Abstract

The main goal of this study was to develop and test a capsule assembly for use in piston-cylinder experiments where oxygen fugacity could be controlled in the vicinity of the QFM buffer without H2O loss or carbon contamination of the sample material. The assembly consists of an outer Pt-capsule containing a solid buffer (Ni–NiO or Co–CoO) plus H2O and an inner AuPd-capsule, containing the sample, H2O and a Pt-wire. No H2O loss is observed from the sample, even after 48 h, but a slight increase in H2O content is found in longer runs due to oxygen and hydrogen diffusion into the AuPd-capsule. Oxygen fugacity of runs in equilibrium with the Ni–NiO (NNO) and Co–CoO (CoCO) buffers was measured by analyzing Fe dissolved in the Pt-wire and in the AuPd-capsule. The second method gives values that are in good agreement with established buffer values, whereas results from the first method are one half to one log units higher than the established values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The most serious problems in piston-cylinder experiments have been iron loss to capsule materials, H2O loss or gain of the sample, graphite contamination, and inadequate oxygen fugacity control. Any one of these issues can significantly change the phase equilibria and thermodynamics of the system.

Iron loss

The iron loss problem can be eliminated or notably reduced by choosing the appropriate capsule material. Platinum, gold, graphite and AgPd alloys have been the most popular capsule materials, each having its advantages and disadvantages. Gold melts at too low a temperature for melting experiments on mafic or ultramafic rocks, graphite imposes a very low oxygen fugacity on the sample, and Pt absorbs too much iron. Even Fe presaturated AgPd-capsules have been reported to dissolve large amounts of Fe from the melt (Baker and Eggler 1987).

Using Au-rich AuPd-capsules in piston-cylinder experiments effectively reduces iron loss from the sample charge to the containing capsule. The melting point of Au80Pd20 at 1 atm is 1,357 °C, which should be high enough for most melting experiments (Okamoto and Massalski 1985). Kawamoto and Hirose (1994) have shown that, under wet conditions at 1,225–1,400 °C, 5–15 kbar and at oxygen fugacities 1.3 log units above the NNO buffer, iron loss to Au75Pd25 is less than 4 % after 24 h. Increasing the Au content of the capsule to 90 % decreased the iron loss even further. The iron loss is \( f_{{{\text{O}}_{2} }} \) dependant and would be expected to increase under reducing conditions. At 1 atm and oxygen fugacities of 10−7 and 10−8 bar, iron loss to Au75Pd25-wire was also investigated and found to be less than 5 % after 48 h. These results have been confirmed by Hall et al. (2004) who found iron loss to capsules at QFM − 1 to QFM + 1, 10 kbar and 1,300–1,350 °C, to be less than 4 %.

Hydrogen permeation and H2O loss

It is often assumed that a properly welded noble metal capsule is impermeable to all but hydrogen, and any changes observed in the sample can be explained by hydrogen loss or gain. H2O loss from capsules is often reported and is usually explained by hydrogen diffusion through the capsule walls.

There is extensive information in the literature on the permeability (product of solubility and diffusivity) of hydrogen through various membrane materials used in industry for hydrogen separation (Ockwig and Nenoff 2007), but research in this area has mostly focused on Pd-rich PdAu- and PdAg-alloys with emphasis on achieving maximum hydrogen permeability. Measurements of hydrogen permeability of low-Pd alloys commonly used in petrological experiments have not been done. At low pressures, the diffusion of hydrogen through pure metals and Pd-rich alloys is well documented (Grashoff et al. 1983; Knapton 1977; Wipf 2001), but not much high-pressure and high-temperature data are available. Solubilities can, however, often be calculated when reliable low-pressure data are available, and Fukai (1992) has shown that the solubility of hydrogen in most metals increases by many orders of magnitude in the piston-cylinder pressure range.

Ebisuzaki et al. (1968) determined diffusion and solubility of hydrogen in Pt at 1 atm and up to 1,000 °C, and their permeability values are in good agreement with values obtained at 2 kbar by Chou et al. (1978) as corrected by Harvie et al. (1980). The extrapolated permeability constant at 1,200 °C is 2.0 × 10−9 g-atom cm−1 s−1 bar−0.5.

Chou (1986) measured hydrogen permeability at 2 kb and 450–812 °C of some noble metals and alloys used in geochemical experiments and found permeation rates of Au and Ag to be the lowest of those measured. The permeation rate of Ag70Pd30 was shown to be 50 times that of Au at the highest temperatures. A small amount of Pd in an alloy increases the permeability exponentially since Pd has high catalytic activity for hydrogen and a unique ability to dissolve large amounts of hydrogen (Gade et al. 2010; Knapton 1977). Maximum permeability in AgPd alloys is attained at 20 wt% Ag (Holleck 1970). Morreale et al. (2003) report a permeation constant of 2.0 × 10−7 g-atom cm−1 s−1 bar−0.5 for hydrogen in pure Pd at 1,200 °C and Nishikawa et al. (1996) a permeation constant for hydrogen in Ag30Pd70 of 2.5 × 10−7 g-atom cm−1 s−1 bar−0.5 (extrapolated values), which is two orders of magnitude higher than the permeation constant for hydrogen in Pt.

Hydrogen permeation in AuPd alloys is similar to that in AgPd alloys; alloying Pd with 5–20 % Au doubles the permeability (Gryaznov 2000), but the permeability decreases in alloys with more than 50 wt% Au and approaches that of pure Au exponentially as the Au content of the alloy increases (Knapton 1977; Maestas and Flanagan 1973). The extrapolated permeation constant for hydrogen in pure Au at 1,200 °C is 2.0 × 10−9 g-atom cm−1 s−1 bar−0.5 (Chou 1986).

Although the hydrogen permeability of Au75–80Pd20–25 alloys cannot be determined exactly from the available data, it is clearly high enough to be of concern in experimental work as confirmed by Hall et al. (2004) who observed H2O loss from Au80Pd20-capsules in a double-capsule assembly with basalt packing in the outer Pt-capsule. They found the H2O loss to be oxygen fugacity dependant, being on the average 9 % from QFM + 1 mixes and 32 % relative from QFM-1 mixes at 10 kbar and 1,300 °C after 24 h. The H2O loss was explained by hydrogen diffusion through capsule walls.

Attempts at reducing or eliminating hydrogen loss from capsules have involved surrounding the capsule with Pyrex powder (Jakobsson and Holloway 1986) or pyrophyllite. Freda et al. (2001) showed that H2O loss at 1,200 °C and 10 kbar could be substantially reduced in samples containing 5.6 wt% H2O and eliminated in samples containing 2 wt% H2O.

Oxygen permeation

Hydrogen may not be the only cause of H2O loss. Truckenbrodt and Johannes (1999) used solid compounds that generate oxygen and other volatiles at experimental conditions to examine oxygen loss from Au, Pt and Ag75Pd25-capsules in piston-cylinder experiments at 10 kbar. No loss was detected at temperatures up to 1,000 °C, but at 1,100 °C, as much as 80 % oxygen was lost from Pt-capsules. In experiments with H2O in Pt-capsules, the H2O loss was 71 and 76 % at 1,100 °C after 6 days. They did not attribute this loss to oxygen permeation through capsule walls but suggested imperfect capsule manufacturing or impurities in the Pt tubing.

Patiño Douce and Beard (1994) reported severe H2O loss from gold capsules in 5–31 day piston-cylinder experiments at 10 kbar and 1,000 °C and suggested molecular H2O diffusion through capsule walls. Such H2O permeability in noble metals has not been documented yet, but some limited data are available on the solubility and diffusion of oxygen in noble metals. Velho and Bartlett (1972) determined diffusivity and solubility of oxygen in Pt at 1 atm and found the permeation to be quite small in the temperature interval 1,435–1,504 °C (~10−13 at 1,450 °C). Hartung (1975) found the permeability of oxygen in Pt at 700–1,000 °C to be below his detection limit of 10−13 g-atom cm−1 s−1, but Brook et al. (1971) measured a significant permeability constant of oxygen in Pt of approximately 10−9 at 1,450 °C. The solubility of oxygen in Pd has been measured at 1 atm by Jehn and Grallath (1984) and Gegner et al. (2009) who also arrived at a permeability constant for oxygen permeation in Pd at 810–1,300 °C (~10−11 g-atom cm−1 s−1 at 1,200 °C).

The available data show that the permeability of oxygen in the alloys used for piston-cylinder capsules is several orders of magnitude less than that for hydrogen and could probably be ignored except in longer runs such as those reported by Patiño Douce and Beard (1994) and Truckenbrodt and Johannes (1999).

Carbon permeation

Selman et al. (1970) investigated the solubility and diffusion of carbon in Pt and Pd and found the solubility of carbon in Pd to be more than 0.4 wt% and in Pt to be less than 0.2 wt% at 1,400 °C. Diffusion was not measured exactly but reported to be “rapid through heated membranes.” The first mention of carbon diffusion in the geochemical literature is by Watson et al. (1982) who suggested that reduced carbon might diffuse through Pt-capsules at high P and T. This was later confirmed by Watson (1987) who found carbon to be slightly soluble in Pt and diffuse rather easily with a diffusivity of ~10−5 cm2 s−1 at temperatures above 1,200 °C, corresponding to a permeation constant of ~5.0 × 10−12 g-atom cm−1 s−1 at 1,200 °C. At 15 kbar and 1,300 °C, a uniform concentration of carbon in Pt was achieved in less than 2 h. Yokoyama et al. (1998) measured solubility and diffusion of C in Pd at 1 atm and found the solubility to be much higher than that measured in Pt by Watson (1987), the diffusion coefficient to be similar and the permeability at 1,200 °C to be ~10−10 g-atom cm−1 s−1, which is only an order of magnitude lower than the permeability of hydrogen in the noble metals measured by Chou (1986).

Blackening of the sample in piston-cylinder experiments is sometimes reported but may often be overlooked. It is usually attributed to hydrogen infiltration and subsequent reduction in CO2 and graphite precipitation. While hydrogen permeation of noble metal capsules may indeed often be the cause of sample blackening, carbon contamination from the graphite furnace must also be considered. This has been confirmed by Brooker et al. (1998) who investigated sample blackening in piston-cylinder experiments at 1,450–1,700 °C and 10–25 kbar using 12C and 13C isotopes. Their results showed a clear infiltration of carbon from the graphite furnace into the capsule. Moore et al. (2008) observed apparent CO2 diffusion into a double-capsule assembly at 3–5 kbar and 1,200 °C after 24 h which they explained by migration of carbon from the graphite furnace.

Oxygen fugacity and double-capsules

The hydrogen diffusivity in noble metal capsules can be utilized to control oxygen fugacity by using double-capsules similar to those used in hydrothermal experiments as pioneered by Eugster (1957) and further developed by Eugster and Wones (1962) and Eugster and Skippen (1967). This double-capsule technique was first used in piston-cylinder experiments by Ganguly and Newton (1968) to fix oxygen fugacity at the NNO and HM buffers and has since then been modified and used by many.

The technique relies on the diffusion of hydrogen from an outer capsule, containing a solid buffer and H2O, to the inner capsule containing the charge and H2O.

The equilibria involved in NNO-buffered reactions are as follows:

where K is the equilibrium constant, a is activity, f is fugacity, and γ is fugacity coefficient.

When both buffer phases are present, the activities of Ni and NiO (or Co and CoO) are equal to unity and the oxygen fugacity is fixed. The fugacities of H2O and H2 can then be calculated, if fugacity coefficients are known, using Eqs. (2b) and (3b). The calculations are usually simplified by omitting the last term in Eq. (3b).

As hydrogen diffuses from the outer capsule, the hydrogen fugacities in both capsules will become identical and so will the oxygen fugacities, both being fixed by the solid buffer. This holds true only when the fluid phases in both capsules are identical. If carbon infiltrates the outer capsule, the fluid in the outer capsule would become a COH-fluid, while the fluid in the inner capsule remains an OH-fluid. Equations (3a, 3b) can then be rewritten as:

The fluid composition in the outer capsule is no longer invariant, but the oxygen fugacity is still fixed by the buffer. With increased carbon activity in the outer capsule, the hydrogen fugacity decreases resulting in higher oxygen fugacities in the inner capsule. Table 1 shows results from fluid phase calculations at increasing carbon activities (increasing carbon contamination) of the fluid using Eq. (3*b) with fugacity coefficients from Saxena and Fei (1987) assuming ideal mixing [French (1966); Holloway (1977)]. The calculations show that to raise the oxygen fugacity of either the NNO or CoCO buffers by half a log unit, a severe graphite flux into the outer capsule would be required, resulting in almost one-to-one ratio of CO2/H2O.

Experimental and analytical

The starting material for all oxygen fugacity experiments was BHE-34, a transitional-alkalic basalt from Hekla volcano (Table 2). Starting material for the albite experiment was synthetic albite glass obtained from John R. Holloway (Mix #68). The albite was remelted in a Pt crucible at 1,200 °C and checked with FTIR for dryness. The tungsten used in the tungsten experiment (Fluka 95390) was scrubbed with a 45/45/10 H2/N2/Ar gas at 1,000 °C for 3 h to eliminate any surface oxidation.

The capsule assembly consists of an outer Pt-capsule (4.5 mm OD, 5 mm long, 0.07 mm wall thickness) and inner AuPd-capsule (3 mm OD) (Au75Pd25 or Au80Pd20) (see Figs. 1, 6) and is similar to that used before by several investigators (e.g., Brey and Green 1975; Brooker et al. 2001; Hall et al. 2004; Moore et al. 2008). To prevent the AuPd-capsule from coming into contact with the buffer phases, which would lead to alloying and subsequent melting of the capsule, it is embedded in finely ground Al2O3 that can, if a sample of the fluid is desired (Frost and Wood 1997), be mixed with coarser precracked corundum and separated from the buffer with a Pt-divider.

The inner capsule was loaded with 30–40 mg of the starting material, H2O and a 2–3 mg Pt-wire (0.2 mm Ø) used for \( f_{{{\text{O}}_{2} }} \)-measurements (Medard et al. 2008). The capsule was star-crimped, frozen and arc-welded shut. Capsules used in dry experiments, containing albite and tungsten, were welded almost shut, placed in a closed, argon-filled glass container, which was then vacuated and refilled three times with Ar before the final weld.

The buffer in the outer capsule consisted of approximately 30 mg pure metal-wire or -foil (Ni or Co) and 30 mg metal oxide (NiO or CoO). The capsule was welded almost shut, leaving a small opening between capsule and lid, the H2O (1–2 mg) inserted with a syringe through the opening, the capsule frozen and then welded shut. Both capsules were weighed before and after welding and kept for at least 24 h above 100 °C to check for H2O loss.

The experiments were conducted at 1,200 °C and 10 kbar for 8–72 h. Capsules were surrounded with Pyrex powder to deter hydrogen and carbon diffusion into the capsules (Jakobsson and Holloway 1986), the run quenched isobarically in 2–3 s to less than 600 °C, the capsules cleaned in HF, weighed, punctured, weight loss measured at 0 and 25 °C and cut in two halves for visual inspection and other analyses (microprobe, ion probe, FTIR).

Insufficient material was left over for Mössbauer after standard analyses, but two samples were prepared especially for Mössbauer analysis. To determine the inherent oxygen fugacity of the starting material, a sample with 2.9 wt% H2O was brought to 1,225 °C in a sealed Pt-capsule and quenched after 5 min, and one sample was prepared in the usual way with NNO as buffer.

Mössbauer analyses were done at Aarhus University using a conventional constant-acceleration system with a 10 mCi 57Co/Rh source calibrated relative to the center of the spectrum of α-Fe at room temperature.

The H2O content of four samples was analyzed at the University of Edinburgh with a Cameca 1270 ion microprobe. The analyses were made using a 5 nA 16O-primary beam of approximately 15 keV net impact energy. The area analyzed was approximately 15 μm across. The surface around the sputter pit was precleaned by rastering the beam over 15 μm2 for 2 min. High-energy (55–95 eV) positive secondary ions were measured. Concentrations were determined using the H/Si ratios measured on both basaltic glass standards and the unknowns under identical conditions. The background signal was determined using a blank de-volatilized glass and an olivine crystal.

Microprobe analyses were done at the Institute of Earth Sciences with an ARL-SEMQ instrument. Beam diameter was 2 μm, beam current 15 nA, and accelerating potential was set to 15 kV. Counting times for glasses were 40 s for all elements except K and P where counting times were 20 s and background was corrected using the MAN-procedure. Counting times for metal analyses were 40 s for both element and background. SEM analyses were done with a Zeiss Supra 25 FE-SEM with a Gemini column at a working distance of 8.5 mm and EHT equal to 20 kV. Several accredited glass compositions were used as standards for microprobe glass analyses and pure metals for Pt, Pd, Au and Fe analyses.

FTIR measurements were done on 100–400 μm polished sections using a Bruker IFS 66 FTIR microscope with an MCT detector corrected for nonlinearity (Keens and Simon 1990). The H2O overtones at 4,500 and 5,200 cm−1 were used to calculate dissolved H2O in the glasses. Densities were estimated using the Gladstone Dale rule (Silver et al. 1990), glass thickness measured with a digital dial indicator, and baselines were corrected using procedure GG as described by Ohlhorst et al. (2001) where gaussian curves are fitted to the relevant spectral regions. A single extinction coefficient for each band was determined from the ion probe results: 0.9218 for the band at 5,200 cm−1 and 0.6821 for the band at 4,500 cm−1. The H2O content of the glasses used in the extinction coefficient determination has a very narrow range of 3.45–4.33 wt%, and the calculated extinction coefficients are, therefore, of limited general value.

Experimental results

The experimental conditions were quite close to the liquidus of the sample composition, and only glass and a metallic iron-rich phase (determined by SEM), too small to analyze, were observed in the run products. Consequently, the glass compositions vary in iron content, with iron being absorbed by the Pt-wire, the capsule and the iron-rich phase. Microprobe analyses of starting material, glasses and calculations of oxygen fugacity are reported in Table 2.

Figure 2 shows iron content of the sample material as a function of time. “Iron loss” in the NNO-buffered experiments ranges from 7.5 % after 8 h to 48 % after 72 h. “Iron loss” in the more reduced CoCO experiments is higher as would be expected, since more metallic iron is present, and ranges from 26 % after 8 h to more than 60 % after 70 h.

Two runs (#51 and #52) contained precracked corundum in the packing material, and several fluid inclusions were formed in the corundum. In both cases, the inclusions contained H2O and a small CO2 bubble as analyzed by the FTIR microscope, confirming diffusion of graphite into the outer capsule. Assuming that weight losses of punctured capsules (Table 2) at 0 °C and at 100 °C correspond to CO2 and H2O, respectively, mole fractions of these two species in the outer capsule fluid phase can be estimated. While such calculations are neither accurate nor precise, they give an indication of how much carbon diffused into the outer capsule during the run. The highest CO2 concentration was found in run #63 with approximately 20 % mol CO2 corresponding to a raise in oxygen fugacity of 0.2 log units (Table 1).

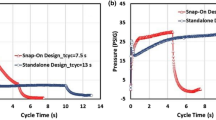

Figures 3 and 4 show the results of oxygen fugacity determinations of runs in equilibrium with the CoCO and the NNO buffers. The oxygen fugacity of the starting material was calculated from the Mössbauer Fe+2/Fe+3 ratio using equation 7 from Kress and Carmichael (1991) and was found to be log \( f_{{{\text{O}}_{2} }} \) = −7.75 that is close to the QFM buffer at 10 kb and 1,200 °C (QFM log \( f_{{{\text{O}}_{2} }} \) = −7.85). The oxygen fugacities of the glasses were determined by analyzing the iron content of the Pt-wire and by analyzing iron dissolved in the AuPd-capsule and applying the calibration by Medard et al. (2008) for Fe dissolved in Pt and the calibration by Barr and Grove (2010, Eq. 2) for Fe dissolved in AuPd alloys.

Oxygen fugacity of glasses in equilibrium with the CoCO buffer versus run duration. The triangle represents calculations based on Mössbauer analyses of the starting material, and the Fe–Pt and Fe–Au–Pd values are based on iron dissolved in a Pt-wire and in the capsule, respectively. Errors for Pt–Fe–\( f_{{{\text{O}}_{2} }} \) estimated as ±0.2 and for Pd–Au–Fe–\( f_{{{\text{O}}_{2} }} \) as ±0.4 log units (Barr and Grove 2010; Medard et al. 2008)

Oxygen fugacity of glasses in equilibrium with the NNO buffer versus run duration. Triangles show oxygen fugacity calculations based on Mössbauer analyses, and the Fe–Pt and Fe–Au–Pd values are based on iron dissolved in a Pt-wire and in the capsule, respectively. Errors for Pt–Fe–\( f_{{{\text{O}}_{2} }} \) estimated as ±0.2 and for Pd–Au–Fe–\( f_{{{\text{O}}_{2} }} \) as ±0.4 log units (Barr and Grove 2010; Medard et al. 2008)

Results from the Fe-AuPd measurements are in good agreement with the established buffer values of the NNO and CoCO buffers as reported by O’Neill and Pownceby (1993), log \( f_{{{\text{O}}_{2} }} \) = −7.42 and −8.86, respectively. The largest deviation was −0.59 log units for the NNO-runs with an average deviation of −0.33 log units for the CoCO-runs; the largest deviation from the buffer value is 0.55 log units with an average of 0.21 log units. The single Mössbauer measurement of run #81 is in good agreement with the NNO buffer value.

While oxygen fugacities, as measured using iron dissolved in the Pt-wire, reflect the difference in oxygen fugacity imposed by the different buffers, the obtained values are consistently higher than both the buffer and Fe-AuPd values. This discrepancy is most likely due to insufficient run time for the PtFe alloy to reach equilibrium at 1,200 °C: the starting composition was pure Pt-wire not a PtFe alloy as recommended by Medard et al. (2008).

Figure 5 shows the H2O content of the run products as measured with the ion probe and with FTIR (for the sake of clarity only one of the 48 h runs is shown). No H2O loss is observed, and the analyzed H2O content agrees well with the loaded values after 8 h run duration. As run duration increases, the H2O content of the samples increases and shows an increase of 25 % after 71 h (run #61) indicating oxygen as well as hydrogen diffusion into the inner capsule. To investigate this further, two runs were done at 10 kbar and 1,200 °C, one with dry albite, the other with pure W, as starting material. FTIR analyses of the albite showed 0.2 wt% H2O after 71 h at 1,200 °C, and since no carbon species were observed in the glass, this increase in H2O content cannot be ascribed to partial failure of the capsule or to micro cracks. In the W-run (68 h), a rim of micron sized WO2 particles and WO2 pockets (SEM analysis) was observed at the capsule/W interface suggesting that AuPd-capsules are permeable to oxygen as well as hydrogen at these conditions (Fig. 6). No W was found to alloy with the capsule.

Cross-section of a tungsten run showing the AuPd-capsule in the center surrounded with Al2O3. The buffer phases Ni (white) and NiO (gray) are kept from physical contact with the AuPd-capsule with a Pt-divider. The inset is a SEM photograph of tungsten and tungsten dioxide from the lower right hand corner of the AuPd-capsule. A black line is drawn at the capsule/sample boundary

In his review of this manuscript, A. C. Withers suggested that the H2O increase could be due to Fe dissolving in the capsule making oxygen available to the hydrogen and increasing the H2O content of the melt according to:

While this could explain H2O increase in runs containing Fe, the H2O content of the albite glass and the presence of WO2 in the tungsten run can only be explained by oxygen diffusion into the capsule.

Conclusions

A double-capsule assembly, consisting of an outer Pt-capsule and an inner AuPd-capsule with a solid buffer and H2O in the outer capsule and the sample plus H2O in the inner capsule, is shown to reach oxygen fugacity equilibrium with the solid buffer in less than 8 h and maintains it as long as both buffer phases are present.

The oxygen fugacity can be conveniently monitored by analyzing the iron content of the AuPd-capsule, and the fluid in the outer capsule can be captured in fluid inclusions by using fractured Al2O3 as packing material.

Carbon from the graphite furnace diffuses through the outer capsule walls as shown in H2O–CO2 fluid inclusions formed in two experiments containing precracked corundum in the packing material. The initial OH-fluid in the outer capsule is thus converted to a COH-fluid and the hydrogen fugacity is lowered, resulting in a slightly increased oxygen fugacity in the inner capsule. A severe graphite contamination corresponding to 50:50 molar H2O/CO2 would increase the inner capsule oxygen fugacities by approximately 0.5 log units.

Carbon contamination of the sample in the inner capsule is eliminated by carbon reacting with H2O in the outer capsule to form CO2 and CO.

In longer duration runs, a slight increase in H2O content of the sample is observed, probably due to hydrogen and oxygen diffusion into the inner capsule.

References

Baker DR, Eggler DH (1987) Compositions of anhydrous and hydrous melts coexisting with plagioclase, augite, and olivine or low-Ca pyroxene from 1 atm to 8 kbar: application to the Aleutian volcanic center of Atka. Am Mineral 72(1–2):12–28

Barr J, Grove T (2010) AuPdFe ternary solution model and applications to understanding the \( f_{{{\text{O}}_{2} }} \) of hydrous, high-pressure experiments. Contrib Mineral Petrol 160(5):631–643

Brey G, Green DH (1975) The role of CO2 in genesis of olivine melilite. Contrib Mineral Petrol 49(2):93–103

Brook RJ, Pelzmann WL, Kroger FA (1971) Platinum electrodes and calcia-stabilized zirconia—relation between electrode processes and electrode structure. J Electrochem Soc 118(2):185–192

Brooker R, Holloway JR, Hervig R (1998) Reduction in piston-cylinder experiments: the detection of carbon infiltration into platinum capsules. Am Mineral 83(9–10):985–994

Brooker RA, Kohn SC, Holloway JR, McMillan PF (2001) Structural controls on the solubility of CO2 in silicate melts: part I: bulk solubility data. Chem Geol 174(1–3):225–239

Chou IM (1986) Permeability of precious metals to hydrogen at 2-kb total pressure and elevated-temperatures. Am J Sci 286(8):638–658

Chou IM, Eugster HP, Berens P, Weare JH (1978) Diffusion of hydrogen through platinum membranes at high-pressures and temperatures. Geochim Cosmochim Acta 42(3):281–288

Ebisuzaki Y, Kass WJ, O’Keefe M (1968) Solubility and diffusion of hydrogen and deuterium in platinum. J Chem Phys 49(8):3329–3332

Eugster HP (1957) Heterogeneous reactions involving oxidation and reduction at high pressures and temperatures. J Chem Phys 26(6):1760–1761

Eugster HP, Skippen GB (1967) Igneous and metmorphic reactions involving gas equilibria. In: Abelson PH (ed) Researches in geochemistry, vol 2. Wiley, New York, pp 492–520

Eugster HP, Wones DR (1962) Stability relations of the ferruginous biotite, annite. J Petrol 3(1):82–125

Freda C, Baker DR, Ottolini L (2001) Reduction of water loss from gold-palladium capsules during piston-cylinder experiments by use of pyrophyllite powder. Am Mineral 86(3):234–237

French B (1966) Some geological implications of equilibrium between graphite and a C-H-O gas phase at high temperatures and pressures. Rev Geophys 4(2):223–250

Frost DJ, Wood BJ (1997) Experimental measurements of the properties of H2O–CO2 mixtures at high pressures and temperatures. Geochim Cosmochim Acta 61(16):3301–3309

Fukai Y (1992) The metal-hydrogen system, vol 21. Springer, Berlin, p 355

Gade SK, Coulter KE, Way JD (2010) Effects of fabrication technique upon material properties and permeation characteristics of palladium–gold alloy membranes for hydrogen separations. Gold Bull 43(4):287–297

Ganguly J, Newton RC (1968) Thermal stability of chloritoid at high pressure and relatively high oxygen fugacity. J Petrol 9(3):444–466

Gegner J, Horz G, Kirchheim R (2009) Diffusivity and solubility of oxygen in solid palladium. J Mater Sci 44(9):2198–2205

Grashoff GJ, Pilkington CE, Corti CW (1983) The purification of hydrogen. A review of the technology emphasising the current status of palladium membrane diffusion. Plat Met Rev 27(4):157–169

Gryaznov V (2000) Metal containing membranes for the production of ultrapure hydrogen and the recovery of hydrogen isotopes. Sep Purif Methods 29(2):171–187

Hall LJ, Brodie J, Wood BJ, Carroll MR (2004) Iron and water losses from hydrous basalts contained in Au80Pd20 capsules at high pressure and temperature. Mineral Mag 68(1):75–81

Hartung R (1975) Untersuchung zur Sauerstoffdurchlässigkeit des Platins bei hohen Temperaturen mit einer Festelektrolytzelle. Z Phys Chem 256(6):997–1000

Harvie C, Weare JH, Okeefe M (1980) Permeation of hydrogen through platinum: a re-evaluation of the data of Chou et al. Geochim Cosmochim Acta 44(6):899–900

Holleck GL (1970) Diffusion and solubility of hydrogen in palladium and palladium–silver alloys. J Phys Chem 74(3):503–511

Holloway JR (1977) Fugacity and activity of molecular species in supercritical fluids. In: Fraser DG (ed) Thermodynamics in geology. D. Reidel, Dordrecht, pp 161–181

Jakobsson S, Holloway JR (1986) Crystal–liquid experiments in the presence of a C–O–H fluid buffered by graphite + iron + wüstite: experimental method and near-liquidus relations in basanite. J Volcanol Geotherm Res 29:265–291

Jehn H, Grallath E (1984) Solid solubility of oxygen in palladium. In: Kudryk V, Corrigan DA, Liang WW (eds) AIME annual meeting precious metals: mining, extraction and processing. Metallurgical Society of AIME, Los Angeles

Kawamoto T, Hirose K (1994) Au–Pd sample containers for melting experiments on iron and water bearing systems. Eur J Mineral 6:381–385

Keens A, Simon A (1990) Correction of non-linearities in detectors in Fourier transform spectroscopy. US Patent 4,927,269, 22 May 1990

Knapton AG (1977) Palladium alloys for hydrogen diffusion membranes. A review of high permeability materials. Plat Met Rev 21(2):45–50

Kress VC, Carmichael ISE (1991) The compressibility of silicate liquids containing Fe2O3 and the effect of compositions, temperature, oxygen fugacity and pressure on their redox states. Contrib Mineral Petrol 108:82–92

Maestas S, Flanagan TB (1973) Diffusion of hydrogen in gold–palladium alloys. J Phys Chem 77(6):850–854

Medard E, McCammon CA, Barr JA, Grove TL (2008) Oxygen fugacity, temperature reproducibility, and H2O contents of nominally anhydrous piston-cylinder experiments using graphite capsules. Am Mineral 93(11–12):1838–1844

Moore G, Roggensack K, Klonowski S (2008) A low-pressure-high-temperature technique for the piston-cylinder. Am Mineral 93(1):48–52

Morreale BD, Ciocco MV, Enick RM, Morsi BI, Howard BH, Cugini AV, Rothenberger KS (2003) The permeability of hydrogen in bulk palladium at elevated temperatures and pressures. J Membr Sci 212(1–2):87–97

Nishikawa M, Shiraishi T, Kawamura Y, Takeishi T (1996) Permeation rate of hydrogen isotopes through palladium–silver alloy. J Nucl Sci Technol 33(10):774–780

Ockwig NW, Nenoff TM (2007) Membranes for hydrogen separation. Chem Rev 107(10):4078–4110

Ohlhorst S, Behrens H, Holtz F (2001) Compositional dependence of molar absorptivities of near-infrared OH- and H2O bands in rhyolitic to basaltic glasses. Chem Geol 174(1–3):5–20

Okamoto H, Massalski T (1985) The Au–Pd (gold–palladium) system. J Phase Equilib 6(3):229–235

O’Neill HS, Pownceby MI (1993) Thermodynamic data from redox reactions at high-temperatures. I. An experimental and theoretical assessment of the electrochemical method using stabilized zirconia electrolytes, with revised values for the Fe–FeO, Co–CoO, Ni–NiO and Cu–Cu2O oxygen buffers, and new data for the W–WO2 buffer. Contrib Mineral Petrol 114(3):296–314

Patiño Douce AE, Beard JS (1994) H2O loss from hydrous melts during fluid-absent piston cylinder experiments. Am Mineral 79(5–6):585–588

Saxena SK, Fei Y (1987) High pressure and high temperature fluid fugacities. Geochim Cosmochim Acta 51:783–791

Selman GL, Ellison PJ, Darling AS (1970) Carbon in platinum and palladium. Solubility determinations and diffusion at high temperatures. Plat Met Rev 14(1):14–20

Silver LA, Ihinger PD, Stolper EM (1990) The influence of bulk composition on the speciation of water in silicate glasses. Contrib Mineral Petrol 104:142–162

Truckenbrodt J, Johannes W (1999) H2O-loss during piston-cylinder experiments. Am Mineral 84:1333–1335

Velho LR, Bartlett RW (1972) Diffusivity and solubility of oxygen in platinum and Pt–Ni alloys. Metall Trans B 3(1):65–72

Watson EB (1987) Diffusion and solubility of C in Pt. Am Mineral 72(5–6):487–490

Watson EB, Sneeringer MA, Ross A (1982) Diffusion of dissolved carbonate in magmas—experimental results and applications. Earth Planet Sci Lett 61(2):346–358

Wipf H (2001) Solubility and diffusion of hydrogen in pure metals and alloys. Phys Scr T94:43–51

Yokoyama H, Numakura H, Koiwa M (1998) The solubility and diffusion of carbon in palladium. Acta Mater 46(8):2823–2830

Acknowledgments

Thanks are due to Richard Hinton for ion probe analyses, Haraldur P. Gunnlaugsson for Mössbauer measurements, Karl Grönvold for microprobe assistance and Niels Oskarsson for many fruitful discussions during the course of this study. John R. Holloway and Sigurdur Steinthorsson read drafts of the manuscript and provided valuable comments. Gordon Moore is thanked for editorial handling, Tony Withers for a constructive review, and an anonymous reviewer is thanked for his review.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by G. Moore.

Rights and permissions

About this article

Cite this article

Jakobsson, S. Oxygen fugacity control in piston-cylinder experiments. Contrib Mineral Petrol 164, 397–406 (2012). https://doi.org/10.1007/s00410-012-0743-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00410-012-0743-7