Abstract

In this work liquid crystalline polymer (LCP) and thermoplastic (TP) blends with and without compatibilizer were studied with respect to their elongational flow behavior, under uniaxial extensional flow. This knowledge is important because in processes involving dominantly extensional deformations, like the case of the formation of the LCP fibrillation, transient extensional flow properties become more important than transient or steady-shear properties. In systems characterized by disperse phase morphologies (10 and 20 wt%) the LCP acts as a plasticizer, decreasing the viscosity of the system and increasing its durability with respect to that of the matrix. On the other hand, for a system in which a co-continuous morphology is present (40 wt% LCP) fibrils and droplets deformation occurs simultaneously, leading to a much higher strain hardening and durability. Moreover, the addition of compatibilizers to the blends gives rise to an increase of the strain hardening and to a decrease of the durability, which is in accordance with the mechanical properties, namely a higher Young’s modulus and lower elongation at break, in comparison with noncompatibilized systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Considerable interest has been focused on blends based on thermoplastic and liquid crystalline polymers. This kind of in situ composites is potentially particularly interesting for industrial purposes, since their use may induce simultaneously significant mechanical improvements and easier processability. These advantages arise respectively from the high level of macroscopic molecular orientation developed in these blends and from the decrease of viscosity, comparing with that of other reinforced materials, like for example, those with glass fibers (see for example the work of Heino et al. 1994; Wanno et al. 2000; Chan et al. 2001). It should be considered, however, that the maximum performance, in terms of mechanical improvement, is usually achieved by the use of compatibilizers that act reducing the interfacial tension between the liquid crystalline polymer and the thermoplastic. Some examples are the works carried out by Datta and Baird (1995), Miller et al. (1995) and Bualek-Limcharoen et al. (1999).

The studies on the extensional behavior of pure liquid crystalline polymers are relatively scarce in the literature, the most notable exceptions being the works of Wilson and Baird (1992) and Gotsis and Odriozola (2000). In the work of Wilson and Baird (1992) with a hydroxipropylcellulose polymer (HPC), it was concluded that the structure of the melt influences the behavior of the material in extensional flow. At low temperatures the material is in an anisotropic state and thus it may have some residual crystallinity. Under these conditions, in uniaxial extensional flow the material presents a strain-hardening behavior, which increases with the increase of the strain rate, as expected. For higher temperatures, however, the material follows the linear viscoelastic behavior, which might be related with the total (or partial) loss of crystallinity, since at this temperature it is already in the isotropic state. Similar observations were described for another liquid crystalline polymer, Vectra A900. According to their results it looks like the strain-hardening behavior of LCPs is similar to that observed for other flexible polymers, even though this behavior occurs at lower strain levels than those of flexible polymers. Done (1987) measured the equibiaxial extensional flow of three different liquid crystalline polymers and verified that the transient biaxial extensional viscosity decreases with the increase of the strain rate and increases with the increase of the strain.

Considering the importance of extensional flow on the majority of industrial processes and its relevance on the formation of highly oriented fibrillar structures in LCP/TP blends and thus on the final properties of the products, it is of great interest to study the extensional flow behavior on blends with and without compatibilizers, evaluating the influence of the LCP content and compatibilizer used. This is the aim of the present work.

Experimental

Materials

Liquid crystalline and thermoplastic blends were prepared using Rodrun LC3000 from Unitika and polypropylene (Stamylan P 12E62) from DSM. The thermoplastic used for the preparation of the blends is polypropylene with a molecular weight of 1,194,406 g/mol obtained by GPC and a melt flow index of 0.8 g/10 min (at 230°C and for 21.6 N). Stamylan P is an isotatic polypropylene with a melting temperature of 165°C.

Rodrun LC3000 is a copolymer constituted by 60% mol of p-hydroxy-benzoic acid (HBA) and 40% mol of polyethylene terephtalate (PET). The transition temperature obtained by DSC for the LCP was 189°C (peak value). The molecular weight for the LCP was not obtainable, since no solvent was found to be soluble with Rodrun LC3000.

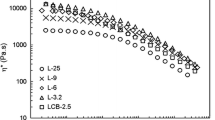

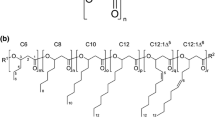

In order to improve the adhesion between the two pure components, several different compatibilizers were used, three of them synthesized and the other two commercial grades. The chemical structures of the compatibilizers above mentioned are depicted in Fig. 1 and the mechanical, rheological (in shear) and morphological properties of the final compatibilized LCP/polypropylene blends are available elsewhere (Filipe et al. 2004c).

Methods

Processing

Noncompatibilized blends with different LCP contents, 10, 20 and 40 wt% were produced by extrusion at 220°C. Additionally, five compatibilized blends with 10 wt% LCP and 2 wt% of compatibilizer (with respect to the amount of thermoplastic) were produced. The extruder configuration and the processing conditions employed are referred in a previous paper (Filipe et al. 2004a).

Characterization

All the materials were characterized under uniaxial extensional flow. This continues the previous works by the authors in Filipe et al. (2004b) and Filipe et al. (2004c), in which the blends were characterized under oscillatory shear (in both linear and the non linear regimes-FT-Rheology), as well as steady and transient shear. For the extensional measurements we used a modified rotational rheometer previously developed and validated by our group (for example, Maia et al. 1999; Barroso et al 2002, 2003) that works according to a Meissner-type configuration. A high-temperature silicone oil, with the commercial name HT100 from Ambersil, was used as supporting media. At the measuring temperature its density (0.93 g/cm3) matched roughly the density of the samples, so that sagging and swelling of the samples were negligible. The uniaxial extensional measurements were carried out by applying strain rates between 0.07 and 0.48 s−1 at 240°C . The strain rates here described are true strain rates obtained by image analysis of the evolution of the diameters at the rollers with time by the use of a digital camera (Maia et al. 1999). This is a necessary procedure because as was demonstrated elsewhere (Barroso et al. 2002), for this type of rheometers in general, the true strain rates are not identical to the theoretical strain rates calculated from the velocity of the pulling rollers due to a variety of end-effects, including slip at the rollers. Also, this is the reason why the strain rates are very similar between different blends but not exactly equal.

Due to experimental constrains related with difficulties during the loading of the neat LCP samples, most precisely with their sagging due to the very low viscosity of the LCP (and consequent very low reproducibility) at the testing temperature (240°C), no reliable results were possible to be obtained for the pure liquid crystalline polymer.

The strands used in the uniaxial extensional flow measurements were prepared in a capillary rheometer Rosand RH8-2 by extruding the material through a die with 2 mm diameter, at a constant and low velocity. In order to avoid residual stresses in the samples, special care was taken before each measurement, by keeping each strand at rest at the test temperature after loading, until the force signal reached zero, which was followed by the removal of any existing slack and, finally, by another rest period until the force signal reached zero again (Barroso et al. 2002). Each experiment was repeated three times and the experimental error was determined to vary between 2 and 4%, depending on the samples. The determination of the error associated was performed using the method outlined by Barroso (2003).

The transient uniaxial extensional viscosity in the linear viscoelastic regime (LVE) was calculated from the relaxation spectra obtained from oscillatory data at 240°C.

The blends were additionally characterized in terms of their morphology, by means of scanning electron microscopy (SEM). For this purpose a scanning electron microscope ZEISS DSM 962 was used. All the cryogenically fractured samples were previously coated using a POLARON SC502 and then examined by SEM at an accelerating voltage of 10 kV.

The mechanical analysis was carried out by testing dog-bone shaped specimens in an Instron Universal Tester Machine model 1.16 at room temperature. A cross-head speed of 5 mm/min and a load cell of 50 kN were used. An extensometer (model Instron 2630-100) was used for these measurements.

Results

Influence of the LCP content and type of compatibilizer on the elongational flow behavior of LCP/TP blends

Knowledge about the influence of the liquid crystalline polymer content on the extensional flow behavior of liquid crystalline polymer/thermoplastic blends is crucial due to the importance of the extensional flow behavior in industrial processes. Therefore, neat PP and Rodrun LC3000/PP blends with various LCP incorporation contents, namely 10, 20 and 40 wt% LCP, were studied with respect to their transient uniaxial extensional viscosity, for two different strain rates (Fig. 2) and the Trouton ratio was additionally determined (Fig. 3).

In what regards the polypropylene, it shows a small degree of strain hardening, which was not expected since it is a linear material. However, not only is this PP of very high-molecular weight, the molecular weight distribution also shows the presence of a small tail of very high-molecular weight material and as is known, the presence of even small amounts of a very high-molecular weight component can produce a strong effect on the strain hardening of linear polymers (see, for example, Sugimoto et al. 2001).

As far as the blends are concerned, and for the lower range of strain rates, between 0.07 and 0.13 s−1 (Fig. 3a), depending on the material, steady state was achieved for PP as well for the blends with 10 and 20 wt% LCP, but not for the blend with the highest LCP content (40 wt%). Additionally, the pure matrix and the blends with 10 and 20 wt% LCP behave similarly in terms of the deviation from the linear viscoelastic regime, within the experimental error. The increase of the LCP content to the higher amount of 40 wt% resulted in a dramatic change of the rheological behavior, with a much higher durability and degree of strain hardening being apparent.

As seen in Fig. 3b, when higher strain rates are applied (ranging from 0.31 to 0.48 s−1 depending on the materials), there are much clearer differences in the behavior of the blends, the increase in LCP content yielding a decrease of the strain-hardening behavior at the same Hencky strains, which is accompanied by an increase in durability, especially for the 40 wt% sample, as seen in Fig. 3b.

An increase of the LCP content from 10 to 20 wt% leads to an increase of the number of fibrils per volume and to the formation of thicker fibrils (see Fig. 4), which in principle, are more easily deformed under uniaxial extensional flow. Also, it is probable that the LCP (in the molten state) is acting as a plasticizer, due to its low viscosity at the measuring temperature, causing a decrease of the viscosity and increase of durability with respect to the matrix.

When the LCP content is increased to 40 wt% the material is in a situation in which the LCP and the matrix exist in a co-continuous morphology, as can be confirmed, in Fig. 4. Under these conditions, PP and LCP strands deform simultaneously and the elongational behavior can no longer be related with the type and number of fibrils, as in the case of the blends with 10 and 20 wt% LCP (in which a dispersed phase morphology, with fibrils clearly distinguishable from the matrix, can be seen).

Although, the strain-hardening behavior of neat LCP (Wilson et al. 1992) was attributed to the presence of some residual crystallinity, in the present case, such conditions are not expected for the LCP/TP blends, since at the measuring temperature (240°C), DSC scans showed that no crystallinity is present.

Since the applicability of LCP/TP blends often requires the use of compatibilizers (see, for example, Datta and Baird 1995; Miller et al. 1995; Bualek-Limcharoen et al. 1999), five different blends containing 10 wt% LCP and 2 wt% of five compatibilizers, A to E, were studied and compared with the noncompatibilized blend (Fig. 5 and 6, extensional viscosity and Trouton ratio, respectively).

The addition of a compatibilizer always leads to a decrease of the durability (see Figs. 5 and 6), which is in agreement with both the morphology present and the mechanical properties (see Fig. 7). The addition of compatibilizer results in thinner LCP fibrils that now resist much more to high deformations, due to the increased interactions across the interface.

As far as the mechanical properties are concerned, there is an improvement of the Young’s modulus that occurs at the expense of the ductility (Fig. 7). Also, apart from the blend in which an elastomeric compatibilizer was used (comp. E), all the compatibilized systems showed a lower durability (Fig. 6), i.e., time to rupture, due to the increase of the elasticity, promoted by the increase of the interactions between LCP and the matrix at the interface.

For the lower strain rates, it looks like the deviation from the LVE is related with the chemical structure of the compatibilizer used (see Fig. 6). For example, the noncompatibilized blend and the blend with compatibilizer A possess higher durability than the other compatibilized blends, which is due to the greater similarity between the matrix and compatibilizer A (comparing with the other compatibilizers), which acts as a plasticizing agent (Filipe et al. 2004b). The blend with an elastomeric compatibilizer (compatibilizer E) presents a much higher Trouton ratio than that of the remaining blends, which was to be anticipated given that compatibilizer E possesses an elastomeric nature. The blend with compatibilizer C showed a deviation from the LVE for a much lower Hencky strain than the remaining blends as well as a much lower degree of durability, which agrees well with the mechanical properties (highest E and lowest elongation at break).

The distinction between the blends with compatibilizers B and D is much more difficult to make and the results are not conclusive, although they seem to be in general agreement with those obtained for the Young’s modulus (Fig. 7).

The application of higher strain rates was not able to distinguish between the different compatibilized blends (A to E), as seen in Fig. 5b.

In conclusion, it is possible to say that both the level of strain hardening and its rate of growth, i.e., the time it takes to reach steady state, are directly related with the mechanical properties (Filipe et al. 2004b), at least at low strain rates where distinctions can be made between the various blends. In fact, the mechanical measurements (Fig. 7) revealed that the highest Young’s modulus was obtained for the blends with compatibilizer C and E and the lowest for the blend with compatibilizer A, the remaining blends (with compatibilizer B and D) presenting values in between those of the blends with the highest and lowest tensile strengths.

Conclusions

The studies performed on non-compatibilized PP/Rodrun LC3000 blends revealed that, for dispersed phase morphologies (with 10 and 20 wt%) the LCP acts as a plasticizer, decreasing the viscosity of the system and increasing its durability with respect to the matrix.

Another conclusion is that for the system in which a co-continuous morphology is present (40 wt% LCP) the percolation threshold should be considered, the deformation of fibrils and droplets occurring simultaneously, leading to a much higher strain hardening and durability.

One can additionally conclude that the compatibilization results in a decrease of the durability with respect to the noncompatibilized blend.

Finally, it can be stated that the higher effectiveness of the compatibilizers, with consequent improvement of the Young’s modulus (arising from fibrils with higher aspect ratio) corresponds to a higher strain hardening and lower durability (as seen for blends with comp. C and comp. E).

References

Barroso VC, Covas JA, Maia JM (2002) Sources of error and other difficulties in extensional rheometry revisited: commenting and complementing a recent paper by T. Schweizer. Rheol Acta 41:154–161

Barroso VC, Ribeiro SP, Maia JM (2003) Unusual extensional behavior of a polystyrene/HIPS blend. Rheol Acta 42:483–490

Barroso VC 2003 Viscoelasticity of polymer melts in uniaxial entension flows, PhD thesis

Bualek-Limcharoen S, Samran J, Amornsakchai T, Meesiri W (1999) Effect of melt viscosity of polypropylene on fibrillation of thermotropic liquid crystalline polymer in in situ composite film. Pol Eng Sci 39:312–320

Chan CK, Whitehouse C, Gao P, Chai CK (2001) Flow induced chain alignment and disentanglement as the viscosity reduction mechanism within TLCP/HDPE blends. Polym 42:7847–7856

Datta A, Baird DG (1995), Compatibilization of thermoplastic composites based on blends of polypropylene with two liquid crystalline polymers. Polym 36:505–514

Done DD (1987) PhD Dissertation,Virginia Polytechnic Institute and State University, Balcksburg, VA

Filipe S, Maia JM, Duarte A, Leal CR, Cidade MT (2004a) Influence of type of compatibilizer on the rheological and mechanical behavior of LCP/TP blends under different stationary and non-stationary shear conditions. J Appl Polym Sci (in press)

Filipe S, Cidade MT, Wilhelm M, Maia JM (2004b) Evolution of morphological and rheological properties along the extruder length for blends of Rodrun LC3000 and polypropylene. Polym 45:2367–2380

Filipe S, Maia JM, Leal CR, Cidade MT (2004c) A study of LCP/TP blends under stationary and non-stationary shear conditions: influence of the LCP content and processing temperature. J Polym Eng (in press)

Gotsis AD, Odriozola MA (2000) Extensional viscosity of a thermotropic liquid crystalline polymer. J Rheol 44:1205–1223

Heino MT, Hietaoja PT, Vainio TP, Seppala JV (1994) Effect of viscosity ratio on the morphology of blends of liquid crystalline polymer and polypropylene. J Appl Pol Sci 51:259–270

Maia JM, Covas JA, Nóbrega JM, Dias TF, Alves FE (1999) Measuring uniaxial extensional viscosity using a modified rotational rheometer. J Non-New Fluid Mech 80:183–197

Meschbal N, Bousmina M (2004) Uniaxial deformation and relaxation of polymer blends: relationship between flow and morphology development. Rheol Acta 43(2):119–126

Miller MM, Cowie JMG, Tait JG, Crydon DL, Mather RR (1995) Fibres from polypropylene and liquid-crystal polymer blends using compatibilizing agents: 1. Assessment of functional and non-functional polypropylene-acrylic acid compatibilizers. Polym 36:3107–3112

Silva LB, Ueki MM, Barroso VC, Maia JM, Bretas RES (2004) Transient uniaxial behavior of blends of PET with a LCP, submitted to Rheol. Acta

Sugimoto M, Masubuchi Y, Takimoto J and Koyama K (2001) Melt Rheology of polypropylene containing small amounts of high-molecular weight chain. 2.Uniaxial and biaxial extensional flow. Macromol 34(17):6056–6063

Wanno B, Samran J, Bualek-Limcharoen S (2000) Effect of melt viscosity of polypropylene on fibrillation of thermotropic liquid crystalline polymer in in situ composite film. Rheol Acta 39:311–319

Wilson TS, Baird DG (1992) Transient extensional flow behavior of thermotropic liquid crystalline polymers. J Non-Newt Flui Mech 44:85–112

Acknowledgements

The authors gratefully acknowledge Prof. Moura Bordado and A. Duarte for the synthesis of compatibilizers A to C. An acknowledgment is also due to Dr Ana Vera Machado that supplied compatibilizers D and E. Finally, we would also like to acknowledge the financial support provided by Science and Technology Foundation (Portugal) under the project POCTI/CTM/32658/99.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Filipe, S., Cidade, M.T. & Maia, J.M. Uniaxial extensional flow behavior of immiscible and compatibilized polypropylene/liquid crystalline polymer blends. Rheol Acta 45, 281–289 (2006). https://doi.org/10.1007/s00397-005-0034-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-005-0034-6