Abstract

Lignin content and composition are largely determined by the composition and quantity of the monolignol precursors. Individual enzymes of the monolignol biosynthetic pathway determine the composition and quantity of monolignols. Monolignol biosynthesis in angiosperms is mediated by ten enzyme families. We developed a method using a total protein extract (soluble and microsomal) for the comprehensive and simultaneous analysis of these ten enzyme activities in a single target tissue, stem differentiating xylem (SDX) of Populus trichocarpa. As little as 300 mg fresh weight of SDX is sufficient for triplicate assays of all ten enzyme activities. To expand the effectiveness of the analysis, we quantified the reaction products directly by HPLC and developed a universal method that can separate the substrates and products of all enzymes. The specific activities measured with this simple approach are similar to those obtained with the optimum conditions previously established for each individual enzyme. This approach is applicable to the enzyme activity analysis for both P. trichocarpa (angiosperm) and Pinus taeda (gymnosperm) and is particularly useful when a large number of samples need to be analyzed for all monolignol biosynthetic enzymes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

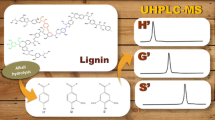

Lignin is a phenolic polymer that provides rigidity and impermeability to plant cell walls (Sarkanen and Ludwig 1971). The conversion efficiency of lignocellulosic biomass to ethanol is determined largely by lignin content and composition (Sarkanen 1976; Chen and Dixon 2007). Lignin content and composition are largely determined by the composition and quantity of monolignols. Modifying lignin biosynthesis could improve the conversion of plants into energy, food, and industrial materials. In most woody plants, the monolignol biosynthetic pathway leads to three monolignols, p-coumaryl, coniferyl, and sinapyl alcohols (Fig. 1). These monolignols when incorporated into lignin are known as p-hydroxyphenyl (H), guaiacyl (G), and syringyl (S) units (Sarkanen 1971; Higuchi 1997; Ralph et al. 2008). Gymnosperms, such as Pinus taeda, and angiosperms, such as Populus trichocarpa, are the two major groups of vascular seed plants. Lignin in gymnosperms is polymerized primarily from coniferyl alcohol. In angiosperms, the syringyl monolignols emerge from a branch of the guaiacyl pathway, and together with the guaiacyl monolignols form a heterogeneous guaiacyl–syringyl lignin (Sarkanen 1971; Higuchi 1997; Osakabe et al. 1999; Li et al. 2001).

In the past two decades, significant headway has been made in the cloning of genes involved in monolignol biosynthesis to better characterize the underlying mechanisms. The enzyme kinetics of the corresponding proteins and the roles of these enzymes were also studied (Whetten and Sederoff 1995; Boerjan et al. 2003; Shi et al. 2010). The major flux through the pathway in P. trichocarpa is typical of woody dicotyledonous angiosperms (gray and light gray, Fig. 1) and begins with the deamination of phenylalanine (1) to cinnamic acid (2), via the action of phenylalanine ammonia-lyase (PAL, EC 4.3.1.5) (Jones 1984; Osakabe et al. 1995; Kao et al. 2002). Cinnamic acid (2) is then converted to p-coumaric acid (3) by a complex of cinnamic acid 4-hydroxylase (C4H, EC 1.14.13.11) and 4-coumarate 3-hydroxylase (C3H, EC 1. 14.13.2) (Chen et al. 2011). p-Coumaric acid (3) can be hydroxylated at the 3-position to yield caffeic acid (4) by the same complex of C4H–C3H (Chen et al. 2011). Caffeic acid (4) can then be methylated by caffeic acid O-methyltransferase (COMT, EC 2.1.1.68) to produce ferulic acid (5) (Shimada et al. 1973; Kuroda et al. 1981). However, COMT-mediated O-methylation of caffeic acid (4) to produce ferulic acid (5) is not a major pathway in angiosperms (Li et al. 2000), and caffeic acid (4) can be converted to caffeoyl-CoA (11) by 4-coumarate: coenzyme A ligase (4CL, EC 6.2.1.12) (Kutsuki and Higuchi 1981) (Fig. 1). On the other hand, there is an alternative pathway that directs flux to caffeoyl-CoA (11) from p-coumaric acid (3). That is, p-coumaric acid (3) is converted by 4CL to p-coumaroyl-CoA (8), which is then converted to p-coumaroyl shikimic acid (9) by p-hydroxycinnamoyl-CoA:quinate/shikimate p-hydroxycinnamoyltransferase (HCT). Subsequently, p-coumaroyl shikimic acid (9) is 3-hydroxylated by the C4H–C3H complex to produce caffeoyl shikimic acid (10), and the shikimic moiety is removed by HCT to produce caffeoyl-CoA (11). Caffeoyl-CoA (11) thus produced via the two pathways is converted by caffeoyl-CoA O-methyltransferase (CCoAOMT) to feruloyl-CoA (12), which is then reduced by cinnamoyl-CoA reductase (CCR, EC 1.2.1.44) to form coniferaldehyde (17). Coniferaldehyde (17), may be either reduced to coniferyl alcohol (22) by cinnamyl alcohol dehydrogenase (CAD, EC 1.1.1.195) (Mansell et al. 1974; Kutsuki et al. 1982) or alternatively coniferaldehyde (17) may be hydroxylated at the 5-position by coniferaldehyde 5-hydroxylase (CAld5H) to form 5-hydroxyconiferaldehyde (18). 5-Hydroxyconiferaldehyde (18) is then methylated by COMT to sinapaldehyde (19), which is then reduced to sinapyl alcohol (24) by CAD and, probably, by sinapyl alcohol dehydrogenase (SAD) (Li et al. 2001). In gymnosperms and in grasses, flux goes through the pathway from p-coumaric acid (3) by 4CL to p-coumaroyl-CoA (8), then to p-coumaraldehyde (15) by CCR, and then to p-coumaryl alcohol (20) by CAD (Luderitz and Grisebach 1981). Gymnosperm lignins are predominantly composed of guaiacyl units, derived from (22) with a minor component of p-hydroxylphenyl units derived from (20) (gray and dark gray, Fig. 1).

Although most of the enzymatic steps involved in the biosynthesis of monolignols and monolignol-derived products are now established, the enzyme activities are still at the core of the research in lignin biosynthesis, particularly for systems research where knowledge of the activities of all pathway enzymes is needed. However, to acquire such knowledge is tedious because currently available methods only allow each activity to be determined by a specific protocol of reaction and monitoring conditions. To establish a high-throughput approach to study all of the different targeted enzyme activities of monolignol biosynthesis pathway simultaneously, we tested and found a standard reaction condition to assay the activities of all of the known monolignol biosynthetic pathway enzymes and a single HPLC method that can separate the substrates and products of all of these enzymes. All monolignol enzyme activities of P. trichocarpa and P. taeda were detected using this standard reaction condition and HPLC separation for protein extracts of SDX. The specific activities observed with this approach are similar to those of the optimum conditions for the individual enzymes, confirming the reliability of this approach. Because of the reliability, efficiency, and convenience, this approach is ideal for the high-throughput surveys of monolignol enzymes needed for studies of large numbers of transgenic plants, or population screens for cell wall traits or mutations.

Materials and methods

Plant materials

SDX from P. trichocarpa used in this study was harvested from six-month-old greenhouse-grown trees. SDX from P. taeda was collected during the growing season from a one-year-old tree grown in North Carolina State University’s Shenck Forest in Raleigh, NC. The harvested trees were debarked and the SDX was separated and collected by scraping. The tissue was stored in liquid nitrogen before use.

Chemical and biochemical synthesis of substrates for enzymatic reactions

Phenylalanine, cinnamic acid, p-coumaric acid, caffeic acid, coniferaldehyde, coniferyl alcohol, sinapaldehyde, and sinapyl alcohol were purchased from Sigma Aldrich (St. Louis MO, USA).

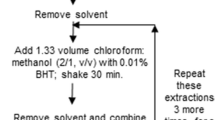

p-Coumaraldehyde, p-coumaryl alcohol, and 5-hydroxyconiferaldehyde were chemically synthesized in our lab as described (Li et al. 2000). p-Coumaroyl-CoA, caffeoyl-CoA and feruloyl-CoA were enzymatically synthesized from each acid (Beuerle and Pichersky 2002). Purified P. trichocarpa 4-coumarate: CoA ligase-3 (Ptr4CL3) (Shuford et al. 2012) recombinant protein from Escherichia coli was used to biochemically synthesize p-coumaroyl-CoA and caffeoyl-CoA. Briefly, 6 mg acid, 4 mg coenzyme A hydrate (CoA), and 14 mg ATP were dissolved in a total volume of 40 ml of 50 mM Tris–HCl (pH 7.5) buffer containing 2.5 mM MgCl2. 0.3 Milligrams of purified protein was added to the mixture to start the reaction. After 30 min at 37 °C, 1.6 g ammonium acetate was added to stop the reaction. The resulting mixture was purified using an SPE cartridge (Chromabond C18 ec, Macherey–Nagel). Yields of 1.7 mg p-coumaroyl-CoA, 2.3 mg caffeoyl-CoA, and 1.5 mg feruloyl-CoA were obtained, which represented 36, 48, and 36 % yield respectively, based on CoA used in the reaction. The purity and identity of all synthesized products were confirmed by tandem MS. Product ion spectra were acquired directly for the [M + H+]+ molecular ion of each compound on a TSQ Quantum Triple Quadrupole mass spectrometer (Thermo Scientific) at a collision energy of 10 eV and 1.5 mtorr of argon. p-Coumaroyl-CoA: MS m/z (%) 914 ([M + H+]+, 56.5), 768 (8.7), 505, (9.9), 428 (40.0), 407 (100), 341 (6.3), 305 (21.1), 261 (10.9). Caffeoyl-CoA: MS m/z (%) 930 ([M + H+]+, 60.2), 768 (20.5), 521 (8.8), 428 (43.3), 423 (100), 410 (7.0), 341 (11.5), 321 (20.6), 261 (14.8). Feruloyl-CoA: MS m/z (%) 944 ([M + H+]+, 56.0), 768 (7.0), 535 (11.7), 437 (100), 428 (48.8), 410 (7.4), 335 (19.4), 261 (13.3), 177 (8.3).

Enzymatic synthesis of p-coumaroyl shikimic acid and caffeoyl shikimic acid used 6 mg p-coumaroyl-CoA, or 6 mg caffeoyl-CoA and 2 mg shikimic acid in a volume of 20 ml of potassium phosphate buffer (pH 7). The reaction was started by the addition of purified PtrHCT6 (Shuford et al. 2012) (0.5 mg). After incubating for 20 min at 30 °C, the product was extracted three times with 20 ml of ethyl acetate. The organic layer was recovered, then dried over Na2SO4, and evaporated to give 1.5 mg p-coumaroyl shikimic acid (65 % yield) or 1.2 mg caffeoyl shikimic acid (54 % yield). p-Coumaroyl shikimic acid: MS m/z (%) 321 ([M + H+]+, 18.2), 303 (3.5), 165 (5.6), 147 (100), 139 (1.6), 119 (2.3). Caffeoyl shikimic acid: MS m/z (%) 337 ([M + H+]+, 20.2), 319 (3.0), 181 (4.1), 163 (100), 145 (2.8), 145 (2.8), 139 (1.4), 117 (1.0).

Assays of enzyme activity

Three grams of SDX tissue from P. trichocarpa or P. taeda was ground in liquid nitrogen, and cells were disrupted in 15 mL extraction buffer [50 mM Tris (pH 7.0), 20 mM sodium ascorbate, 0.4 M sucrose, 100 mM NaCl, 5 mM DTT, 10 % (wt/wt) polyvinylpolypyrrolidone, 1 mM PMSF, 1 mg/mL pepstatin A, 1 mg/mL leupeptin], using a homogenizer for 2 min on ice. After removal of cell debris by centrifugation (3,000×g, 4 °C, 15 min, twice), the protein concentration of the crude extract was determined by the Bradford method (Bradford 1976). The protein concentrations of P. trichocarpa and P. taeda SDX tissue extracts were 0.38 and 1.0 μg/μL, respectively. If the amount of tissue is limited, the entire extraction can be scaled down. We recommend a minimum of 300 mg SDX in 1.5 mL extraction buffer to allow enough protein for triplicate assays of all ten enzymes.

The substrate (for a final concentration of 50 μM) was mixed with the assay solution [50 mM sodium phosphate buffer (pH 7.0), plus cofactors] to a final volume of 100 μL in a 200 μL tube. Each reaction was repeated for three times. The reaction mixture was held at 30 °C for 3 min, followed by the addition of SDX crude protein extract (8–20 μg for P. trichocarpa or P. taeda) to initiate the enzymatic reactions at 30 °C for 30 min. The reaction was terminated by the addition of 5 μL of 3 M trichloroacetic acid except CAD reaction. CAD reaction was terminated by addition of 40 μL of 50 % acetonitrile because of the degradation of products in low pH. After the mixture was centrifuged at 20,000×g for 20 min, 90 μL of supernatant reaction mixture was transferred to HPLC sample vial and 75 μL of supernatant was injected directly for HPLC separation. The mobile phases, A and B, were 5 mM ammonium acetate (pH 5.6) and 2/98/0.2 (water/acetonitrile/formic acid, v/v/v), respectively. The reaction mixture was loaded directly onto a 4.6 × 150 mm Zorbax Eclipse XDB-C18 column (Agilent) at 1 mL/min for 2 min using 10 % mobile phase B. Over the next 6 min, the gradient was ramped to 40 % mobile phase B, and remained at 40 % mobile phase B for 3 min. We ran three replicates for each of ten enzyme reactions with above mobile phases on an auto-sampler, so that the data for all enzymes are obtained in essentially a single experiment. The structural identities and quantities of the separated reaction products were confirmed on the basis of the diode array UV signatures obtained from authentic compounds.

Optimum conditions for enzyme activities

The optimum conditions for C4H–C3H (Chen et al. 2011), CCoAOMT (Li et al. 1999), CCR (Li et al. 2005), CAld5H (Osakabe et al. 1999), COMT (Li et al. 2000) and CAD (Li et al. 2001) were the same as those reported. The optimum conditions for PAL, HCT, and 4CL were based on our current studies (Table 1) and the SDX crude protein extract were used for each reaction.

Results and discussion

Enzyme activities of xylem proteins under our developed standard conditions

Monolignol biosynthesis is likely accomplished through a grid pathway consisting of a major path and few minor branch paths (Higuchi 1997; Osakabe et al. 1999; Li et al. 2001) (Fig. 1). The entire grid pathway is mediated by ten different types of known enzymatic reactions. Each of the reactions is mediated by one or more members of an enzyme family. To assay the activity of all monolignol pathway enzymes, we extracted total protein, which includes soluble and microsomal proteins, from SDX. A standard reaction condition, 50 μM substrate, 50 mM sodium phosphate buffer (pH 7.0), and 30 min reaction time at 30 °C, was used for all enzyme activity analysis (Table 1). Enzyme activities of SDX protein extracts were estimated spectrophotometrically by monitoring the increase in absorbance attributable to the increase in the product of each specific enzyme reaction, presumably coupled exclusively with the reduction of each substrate. The elution gradient resulted in good separation of the products from the substrates of all enzyme reactions (Table 2). Instead of different separation systems which were used in previous reports, this convenient single HPLC separation system can be used to separate the substrate and product for all monolignol biosynthetic pathway enzymes. Under the chromatographic conditions used in this study, all product calibration curves, using the authentic compounds, exhibited good linear regression of correlation coefficients (r 2 > 0.998).

We tested the enzymes associated with the major monolignol biosynthetic pathway in P. trichocarpa (Fig. 1) with the following substrates: PAL (using substrate 1), C4H–C3H (substrates 2 and 9), 4CL (substrates 3 and 4), HCT (substrate 8), CCoAOMT (substrate 11), CCR (substrate 12), CAld5H (substrate 17), COMT (substrate 18), and CAD (substrates 17 and 19). The C4H–C3H activity converting substrate 2 was weaker than that for 9, indicating that 9 is a better substrate for C4H–C3H than 2. For the same reason, 3 is a better substrate for 4CL than 4, and 19 is a better substrate for CAD than 17. The enzymes associated with the major pathway in P. taeda were also tested (Fig. 1). These enzymes are PAL (substrate 1), C4H–C3H (substrate 2 and 9), 4CL (substrate 3 and 4), HCT (substrate 8), CCoAOMT (substrate 11), CCR (substrate 8 and 12), and CAD (substrate 15 and 17). The following tendencies were observed: 9 is a better substrate for C4H–C3H than 2, and 3 is a better substrate for 4CL than 4. For other enzymes, 12 is a better substrate for CCR than 8, and 17 is a better substrate for CAD than 15. For the same enzyme families of P. trichocarpa and P. taeda, different enzyme specific activities were found. For example, PAL showed a higher specific activity in P. trichocarpa than in P. taeda. In contrast, CCR showed a lower specific activity in P. trichocarpa than in P. taeda (Tables 3, 4).

Enzyme activities of xylem protein reaction under optimum conditions

In enzyme kinetics, the reaction rate is measured and the effects of varying the conditions of the reaction investigated. Enzyme activity is affected by a number of factors including concentration of enzyme, concentration of substrate, temperature, and pH. Optimum conditions are usually used in the enzyme activity analysis. Because there is an optimum condition for each enzymatic reaction (Table 1), assaying ten enzymatic reactions at the optimum conditions all at once is time consuming. Therefore, we found a standard condition for all ten enzymes. Optimum conditions are usually used to get the highest reaction rate. To make our standard condition also give maximum reaction rates, we used high concentration of substrate (50 μM). It was reported that the xylem has a neutral pH value (Herrmann and Tesche 1992) and the optimum conditions of pH for ten enzymes vary from pH 5.4 to 8.5. We chose a pH 7 phosphate buffer. The optimum temperatures vary from 20 to 45 °C, and we chose 30 °C for our standard condition.

We detected all enzyme activities under our standard condition and compared this activity with that under optimum conditions to make sure our standard condition is reliable. The specific activities under the optimum conditions and our standard condition for the target enzymes are essentially the same. This result showed that pH and temperature did not significantly affect the specific activity and a standard condition is reliable for enzyme activity analysis. Using the same pH buffer and temperature for all monolignol enzyme families will make this approach convenient for studies of large numbers of samples. The only exception, PAL in P. taeda, showed a statistically significant difference. In this study, the PAL activity in P. taeda is 0.01 nmol/min/mg protein under our standard condition, and 0.13 nmol/min/mg protein under optimum conditions. It is not clear why PAL activity of P. taeda was different between standard and optimum conditions.

As a major component of plant cell walls that is particularly significant for the recalcitrance of biomass, lignin has been one of the most intensively studied products in plant biochemistry. Strategies for its down-regulation have been of considerable interest. Genetic engineering and analysis of mutations affecting monolignol biosynthesis have yielded substantial information, but much more work is needed. In this study, we developed an approach to measure the enzyme activity for all SDX enzyme families under the standard condition, and this approach can be used for both gymnosperm and angiosperm wild-type plants, and is currently being used for transgenic P. trichocarpa (data not shown). This approach permits a comprehensive and simultaneous investigation for different enzyme families and could be used in wild-type and transgenic plants of both gymnosperm and angiosperm plants.

Abbreviations

- SDX:

-

Stem differentiating xylem

- PAL:

-

Phenylalanine ammonia-lyase

- C4H:

-

Cinnamate 4-hydroxylase

- C3H:

-

4-Coumarate 3-hydroxylase

- 4CL:

-

4-Coumarate: coenzyme A ligase

- HCT:

-

p-Hydroxycinnamoyl-CoA: quinate shikimate p-hydroxycinnamoyltransferase

- CCoAOMT:

-

Caffeoyl-CoA O-methyltransferase

- CAld5H:

-

Coniferaldehyde 5-hydroxylase

- COMT:

-

Caffeic acid O-methyltransferase

- CCR:

-

Cinnamoyl-CoA reductase

- CAD:

-

Cinnamyl alcohol dehydrogenase

- SAD:

-

Sinapyl alcohol dehydrogenase

References

Beuerle T, Pichersky E (2002) Enzymatic synthesis and purification of aromatic coenzyme A ester. Anal Biochem 302:305–312

Boerjan W, Ralph J, Baucher M (2003) Lignin biosynthesis. Annu Rev Plant Biol 54:519–546

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein–dye binding. Anal Biochem 72:248–254

Chen F, Dixon R (2007) Lignin modification improves fermentable sugar yields for biofuel production. Nat Biotechnol 20:557–558

Chen HS, Li QZ, Shuford CM, Liu J, Muddiman DC, Sederoff RR, Chiang VL (2011) Membrane protein complexes catalyze both 4- and 3-hydroxylation of cinnamic acid derivatives in monolignol biosynthesis. PNAS 108:21253–21258

Herrmann V, Tesche M (1992) In vivo pH measurement in the xylem of broad-leaved trees using ion-sensitive field effect transistors. Trees 6:13–18

Higuchi T (1997) Biochemistry and molecular biology of wood. Springer, New York, pp 131–181

Jones DH (1984) Phenylalanine ammonia-lyase: regulation of its induction and its role in plant development. Phytochem 23:1349–1359

Kao YY, Harding SA, Tsai CJ (2002) Differential expression of two distinct phenylalanine ammonia-lyase genes in condensed tannin-accumulating and lignifying cells of quaking aspen. Plant Physiol 130:796–807

Kuroda H, Shimada M, Higuchi T (1981) Characterization of a lignin-specific O-methyltransferase in aspen wood. Phytochem 20:2635–2639

Kutsuki H, Higuchi T (1981) Activities of some enzymes of lignin formation in reaction wood of Thuja orientalis, Metasequoia glyptostroboides and Robinia pseudoacacia. Planta 152:365–368

Kutsuki H, Shimada M, Higuchi T (1982) Regulatory role of cinnamyl alcohol dehydrogenase in the formation of guaiacyl and syringyl lignins. Phytochem 21:19–23

Li L, Osakabe Y, Joshi CP, Chiang VL (1999) Secondary xylem-specific expression of caffeoyl-coenzyme A 3-O-methyltransferase plays an important role in the methylation pathway associated with lignin biosynthesis in loblolly pine. Plant Mol Biol 40:555–565

Li L, Popko JL, Umezawa T, Chiang VL (2000) 5-Hydroxyconiferyl aldehyde modulates enzymatic methylation for syringyl monolignol formation, a new view of monolignol biosynthesis in angiosperms. J Biol Chem 275:6537–6545

Li L, Cheng XF, Leshkevich J, Umezawa T, Harding SA, Chiang VL (2001) The last step of syringyl monolignol biosynthesis in angiosperms is regulated by a novel gene encoding sinapyl alcohol dehydrogenase. Plant Cell 13:1567–1586

Li L, Cheng XF, Lu SF, Nakatsubo T, Umezawa T, Chiang VL (2005) Clarification of cinnamoyl co-enzyme A reductase catalysis in monolignol biosynthesis of aspen. Plant Cell Physiol 46:1073–1082

Luderitz T, Grisebach H (1981) Enzymic synthesis of lignin precursors. Comparison of cinnamoyl CoA reductase and cinnamyl alcohol: NADP+ dehydrogenase from spruce (Picea abies L.) and soybean (Glycine max L.). Eur J Biochem 119:115–124

Mansell RL, Gross GG, Stöckigt J, Franke H, Zenk MH (1974) Purification and properties of cinnamyl alcohol dehydrogenase from higher plants involved in lignin biosynthesis. Phytochem 13:2427–2435

Osakabe Y, Ohtsubo Y, Kawai S, Katayama Y, Morohoshi N (1995) Structures and tissue-specific expression of genes for phenylalanine ammonia-lyase from a hybrid aspen. Plant Sci 105:217–226

Osakabe K, Tsao CC, Li L, Popko JL, Umezawa T, Carraway DT, Smeltzer RH, Joshi CP, Chiang VL (1999) Coniferyl aldehyde 5-hydroxylation and methylation direct syringyl lignin biosynthesis in angiosperms. Proc Natl Acad Sci USA 96:8955–8960

Ralph J, Brunow G, Harris PJ, Dixon RA, Schatz PF, Boerjan W (2008) Lignification: are lignins biosynthesized via simple combinatorial chemistry or via proteinaceous control and template replication? In: Daayf F, El Hadrami A, Adam L, Balance GM (eds) Recent advances in polyphenol research. Wiley-Blackwell Publishing, Oxford, pp 36–66

Sarkanen KV (1971) Precursors and their polymerization. In: Sarkanen KV, Ludwig CH (eds) Lignins, occurrence, formation, structure and reactions. Wiley, New York, pp 95–163

Sarkanen K (1976) Renewable resources for production of fuels and chemicals. Science 191:773–776

Sarkanen KV, Ludwig CH (1971) Definition and nomenclature. In: Sarkanen KV, Ludwig CH (eds) Lignins: occurrence, formation, structure, and reactions. Willey, New York

Shi R, Yang CM, Lu S, Sederoff R, Chiang VL (2010) Specific down-regulation of PAL genes by artificial microRNAs in Populus trichocarpa. Planta 232:1281–1288

Shimada M, Fushiki H, Higuchi T (1973) Mechanism of biochemical formation of the methoxyl groups in softwood and hardwood lignins. Mokuzai Gakkaishi 19:13–21

Shuford CM, Li QZ, Sun YH, Chen HC, Wang J, Shi R, Sederoff RR, Chiang VL, Muddiman DC (2012) Comprehensive quantification of monolignol-pathway enzymes in Populus trichocarpa by protein cleavage isotope dilution mass spectrometry. J Proteome Res (in press)

Whetten R, Sederoff R (1995) Lignin biosynthesis. Plant Cell 7:1001–1013

Acknowledgments

We thank Christopher M. Shuford and Dr. David C. Muddiman for mass spectrometry information of synthesized compounds; Hsi-Chuan Chen and Jack P. Wang for optimum condition information. This work was supported by National Science Foundation Plant Genome Research Program Grant DBI-0922391 (to V.L.C).

Author information

Authors and Affiliations

Corresponding author

Additional information

A contribution to the Special Issue on Metabolic Plant Biology.

Rights and permissions

About this article

Cite this article

Liu, J., Shi, R., Li, Q. et al. A standard reaction condition and a single HPLC separation system are sufficient for estimation of monolignol biosynthetic pathway enzyme activities. Planta 236, 879–885 (2012). https://doi.org/10.1007/s00425-012-1688-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00425-012-1688-9