Abstract

Pickering emulsions are emulsions whose drops are stabilized against coalescence by particles adsorbed at their interface. Recent research on oil/water/particle systems shows that particles can sometimes adsorb at two oil/water interfaces. Such “bridging particles” can glue together drops of oil in water or vice versa. We hypothesize that the same effect should apply in immiscible polymer blends with droplet-matrix morphologies, viz., added particles should glue together drops and give rise to particle-bridged drop clusters. We test this hypothesis in PIB-in-PDMS blends [PIB, poly(isobutylene); PDMS, poly(dimethylsiloxane)] with fumed silica particles. Direct visualization shows that the particles can indeed induce clustering of the drops, and the blends appear to show gel-like behavior. Such gel-like behavior is confirmed by dynamic oscillatory experiments. However, we are unable to conclusively attribute the gel-like behavior to droplet clustering: Association of the fumed silica particles in the bulk, which itself causes gel-like behavior, confounds the results and prevents clear analysis of the gluing effect of the particles. We conclude that PIB/PDMS/fumed silica is not a good model system, for studying particle-containing polymer blends. We instead propose that spherical monodisperse silica particles can offer a far more convenient model system, and provide direct visual evidence of gluing of PIB drops in a PDMS matrix.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

When an interface between two immiscible fluids touches a solid surface, it makes a specific equilibrium contact angle θ at the surface (Fig. 1a). Such a solid surface is partially wetting towards both the liquids. If a solid spherical particle has the same surface characteristics, the particle can adsorb at the interface such that the equilibrium contact angle is satisfied at the contact line (Fig. 1b; Edwards et al. 1991). Monolayers of such partially wettable particles adsorbed at the interfaces can stabilize emulsions of drops of one liquid dispersed in the other; such emulsions are called Pickering emulsions (Fig. 1c; Ramsden 1903; Pickering 1908; Tambe and Sharma 1994; Binks 2002). We emphasize that unlike many other surfactants, these particles are interfacially active but not amphiphilic (Binks 2002). Furthermore, partial wettability of the particle is critical to its interfacial activity; if the particle surface is fully wetted by either of the fluids (θ = 0° or 180°), the particle will not adsorb at the interface.

a An A/B interface makes a contact angle of θ at the solid surface. An angle of θ < 90° implies that the particle is preferentially wetted by fluid A. b A particle with the same solid surface comes to equilibrium, making the corresponding contact angle at the A/B interface. c A Pickering emulsion in which drops of B are stabilized by particles adsorbed at the interface. d Each particle satisfies the equilibrium contact angle condition at two A/B interfaces and bridges across the film of A. The film of fluid A is now stable, and the two “bodies” of fluid B are held together by the particles. Stabilizing a film of fluid A requires that particles be preferentially wetted by A, i.e., that 0 <θ < 90°

In many cases, the particles are wetted more by one of the two fluids than by the other (i.e., the contact angle is often far from 90°). The particles will then “sit” more into the preferentially wetting phase than into the other. Perhaps, the most common examples occur in oil/water systems: Relatively hydrophobic particles may be expected to sit more in the oil phase and vice versa. In such cases when the particles sit asymmetrically on the interface, their effects can also be “asymmetric” with respect to the two fluids. For example, in particle-stabilized emulsions, the particles generally cause the preferentially wetting phase to form the continuous phase, with the less wetting phase forced to form drops (Fig. 1c; Binks 2002). The common explanation for this is that particles can suppress coalescence if they protrude far outside the drops (i.e., the preferred phase is the continuous phase) but cannot suppress coalescence if they protrude only slightly (i.e., the preferred phase is the continuous phase).

This paper is motivated by another asymmetric effect noted recently (Vignati et al. 2003; Ashby et al. 2004; Stancik and Fuller 2004; Stancik et al. 2004; Horozov et al. 2005): Particles can simultaneously adsorb at two liquid/liquid interfaces and bridge across a film of the preferentially wetting liquid (Fig. 1d). Since the equilibrium contact angle condition must be satisfied all along both the three-phase contact lines, the thin fluid film held by these particles is now stable and resists both thinning and thickening. A dramatic illustration of this was provided by Stancik and Fuller (2004) and Stancik et al. (2004). These researchers suspended a water drop over a flat oil/water interface. The drop, as well as the flat interface, was covered with relatively hydrophobic particles. Upon lowering the drop to make contact with the interface, a monolayer of particles bridging across the oil film was observed. The drop would not coalesce with the interface (i.e., the bridging particles resisted thinning of the oil film), but it would not readily separate from the interface either (the particles resisted thickening of the oil film). Stancik et al. (2004) confirmed that this bridging effect was indeed asymmetric as expected and that only oil films could be stabilized by the relatively hydrophobic particles; water films behaved quite differently.

We hypothesize that such bridging interactions should have a significant effect when particles are added to droplet-matrix blends of immiscible homopolymers. In particular, if the particles are wetted preferentially by the continuous phase, the dispersed phase droplets should be able to stick to each other without coalescing, giving rise to drop clusters. Such clustering is likely to have rheological consequences, especially if the clusters are large or form an extended network.

In a recent paper, Vermant et al. (2004) studied the effect of adding fumed silica particles to droplet-matrix blends of poly(isobutylene) (PIB) and poly(dimethylsiloxane) (PDMS). Cryo-scanning electron microscopy images showed that the silica particles were adsorbed at the interface between PIB and PDMS. Furthermore, rheological investigations revealed that the particles could prevent coalescence in blends with droplet-matrix morphologies, provided that PIB formed the drop phase and the PDMS formed the matrix case. In the reverse morphology (PDMS drops in a PIB matrix), coalescence was not suppressed. This asymmetry of coalescence led Vermant et al. to suggest that the particles were preferentially wetted by the PDMS phase: In PIB-in-PDMS blends, these particles would then protrude well outside the drops and suppress coalescence, whereas in PDMS-in-PIB blends, coalescence would not be suppressed. Based on the discussion above, we hypothesize that in PIB-in-PDMS blends, fumed silica particles will be able to glue together PIB drops, and the resulting drop clusters will significantly affect the rheological properties of the blend. The first goal of this paper is to test this hypothesis by optical and rheological methods. If the hypothesis is borne out, i.e., bridging is indeed evident, the PIB/PDMS/fumed silica system may be a convenient model for further, much more detailed studies of the effects of particle bridging. Thus, the second goal of this paper is to critically evaluate the suitability of this system as a model system for studying particle-bridging effects in polymer blends.

Experimental

Experiments were conducted on blends of PIB (Soltex, viscosity 69 Pa s) and PDMS (Rhodia, viscosity 95 Pa s). Both homopolymers are nearly Newtonian fluids under experimental conditions. Hydrophobic fumed silica particles (Aerosil Rhodorsil R972, Degussa) were used up to 1% by weight. These are the same particles used by Vermant et al. (2004). They have a primary particle diameter of 16 nm, and the manufacturer coats them with dichlorodimethylsilane (DCDMS) to render them hydrophobic. Samples were blended by two methods, either by hand blending with a spatula (following Vermant et al.) or by a Minimax mechanical mixer (Maric and Macosko 2001), as described later in the text. Samples are designated Bx–y, where x is the weight percent of PIB in the blends (either 10 or 30%), and y is the weight percent of the fumed silica particles (either 0 or 1%).

The rheological measurements were carried out in a stress-controlled rheometer (AR 2000) using a stainless steel cone and plate geometry (cone angle of 1° and a diameter of 40 mm). Sample temperature was maintained at 23 °C with a Peltier plate device. The blends were presheared at 400 Pa for 2,000 s. Shearing was then stopped, and the dynamic moduli were measured at 25% strain in the frequency range 100–0.02 rad/s. The oscillatory measurements were repeated three times, with the sample remaining under quiescent conditions for 2 h between successive frequency sweeps.

Results

Optical microscopy of hand-mixed samples

The hypothesis is that the drops of the particle-containing blend are able to glue together and form clusters. Thus, the first goal is to validate such cluster formation by direct visualization. Obviously, cluster formation requires that drops come sufficiently close to each other so that the particles can glue them together. We considered two different ways of doing so: inducing collisions by shear flow and inducing collisions under quiescent conditions due to van der Waals forces or buoyancy forces.

The first method, shear-induced coalescence, used a homebuilt parallel plate apparatus, which consists of two glass plates that can be mounted on an ARES rheometer in a parallel plate geometry. The sample is loaded between the plates at the desired gap and subjected to the desired shear history. The plates can then be removed from the rheometer without disturbing the sample between them (i.e., maintaining the gap) and examined under a standard microscope.

A B10-1 blend was loaded in this apparatus at a gap of 0.127 mm, sheared at 0.1 s−1 for 2.5 h to induce collisions between drops, and then examined under a microscope. Some ill-defined drop clusters were evident to the eye, but the image quality at this gap of 0.127 mm was poor due to intense scattering. The plates were therefore gently squeezed together over several hours so as to reduce the gap and improve the image quality. When the gap is sufficiently small, droplet clustering becomes more clearly evident (Fig. 2).

The second method, quiescent coalescence, was conducted by storing a B10-1 sample in a petri dish under quiescent conditions for several weeks and then examining it under a microscope. Once again, ill-defined drop clusters were evident to the eye, but due to the small drop size (see Fig. 4b, to be discussed later), image quality was very poor. Therefore, a small sample of this blend was placed in a petri dish, and 2–3 ml of low viscosity (0.1 Pa s) silicone oil (PDMS) was added to this dish. This silicone oil is fully miscible with the PDMS used as the matrix of the blend and hence acts as a solvent or diluent for the matrix phase. The dish was then tilted back and forth gently several times to force the low-viscosity PDMS to wash over the blend and gently disperse it throughout the petri dish. The petri dish was examined frequently under a microscope during this process. The rationale behind this procedure was that if drops of B10-1 were indeed glued together into large clusters, at the very low stresses involved in the gentle flow, at least some drop clusters should survive. Indeed, we found large clusters breaking off the periphery of the B10-1 sample and dispersing. Figure 3 shows some examples of such clusters. We were also able to image some of these clusters during gentle flow in the petri dish and observe their undulating motions, as well as tumbling about the vorticity direction under shear. Finally, upon swirling the petri dish violently, the clusters broke apart into small clusters or individual drops.In summary, Figs. 2 and 3 are evidence that cluster formation is possible in PIB/PDMS/fumed silica blends. In the remainder of this paper, we will consider the rheological consequences of such clustering.

Rheology of hand-mixed samples

Before proceeding with well-controlled rheological experiments, it is interesting to note the large qualitative change in the rheology in the above B10-1 sample left in the petri dish for several weeks. This sample had been mixed by a spatula, and hence, it had—naturally—been unevenly distributed in the petri dish with a few “bare” patches. After several weeks, it was evident even to the naked eye that the sample had not spread out evenly in the dish. Some portions of the dish had a much thicker layer of the sample than others, and some portions remained bare without any blend (Fig. 4a). In these bare patches, the bottom of the petri dish had a wetting layer of PDMS but had no PIB drops. This uneven thickness of the sample layer in the petri dish is perhaps the best indication that this sample has converted into a gel with some finite yield stress. Observation of the edge of the bare patch reveals tightly packed drops forming a barrier (Fig. 4b) and preventing the patch from being filled in by the blend.

In the rest of this paper, only the simplest shear history is considered: quiescent annealing with the protocol mentioned in the Experimental Section (preshear at 400 Pa for 2,000 s, followed by frequency sweeps at 2-h intervals). Figure 5 shows the storage modulus G′ and the magnitude of the complex viscosity |η*| of various blends of the particles, PIB, and PDMS. We first focus on the samples without particles. Comparing the particle-free blend B30-0 (circles) with the matrix PDMS (solid line), B30-0 shows enhanced G′ and |η*| at low frequency, indicative of an additional relaxation process in the blend. Furthermore, after 6 h of quiescent annealing, there is a slight shift in the relaxation process to lower frequency (open vs solid circles); this may be noted by the slight increase in G′ at low frequency and in the shift of the shoulder in |η*| towards lower frequency. From extensive past literature on such blends, it is well known that the additional relaxation process causing the shoulder in |η*| and G′ corresponds to deformation and relaxation of the drops in the blends (Oldroyd 1953; Palierne 1990; Graebling et al. 1993; Vinckier et al. 1998). Dimensional analysis suggests, and detailed theory (Oldroyd 1953; Palierne 1990) confirms, that the characteristic frequency of this process must be scaled as σ/ηR, where R is the mean drop size, and η is the viscosity of the matrix phase. Thus, the slight shift to lower frequency is indicative of a corresponding increase in mean drop size by quiescent coalescence.

Next, we consider the effect of particles. Figure 5 shows that the addition of particles to the PDMS homopolymer increases the G′ and |η*| only slightly (solid vs dashed lines). However, in the B30-1 blend, there is a very large increase in these quantities at low frequency. After 6 h of annealing, the G′ shows a low-frequency plateau, and the |η*| shows a significant upturn at low frequency with no sign of leveling off at a limiting value. Both of these features are indicative of gel-like behavior in the sample. Such behavior may be attributable to the particles gluing the drops together into large clusters. A more critical evaluation may be performed by comparing blends with different volume fractions of drops: Certainly, any gel-like behavior induced by drops sticking to each other should become far weaker upon reducing the volume fraction of the drops. Accordingly, Fig. 6 compares blends containing 10% drops vs 30% drops. Indeed, B10-1 shows only a modest rise in |η*| at low frequency as compared to B30-1. The results for G′ (not shown) are similar: The plateau in G′ is considerably weaker in B10-1 as compared to B30-1. These observations lend support to the idea that particles cause the drops to stick to each other and that the resulting drop clusters are responsible for the plateau in G′ and the upturn in |η*| at low frequency.

Rheology of machine-mixed samples

During our studies of these blends, we noted that the rheological results on particle-containing blends were not highly reproducible. For example, several samples of B30-1 were mixed independently on different days and subjected to the same shear history as described above (400-Pa preshear followed by quiescent annealing). While the results were always qualitatively similar to the squares shown in Fig. 5, there were, nevertheless, substantial differences in the plateau in G′ and the rise in |η*| at low frequency. These differences were attributed to inconsistent hand mixing; preshearing is known to erase inconsistencies of hand mixing in particle-free blends (Vinckier et al. 1996), but that may not be true in the present samples. Therefore, we sought to develop a blending procedure that could be applied consistently. A small batch mixer, similar to the Minimax mixer (Maric and Macosko 2001), was used for this purpose. This mixer resembles a parallel-plate geometry, with the sample being sheared by rotating the top plate with respect to the bottom; however, three balls are added to the sample to induce chaotic streamlines, leading to efficient blending (Maric and Macosko 2001). We used a mixer of diameter ∼30 mm with a gap (equal to the ball diameter) of ∼9.5 mm. Samples were mixed by rotating at 100 rpm for 10 min.

Figure 7 compares the |η*| of the B30-1 blend prepared in the Minimax mixer with B30-1 blend prepared by hand mixing. Both sets of data were measured immediately after the preshearing step (400 Pa for 2,000 s). It is clear that mixing has a large effect on the rheological properties and that the gel-like behavior is substantially stronger in the B30-1 prepared in the Minimax mixer.

The mixer was also used to make a suspension of 1% fumed silica particles in PDMS (without any drop phase at all). Figure 7 shows that in contrast to the hand-mixed suspension (dashed lines, same as in Fig. 5), this Minimax-mixed suspension has a significant upturn in |η*| at low frequency. The results for G′ (not shown) also show gel-like behavior: The low-frequency G′ is far higher in the Minimax-mixed samples than in the hand-mixed samples. These observations on the fumed silica-in-PDMS suspensions indicate that the particles can form a gel by themselves even in the absence of any drops. Such gelation in suspensions of fumed silica is well known and is the basis of the commercial use of fumed silica as a rheology modifier.

Discussion

This research started with the hypothesis that bridging particles can cause drops to cluster together and that such clustering will be evident rheologically. Optical microscopy of hand-mixed samples has demonstrated conclusively that it is indeed possible for particles to glue drops together and form clusters. Rheological studies indicate that particles cause gel-like behavior in blends; however, the interpretation of this result is complicated by the observation that particles/PDMS suspensions, i.e. in the absence of any drop phase, also show gel-like behavior. Thus, we first consider a very limited question: Can at least some of the gel-like behavior of particle-containing blends be attributed to clustering of drops? The best evidence comes from Fig. 6, which shows that the effect of added particles on |η*| at low frequency increases in the sequence: (PDMS + 1% particles) < B10-1 < B30-1. This trend of increasing gel-like behavior with drop content shows that particle-induced droplet–droplet interactions are at least partially responsible for the gel-like behavior. Yet, this still does not conclusively prove that drop clustering is responsible: Hydrodynamic interactions between the drops, combined with the weak gel-like behavior of the matrix, may be responsible for the upturn in |η*|. To test this, we performed model calculations using the Palierne model, which can predict the linear viscoelastic properties of droplet-matrix blends composed of linear viscoelastic phases. For these calculations, the immiscible phases were given gel-like properties that roughly matched those of the B30-1 suspension of Fig. 5. We found that while hydrodynamic interactions can account for a part of the upturn in |η*| at low frequency, the observed magnitude of the upturn is substantially larger than that predicted by Palierne model. Therefore, we tentatively conclude that the clustering is responsible for a part of the gel-like behavior of the blends. In summary, the gel-like behavior has three causes: particle–particle association in the bulk, hydrodynamic interactions between drops (given that the matrix is a weak gel), and drop clustering. This paper is most interested in the rheological effects of drop clustering; however, there seems to be no simple way of subtracting out the effects of particle–particle associations and hydrodynamic interactions of drops.

Next, we note two differences with the research by Vermant et al. (2004) on blends composed of very similar PIB and PDMS and the same grade of fumed silicas (R972 from Degussa). (1) We found gel-like behavior at low frequency for all particle-containing blends. This includes hand-blended samples measured immediately following preshearing, a shear history for which Vermant et al. found only liquid-like behavior. (2) We found that the rheological properties were sensitive to blending procedures, whereas Vermant et al. tested various hand-blending procedures and found that the rheological properties were insensitive to the blending procedure. We are unable to cite a reason for these differences. Moldenaers (2005, personal communication) suggested that the gel-like behavior of our samples may be due to a higher moisture content in our silica particles. Therefore, we repeated experiments on a dried B30-1 sample prepared as follows: Weighed particles were dried for several hours at 75 °C in vacuum, then immediately added to a petri dish already containing appropriate quantities of dried PIB and PDMS, and hand blended. This allows no opportunity for atmospheric moisture to readsorb onto the particles. The blends were degassed and loaded promptly into the rheometer. Yet, the gel-like behavior was nearly unaffected. Thus, the cause for the discrepancy between our results and those of Vermant et al. remains unclear.

Finally, we turn to the question of whether PIB/PDMS/fumed silica would be a good model system to study the particle-bridging effects between drops in polymer blends. The results above point to at least two undesirable aspects of this system: that the results are highly sensitive to mixing procedures and that the fumed silica particles tend to form a gel in the bulk phases, making it difficult to isolate the effects of drops sticking together. Furthermore, there are at least two more disadvantages: that the particles are too small to be resolved optically (hence, bridging cannot be observed directly) and that fumed silicas are known to be fractal-like aggregates, making them more difficult to model than spherical particles.

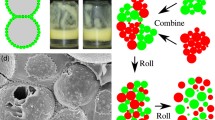

We instead propose that colloidal silica particles provide a model system that may address all the deficiencies of the fumed silica particles. Monodisperse spherical silicas can be purchased in a wide variety of sizes; their surface-wetting properties can be tuned by surface grafting (Van Helden et al. 1981; Brandriss and Margel 1993; Horozov et al. 2005), and they can be synthesized with fluorescent cores to enable fluorescent or confocal microscopy (Van Blaaderen and Vrij 1992). We have followed this route. Monodisperse silicas of 2.7-μm diameter were purchased from Tokuyama Industries, and their surfaces were coated with DCDMS in cyclohexane solution using the procedure described in literature (Brandriss and Margel 1993). DCDMS, in slight excess of that required to fully coat the particle surfaces, was used in the reaction. After the surface-coating reaction was completed, the particles were then washed thoroughly with cyclohexane and chloroform, dried, and blended with PIB and PDMS. Figure 8 shows that the particles do indeed adsorb at the PIB/PDMS interface, and that drops of PIB can indeed be glued together by the particles. An obvious advantage of the large particle size used here is that the particle bridging is unambiguous and the contact angles can be measured directly, thus facilitating modeling efforts. However, with such large particles, a relatively large volume fraction is needed to cover a given interfacial area. Hence, for studying issues such as effects of particles on coalescence, smaller particles may be more desirable. A detailed study of polymer blends containing such monodisperse spherical silica particles will be published in the future.

DCDMS-coated particles on PIB drops. a Two drops bridged by a single particle. b, c Multidrop clusters. Note the pronounced flattening of the drops in the region where the particles bridge them. d The dotted rectangle in c imaged with a higher magnification objective. Individual bridging particles are visible

Summary and conclusions

Recent results on particle-stabilized oil/water systems show that partially wetting particles can adsorb at two liquid/liquid interfaces simultaneously. We propose that such particles added to a blend of immiscible polymers can bridge across drops and glue them together and that such gluing will significantly affect the rheological properties of the blends. This paper demonstrates that

-

1.

Fumed silica particles can cause PIB drops in PDMS to stick together.

-

2.

Blends of PIB, PDMS, and fumed silicas show complex rheological properties, with gel-like behavior evident in the low-frequency dynamic moduli. This gel-like behavior has at least three causes: (1) particle–particle interactions in the bulk, (2) drop–drop hydrodynamic interactions, and (3) particle-induced drop clustering.

-

3.

The rheological properties of such blends are dependent on mixing history.

-

4.

Spherical monodisperse colloidal silica particles offer a more convenient model system than fumed silica to study bridging effects of particles in immiscible polymer blends.

References

Ashby NP, Binks BP, Paunov VN (2004) Bridging interaction between a water drop stabilised by solid particles and a planar oil/water interface. Chem Commun 436–437

Binks BP (2002) Particles as surfactants—similarities and differences. Curr Opin Colloid Interface Sci 7:21–41

Brandriss S, Margel S (1993) Synthesis and characterization of self-assembled hydrophobic monolayer coatings on silica colloids. Langmuir 9:1232–1240

Edwards DA, Brenner D, Wasan DT (1991) Interfacial transport processes and rheology. Butterworth-Heinemann, Boston

Graebling D, Muller R, Palierne JF (1993) Linear viscoelasticity of incompatible polymer blends in the melt in relation with interfacial properties. J Phys IV 3:1525–1534

Horozov TS, Aveyard R, Binks BP, Clint JH (2005) Structure and stability of silica particle monolayers at horizontal and vertical octanewater interfaces. Langmuir 21: 7405–7412

Maric M, Macosko CW (2001) Improving polymer blend dispersions in mini-mixers. Polym Eng Sci 41:118–130

Oldroyd JG (1953) The elastic and viscous properties of emulsions and suspensions. Proc R Soc Lond A218:122–132

Palierne JF (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta 29:204–214

Pickering SU (1908) Emulsions. J Chem Soc Abstr 91–92:2001–2021

Ramsden W (1903) Separation of solids in the surface-layers of solutions and ‘suspensions’ (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation).—Preliminary account. Proc R Soc Lond A 72:156–164

Stancik EJ, Fuller GG (2004) Connect the drops: using solids as adhesives for liquids. Langmuir 20:4805–4808

Stancik EJ, Kouhkan M, Fuller GG (2004) Coalescence of particle-laden fluid interfaces. Langmuir 20:90–94

Tambe DE, Sharma MM (1994) The effect of colloidal particles on fluid–fluid interfacial properties and emulsion stability. Adv Colloid Interface Sci 52:1–63

Van Blaaderen A, Vrij A (1992) Synthesis and characterization of colloidal dispersions of fluorescent, monodisperse silica spheres. Langmuir 8:2921–2931

Van Helden AK, Jansen JW, Vrij A (1981) Preparation and characterization of spherical monodisperse silica dispersions in nonaqueous solvents. J Colloid Interface Sci 81:354–368

Vermant J, Cioccolo G, Nair KG, Moldenaers P (2004) Coalescence suppression in model immiscible polymer blends by nano-sized colloidal particles. Rheol Acta 43:529–538

Vignati E, Piazza R, Lockhart TP (2003) Pickering emulsions: interfacial tension, colloidal layer morphology, and trapped-particle motion. Langmuir 19:6650–6656

Vinckier I, Mewis J, Moldenaers P (1996) Relationship between rheology and morphology of model blends in steady shear flow. J Rheol 40:613–632

Vinckier I, Moldenaers P, Terracciano AM, Grizzuti N (1998) Droplet size evolution during coalescence in semiconcentrated model blends. AIChE J 44:951–958

Acknowledgements

This research was supported by grant #ENG-CTS-0431349 from the National Science Foundation. We are grateful to Soltex, Inc., Rhodia, Inc., and Degussa for making the PIB, PDMS, and the silica particles available for this research.

Note added to proofs

A very recent article, Horozov et al., Angewandte Chemie-International Edition (2006) Particle–stabilized emulsions: A bilayer or a bridging monolayer? 45:773–776, discusses oil/water emulsions stabilized by bridging particles. They have followed the same strategy as described at the end of this paper: using monodisperse micron-sized silica particles rendered hydrophobic by silanization, to visualize bridging directly.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thareja, P., Velankar, S. Particle-induced bridging in immiscible polymer blends. Rheol Acta 46, 405–412 (2007). https://doi.org/10.1007/s00397-006-0130-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-006-0130-2