Abstract

Background

Recent data indicate that enhanced wear resistance can be obtained with new cross-linked ultra-high-molecular weight polyethylene (CL-UHMWPE) liners, in comparison with previous-generation liners. The current prospective, cohort study was undertaken to analyse whether the use of a new CL-UHMWPE (Rexpol) results in a lower wear rate than ultra-high-molecular weight polyethylene (UHMWPE) in a group of similar patients undergoing total hip arthroplasty (THA). This study provides the first clinical data with this particular CL-UHMWPE.

Methods

Between January 2001 and December 2001, patients underwent THA with biconical threaded cups and ceramic femoral heads using either a CL-UHMWPE liner (n = 50) or a regular UHMWPE liner (n = 57). At the time of the final 5-year evaluation, there were 48 patients available in the CL-UHMWPE and 54 patients available in the UHMWPE group.

Results

After a mean 5.6 years follow-up, there were no significant differences between the groups in Harris Hip Score outcomes. However, there was a 69.1% decrease in wear at 5 years for the CL-UHMWPE group in comparison with the UHMWPE group (p < 0.01).

Conclusion

The use of CL-UHMWPE significantly reduced the risk of polyethylene wear in patients undergoing THA with biconical threaded cups and ceramic femoral heads. Further follow-up is needed to determine how this will influence long-term outcomes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ultra-high-molecular weight polyethylene (UHMWPE) has been used as the main material for contact surfaces in total hip arthroplasty (THA) for over four decades. In that time period, it has become apparent that the production of wear particles associated with this material can have a significantly deleterious effect on patient outcomes [1]. The presence of these particles—especially when found in high concentrations—can stimulate an inflammatory response that promotes periprosthetic osteolysis [1–5]. In the long term, this osteolysis is responsible for the aseptic loosening of the implant that constitutes the main cause of THA failure [1].

Several changes in the manufacturing process for UHMWPE have been instituted over the last decade to make it more resistant to wear. The most relevant modifications have been the use of high-dose irradiation to increase the number of cross-links between the polymer chains and improve the final resistance of the polyethylene; the ulterior heating of the material in order to decrease the number of free radicals on the surface and limit oxidative deterioration; and sterilizing the component with gas and packaging it in a low-oxygen environment to minimize the possible oxidative effect during storage [1, 6].

The ability of the new cross-linked ultra-high-molecular weight polyethylene (CL-UHMWPE) to lower wear rates in the short term was initially suggested by experimental studies in laboratory hip simulators [7–10] and has since been corroborated in randomized clinical trials in patients undergoing THA, in which wear rates at a medium-term follow-up period favoured CL-UHMWPE over UHMWPE [11–17].

The current prospective, cohort study provides the first clinical data with a new CL-UHMWPE (REXPOL®; Smith & Nephew Orthopaedics AG, Baar, Switzerland) and, to the authors’ knowledge, is the first study to analyse this material in a ceramic–polyethylene friction pair used in biconical threaded cups. It was hypothesized that (1) this CL-UHMWPE would produce less wear than UHMWPE and (2) that there would be no relevant differences in terms of clinical outcomes or the occurrence of complications between the two groups.

Materials and methods

Patients and study design

This study was approved by the hospital ethics committee, and all patients completed an informed consent form prior to participation.

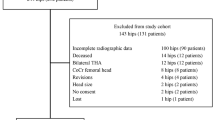

Between January 2001 and December 2001, 134 primary THAs were implanted at our centre. Seventeen patients affected by tumours, post-traumatic arthritis, rheumatoid arthritis, or sequelae from septic arthritis were excluded from the study. Six patients refused to participate. This left 111 patients with primary hip osteoarthritis for whom a THA was indicated, with 107 eventually receiving the allocated intervention (Fig. 1).

Patients were assigned to one study group or another as determined by the substitution of UHMWPE for CL-UHMWPE at our institution in June 2001. Therefore, the 57 patients in the UHMWPE arm were enrolled in the first half of the year, when only the UHMWPE was available, and the 50 patients in the CL-UHMWPE arm were enrolled in the second half of the year, when only CL-UHMWPE was available. No patients experienced changes in their surgery dates (established 2–3 months earlier) that would suppose the inclusion in a different group than the one expected.

The following baseline variables were recorded for each patient: age, body mass index (BMI), which hip was operated on, and the etiology leading to THA (osteoarthritis, avascular necrosis, other). No statistically significant differences between the two groups were found (Table 1).

At the 5-year follow-up point, three patients in the UHMWPE group and two patients in the CL-UHMWPE group could not be contacted, and were therefore considered to be lost to follow-up.

Implants

All patients received a titanium non-cemented threaded biconical cup (BICON-PLUS®; Smith & Nephew Orthopaedics AG), a 28-mm ceramic head (Biolox®: Ceramtec, Plochingen, Germany), and a titanium rectangular stem (SL-PLUS®; Smith & Nephew Orthopaedics AG).

The UHMWPE (PE Standard, Smith & Nephew Orthopaedics AG) used in this study is obtained by moulding via compression or resin GUR 1020. It is then submitted to a Gamma irradiation dose of 25.40 KGy. It does not receive subsequent thermal treatment and is sterilized by irradiation with nitrogen.

The CL-UHMWPE used in this study is obtained by moulding via compression or resin GUR 1020. It is then submitted to irradiation by means of an electron-beam at a dose of 70 KGy. It receives a subsequent thermal heating treatment and is sterilized by ethylene oxide gas.

Surgery and rehabilitation

All of the THAs were performed by two surgeons (one of whom [initials removed] is an author of this study) using the lateral Hardinge approach. Both surgeons were aware of the type of polyethylene implanted at the time of surgery according to whether it was performed before or after June 2001, and did not have the possibility of choosing one polyethylene or the other peri-surgically.

The same postsurgical rehabilitation protocol was followed by all patients. It consisted of sitting up the day after the surgery and partial weight-bearing with the aid of crutches from the second day through to the first 2 months following surgery.

Clinical outcomes

Functional evaluation after surgery was determined using the Harris Hip Score (HHS) [18]. Following the protocol at our centre, functional evaluations were performed immediately after surgery and 5 years after surgery.

Radiographic outcomes

Radiographic wear measurements were performed at the 3-month and 5-year follow-up visits. Initial wear measurements were performed 3 months following implantation so as to limit the influence of the “bedding-in” phenomena in the detection of the true wear [19].

Radiological measurements were performed by two investigators (initials removed) who were blinded as to which group each radiograph belonged. Measurements were performed on the control radiographs to determine polyethylene wear. At 3 months, measurements were made independently by each investigator, as per the centre’s follow-up protocol for THAs. At the 5-year follow-up, the two investigators performed the measurements at the same time and recorded the results by consensus.

The manual measurement system described by Dorr and Wann [20] was used to assess polyethylene wear in the metal-backed cups, by measuring the displacement of the femoral head on the horizontal line that joins the edges of the cup. For this, we subtract the distance from the lower edge and higher edge of the cup to the lower edge and higher edge of the femoral head, respectively, and divide these differences in two. As suggested by Kang et al. [21], a correction factor in dependence of the cup inclination was applied in order to increase accuracy of the method. Measurements of wear during a certain time period result in the difference of wear measured at the limits of said time period [20, 22].

Increased measurement precision was sought through the use of a caliper (X-Caliper®; Eisenlohr Technologies, Inc., Davis, CA), an instrument that allows for the elimination of possible variations in the measurements derived from magnified radiographs. In this process, the size of the prosthesis head (e.g., 28 mm) is marked as the value reference in the caliper. The caliper is then calibrated to the real measurement, given that head size is a known variable, which means that precise measurements can in turn be recorded independently of the X-ray magnification. The caliper also has the secondary advantage of allowing precise measurements on a scale of 0.1 mm (Fig. 2a–e).

a The caliper (X-Caliper®; Eisenlohr Technologies, Inc.) used during manual measurements; b the limits for the truncated cone-shaped cup and 28-mm ceramic femoral head marked on the X-ray; c 0.24 mm wear measurement at 5 years follow-up; d the centred lines of the head size-calibrated caliper match up with the limits of the head at 3 months follow-up; and e the centred lines of the head size-calibrated caliper differ from the limits of the head in 0.24 mm at 5 years follow-up due to wear

Statistical analysis

A power analysis was performed prior to beginning the study. Assuming a standard deviation of 0.25 mm, a minimal difference of 0.1 mm wear between the groups, a type I error (α) of 5%, and a power of 80% (1—type II error [β]), a sample size estimation of 49 patients for each group was obtained.

Between-group comparisons were performed with the Mann–Whitney test for continuous variables and the Pearson’s Chi-square test was used for nominal scaled variables.

Results

Patients

Patients were followed up for a mean follow-up of 5.6 years (range 5.1–6.1 years; Table 2). At the time of the final 5-year evaluation, there were 48 patients available in the CL-UHMWPE and 54 patients available in the UHMWPE group (Fig. 1).

Clinical outcomes

There was no difference between the groups in terms improvements in HHS (Table 2).

In 5 years, the only complications experienced by study patients were a case of luxation in the UHMWPE group, which was treated by reduction in tandem with temporary limitation of the adduction and flexing by orthesis, and a case of superficial infection of the surgical wound a month after surgery in the CL-UHMWPE group, which was solved by surgical cleaning without removing the implant.

Radiographic outcomes

The average linear wear detected at 5 years was 0.311 mm in the UHMWPE group, with an average linear wear rate of 0.065 mm/year, in comparison with 0.096 mm in the CL-UHMWPE group, with an average linear wear rate of 0.020 mm/year. This translates into a 69.1% decrease in wear at 5 years for the CL-UHMWPE group in comparison with the UHMWPE group (p < 0.01) (Table 2).

Discussion

Evidence from earlier in vitro studies first suggested that the use of CL-UHMWPE would reduce wear rates over those observed with UHMWPE [7–10]. These findings have since been confirmed in the clinical setting in studies with 5-year follow-up periods similar to the current analysis [11–17].

This is the first study to present clinical data with the Rexpol liner. We have shown this liner to be superior to its UHMWPE counterpart in addressing wear at the midterm follow-up period. In comparison with UHMWPE, a 69.1% decrease in wear was reported at 5 years. The average linear wear rate of 0.020 mm/year is well under the threshold of 0.05 mm/year at which it has been theorized that osteolysis could be eliminated [23]. These reductions in wear rates are in line with other medium-term clinical trials comparing CL-UHMWPE with conventional PE [11–17]. Mean annual wear rates for CL-UHMWPE ranged from 0.01 to 0.036 in these studies, accounting for reductions of up to approximately 95% in comparison with conventional PE [11–17]. When taken together, results from both these studies and the current analysis are highly supportive of the design modifications undertaken in the last decade to create this class of material.

Important data regarding the long-term clinical prospects of first-generation CL-UHMWPEs was provided by Kurtz et al., who conducted a multicentre retrieval analysis of implants revised over a 10-year-period. Their findings confirmed the superior wear performance of CL-UHMWPEs over conventional liners, with different methods of producing this material yielding comparable linear penetration rates. Aseptic loosening remained the most prevalent reason underlying revision of TKA with CL-UHMWPEs, though there was no discernible relationship between this outcome and wear. It is also worth noting that the risk of infection, which continued to be a major cause of revision (21% of cases), is likely not addressed by this bearing material [24].

Although the use of CL-UHMWPE has been reported in metal–polyethylene friction pairs inside hemispheric cups, to the authors’ knowledge this is the first study to analyze this material in a ceramic-polyethylene friction pair used in biconical threaded cups. This biconical threaded cup design has been associated with relatively good medium-term wear rates [25], but it is unknown whether metal or ceramic femoral heads will lead to different results when used with CL-UHMWPE [24].

We utilized the manual measurement system described by Dorr and Wan [20], under application of the correction method as proposed by Kang et al. [21], to ascertain wear rates in this analysis. Computerized methods were not available to us, given the absence of specialized software for the analysis of wear in biconical threaded cups. The method that we applied is known to be simple and reproducible, with an accuracy comparable to that of the computerized method from Devane [21].

A randomized design was not used in this study. If the exclusive availability of UHMWPE and CL-UHMWPE before and after June 2001, respectively, has impeded a true randomized design, the general characteristics of such a design have been maintained given that none of the patient intervention dates were modified and that all patients ended up being part of the groups they were originally intended to be upon enrolment.

Additionally, all patients were operated upon at the same institution with identical prostheses, and the absence of relevant differences between the groups at baseline was statistically confirmed. We believe limiting the number of major confounding study variables to the contact surface material sufficiently allows for a comparison between UHMWPE and CL-UHMWPE.

In conclusion, the use of CL-UHMWPE in THAs with biconical threaded cups and ceramic heads reduced wear by approximately 70% at 5 years in comparison with UHMWPE. It can be expected that the benefits of using CL-UHMWPE will be maintained over the long term, resulting in lower rates of wear and decreased particle production. In theory, the improved conditions in the periprosthetic environment could also result in less formation of osteolysis and, consequently, a reduced long-term risk of aseptic loosening of the implant, the main factor contributing to follow-up surgery at this time [1, 5]. However, randomized clinical studies with extended follow-up periods will be required to confirm the long-term clinical outcomes associated with this bearing material, including the biological effects of wear particles resulting from its use and whether results will vary according to the type of femoral head employed.

The experiments described herein comply with the current laws of the country in which they were performed (Spain).

References

Brach Del Prever EM, Bistolfi A, Bracco P, Costa L (2009) UHMWPE for arthroplasty: past or future? J Orthop Traumatol 10:1–8

Wroblewski BM, Siney PD, Fleming PA (2009) Charnley low-frictional torque arthroplasty: follow-up for 30 to 40 years. J Bone Joint Surg Br 91:447–450

Wang CT, Lin YT, Chiang BL, Lee SS, Hou SM (2010) Over-expression of receptor activator of nuclear factor-kappaB ligand (RANKL), inflammatory cytokines, and chemokines in periprosthetic osteolysis of loosened total hip arthroplasty. Biomaterials 31:77–82

Zolotarevová E, Hudeček J, Spundová M, Entlicher G (2010) Binding of proteins to ultra high molecular weight polyethylene wear particles as a possible mechanism of macrophage and lymphocyte activation. J Biomed Mater Res A 95:950–955

Maitra R, Clement CC, Scharf B et al (2009) Endosomal damage and TLR2 mediated inflammasome activation by alkane particles in the generation of aseptic osteolysis. Mol Immunol 47:175–184

Atienza C Jr, Maloney WJ (2008) Highly cross-linked polyethylene bearing surfaces in total hip arthroplasty. J Surg Orthop Adv 17:27–33

McKellop H, Shen FW, Lu B, Campbell P, Salovey R (2000) Effect of sterilization method and other modifications on the wear resistance of acetabular cups made of ultra-high molecular weight polyethylene. A hip simulator study. J Bone Joint Surg Am 82-A:1708–1725

D’Lima DD, Hermida JC, Chen PC, Colwell CW Jr (2003) Polyethylene cross-linking by two different methods reduces acetabular liner wear in a hip joint wear simulator. J Orthop Res 21:761–766

Saikko V, Calonius O, Keranen J (2002) Wear of conventional and cross-linked ultra-high-molecular-weight polyethylene acetabular cups against polished and roughened CoCr femoral heads in a biaxial hip simulator. J Biomed Mater Res 63:848–853

Wroblewski BM, Siney PD, Dowson D, Collins SN (1996) Prospective clinical and joint simulator studies of a new total hip arthroplasty using alumina ceramic heads and cross-linked polyethylene cups. J Bone Joint Surg Br 78:280–285

Digas G, Kärrholm J, Thanner J, Herberts P (2007) 5-year experience of highly cross-linked polyethylene in cemented and uncemented sockets: two randomized studies using radiostereometric analysis. Acta Orthop 78:746–754

Bitsch RG, Loidolt T, Heisel C, Ball S, Schmalzried TP (2008) Reduction of osteolysis with use of Marathon cross-linked polyethylene. A concise follow-up, at a minimum of five years, of a previous report. J Bone Joint Surg Am 90:1487–1491

García-Rey E, García-Cimbrelo E, Cruz-Pardos A, Ortega-Chamarro J (2008) New polyethylenes in total hip replacement: a prospective, comparative clinical study of two types of liner. J Bone Joint Surg Br 90:149–153

Glyn-Jones S, Isaac S, Hauptfleisch J, McLardy-Smith P, Murray DW, Gill HS (2008) Does highly cross-linked polyethylene wear less than conventional polyethylene in total hip arthroplasty? A double-blind, randomized, and controlled trial using roentgen stereophotogrammetric analysis. J Arthroplasty 23:337–343

Miyanishi K, Hara T, Kaminomachi S, Maekawa M, Iwamoto M, Torisu T (2008) Short-term wear of Japanese highly cross-linked polyethylene in cementless THA. Arch Orthop Trauma Surg 128:995–1000

Garvin KL, Hartman CW, Mangla J, Murdoch N, Martell JM (2009) Wear analysis in THA utilizing oxidized zirconium and crosslinked polyethylene. Clin Orthop Relat Res 467:141–145

Rajadhyaksha AD, Brotea C, Cheung Y, Kuhn C, Ramakrishnan R, Zelicof SB (2009) Five-year comparative study of highly cross-linked (crossfire) and traditional polyethylene. J Arthroplasty 24:161–167

Harris WH (1969) Traumatic arthritis of the hip after dislocation and acetabular fractures: treatment by mold arthroplasty. An end-result study using a new method of result evaluation. J Bone Joint Surg Am 51:737–755

Sychterz CJ, Engh CA Jr, Yang AM, Eng CA (1999) Analysis of temporal wear patterns of porous-coated acetabular components: distinguishing between true wear and so-called bedding-in. J Bone Joint Surg Am 81:821–830

Dorr LD, Wan Z (1995) Ten years of experience with porous acetabular components for revision surgery. Clin Orthop Relat Res 319:191–200

Kang JS, Park SR, Ebramzadeh E, Dorr LD (2003) Measurement of polyethylene wear in total hip arthroplasty—accuracy versus ease of use. Yonsei Med J 44:473–478

McCalden RW, Naudie DD, Yuan X, Bourne RB (2005) Radiographic methods for the assessment of polyethylene wear after total hip arthroplasty. J Bone Joint Surg Am 87:2323–2334

Dumbleton JH, Manley MT, Edidin AA (2002) A literature review of the association between wear rate and osteolysis in total hip arthroplasty. J Arthroplasty 17:649–661

Kurtz SM, Medel FJ, Macdonald DW, Parvizi J, Kraay MJ, Rimnac CM (2010) Reasons for revision of first-generation highly cross-linked polyethylenes. J Arthroplasty 25(6 Suppl):67–74

Zweymuller KA, Steindl M, Schwarzinger U (2007) Good stability and minimal osteolysis with a biconical threaded cup at 10 years. Clin Orthop Relat Res 463:128–137

Conflict of interest

The authors declare they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Orradre Burusco, I., Romero, R., Brun, M. et al. Cross-linked ultra-high-molecular weight polyethylene liner and ceramic femoral head in total hip arthroplasty: a prospective study at 5 years follow-up. Arch Orthop Trauma Surg 131, 1711–1716 (2011). https://doi.org/10.1007/s00402-011-1340-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00402-011-1340-3