Abstract

Selenium (Se) can be assimilated and volatilized via the sulfate assimilation pathway. Cystathionine-γ-synthase (CGS) is thought to catalyze the synthesis of Se-cystathionine from Se-cysteine, the first step in the conversion of Se-cysteine to volatile dimethylselenide. Here the hypothesis was tested that CGS is a rate-limiting enzyme for Se volatilization. Cystathionine-γ-synthase from Arabidopsis thaliana (L.) Heynh. was overexpressed in Indian mustard [Brassica juncea (L.) Czern & Coss], and five transgenic CGS lines with up to 10-fold enhanced CGS levels were compared with wild-type Indian mustard with respect to Se volatilization, tolerance and accumulation. The CGS transgenics showed 2- to 3-fold higher Se volatilization rates than wild-type plants when supplied with selenate or selenite. Transgenic CGS plants contained 20–40% lower shoot Se levels and 50–70% lower root Se levels than the wild type when supplied with selenite. Furthermore, CGS seedlings were more tolerant to selenite than the wild type. There were no differences in Se accumulation or tolerance from selenate, in agreement with the earlier finding that selenate-to-selenite reduction is rate-limiting for selenate tolerance and accumulation. In conclusion, CGS appears to be a rate-limiting enzyme for Se volatilization. Overexpression of CGS offers a promising approach for the creation of plants with enhanced capacity to remove Se from contaminated sites in the form of low-toxic volatile dimethylselenide.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Selenium (Se) has been established as an essential element for many animals and bacteria as well as for some algae, as an essential component of seleno-enzymes and tRNAs (Stadtman 1990; Fu et al. 2002). At higher concentrations, however, Se is toxic. Due to its chemical similarity to sulfur Se can, non-specifically, replace sulfur in proteins leading to disruption of protein function (Brown and Shrift 1982; Stadtman 1990). The difference between the amount of Se required to function optimally and the amount that is toxic is quite small (Terry et al. 2000). As a result, both Se deficiency and toxicity are widespread problems. Selenium is naturally present in alkaline soils derived from Cretaceous shales or seleniferous rocks (Kabata-Pendias 1998). Irrigation of such Se-rich soils increases the availability of Se to the biosphere, and as Se is transferred through the biosphere it becomes bioconcentrated, leading to toxicity (Harris 1991; Terry et al. 2000). For accounts of Se toxicity, see Draize and Beath (1935), Rosenfeld and Beath (1964), Wilber (1980), Ohlendorf et al. (1986), Saiki and Lowe (1987), Harris (1991), von Vleet and Ferrans (1992), and Skorupa (1998).

A method that has been applied to remove Se from seleniferous soils and Se-contaminated water is phytoremediation. Plants may be used to accumulate Se in harvestable biomass (phytoextraction), as well as to convert and release Se in a volatile form (phytovolatilization; Duckart et al. 1992; Terry et al. 1992). The most common volatile form of Se, dimethylselenide (DMSe), has been reported to be 500–700 times less toxic than the selenate and selenite forms of Se found in soils (Ganther et al. 1966; Wilber 1980). Thus, phytovolatilization is an attractive application of phytoremediation because it detoxifies and completely removes Se from the local environment, releasing it to the atmosphere. This limits the amount of Se entering trophic chains (Terry et al. 2000). Indian mustard (Brassica juncea) has been one of the most popular species for phytoremediation of Se from soils (Bañuelos and Meek 1990; Bañuelos et al. 1993).

Selenium uptake, assimilation and volatilization are thought to occur via the sulfur assimilation pathway (Anderson 1993; Pilon-Smits et al. 1999; Tagmount et al. 2002). In plants this pathway is localized mainly in the chloroplast (Leustek and Saito 1999). Selenate is taken up actively via a sulfate transporter in the root plasma membrane, while selenite is thought to be taken up passively (Arvy 1993). After uptake, selenate and selenite can be incorporated into selenocysteine (SeCys; Leustek and Saito 1999). Selenocysteine can be non-specifically incorporated into proteins, replacing cysteine; this disrupts protein function and thus leads to toxicity (Stadtman 1990; Neuhierl and Bock 1996). Incorporation of SeCys into protein may be prevented to some extent by its conversion to volatile DMSe via the sulfur assimilation pathway. Selenocysteine is thought to be converted to selenomethionine (SeMet) via selenocystathionine and selenohomocysteine; further methylation of SeMet gives rise to volatile DMSe production (Terry et al. 2000; Tagmount et al. 2002).

The reduction of selenate to selenite was previously shown to be a rate-limiting step in the Se assimilation pathway, since selenate-supplied wild-type (WT) Indian mustard plants accumulated selenate while plants supplied with selenite accumulated organic Se (de Souza et al. 1998). The reduction of selenate to selenite involves the enzyme ATP sulfurylase. When ATP sulfurylase was overexpressed, selenate-supplied plants accumulated organic Se and also showed enhanced Se accumulation and tolerance (Pilon-Smits et al. 1999). However, the ATP sulfurylase-overexpressing transgenics did not show a significant increase in Se volatilization. Therefore, another enzyme downstream in the S-assimilation pathway appeared to be rate-limiting for Se volatilization.

In the present study, the hypothesis was tested that cystathionine-γ-synthase (CGS) is a rate-limiting enzyme for Se volatilization. Cystathionine-γ-synthase is thought to mediate the conversion of SeCys to Se-cystathionine, in analogy to its role in the sulfur assimilation pathway where it catalyzes the formation of cystathionine from O-phosphohomoserine (OPH) and cysteine (Kim and Leustek 1996). As such, it is the key enzyme in the conversion of SeCys to volatile DMSe. There are several arguments for a possible rate-limiting role for CGS in Se volatilization. First, Se volatilization rates of Indian mustard are similar from SeCys and selenite, while volatilization from SeMet is many-fold faster (de Souza et al. 2000). Second, both CGS and threonine synthase (TS) use OPH as a substrate, forming a branch point between carbon flow towards methionine and threonine (Amir et al. 2002). In vitro experiments showed that plant TS has a 500-fold greater affinity for OPH than plant CGS (Curien et al. 1998; Ravanel et al. 1998). If a similar affinity occurs in vivo, then most of the carbon flux would go towards threonine (Amir et al. 2002), making CGS a possible rate-limiting step for methionine synthesis. Indeed, mutant and transgenic Arabidopsis and potato plants with reduced TS activity showed a substantial increase in methionine levels and a small decrease in threonine levels, suggesting that reduced TS activity increases the flow of carbon towards methionine (Bartlem et al. 2000; Zeh et al. 2001). Furthermore, mutant and transgenic Arabidopsis plants with increased CGS activity were shown to accumulate up to 40 times more methionine than WT plants (Inba et al. 1994; Chiba et al. 1999; Suzuki et al. 2001; Hacham et al. 2002; Kim et al. 2002). However, in another study, overexpression of CGS in potato did not affect soluble methionine levels (Kreft et al. 2003), and antisense Arabidopsis plants with a 5- to 20-fold reduction in CGS concentration showed no more than a 35% reduction in methionine levels (Gakiere et al. 2000; Kim and Leustek 2000). Therefore, it is not completely clear whether CGS is a rate-limiting enzyme for the S assimilation pathway. As for Se assimilation, the involvement of CGS has not been shown in vivo, much less any rate limitation imposed by this enzyme on Se volatilization. In the present study, CGS from Arabidopsis was overexpressed in Indian mustard, in order to analyze the importance of CGS for Se volatilization. The transgenic CGS plants were compared with WT Indian mustard with respect to Se volatilization, as well as Se tolerance and accumulation.

Materials and methods

Plant transformation

Wild-type (WT) Brassica juncea (L.) Czern & Coss seeds (accession no. 173874) were obtained from the North Central Regional Plant Introduction Station (Ames, IA, USA). The DNA construct used to transform the plants contained the Arabidopsis thaliana (L.) Heynh. CGS1 cDNA, including its chloroplast transit sequence, controlled by the cauliflower mosaic virus 35S promoter (Chen et al. 1997; Kim et al. 2002). Transformation was performed as described by Pilon-Smits et al. (1999). Kanamycin-resistant lines were confirmed to be CGS transgenics by polymerase chain reaction (PCR). The following primers were used for PCR: a 35S promoter-specific forward primer with the sequence 5′ CCT TCG CAA GAC CCT TCC TC 3′ and a CGS-specific reverse primer with the sequence 5′ CCA CGA TCT GTG CAA CAC CG 3′. Five transgenic lines were identified and propagated for further experiments via self-pollination; these lines were designated CGS3, 11, 12, 13, and 15. Seeds from the T2 generation were used for further experiments.

Expression studies

The expression of the A. thaliana CGS protein in the transgenic Indian mustard plants was analyzed at the RNA and protein level via Northern blotting and immunoblotting, respectively.

For Northern blotting, total RNA from 7-day-old B. juncea and 14-day-old Arabidopsis seedlings (T2 seeds, after selection for homozygosity) was isolated using the TRIzol reagent method (Invitrogen, Carlsbad, CA, USA). Twenty-five micrograms of RNA was electrophoresed on a 1% (w/v) agarose gel containing 4% (w/v) formaldehyde, transferred to a nylon membrane, and probed with a 32P-labelled 1.0-kb Arabidopsis CGS cDNA. Hybridization was performed at 42 °C in a solution containing 50% formamide, 5×SSPE, 5×Denhardt's solution, 0.1% (w/v) SDS, and 100 μl/ml salmon sperm DNA. After hybridization, the membrane was washed with 0.1×SSC and 0.1% SDS at 65 °C, and radioactive bands were visualized and quantified in a PhosphorImager (STORM, Molecular Dynamics, Sunnyvale, CA, USA). As a control for loading, the 28S ribosomal RNA band was quantified from the ethidium bromide-stained gel, using Gel-Pro Analyzer (Media Cybernetics, Silver Spring, MD, USA). The intensities of the CGS bands were quantified using ImageQuant (Molecular Dynamics). The relative expression levels of CGS were then calculated as a ratio of the detected CGS bands to the amount of 28S ribosomal RNA.

For immunoblotting, total protein extracts were prepared from true leaves of 25-day-old seedlings of CGS and WT Indian mustard, as well as from A. thaliana as a positive control, all grown on half-strength Murashige and Skoog medium (Murashige and Skoog 1962). The extraction buffer contained 100 mM NaCl, 50 mM Tris–HCl (pH 7.5), 0.5% Triton X-100, 1 mM dithiothreitol (DTT), and 1 mM phenylmethylsulfonyl fluoride (PMSF). Total protein content was assayed according to Bradford (1976). Equal amounts of total protein (20 μg) were loaded for each sample, separated by SDS–PAGE (Laemmli 1970) and transferred to nitrocellulose membrane by electroblotting. Immunostaining was used to visualize the A. thaliana CGS protein, using polyclonal antibodies raised against purified A. thaliana CGS. As controls for the specificity of the CGS antiserum and for equal loading, immunostaining was also performed with preimmune serum and with antibodies raised against Rubisco (Agrisera, Vännäs, Sweden). Immunoblot visualization was through conjugation of the secondary antibody to alkaline phosphatase and the ECF fluorescent substrate (Amersham, Piscataway, NJ, USA). Quantitation of the bands was performed using the ImageQuant analysis program (Molecular Dynamics).

Measurement of plant Se tolerance, accumulation and volatilization

Selenium tolerance and accumulation were analyzed as described by Pilon-Smits et al. (1999). In short, seeds for seedling experiments were surface-sterilized (n=36 per plant type per treatment) and cultured for seven days at 25 °C, 16 h/8 h light/dark (L/D) on half-strength Murashige and Skoog (1962) agar medium with or without Se added as sodium selenate (200 μM) or sodium selenite (100 μM). The lower selenite concentration was chosen because selenite is more toxic to plants than selenate. After 7 days, root growth was measured as an indication of tolerance and the ratio of root growth plus vs. minus Se was calculated. Seedling shoots were harvested and dried overnight at 70 °C for Se and S analysis as described below.

For mature plant Se accumulation experiments, 4-week-old sand-grown plants (25 °C, 16 h/8 h L/D, n=6 per plant type per treatment) were washed to remove the sand, transferred to 4 l containers, left to adjust for 1 week, and then supplied with 20 μM Se for 1 week, as sodium selenate or sodium selenite. Shoot tissue Se and S levels were analyzed by means of ICP-AES (inductively coupled plasma atomic emission spectrometry) after acid digestion. Six seedling samples, each pooled from six seedling shoots, were analyzed by ICP-AES per plant type and treatment. Roots and shoots of each individual mature plant were analyzed separately (n=6 per plant type per treatment).

For measurement of Se volatilization, 4-week-old sand-grown plants (25 °C, 16 h/8 h L/D, n=6 per plant type per treatment) were transferred to 4-l containers, left to adjust for 1 week, and then supplied with 40 μM Se for 2 weeks, as sodium selenate or sodium selenite. Selenium volatilization rates were then measured from the entire plant over a 24 h period, as described by de Souza et al. (1998). The volatile Se was trapped in alkaline peroxide solution, which was analyzed for Se content using AAS (atomic absorption spectrometry) after reduction with HCl (Ward and Gray 1996).

Statistical analyses

For statistical analyses the software package JMP-IN was used (version 3.2.6; SAS Institute, Cary, NC, USA). Pairs of means were compared statistically using t-tests. Statistically significant differences (α=0.05) are described in the text.

Results

Overexpression of Arabidopsis CGS in Indian mustard

Transgenic Indian mustard plants were obtained using a gene construct containing the A. thaliana CGS gene with its own transit sequence, coupled to the 35S constitutive promoter (Kim et al. 2002). Five transgenic lines were identified by PCR (not shown) and propagated. These lines were designated CGS 3, 11, 12, 13 and 15. No phenotypic differences were observed between the transgenics and WT plants when grown under standard conditions on agar or soil.

To examine the expression of Arabidopsis CGS in the B. juncea transgenics at the RNA level, Northern blot analysis was performed using total RNA isolated from 7-day-old WT and transgenic B. juncea T2 seedlings, as well as from 14-day-old Arabidopsis plants. A transcript of about 2.9 kb was detected in both Arabidopsis and WT Brassica; in addition, a slightly larger mRNA was detected in all transgenic lines (Fig. 1a). Based on the relative intensity of the CGS signal, all five transgenic CGS lines showed 3- to 4-fold higher CGS expression levels than WT B. juncea at the mRNA level (Fig. 1c). The reason why the transgenic mRNA runs at a slightly larger size than the WT and the Arabidopsis CGS is because of differences in the 5′ and 3′ untranslated regions, as a result of the design of the gene construct.

Expression analysis of A. thaliana CGS in the Indian mustard transgenics at the mRNA level. Total RNA isolated from 7-day-old B. juncea seedlings and 14-day-old Arabidopsis seedlings was electrophoresed, transferred to Hybond-N membrane, and probed with 32P-labelled Arabidopsis CGS cDNA (a). Ethidium bromide-stained rRNA is shown as a control for loading (b). The 28S ribosomal RNA was quantified using Gel-Pro Analyzer (Media Cybernetics, Silver Spring, Md.), and the CGS bands were quantified using the ImageQuant analysis program (Molecular Dynamics, Sunnyvale, Calif.). Numbers indicate the length of size markers in bp. The relative expression levels of CGS were calculated as a ratio of the detected CGS bands to the amount of 28S ribosomal RNA (c). Arab, A. thaliana positive control; WT Brassica, wild-type Indian mustard

The transgenic CGS plants contained a protein that reacted with antiserum raised against the A. thaliana CGS enzyme (Fig. 2a), of the same size as the A. thaliana CGS protein (53 kDa, Ravanel et al. 1998). The WT B. juncea plants contained a protein that cross-reacted with the CGS antiserum; presumably this is the endogenous CGS. The intensity of the band in the transgenic CGS lines, however, was up to 10-fold higher than in WT plants (Fig. 2c), indicating successful overexpression of the A. thaliana CGS protein in Indian mustard. Judged from Fig. 2, transgenic line CGS15 appears to be the highest expressor of the CGS protein (10-fold higher than WT), followed by CGS3 (4-fold higher), CGS13 and CGS12 (2-fold higher), and CGS11 (1.3-fold higher). Thus, the increase in CGS protein level tended to be more pronounced than the increase in CGS mRNA level in the CGS transgenics. This could be due to the differences in age of the seedlings used or to instability of the CGS mRNA. The equal size of the A. thaliana CGS protein and the CGS protein in the transgenic Indian mustard plants suggests that the transit sequence is cleaved off, and thus that the protein is correctly targeted to the chloroplast.

Expression analysis of A. thaliana CGS in the Indian mustard transgenics at the protein level. Total protein was extracted from the first true leaves of 25-day-old seedlings grown axenically on half-strength Murashige and Skoog medium. Equal amounts (20 μg) of homogenate protein were fractionated by SDS-polyacrylamide gel electrophoresis, blotted and immunostained using antiserum raised against A. thaliana CGS protein (a). Blots were also immunoprobed with Rubisco antibody (b) and pre-immune serum (not shown), as controls for equal loading and cross-reactions, respectively. Molecular mass markers (kDa) are shown on the left. c The intensities of the CGS bands shown in a, as quantified using ImageQuant. Arab, A. thaliana positive control; WT Brassica, wild-type Indian mustard

Effect of CGS overexpression on Se tolerance and accumulation in seedlings

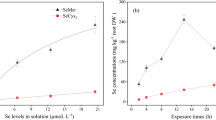

To determine the effect of CGS overexpression on Se tolerance and accumulation at the seedling level, WT and CGS seeds were cultured for 7 days on agar medium with or without Se, supplied as selenate or selenite. Root length was measured as a suitable tolerance parameter (Murphy and Taiz 1995) and shoot tissue Se levels were determined. All five CGS lines exhibited a significantly higher tolerance than WT when grown on agar medium containing 100 μM selenite (P<0.05, Fig. 3a). When treated with 200 μM selenate, however, there were no significant differences in tolerance between CGS lines and WT (Fig. 3b). Similarly, under control conditions there were no differences in seedling growth (results not shown).

Tolerance of WT and CGS transgenic Indian mustard seedlings to 100 μM selenite (a) or 200 μM selenate (b). Tolerance was measured as root length and expressed as the root length ratio of seedlings grown for 7 days in the presence or absence of Se. Shown are the means ± SE of 36 seedlings per treatment per line

All of the CGS lines except CGS13 showed significantly (P<0.05) lower shoot Se concentrations than WT when treated with selenite (−25%, Fig. 4a). In contrast, when treated with selenate, three of the transgenic lines (CGS 3, 11, and 13) contained a significantly higher shoot Se concentration than WT seedlings (P<0.05; Fig. 4b).

Shoot selenium concentrations in WT and transgenic CGS Indian mustard seedlings, grown for 7 days on agar medium supplied with 100 μM selenite (a) or 200 μM selenate (b). Shown are the means ± SE of six samples from six seedlings each, per treatment per line. Note: standard errors not shown were too small to be plotted by the graphing program

Since the CGS enzyme is involved in sulfur assimilation, the effect of its overexpression on sulfur (S) levels in the plant was also analyzed. The CGS transgenics contained lower S concentrations in their shoot tissue than WT seedlings, irrespective of treatment (Fig. 5). Under control conditions or selenite treatment (Fig. 5a, b) all five CGS lines contained significantly lower S levels than WT (P<0.05), and selenate-treated seedlings of all CGS lines except CGS3 and CGS13 also showed lower S levels than WT (Fig. 5c). The highest expressor line CGS15 showed the biggest decrease in S concentration under all conditions, and the decrease in S was most pronounced after selenite treatment for all lines (−38% for CGS15). No significant differences in soluble cysteine and methionine levels were found between CGS and WT seedlings grown on control agar medium for two weeks (results not shown).

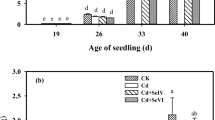

Effect of CGS overexpression on Se accumulation in mature plants

To determine the effect of CGS overexpression on Se accumulation at the mature plant level, WT and CGS plants were treated with 20 μM selenate or selenite for 7 days in a hydroponic setup, and shoot and root tissue Se levels were determined. This concentration did not result in a significant reduction in growth (results not shown). When treated with selenite, all of the CGS lines contained significantly lower shoot Se concentrations than WT (P<0.05), ranging from 20% lower levels for CGS3, 11, 12 and 13 to 40% lower levels for CGS15 (Fig. 6a). When supplied with selenate on the other hand, there were no significant differences in shoot Se concentrations between WT and the CGS lines except that CGS3 contained a higher Se level (+23%, Fig. 6b). Similar results were found for root Se concentration. All transgenic lines except CGS13 contained significantly lower root Se levels than WT, ranging from a 50% reduction for lines CGS3, 11 and 12 to a 70% reduction in CGS15 (P<0.05; Fig. 6a). Among the selenate-treated plants there were no significant differences in root Se concentration between any of the plant lines (Fig. 6b).

The S levels in shoots and roots of CGS plants were not markedly different from those in WT plants (Table 1). The only line that showed any significant differences compared to WT was CGS15, which contained lower S levels than WT in its roots after both treatments, and line CGS3 which contained higher shoot S levels than WT after selenate treatment.

Effect of CGS overexpression on Se volatilization in mature plants

To determine the effect of CGS overexpression on Se volatilization in mature plants, WT and CGS plants were treated with 40 μM selenate or selenite for 14 days in a hydroponic setup, followed by Se volatilization measurement from the entire plant over 24 h. This longer treatment at higher Se levels was chosen in order to obtain more reliable measurements. All transgenic CGS lines showed significantly higher Se volatilization rates from selenite than WT, ranging from ≈2-fold for lines CGS3, 11, 12 and 13 to ≈3-fold for CGS15 (P<0.05; Fig. 7a). Similarly, when treated with selenate, all transgenic lines except CGS12 volatilized Se at higher rates than WT (P<0.05), ranging from ≈2-fold higher for lines CGS3, 11, and 13 to ≈3-fold higher for CGS15 (Fig. 7b).

Discussion

Transgenic Indian mustard plants overexpressing CGS showed 2- to 3-fold higher Se volatilization rates compared to untransformed WT plants. These results show for the first time that CGS is involved in Se volatilization in vivo and that CGS is a rate-limiting enzyme for this process.

The CGS plants showed 20–40% lower shoot tissue Se levels and 50–70% lower root Se levels than WT when supplied with selenite, most likely because more Se was removed from the plant system via volatilization. Among the CGS transgenic lines, the highest expressor, CGS15, showed the highest Se volatilization rates from both selenate and selenite and the biggest decrease in shoot and root Se concentrations. The fact that the reduction in tissue Se level was greatest in the roots compared to the shoots is in agreement with the earlier finding that volatile Se is predominantly emitted by the plant root (Zayed and Terry 1994), while the shoot appears to be involved in the assimilation of selenate to organic forms of Se (Pilon-Smits et al. 1999). The CGS seedlings were more tolerant to selenite than WT, possibly because of their lower tissue Se levels.

The effect of CGS overexpression on Se tolerance and accumulation was markedly different for selenate and selenite: while CGS transgenics were more tolerant to selenite and accumulated less Se from selenite than WT, there were no differences found in Se tolerance or accumulation between selenate-treated CGS and WT plants. This may be explained by a slower conversion rate of selenate to SeCys relative to selenite–SeCys. The reduction of selenate to selenite was found earlier to be a rate-limiting step for Se assimilation into organic compounds in Indian mustard (de Souza et al. 1998; Pilon-Smits et al. 1999). Selenate-supplied plants accumulated ≈95% selenate while plants supplied with selenite accumulate ≈100% organic Se. Thus, overexpression of CGS is not expected to influence Se accumulation (and hence, tolerance) from selenate much, since it is located downstream from the rate-limiting reaction.

There was a significant difference in Se volatilization between CGS and WT plants however, even from selenate. This indicates that the rate of production of SeCys from selenate by the sulfate assimilation pathway was high enough for CGS to be rate-limiting for the further conversion to volatile DMSe. This may be explained by the fact that selenate is taken up and translocated by plants at a much faster rate than selenite (Arvy 1993; de Souza et al. 1998; Fig. 6a, b). Thus, even if only a small fraction (e.g. 5%) of the Se in shoots of selenate-treated plants is SeCys, this level may still be comparable to the SeCys levels in selenite-treated plants, making Se volatilization rates from selenate and selenite subject to the same rate limitation.

Overexpression of CGS holds promise for enhancing Se phytoremediation efficiency. The CGS transgenics showed 2- to 3-fold higher Se volatilization rates compared to WT plants, both when supplied with selenate and selenite, the two predominant forms of bioavailable Se present in the environment. A higher Se volatilization rate is an attractive feature for phytoremediation since Se volatilization totally removes Se from the site in a low-toxic volatile form. The contribution of volatilization as a fraction of the total amount of Se removed from a field site was estimated to be 10–30% in a constructed wetland used to clean up selenite-laden industrial wastewater (Hansen et al. 1998), and 6.5% in a constructed wetland used to treat selenate-rich agricultural wastewater (Lin et al. 2000). Thus, a 2- to 3-fold increase in Se volatilization rate may substantially enhance the rate of Se removal in such situations.

In addition to volatilizing more Se, the CGS plants contained lower tissue Se levels than WT when supplied with selenite. Since selenite is the predominant form of Se under reducing conditions such as constructed wetlands (Hansen et al. 1998), and exposure of wildlife to accumulated Se is a concern when using constructed wetlands, the lower tissue Se levels in the presence of selenite are an additional attractive feature of CGS-overexpressing plants.

Abbreviations

- CGS:

-

cystathionine-γ-synthase

- DMSe:

-

dimethylselenide

- SeCys:

-

selenocysteine

- WT:

-

wild type

References

Amir R, Hacham Y, Galili G (2002) Cystathionine-γ-synthase and threonine synthase operate in concert to regulate carbon flow towards methionine in plants. Trends Plant Sci 7:153–156

Anderson JW (1993) Selenium interactions in sulfur metabolism. In: De Kok LJ (ed) Sulfur nutrition and assimilation in higher plants—regulatory, agricultural and environmental aspects. SPB Academic publishing, The Hague, pp 49–60

Arvy MP (1993) Selenate and selenite uptake and translocation in bean plants (Phaseolus vulgaris). J Exp Bot 44:1083–1087

Bañuelos GS, Meek DW (1990) Accumulation of selenium in plants grown on selenium-treated soil. J Environ Qual 19:772–777

Bañuelos GS, Cardon G, Mackey B, Ben-Asher J, Wu L, Beuselink P, Akohoue S, Zambrzuski S (1993) Boron and selenium removal in boron laden soils by four sprinkler irrigated plant species. J Environ Qual 22:786–792

Bartlem D, Lambein I, Okamoto T, Itaya A, Uda Y, Kijima F, Tamaki Y, Nambara E, Naito S (2000) Mutation in the threonine synthase gene results in an over-accumulation of soluble methionine in Arabidopsis. Plant Physiol 123:101–110

Bradford MM (1976) A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein–dye binding. Anal Biochem 72:248–254

Brown TA, Shrift A (1982) Selenium: toxicity and tolerance in higher plants. Biol Rev 57:59–84

Chen Y, Leustek T, Lee S (1997) Analysis of ATP sulfurylase overexpression in Arabidopsis thaliana (abstract no. 702). Plant Physiol 114:S-148

Chiba Y, Ishikawa M, Kijima F, Tyson RH, Kim J, Yamamoto A, Nambara E, Leustek T, Wallsgrove R, Naito S (1999) Evidence for autoregulation of cystathionine-γ-synthase mRNA stability in Arabidopsis. Science 286:1371–1374

Curien G, Job D, Douce R, Dumas R (1998) Allosteric activation of Arabidopsis threonine synthase by S-adenosylmethionine. Biochemistry 37:13212–13221

de Souza MP, Pilon-Smits EAH, Lytle CM, Hwang S, Tai J, Honma TSU, Yeh L, Terry N (1998) Rate-limiting steps in selenium assimilation and volatilization by Indian mustard. Plant Physiol 117:1487–1494

de Souza MP, Lytle CM, Mulholland MM, Otte ML, Terry N (2000) Selenium assimilation and volatilization from dimethylselenoniopropionate by Indian mustard. Plant Physiol 122:1281–1288

Draize JH, Beath OA (1935) Observation on the pathology of "blind staggers" and "alkali disease". Am Vet Med Assoc J 86:753–763

Duckart EC, Waldron LJ, Donner HE (1992) Selenium uptake and volatilization from plants growing in soil. Soil Sci 153:94–99

Fu L-H, Wang X-F, Eyal Y, She Y-M, Donald LJ, Standing KG, Ben-Hayyim G (2002) A selenoprotein in the plant kingdom: Mass spectrometry confirms that an opal codon (UGA) encodes selenocysteine in Chlamydomonas reinhardtii glutathione peroxidase. J Biol Chem 277:25983–25991

Gakiere B, Ravanel S, Droux M, Douce R, Job D (2000) Mechanisms to account for maintenance of the soluble methionine pool in transgenic Arabidopsis plants expressing antisense cystathionine-γ-synthase cDNA. C R Acad Sci Ser III Sci Vie 323:841–851

Ganther HE, Levander OA, Saumann CA (1966) Dietary control of selenium volatilization in the rat. J Nutr 88:55–60

Hacham Y, Avraham T, Amir R (2002) The N-terminal region of Arabidopsis cystathionine γ–synthase plays an important regulatory role in methionine metabolism. Plant Physiol 128:454–462

Hansen D, Duda P, Zayed AM, Terry N (1998) Selenium removal by constructed wetlands: role of biological volatilization. Environ Sci Technol 32:591–597

Harris T (1991) Death in the marsh. Island Press, Washington DC

Inba K, Fujiwara T, Hayashi H, Chino M, Komeda Y, Naito S (1994) Isolation of Arabidopsis thaliana mutant, mto 1, that overaccumulates soluble methionine: temporal and spatial patterns of soluble methionine accumulation. Plant Physiol 104:881–887

Kabata-Pendias A (1998) Geochemistry of selenium. J Environ Pathol Toxicol Oncol 17:173–177

Kim J, Leustek T (1996) Cloning and analysis of the gene for cystathionine-γ-synthase from Arabidopsis thaliana. Plant Mol Biol 32:1117–1124

Kim J, Leustek T (2000) Repression of cystathionine-γ-synthase in Arabidopsis thaliana produces partial methionine auxotrophy and developmental abnormalities. Plant Sci 151:9–18

Kim J, Lee M, Chalam R, Martin MN, Leustek T, Boerjan W (2002) Constitutive overexpression of cystathionine-γ-synthase in Arabidopsis leads to accumulation of soluble methionine and S-methylmethionine. Plant Physiol 128:95–107

Kreft O, Hoefgen R, Hesse H (2003) Functional analysis of cystathionine γ–synthase in genetically engineered potato plants. Plant Physiol 131:1843–1854

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Leustek T, Saito K (1999) Sulfate transport and assimilation in plants. Plant Physiol 120:637–643

Lin ZQ, Schemenauer RS, Cervinka V, Zayed A, Lee A, Terry N (2000) Selenium volatilization from a soil-plant system for the remediation of contaminated water and soil in the San Joaquin Valley. J Environ Qual 29:1048–1056

Murashige T, Skoog F (1962) A revised medium for rapid growth and bio assays with tobacco tissue culture. Physiol Plant 15:437–497

Murphy A, Taiz L (1995) A new vertical mesh transfer technique for metal-tolerance studies in Arabidopsis: ecotypic variation and copper-sensitive mutants. Plant Physiol 108:29–38

Neuhierl B, Bock A (1996) On the mechanism of selenium tolerance in selenium-accumulating plants: purification and characterization of a specific methyltransferase from cultured cells of Astragalus bisulcatus. Eur J Biochem 239:235–238

Ohlendorf HM, Hoffman DJ, Saiki MK, Aldrich TW (1986) Embryonic mortality and abnormalities of aquatic birds: apparent impacts of selenium from irrigation drain water. Sci Total Environ 52:49–63

Pilon-Smits EAH, Hwang S, Lytle CM, Zhu Y, Tai JC, Bravo RC, Chen Y, Leustek T, Terry N (1999) Overexpression of ATP sulfurylase in Indian mustard leads to increased selenate uptake, reduction, and tolerance. Plant Physiol 119:123–132

Ravanel S, Gakiere B, Job D, Douce R (1998) Cystathionine-γ-synthase from Arabidopsis thaliana: purification and biochemical characterization of the recombinant enzyme overexpressed in Escherichia coli. Biochem J 331:639–648

Rosenfeld I, Beath OA (1964) Selenium, geobotany, biochemistry, toxicity, and nutrition. Academic, New York

Saiki MK, Lowe TP (1987) Selenium in aquatic organisms from subsurface agricultural drainage water, San Joaquin Valley, California. Arch Environ Contam Toxicol 19:496–499

Skorupa JP (1998) Selenium poisoning of fish and wildlife in nature: lessons from twelve real-world examples. In: Frankenberger WT Jr, Engberg RA (eds) Environmental chemistry of selenium. Dekker, New York, pp 315–354

Stadtman TC (1990) Selenium biochemistry. Annu Rev Biochem 59:111–127

Suzuki A, Shirata Y, Ishida H, Chiba Y, Onouchi H, Naito S (2001) The first exon coding region of cystathionine-γ-synthase gene is necessary and sufficient for down regulation of its own mRNA accumulation in transgenic Arabidopsis thaliana. Plant Cell Physiol 42:1174–1180

Tagmount A, Berken A, Terry N (2002) An essential role of S-adenosyl-l-methionine S-methyltransferase in selenium volatilization by plants. Methylation of selenomethionine to selenium-methyl-l-selenium-methionine, the precursor of volatile selenium. Plant Physiol 130:847–856

Terry N, Carlson C, Raab TK, Zayed AM (1992) Rates of selenium volatilization among crop species. J Environ Qual 21:341–344

Terry N, Zayed AM, de Souza MP, Tarun AS (2000) Selenium in higher plants. Annu Rev Plant Physiol Plant Mol Biol 51:401–432

von Vleet JF, Ferrans VJ (1992) Etiological factors and pathologic alterations in selenium–vitamin E deficiency and excess in animals and humans. Biol Trace Elem Res 33:1–21

Ward M, Gray A (1996) Vapor generation accessory VGA-77. Varian Australia Pty Ltd, Publication No 85-101047-00

Wilber CG (1980) Toxicology of selenium: a review. Clin Toxicol 17:171–230

Zayed AM, Terry N (1994) Selenium volatilization in roots and shoots: effects of shoot removal and sulfate level. J Plant Physiol 143:8–14

Zeh M, Casazza AP, Kreft O, Roessmer U, Bieberich K, Willmitzer L, Hoefgen R, Hesse H (2001) Antisense inhibition of threonine synthase leads to high methionine content in transgenic potato plants. Plant Physiol 127:791–802

Acknowledgements

This work was supported by U.S. National Science Foundation (NSF) CAREER grant # MCB-9982432 to E.A.H.P.S. We thank Tom Leustek for generously providing the CGS gene construct and CGS antibodies, and Mark de Souza, Gulnara Garifullina and Stormy Dawn Lindblom for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Van Huysen, T., Abdel-Ghany, S., Hale, K.L. et al. Overexpression of cystathionine-γ-synthase enhances selenium volatilization in Brassica juncea . Planta 218, 71–78 (2003). https://doi.org/10.1007/s00425-003-1070-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00425-003-1070-z