Abstract

A new cyber infrastructure for rheology (CIR) has the potential of integrating the diverse rheological knowledge of experts around the world. In a multi-disciplinary effort, experts in specialized topics of rheology began to write CIR-modules that seamlessly merge into a general code so that it can be used by a wide range of engineers and scientists. At the center of CIR is a platform operating system that connects a wide range of dedicated software modules. These CIR-modules perform calculations and return the corresponding results to a central graphics screen. The computer platform allows the detailed analysis of experimental data, the communication of data, and the prediction of rheological material functions from a wide range of theories in rheology. Rheologists can access each other’s experimental results, make predictions with each other’s theories and simulate with each other’s computer codes. Through such collaboration, seemingly disparate theories and experimental observations can be linked and taken to their limits, thereby leading to unexpected insights and new questions. Beyond the pool of experts, CIR will draw industrial users into the rheology discussion. Easy-to-use CIR-tools will allow industrial rheologists to adjust rapidly to the changing needs and the pressure to obtain short-term solutions in a competitive environment. CIR has the potential of generating ideas for novel materials and novel manufacturing methods. At the same time, it will supply the tools to examine ideas quantitatively and to push these ideas even further. User-friendly methods are essential not only for research and application, but also for the teaching of rheology. We envision tools that allow a student to move seamlessly and rapidly between experimental data and the most advanced rheological theories, simulations, and modeling of applications. In-depth data analysis and evaluation of theory should become easy enough to be performed after reasonable training and without relying on over-simplifications. This will enable the student to reach a deeper understanding of rheology and to appreciate the significance that rheology has in technical applications. Even untrained talent may get introduced quickly into advanced concepts of rheology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rheology is still difficult to access. This is one of its biggest unsolved problems. Rheology combines mathematics, physics, chemistry, and engineering in complicated ways that make it difficult to utilize rheological knowledge. The gap between research and education had grown larger and larger in recent years. The full use of rheology is limited to a small group of highly trained scientists. If there is widespread use of rheology today, it has been achieved mostly by simplifications of rheological concepts, sometimes over-simplification. In spite of this, rheology has still proven to be useful to a certain extent, but simplified methods fall way short of revealing the full potential of the rheological information of a specific material of interest. Rheology will gain by the development of user-friendly methods that express rheology in its full complexity. For these reasons, we have initiated a cyber infrastructure for rheology (CIR) that has the objective to integrate experiments with theory and simulation. This includes methods of seamlessly communicating rheological data. CIR has the potential of bridging the gap between research and education in rheology and to broaden the access to rheology.

Laboratories worldwide generate large amounts of experimental data without fully utilizing them. Surprisingly, it is still difficult to find reliable and complete rheological data sets for a wide variety of material classes, and this is in spite of the abundance of quality rheological data that get measured on a daily basis . This discrepancy raises new questions such as: How can we cope with myriads of rheological data? How can we extract useful information in a reasonably short time? Are the data self-consistent? What are the dominating experimental parameters? To overcome this problem, CIR needs to be designed to accommodate the high data volume in rheology. Data from heterogeneous sources can be shared by introducing a data exchange standard. The universal data standard of CIR facilitates communication between laboratories worldwide (and even between various rheometers that are housed in the same laboratory).

A steady effort is needed to narrow the gap between experiment and theory. Major advances can be expected from a CIR that integrates standardized databases with predictive modeling and simulation tools. An experimentalist in a rheometry laboratory will not be limited to produce data but is also able to understand the data’s significance; a theoretician can explore the underlying principles that govern his/her theory and directly compare to experiments. A deeper understanding will be gained when generating an interactive modeling/data environment.

Lack of speed is another obstacle for rheological research and application. A careful rheological experiment will always require time, and long calculation times are natural for simulation work. This slowness of rheological work is in discrepancy with nearly instantaneous access to information in other areas and with our desire to make decisions without delay. Here it is important to notice that, in many rheology projects, the most time-consuming steps are the slow access to data and the tedious initiation of a calculation. Such lengthy access times will disappear with a well-designed CIR. Rheology will gain wider application with CIR-tools that produce information promptly whenever possible.

When developed to its full strength, CIR promises to have a profound impact on the practice of rheology. The new tools will enable individuals, groups, and organizations to advance rheology in ways that revolutionize what they can do, how they do it, and who can participate [as argued in a recent National Science Foundation report, “Revolutionizing Science and Engineering through Cyberinfrastructure” (Atkins et al. 2003)]. CIR has its strength in rapid data analysis, visualization, documentation, building and use of libraries, search for patterns, comparisons, and predicting from theory. In using CIR’s integration approach, rheologists can flexibly plot experimental data in many different ways and combine their data with predictions derived from the foremost theories; complex questions can be formulated and answered without delay. CIR promises to make state-of-the-art rheology and rheology research more accessible to all.

Rheology platform

In order to address the above needs of CIR, a new framework had to be developed. In the following, it will be called the rheology platform (RP). RP is the home base for a family of dedicated software modules, which perform rheology calculations and return the corresponding results to the graphics screen of RP, see Fig. 1. The main strength of this approach is that it can combine different levels of complexity into a single platform. Modules for RP have been written by several of the world’s leading research groups in rheology.

Doi (2003) has created a somewhat similar platform approach, however, with the emphasis on the simulation of polymeric systems. The current CIR only began to include simulation. It mostly emphasizes experiments and theory models.

The purpose of the platform is to integrate the modules into a single tool. The user only sees the graphics screen of RP where he/she analyzes rheological experiments, performs calculations with the help of modules, plots the results, generates new data files, and continues with further calculations or with writing a report (for example). Data remain in the background but are available at any state of the work.

Rheology platform has been shown to be a unifying workspace that seamlessly combines modules of different kinds (experiments, theories, simulation, molecular structure). The following guidelines were chosen for creating the current RP:

-

user-friendliness

-

rapid access to data and to theoretical prediction

-

leading expert groups contribute to the project

-

central data storage on server: security, documentation, data libraries

-

single data format

-

worldwide access by users

-

connectivity, simplicity, and flexibility

-

communication of results (analyzed data, predictions from theory)

-

fast response that allows utilizing large data volume

Current CIR capabilities

The experimental part of CIR is fairly complete, implementing the most powerful tools of data analysis and visualization. In addition, rheology experts have begun to write theory modules that seamlessly connect into a platform; several modules are fully implemented and more are in progress. In-depth data analysis and evaluation of theory has become easy enough to be performed by non-rheologists after reasonable training (1 week of training seems acceptable) and without relying on over-simplifications. The CIR has also been the basis for several rheology short courses (Amherst, Lubbock, Berlin).

Theory

Theoretical predictions of linear viscoelastic material functions can be made directly in CIR. Available are classical theories of polymer melts and solutions (Maxwell, Rouse, Doi-Edwards) and empirical models. CIR allows the user to combine such experiments (dynamic mechanical, steady shear, start-up of shear, start-up of various extensional flows, molecular weight distribution) with a range of theories: classical theories (Maxwell, Rouse, Lodge, Doi-Edwards), two advanced polymer dynamics theories [‘tube dilation’ of McLeish and coworkers (McLeish and Larson 1998; McLeish et al. 1999; Milner and McLeish 1997, 1998; Blackwell et al. 2001; Pryke et al. 2002), ‘molecular stress function’ of Wagner et al. 2003, and with simulation (‘NAPLES’; Masubuchi et al. 2001, 2003, 2004)]. Effects of molecular weight distribution were implemented for linear polymers (Nobile and Cocchini 2001, Cocchini and Nobile 2003).

A common goal of these theories is to find a relation between molecular parameters (architecture, distributions, intrinsic parameters) and molecular dynamics as expressed in rheology. The theory part of the current CIR also extends into non-linear rheology. The most common transient flows of polymer melts and solutions can be modeled. Predictive tools allow calculating flow-induced molecular stretch and orientation in polymer melts as function of molecular topology (linear, short-chain-branched, stars, pom-pom; size).

Experiment

For complex materials, the understanding of rheological behavior can be greatly advanced through careful experiments that are followed by a detailed data analysis (Mours and Winter 2000). Our initial focus was solely on the data analysis. There, we used and still use a comprehensive and efficient code that is designed to analyze data to the fullest extent and at high rate. Take mechanical spectroscopy data G′(ω),G′ ′(ω) as example, where a typical 5- to 10-min analysis provides time–temperature superposition, spectrum calculation, and plotting of the main material functions. The most commonly found rheological experiments are included in CIR:

-

dynamic mechanical spectroscopy

-

time-resolved mechanical spectroscopy

-

wave analysis

-

steady shear

-

start-up of shear at constant rate

-

start-up of extension (uniaxial, planar, equibiaxial) at constant rate

-

step strain

-

creep

Data from heterogeneous sources (various rheometers, literature data, e-mail, spreadsheet) merge into a standardized format. Steady shear data can be expressed in fit-functions that are commonly incorporated in models for polymer-processing flows. Typically, time–temperature super position should be checked and used if applicable (Arrhenius and WLF function, density effects). The relaxation time spectrum and the retardation time spectrum are calculated from dynamic mechanical data (Baumgärtel and Winter 1989).

CIR case study

A short CIR demonstration (for experimental rheology) may start with a typical data set of mechanical spectroscopy for a group of polymer melts. Time–temperature superposition will combine these data for each of the polymers, and time–molecular-weight superposition will combine the data into a single master curve. Data will then be shifted to new temperatures and/or to new molecular weights (if so desired). After spectrum calculations, the modulus and the creep compliance will be predicted. A wide range of viscoelastic material functions can be plotted and patterns may be discovered in this process. Viscosities will be predicted from the Cox-Merz relation and then fitted with the most common functions (Carreau, Cross, etc.). Steady shear viscosity data can be superimposed for comparison. These are just a few of the options.

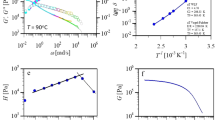

The analysis of rheological experiments may be supported by polymer dynamics predictions from several theories (expert modules). For example, in continuation of the above experiments, uniaxial extension can be predicted and compared to experiments, as shown in Fig. 2. Many more case studies can be found on the web (http://rheology.tripod.com/ALLcases.htm).

In another case study, time-resolved rheological data get de-convoluted (Mours and Winter 1994). This allows the study of evolving structure in a material (gelation, reverse gelation, crystallization, melting, degradation). In this example, Fig. 3 shows the data that were taken on a polymer during chemical gelation. CIR analysis generates “snapshots” of the polymer rheology at discrete times (Fig. 4).

Interpolation of data of Fig. 3 to obtain the loss angle δ at discrete reaction times t = 610, 720, 845, 940, 985, 1,205, 1,330, 1,500, 1,750, 2,295, 2,735, 3,110, 3,670 s. The fluid behavior is characterized by high δ-values and, vice versa, solids exhibit low δ-values. The gel point has a flat δ(G*) at low G* (sample in between t=985 s and t=1,205 s). G* is the magnitude of the complex modulus. This type of gelation-plot was suggested by C. Garcia-Franco (private communication)

Results from many such experiments and calculations merge into so-called “CIR projects”. CIR projects are most convenient for communicating large data sets and for exchanging ideas. CIR projects are stored in a data format that allows rapid access, provides a complete set of all the data involved, supplies literature references to the sources, and still requires little storage space. These criteria are essential for globally communicating among researchers.

CIR in education

The meaningful use of rheology requires a deeper understanding of the underlying principles. Such understanding is critically needed both in industry and in academia. The interactive graphics can visualize complex concepts that are otherwise difficult to comprehend. This makes it possible to teach rheology to students at an early state of their education. It also helps non-rheologists to develop rheological skills that are necessary for understanding experiments or applications.

Cyber infrastructure for rheology helps students to perform calculations with the most advanced theories and with widely diverse data sets. Imagine the following scenario: a student selects a polymer (star architecture mixed with a linear polymer, for instance), predicts the stresses when stretching the polymer into a fiber, and then compares the quantitative predictions to time-dependent stress measurements. The procedure gets repeated with molecules of different architecture, size, and/or size distribution, and at different stretching conditions. Comparison of the different predictions leads to an intuitive understanding of the effects of molecular architecture on the specific flow of interest. As an essential part of CIR, literature references are provided for all calculations that the student invoked during the CIR session. The student will be able to read these essential papers for her/his project, thereby learning the underlying physics or mathematics, and then to advance the project to greater depths. Students will acquire skills that are necessary for understanding experiments, theories, and/or applications. At the same time, they will explore the molecular origin of their observed flow phenomena. In the current example, CIR should allow predictions of flow-induced molecular stretch and orientation in polymer melts as function of molecular topology (linear, short-chain-branched, stars, pom-pom; size).

Cyber infrastructure for rheology (in its current form) can be installed on a laptop PC. It is easy to learn and fast responding (except for simulation work) so that students can perform calculations jointly with the teacher in the classroom in real time.

In the long range, cyber infrastructure (CI) technology will integrate research activities into the teaching of materials science and engineering. Engineering applications in the materials area require not only a solid foundation in engineering but also advanced knowledge in mathematics, condensed matter physics, and chemistry. Such breadth of knowledge can only be found in advanced students. With the materials CI approach, basic concepts of materials science can be taught to younger students, and this will put these students at an advantage professionally. Untrained talent gets introduced quickly into the most advanced concepts of material structure and dynamics.

CIR in research

We envision CIR as a tool for developing new theory, for comparing theories with each other, and for comparing theoretical predictions with experimental observations. Computer simulation will allow exploration of the fundamental principles that govern the dynamics of complex materials during deformation and, thus, will help developing truly novel materials.

Theory has advanced rapidly in recent years, but these advances have gone different ways for different research groups. In contrast to the well-established analysis of rheometry data, theory is far from being consolidated. Because of this exciting diversity and novelty of ideas, it is important to have several theories represented on the CIR platform and to visualize these theories together with experimental data. Predictions of one theory can be plotted against predictions of another theory. This will allow critical evaluation of the theories. Beyond this practical aspect, theory describes the underlying molecular dynamics to a level that exceeds the realm of current experimentation. The gained insight in molecular details produces new challenges for experimentalists and for the practice of rheology.

Rheological instruments have reached a high level of sophistication and, as a consequence, an abundance of high-quality rheological data have become available for a wide variety of material classes. The high data volume in rheology has three main aspects: (1) the actual measurement and all its complications, (2) the analysis of the experimental data, and (3) the seamless communication of the results to larger user groups. Seamless communication in combination with detailed analysis is achieved with unified data structure and unified CI methods of applying these data.

Industrial application of CIR

In industry, CIR has the potential of removing barriers between departments (within a company) and between a company and its customers. An application engineer, for instance, can perform rheological calculations independently, without delay, and at any location.

The building of a CI environment is especially timely for tailoring the production of polymeric materials towards specific applications. For the polymer industry, several favorable factors are poised to merge into a CIR. These favorable factors are

-

New manufacturing methods allow large-scale production of polyolefins with well-defined composition, architecture, and polydispersity. Most importantly, these polymers can be produced at competitive cost.

-

Polymer science has reached a deeper understanding of relating molecular composition, architecture, and polydispersity to macroscopic properties.

-

Novel rheological concepts can be accessed through a user-friendly computer program (IRIS; http://rheology.tripod.com/) that mostly relies on visualization and graphical representations.

-

Commercial computer codes are available for applying the newly gained rheology information to the modeling of processing flows. Practical applications would immediately gain from such relation between molecular architecture and end-use performance.

With a suitable CIR, application requirements can merge with the results from the rheology laboratory and with predictions from molecular dynamics theory. It is conceivable that CIR will connect the polymerization reaction kinetics with reactor-operating conditions (using commercial software), with the resulting rheology, with a suitable choice of processing, and with the deformation behavior of the final product. This is an ambitious goal, but it is within reach. Material and energy would be conserved and the time to market would be drastically reduced for new materials.

Documentation

Documentation is essential for the functioning of CIR. At all steps in an evolving CIR project, the origin of the calculations gets posted on the screen and in the newly generated data files. Reference to specific publications promotes further study of the underlying principles, the respective solution procedure, the simplifying assumptions and limitations. A CIR user can contact the known author of the CIR-module that he/she had worked with. This removes communication barriers and builds trust. The exchange of material data and the access to each other’s theory requires a great deal of trust. Ethical standards of practice will guarantee a high level of credibility.

Barriers for CIR

Cyber infrastructure for rheology is an environment for the seamless exchange of data and ideas. Ideally, there should be no noticeable barriers (“seamless”) to this global communication while, in reality, occasional concerns of security, confidentiality, and documentation might establish barriers that need to be realized in the overall plan for CIR. Users of CIR and partners in the development of CIR are requested to honor the needs for confidentiality of others in the CIR community whenever such need arises.

Licensing fees also constitute a barrier. CIR will involve a wide range of software that is costly to generate and maintain. While some software is supported by large institutions and comes free to the user, the entire CI range can be covered only by including commercial software. The current CIR is available under the name “IRIS” (http://rheology.tripod.com/) and requires licensing. The intellectual property of expert modules remains with the individual expert groups that author a module. A future CIR might involve codes for calculating molecular parameters and/or for calculating viscoelastic flows. These codes will also require licensing. The licensing conditions vary greatly and need to be clarified case by case.

Conclusions

The basic framework for interactive theory and experiment in rheology is now defined. The unified platform (RP) supports rheological research, education, and industrial application. Theories and experimental data can be shared and explored by large groups of experimentalists, theoreticians, and applied engineers (seamless communication). Several theories have already been implemented. Many more modules are in progress and will be added in the near future. A broad participation of research groups worldwide will accelerate the generation of new knowledge and the meaningful application of rheology.

As Alkire and Ratner (2003) explain in a more general context, “significant breakthroughs are still needed to provide new means to deal with complex systems on a rational basis, to integrate simulations with theory and experiment, and to construct multi-scale simulations of entire systems. .....The challenges come at several levels. Major exploration will be needed to develop new and better tools, educational techniques, computational and modeling strategies, and integrative approaches.” This assessment directly applies to rheology. Rheology’s full value will be realized only when the deeper understanding of theory and simulation get combined with the quantitative information of the rheological experiment. This is the task before us. A beginning is made but much more needs to be done.

References

Alkire RC, Ratner MA (2003) Information and communications: challenges for the chemical sciences in the 21st century. NSF publication (http://www.nap.edu/ catalog/10831.html)

Atkins DE, Droegemeier KK, Feldman SI, Garcia-Molina H, Klein ML, Messerschmitt DG, Messina P, Ostriker JP, Wright MH (2003) Revolutionizing science and engineering through cyberinfrastructure, NSF publication (http://www.cise.nsf.gov/ sci/reports/atkins.pdf)

Baumgärtel M, Winter HH (1989) Determination of the discrete relaxation and retardation time spectra from dynamic mechanical data. Rheol Acta 28:511–519

Blackwell RJ, Harlen OG, McLeish TCB (2001) Theoretical linear and nonlinear rheology of symmetric treelike polymer melts. Macromolecules 34:2579–2596

Cocchini F, Nobile MR (2003) Constrained inversion of rheological data to molecular weight distribution for polymer melts. Rheol Acta 42:232–242

Doi M (2003) Challenge in polymer physics. Pure Appl Chem 75:1395–1402

Masubuchi Y, Takimoto J, Koyama K, Ianniruberto G, Greco F, Marrucci G (2001) Brownian simulations of a network of reptating primitive chains. J Chem Phys 115:4387–4394

Masubuchi Y, Ianniruberto G, Greco F, Marrucci G (2003) Entanglement molecular weight and frequency response of sliplink networks. J Chem Phys 119:6925–6930

Masubuchi Y, Ianniruberto G, Greco F, Marrucci G (2004) Molecular simulations of longtime behavior of entangled polymeric liquids by the primitive chain network model, modelling simulation. Mat Sci Eng 12:91–100

McLeish TCB, Larson RG (1998) Molecular constitutive equations for a class of branched polymers: the pom-pom polymer. J Rheol 42: 81–110

McLeish TCB, Allgaier J, Bick DK, Bishko G, Biswas P, Blackwell R, Blottiere B, Clarke N, Gibbs B, Groves DJ, Hakiki A, Hoenan RK, Johnson JM, Kant R, Read DJ, Young RN (1999) Dynamics of entangled H-polymers: theory, rheology, and neutron scattering. Macromolecules 32:6734–6758

Milner ST, McLeish TCB (1997) Parameter-free theory for stress relaxation in star polymer melts. Macromolecules 30:2159–2166

Milner ST, McLeish TCB (1998) Reptation and contour-length fluctuations in melts of linear polymers. Phys Rev Lett 81:725–728

Mours M, Winter HH (1994) Time resolved rheometry. Rheol Acta 33:385–397

Mours M, Winter HH (1996) Relaxation patterns of nearly critical gels. Macromolecules 29:7221–7229

Mours M, Winter HH (2000) Mechanical spectroscopy. In: Tanaka T (ed) Experimental methods in polymer science: modern methods in polymer research and technology. Academic Press, San Diego, pp 495–546

Nobile MR, Cocchini F (2001) Evaluation of molecular weight distribution from dynamic moduli. Rheol Acta 40:111–119

Pryke A, Blackwell RJ, McLeish TCB, Young RN (2002) Synthesis, hydrogenation, and rheology of 1,2-polybutadiene star polymers. Macromolecules 35:467–472

Wagner MH, Yamaguchi M, Takahashi M (2003) Quantitative assessment of strain hardening of low-density polyethylene melts by the molecular stress function model. J Rheol 47:779–793

Acknowledgements

The rheology platform was developed with the help of licensing fees from its users. The development greatly benefited from suggestions of many rheologists (worldwide). Theory modules were written by Richard J. Blackwell (Tube Dilation Theory), Manfred H. Wagner (Molecular Stress Function Theory), and Rosella Nobile and Franco Cocchini (molecular weight determination). HHW is especially grateful for the 2004 Conti Faculty Fellowship that UMass Amherst awarded to him for establishing an interactive rheology course that utilizes the CIR tools in the classroom. The anonymous review was conducted by M.H. Wagner as member of the Rheologica Acta Editorial Board.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Winter, H.H., Mours, M. The cyber infrastructure initiative for rheology. Rheol Acta 45, 331–338 (2006). https://doi.org/10.1007/s00397-005-0041-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-005-0041-7