmentalization based on carbon-source in the algal cell. Of note, in 7 days, this strain produced 80 mg manoyl oxide/g dry biomass when grown on CO2 (Fig. 11d). Although not possible to quantify the carbon partitioning in this system as CO2 was flushed through the chamber continuously to saturating levels, the total 13R(+) manoyl oxide productivity was 8% of the complete biomass of the system without changes in pigmentation (Lauersen et al. 2018). The results indicate that the algal MEP pathway has an innate flexibility as well as tolerance for high flux and that the alga chassis may be a powerful future host for the production of heterologous isoprenoid products.

Diterpenoid hydroxy-functionalization by a heterologous CYP

High value diterpenoids like those mentioned above are often chemically functionalized derivatives of the C20 isoprenoid backbones produced by diTPSs. These final decorated forms are created by the concerted activity of specific cytochrome P450 enzymes (CYPs). It could be additionally shown in C. reinhardtii that co-expression of a truncated and soluble C. forskohlii microsomal P450 targeted to the algal chloroplast mediated the hydroxylation of heterologous 13R(+) manoyl oxide to 9-OH 13R(+) manoyl oxide (Lauersen et al. 2018). The heterologous CfCYP was able to take electrons from a native source in the algal chloroplast and use this energy to cause hydroxylation of the manoyl oxide backbone in absence of a dedicated CPR. Although the conversion amount in mixotrophic screening conditions was only ~ 11% of the total 13R(+) manoyl oxide produced, it is the first step towards the production of more complex decorated diterpenoid products with this host. Future investigations will be able to more systematically investigate whether electron donor fusion strategies can improve activity of these enzymes in the algal chloroplast.

Current technical limitations to engineering algal systems

For all algal strains, availability of selectable markers and low transgene expression rates are still limiting factors to complex trait stacking and eventual pathway transfer into the algal hosts. For C. reinhardtii, the pOptimized (pOpt2) vectors have 4 selectable markers for antibiotic resistance which have been used in combination with fluorescent reporters to rapidly generate transformants and select individual strains with robust expression profiles (Wichmann et al. 2018; Lauersen et al. 2018). There are also many other potential selectable markers which could be adapted to this system (Bruggeman et al. 2014; Mussgnug 2015; Scaife and Smith 2016). There is currently a movement by the greater Chlamydomonas research community to adopt the common syntax for the modular cloning (MoClo) DNA parts design strategy to facilitate construct exchange and generate more reliable expression vector constructs (Engler et al. 2008; Weber et al. 2011; Crozet et al. 2018). Using individual selectable markers, trait stacking is possible by serial transformation and screening events. However, this strategy is limited to marker availability and often results in strains carrying multiple antibiotic resistance genes, which is undesirable. Although it is also possible to combine traits from one C. reinhardtii to another via sexual crossing (Rasala et al. 2013), domesticated strains which robustly express transgenes such as the UVM4/11 and are capable of mating are not yet readily available (Barahimipour et al. 2016).

Phaeodactylum tricornutum has an innate capacity for expression of multiple transgenes with minimal adaptation to the host genomic context (discussed above). This is exemplified in the co-transformation and expression of multiple plasmids in a single transformation round conducted towards the production of the intermediate betulin in P. tricornutum (D’Adamo et al. 2018). This strategy minimized the need for multiple selection rounds; however, it still exhibited low overall efficiencies in positive expression for all transgenes simultaneously (1 out of 30 colonies). Although more amenable to transformation of multiple constructs at a time, depending on construct length, selection markers will also become an issue for reliable engineering efforts in this host.

A promising recent report may have solved this issue by designing selection markers flanked by the loxP recombinase sites and using an inducible expression strategy for the Cre recombinase in Nannochloropsis gaditana (Verruto et al. 2018). Although there are no reports in literature currently of heterologous isoprenoid production from Nannochloropsis sp., engineering in these hosts is also reaching mature levels (Ajjawi et al. 2017; Poliner et al. 2018a, b, c; Verruto et al. 2018). The Cre recombinase/loxP system was employed for serial transformation of a selectable marker and small guide RNAs for Cas9 induced knock-out trait stacking (Verruto et al. 2018). Such techniques could be equally applied to protein over-expression constructs to enable gene stacking and metabolic pathway construction. Adapting a Cre recombinase/loxP recyclable selection cassette into other algal systems may encourage higher-order gene stacking and synthetic pathway designs. This would be especially valuable for some complex isoprenoid products, for example, the highly decorated diterpenoid forskolin is built from 6 enzymatic steps: two enzymatic steps required to produce 13R(+) manoyl oxide from GGPP, followed by 3 CYPs and one acetyl transferase (Pateraki et al. 2017). Although technically possible to achieve with the current tools for both C. reinhardtii and P. tricornutum, such engineering pushes the limit of what is currently practical with these hosts. A recyclable selection cassette system would be valuable for enabling multiple transformation and selection rounds in order to facilitate complex trait stacking.

Although potentially more amenable to straightforward engineering, P. tricoronutum still exhibits slow and sensitive growth when compared to the more rapidly growing model green microalga C. reinhardtii. The desire to engineer C. reinhardtii, and other green algae strains, lies specifically with their ease of handling in the lab and rapid generation times. Through the added step of intron integration into codon-optimised transgenes, we have been able to unlock the power of nuclear gene expression in C. reinhardtii (Baier et al. 2018). This is an enabling technology towards the increased use of C. reinhardtii in biotechnological applications. However, even for over expression of single sTPSs or diTPSs, multiple rounds of transformation and selection were required to boost amounts of a single construct in the cell (Lauersen et al. 2016, 2018; Wichmann et al. 2018). Currently, transcriptional limitation is still a major hurdle to enabling mature metabolic engineering in this alga. Indeed, our understanding of the regulatory mechanisms which result in intron mediated enhancement of transgene expression is still minimal. Greater insights into the regulatory machinery in green algal hosts is certainly required to design smart transgene expression constructs which work with the inherent transcriptional machinery for improved expression rates towards enabling future mature engineering concepts (Gallegos and Rose 2015).

Although powerful, intron spreading also does not overcome some of the marked limitations of engineering in the green algal system, specifically NHEJ integration and nuclease digestion of constructs during transformation (discussed above). These issues still limit reliable engineering in this host by requiring large numbers of transformants to be screened to identify individual strains with robust expression, especially of larger genetic constructs (see Fig. 6). Novel innovations in gene delivery are needed to improve GOI expression rates. Future investigations of chemical or biological DNA stabilizing agents and reduction of inherent nuclease activities may help improve reliable integration of large DNA sequences into the nuclear genome. As DNA synthesis is rapidly becoming more reliable and less costly, it may soon be possible to design constructs which contain complex metabolic pathways on synthetic algal chromosomes. Such genetic constructs could enable customized remodeling of cellular metabolism towards desired product generation. However, this cannot be realized until DNA can be more reliably transfected to the algal host and multiple genes can be reliably expressed to tunable levels simultaneously without exhaustive screening efforts being required.

Scalability, technical limitations, and economic considerations of heterologous isoprenoid production from phototrophic algal systems

The key benefit of algal hosts for bio-production is the capacity for low-input, scalable, and sustainable production concepts using CO2 as a carbon source and growth driven by energy obtained from (sun)light. Nevertheless, algal cells still represent emerging host systems that require improvements in cultivation strategies in addition to genetic engineering techniques to economically compete with established fermentative microbial hosts or natural product extraction. To date, commercial processes with microalgal hosts are entirely focused on natural products such as carotenoids (Raja et al. 2007; Benemann 2013; Hallmann 2016), and facilities for large-scale cultivation of engineered algal cells are rare. The current market value of some exemplary isoprenoid products which can also be produced in heterologous systems are presented in Table 1.

At current rates of production, economic feasibility of heterologous isoprenoid production will not be achieved with algal systems. For example, the sesquiterpenoid cosmetic and perfume ingredient patchoulol is sold as a pure crystal for 50 cents/g and a heterologous patchouli oil, produced by microbial fermentation, is already marketed under the name Clearwood by Firmenich. Bisabolene was also shown to be produced in fermentative microbial hosts up to 900 mg/L in only several days (Peralta-Yahya et al. 2011) and is commercially available from Alfa Aesar as a natural product extract at several dollars per gram (Table 1). Maximal yields of patchoulol and bisabolene in C. reinhardtii were 1 mg/g dry biomass and 10 mg/g dry biomass in almost 1 week of cultivation, respectively (Lauersen et al. 2016; Wichmann et al. 2018). At these productivities, 100 L of algal culture would be required to produce 1 g of bisabolene if lab-scale productivities could be extrapolated, although productivities are usually lower in scale-up.

Diterpenoids and triterpenoid products have higher market value, while natural carotenoids are already sold as dietary supplements with medium–low prices. Although highly purified isoprenoid products used as analytical standards can be sold at high price points (Table 1), active isoprenoid ingredients can be acquired and used as mixtures or in extracts from their natural hosts. For diterpenoids and triterpenoids, yields from algal hosts are also still too-low to compete with natural or heterologous production in fermentative microbial systems. Additionally, current reports have only begun to demonstrate partial CYP-mediated functionalization of base terpenoid products into higher-functionalized active molecules. For example, generation of 9-OH 13R(+) manoyl oxide from C. reinhardtii is one of several functionalization steps towards forskolin and functionalization of lupeol to betulin in P. tricornutum is one functionalization step towards betulinic acid (D’Adamo et al. 2018; Lauersen et al. 2018). Both forskolin and betulinic acid can be extracted from natural plant sources and sold as pure products (Table 1).