Abstract

We demonstrate the synthesis of SiOH-functionalized composite particles with buckled surface via a seeded emulsion polymerization method, their evolution into bicompartmental particles and their application in superhydrophobic coatings. By using polystyrene spheres swelled with non-polymerizable solvent as seeds, emulsion polymerization of 3-(trimethoxysily) propyl methacrylate and styrene leads to the formation of deflated ball- or dried plum-shaped composite particles. The change of solvent amount causes the variation of the morphologies of the obtained particles. With these composite particles as seeds for further emulsion polymerization, bicompartmental particles with unique morphologies are fabricated. On account of the silanol groups generated by hydrolysis of 3-methacryloxy propyl trimethoxysilane (MPS) on their surface, these particles are easily functionalized with organosilane for various applications and also could be applied in the synthesis of more complex organic–inorganic hybrid materials. The modification of the particles with fluorinated silane and their application in the fabrication of superhydrophobic surfaces are demonstrated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The synthesis of uniform non-spherical particles has attracted wide research interests due to their applications in the field of self-assembly [1–8], molecular recognition [9, 10], superhydrophobic materials [11–13], and Pickering emulsion [14, 15]. Seeded polymerization is undoubtedly a powerful approach to synthesizing particles with complex morphologies. Actinia-like [16], half-cauliflower [17], sea urchin [18] and particles with protruding edges on the surface [19] were synthesized by seeded polymerization.

By triggering phase separation [20, 21] during seeded polymerization, multicompartmental particles could be achieved. EL-Aasser et al. [22] swelled micrometer-sized cross-linked polymer spheres with monomer and subsequent polymerization led to the separation of phase with different crosslinking degree to form bicompartmental particles. Weitz et al. [15] and Wu et al. [23] modified the cross-linked PS sphere surface with 3-methacryloxy propyl trimethoxysilane (MPS) to impart the resulted bicompartmental particles with tunable surface properties. Zhang et al. [24] extended this method to fabricate Janus polyacrylonitrile/PS particles by seeded polymerization with a crosslinked PAN hollow spheres. Dufresne [25] employed core shell spheres with a linear hydrophobic polystyrene core and hydrophilic shell as seeds for seeded polymerization, during which phase separation leads to the formation of uniform dumbbell particles. Sacanna et al. [26] encapsulated PS spheres into polymerizable silicon oil droplets, and polymerization of the oil generated multicompartmental particles with various morphologies.

Particles with surface buckling or holes are of great interest for self-organization for novel structures [27, 28], high-contrast particle tracking [29], and study of colloidal crystallization [30]. Sacanna et al. fabricated spheres with a spherical cavity and demonstrated the lock and key recognition between these particles and smaller colloidal spheres [27]. During their approach, MPS was polycondensed to form spheres with crosslinked shells and liquid cores, and subsequent radical polymerization of the liquid core produced the lock particles. Wang et al. synthesized particles with single-cavity or multicavity through controlling the feeding mode of divinylbenzene (DVB) during seeded polymerization [31]. Sun et al. converted polystyrene/carbon core–shell spheres to concaved particles by swelling with solvent and deswelling [30].

During seeded dispersion polymerization, the addition of solvent is found effective for the production of particles with surface buckling. Okubo et al. reported a seeded dispersion polymerization in the presence of a solvent for preparation of non-spherical particles [32, 33]. During this approach, most of the solvent was absorbed by the newly formed domain of the composite particles. The evaporation of the solvent caused the volume reduction of these domains, leading to the formation of a school of non-spherical particles, including particles with dents on their surfaces [32] and disk-like and polyhedral particles [33]. Saadat et al. prepared almond shell-like and void-containing-shaped particles using dual-seeded polymerization with the aid of solvents [34]. Seeded dispersion polymerization of cross-linkable monomer in the presence of solvent was employed to fabricate rugby ball-like [35], red blood corpuscle-like hollow particles [36]. Zumbusch et al. fabricated PS/PMMA core shell particles with wrinkled surface through non-aqueous dispersion polymerization with highly cross-linked spheres as seeds [29]. Through stretching, these particles could be transformed to shape-anisotropic particles. However, all the abovementioned approaches employed dispersion polymerization, which were mainly suitable for micron-sized particles. There is a lack of reports on the extension of these methods to seeded emulsion polymerization, which is of great interest for the fabrication of submicron-sized particles.

Additionally, particles with SiOH groups on their surface are highly desirable due to their ease of further functionalization by organosilane for applications in various fields and in synthesizing more intricate organic–inorganic structures [37]. In this article, we propose a facile approach of synthesizing SiOH-functionalized composite particles with buckled surface by a seeded emulsion polymerization with the aid of a non-polymerizable solvent. Specifically, as shown in Fig. 1, PS spheres are first swelled with p-xylene (PX), which are subsequently employed as seeds for emulsion polymerization of the mixture of styrene and MPS. Deflated-ball- or dried-plum-shaped composite particles are obtained and due to the hydrolysis of MPS, the surface of the particles is SiOH functionalized. Their size and shape could be adjusted by changing the weight ratio of PX to seed microspheres. Interestingly, if the sequence of swelling and seeded polymerization is altered, snowman-like particles are produced, which gives hints on the mechanism of the morphology formation. Further polymerization with these particles as seeds leads to the formation of bicompartmental particles with unique shapes. After modification with fluorinated organosilane, the application of these particles on the fabrication of superhydrophobic surfaces is demonstrated.

Materials and methods

Materials

Styrene (St) and potassium persulfate (KPS) were purchased from Sigma-aldrich. 3-(trimethoxysily) propyl methacrylate (MPS), perfluorodecyltrimethoxysilane (PFTMS), and azobis(isobutyronitrile) (AIBN) were provided by Adamas Reagent Co., Ltd. Polyvinylpyrrolidone (PVP, Mw = 30 K g/mol), PX, alcohol, and ammonia were purchased from Sinopharm Chemical Reagent Co., Ltd. All chemicals were used as received without further purification except that AIBN was purified by recrystallization in ethanol.

Synthesis of PS/P(St-MPS) composite particles

PS spheres of 595 ± 10, 705 ± 12, 755 ± 11, and 895 ± 8 nm were synthesized by emulsifier-free emulsion polymerization [38], which were used as seeds to prepare PS/P(St-MPS) composite particles in the following seeded polymerization. Aqueous PS latex (2.5 wt%, 20 g) and a certain amount of PX were added into a 100-mL three-necked round-bottom flask. The mixture was stirred at 300 rpm for 18 h to allow the PS spheres to be swollen by PX. Subsequently, the above emulsion was heated to 70 °C under nitrogen bubbling and a solution of AIBN (0.005 g) dissolved in a mixture of St (0.5 g) and MPS (0.05 g) was added. After 12 h of polymerization, the composite particles were washed with deionized water for three times by repeated centrifugation and redispersion and collected after drying in a 60 °C oven overnight.

Synthesis of PS/P(St-MPS)@PS composite particles

PS/P(St-MPS)@PS composite particles were prepared by further seeded polymerization. PS/P(St-MPS) latex (2.5 wt%, 20 g), a PVP solution (5 wt%, 5 g), and a monomer solution consisting of a certain amount St and AIBN (1 wt% based on St amount) were added into a 100-mL three-necked round-bottom flask sequentially. After being stirred at 300 rpm for 24 h, the above mixture was heated to 70 °C under nitrogen atmosphere. After 12 h of polymerization, the composite particles were washed by repeated centrifugation and redispersion in water and collected after drying in a 60 °C oven overnight.

Modification of PS/P(St-MPS) composite particles by PFTMS and fabrication of superhydropobic coatings

The as-prepared PS/P(St-MPS) composite particles (0.1 g) were first redispersed in the mixture of ethanol (10 g) and ammonia (0.3 mL) under ultrasonication. Then, a solution containing ethanol (5 g) and PFTMS (0.02 mL) was added to the above emulsion under 800 rpm magnetic stirring. The hydrolysis reaction was carried out at room temperature for 4 h before the sample was centrifuged and washed with ethanol for three times.

A fluorinated PS/P(St-MPS) latex (3 wt%, 100 μL) was dropped on a pretreated glass slide (2.5 × 2.5 cm) and spread evenly on a glass substrate. With the evaporation of ethanol, the particles assembled and deposited, relying on gravity and capillary forces among the particles. Then, the particulate coatings were sintered in a 105 °C oven for 10 min.

Characterization

The morphology and size of particles were characterized on a scanning electron microscope (SEM, Hitachi, S-4800, 20 kV) and a transmission electron microscope (TEM, JEOL, JEM-2100, 200 kV). The SEM samples were sputtered with Au to improve the conductivity. The TEM samples were prepared by dropping dilute emulsions on copper grids, which were dried in the vacuum oven subsequently. The hydrophobic property of particulate coatings was analyzed with an optical contact angle (OCA) meter (Dataphysics, OCA40) via the sessile drop method using the Laplace–Young fitting algorithm. The volume of water drop was 3 μL and the dispense speed was 0.5 μL/s. The contact angle values were determined from the average of three measurements at different positions.

Results and discussion

Synthesis of PS/P(St-MPS) composite particles

Influence of the amount of PX on the particle morphologies

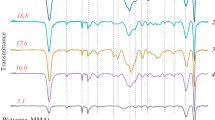

During the seeded polymerization, 705 nm linear PS spheres were used as seeds during the polymerization of the mixture of styrene and MPS. Swelling the spheres with non-polymerizable solvent before polymerization was found crucial for the formation of particles with buckled surface. As shown in Fig. 2a, with spheres not swelled with PX, the seeded polymerization just led to the formation of PS/P(St-MPS) composite spheres (CP705–0), with the increase of the sphere diameter from 705 to 831 ± 10 nm, which is in good accordance with previous report [25]. When PX was introduced to swell the seeds before polymerization, the morphologies of the particles changed dramatically, as shown in Fig. 2b–d. It could be observed that the spherical surface is collapsed and particles become deflated-ball-shaped. There are also small dimples distributed on the composite particle surface. The sizes of the particles are 918 ± 24, 1051 ± 79, and 1178 ± 96 nm, when weight ratios of PX to PS spheres (w PX/w particles) are 1, 2, and 4, respectively. The more PX is added, the more the particles are deflated and the more the particle surface is wrinkled. From the TEM images, we could observe that the particles are solid rather than hollow.

The mechanism of the morphology formation

To understand the formation mechanism of the deflated-ball-like particles, the sequence of swelling and seeded polymerization was altered. The PS/P(St-MPS) composite spheres obtained by seeded polymerization without addition of PX, CP705-0, as illustrated in Fig. 2a, were swelled with PX (w PX/w particles = 2/1) at room temperature and at 70 °C. After being swelled at room temperature and deswelling, interestingly, a part of the spheres was transformed into snowman-like particles (Fig. 3a). It means the sequence of swelling and seeded polymerization influences the mophorlogy of the particles greatly. Additionally, in contrast to PS spheres, the composite particles CP705-1 could not be completely solved in PX, dimethylformamide, or tetrahydrofuran (Supporting Information Fig. S3), which hints that the shell is crosslinked due to the condensation of the silanol groups. In the FTIR spectrum of CP705-1 (Supporting Information Fig. S2), the peak at 1080 cm−1 can be attributed to Si–O–Si bonds [39], which also verify the crosslinking induced by the polycondensation of silanol groups.

After comparing the two apparently different morphologies of the obtained particles, a formation mechanism could be proposed as follows. As illustrated in Fig. 4, for the seeded polymerization of PS spheres without being swelled with PX, a P(St-MPS) shell [37] is formed on the PS core. Upon exposure to solvent, the shell could absorb much less solvent than the PS core could due to the existence of hydrophilic silanol group and crosslinking. Consequently, the relative volume expansion of the core is much larger than the shell, causing a strong elastic stress and squeezing out part of the core during swelling to form a bulge on the sphere. However, due to the protection of the P(St-MPS) shell, the swelling of the cores might not be uniform, which causes some of the composite spheres to transform to snowman particles while others are still spheres.

The mechanism of the morphology evolution of the PS/P(St-MPS) core shell spheres exposed to solvent. (1) Seeded polymerization to form PS/P(St-MPS) core shell sphere; (2) swelling the core shell spheres with PX leads to the expansion of the PS cores and formation of a budge; (3) deswelling of the particles causes the contraction of the snowman particles

When the swelling temperature was increased to 70 °C, the raised temperature promotes the diffusion of PX and more absorption by the hydrophobic core and leads to its larger volume expansion. The extrusion of the core by the hydrophilic shell produces a larger bulge than that formed at room temperature, as indicated by the arrow in Fig. 3b. At the same time, the expansion of the P(St-MPS) shell at 70 °C might not be resilient, which causes that the original shell becomes buckled.

On the other hand, when the PS spheres are swelled before seeded polymerization, as illustrated in Fig. 1, the swelling process leads to the volume expansion of the PS spheres. Subsequent polymerization of styrene and MPS generates a P(St-MPS) shell on the enlarged PS core. Also, due to the existence of hydrophilic silanol groups and crosslinking, the shells have a much smaller swelling ratio than the core. Consequently, the cores have a much stronger tendency to contract than do shells during deswelling, causing localized depressions of the surface and buckling of the spheres. Increase of the solvent amount leads to absorption of more solvent by the PS spheres and greater volume enlargement. The volume discrepancy of the swelled and shrunk state is enhanced, which leads to a higher degree of buckling.

Influence of the size of PS spheres on the particle morphologies

PS spheres of 595, 755, and 895 nm are also employed to fabricate PS/P(St-MPS) composite particles with a fixed w PX/w particles of 2, which are shown in Fig. 5. For 595-nm PS spheres, the particles are also deflated-ball like with their size enlarged to 784 ± 27 nm. There are obvious surface folding and wrinkles appearing on the surface of the resulted particles, as the particles obtained previously from the 705-nm spheres. The particles obtained from the 755- and 895-nm spheres are enlarged to 1024 ± 15 and 1109 ± 22 nm, respectively. However, they both show dried-plum-like morphology, with wrinkles but without big surface buckling. During the seeded polymerization experiments, the weight of the PS spheres and monomer added was fixed at 0.5 and 0.55 g, respectively, in every experiment. If most of the monomer contributes to the shells of the composite particles, the shell thickness should be relative to the PS sphere diameter. The increase of the PS sphere diameter leads to the increase of the shell thickness and better ability of the shell to resist deformation. Consequently, for spheres with larger diameter, the formation of small wrinkles is preferred to that of the big surface folding.

Synthesis of PS/P(St-MPS)@PS bicompartmental particles

PS/P(St-MPS) composite particles were further employed in the seeded polymerization with styrene as monomer. Figure 6 shows the PS/P(St-MPS)@PS particles obtained from CP705-2 and CP755-2. As shown in Fig. 6, all resulted particles have bicompartmental structure of deflated ball connected with a spherical bulb. During the synthesis, the composite particles are first swelled with styrene. Subsequent elevation of temperature and polymerization process cause the relaxation of the polymer chains, which produces an elastic force to squeeze out the styrene [22]. The hydrophilic surface of the particles makes it thermodynamically unfavorable for the monomer to wet the particle surface, thus promoting the formation of a new bulb [40]. With the increase of w st/w particles from 2 to 3 and 4, the diameter of the newly formed bulb increases from 310 ± 14 to 392 ± 20 nm and 480 ± 38 nm for the particles originated from 705 nm PS spheres and from 389 ± 21 to 443 ± 30 nm and 554 ± 43 nm for the particles originated from 755 nm PS spheres. The increase of w st/w particles leads to larger amount of monomer absorbed by the particles, and consequently, during the phase separation, more monomer is repelled out from the particles, and larger bulbs are formed.

SEM images of PS/P(St-MPS)@PS bicompartmental particles synthesized from CP705–2 (a, b, c, d) and CP755–2 (e, f, g, h), with various weight ratios of St to PS/P(St-MPS) composite particles: w st/w particles = a, e 2, b, f 3, c, g 4. For the TEM images (d, h) of PS/P(St-MPS)@PS composite particles, w st/w particles = 3

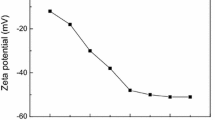

The application of the composite particles in superhydrophobic coatings

The fabrication of superhydrophobic surface normally combines a high surface roughness and a low surface energy. The unique morphologies of the composite particles could be applied to fabricate a surface with multiscale surface roughness. After modification of the PS/P(St-MPS) composite particles with PFTMS, the particles were successfully functionalized with fluorinated chains, which could be confirmed by the FTIR spectrum (Supporting Information Fig. S2). The emulsion of the fluorinated particles was spread on a glass slide and after drying the coatings were sintered to improve the connection among particles. The hydrophobicity of particulate coating is illustrated by water contact angle (CA) measurement. As shown in Fig. 7, the coating prepared by PS/P(St-MPS) composite spheres, CP705-0, exhibits a CA of 134.7°. For the surface prepared with composite particles CP705-1, CP705-2 and CP705-4, the CAs were 142.9°, 158.9°, and 160.4°, respectively. The trend corresponds well with the increase of the surface roughness caused by elevated amount of PX. Additionally, composite particles CP755-2 and CP895-2 were also used to fabricate superhydrophobic surfaces, which show CAs of 155.3°and 152.5°, respectively. This indicates that these particles are applicable for the fabrication of superhydrophobic surfaces.

Conclusions

We have demonstrated a facile approach of synthesizing SiOH-functionalized composite particles with buckled surface by seeded emulsion polymerization with the aid of solvent. By taking PS microspheres swollen with PX as seeds for the polymerization of styrene and MPS, deflated-ball- or dried-plum-shaped composite particles are obtained. The formation mechanism of surface buckling is analyzed. It is found that w PX/w particles plays an important role in the final morphologies of the composite particles. The increase of w PX/w particles leads to more obvious wrinkles and higher surface roughness. Further emulsion polymerization of styrene with these composite particles as seeds produces bicompartmental particles with unique shapes. Due to the silanol groups generated by hydrolysis of MPS on their surface, these particles could be easily functionalized with organosilane for various applications and also could be applied in the synthesis of more intricate organic–inorganic hybrid materials. The modification of the particles with fluorinated silane and their application in the fabrication of superhydrophobic surfaces are demonstrated.

References

Walther A, Müller AHE (2013) Janus particles: synthesis, self-assembly, physical properties, and applications. Chem Rev 113:5194–5261

Duguet E, Desert A, Perro A, Ravaine S (2011) Design and elaboration of colloidal molecules: an overview. Chem Soc Rev 40:941–960

Glotzer SC, Solomon MJ (2007) Anisotropy of building blocks and their assembly into complex structures. Nature Mater 6:557–562

Mao ZW, Xu HL, Wang DY (2010) Molecular mimetic self-assembly of colloidal particles. Adv Funct Mater 20:1053–1074

Hosein ID, Ghebrebrhan M, Joannopoulos JD, Liddell CM (2010) Dimer shape anisotropy: a nonspherical colloidal approach to omnidirectonal photonic band gaps. Langmuir 26:2151–2159

Yang S-M, Kim S-H, Lim J-M, Yi G-R (2008) Synthesis and assembly of structured colloidal particles. J Mater Chem 18:2177–2190

Peng B, Smallenburg F, Imhof A, Dijkstra M, van Blaaderen A (2013) Colloidal clusters by using emulsions and dumbbell-shaped particles: experiments and simulations. Angew Chem -Int Edit 52:6709–6712

Zheng L, Ma ZH, Geng C, Yan QF (2013) Solvent-assisted interfacial tension deformation of spherical particles for the fabrication of non-spherical particle arrays. Part Part Syst Charact 30:812–817

Suci PA, Kang S, Young M, Douglas T (2009) A streptavidin-protein cage Janus particle for polarized targeting and modular functionalization. J Am Chem Soc 131:9164–9165

Benyettou F, Zheng X, Elacqua E, Wang Y, Dalvand P, Asfari Z, Olsen JC, Han DS, Saleh N, Elhabiri M, Weck M, Trabolsi A (2016) Redox-responsive viologen-mediated self-assembly of CB[7]-modified patchy particles. Langmuir 32:7144–7150

Bellanger H, Darmanin T, Taffin de Givenchy E, Guittard F (2014) Chemical and physical pathways for the preparation of superoleophobic surfaces and related wetting theories. Chem Rev 114:2694–2716

Kim S-H, Lee SY, Yang S-M (2010) Janus microspheres for a highly flexible and impregnable water-repelling interface. Angew Chem -Int Edit 49:2535–2538

Tian Y, Su B, Jiang L (2014) Interfacial material system exhibiting superwettability. Adv Mater 26:6872–6897

Zhu Y, Zhang S, Hua Y, Zhang H, Chen J (2014) Synthesis of latex particles with a complex structure as an emulsifier of pickering high internal phase emulsions. Ind Eng Chem Res 53:4642–4649

Kim J-W, Lee D, Shum HC, Weitz DA (2008) Colloid surfactants for emulsion stabilization. Adv Mater 20:3239–3243

Ji X, Wang M, Ge X, Liu H (2013) Synthesis of anisotropic polymer/inorganic particles via asymmetric swelling-dissolving process. Langmuir 29:1010–1016

Zhai WZ, Li T, He YF, Xiong YB, Wang RM (2015) One-pot facile synthesis of half-cauliflower amphiphilic Janus particles with pH-switchable emulsifiabilities. RSC Adv 5:76211–76215

Yang M, Cao LJ, Tan L (2014) Synthesis of sea urchin-like polystyrene/polyaniline microspheres by seeded swelling polymerization and their catalytic application. Colloid Surf A-Physicochem Eng Asp 441:678–684

Wang L, Xia L, Li G, Ravaine S, Zhao XS (2008) Patterning the surface of colloidal microspheres and fabrication of nonspherical particles. Angew Chem -Int Edit 47:4725–4728

Motoyoshi K, Tajima A, Higuchi T, Yabu H, Shimomura M (2010) Static and dynamic control of phase separation structures in nanoparticles of polymer blends. Soft Matter 6:1253–1257

Tanaka T, Okayama M, Kitayama Y, Kagawa Y, Okubo M (2010) Preparation of "mushroom-like" Janus particles by site-selective surface-initiated atom transfer radical polymerization in aqueous dispersed systems. Langmuir 26:7843–7847

Sheu HR, El-Aasser MS, Vanderhoff JW (1990) Phase separation in polystyrene latex interpenetrating polymer networks. J Polym Sci, Part A: Polym Chem 28:629–651

Wang S, Wu N (2015) The impact of nonpolymerizable swelling agents on the synthesis of particles with combined geometric, interfacial, and compositional anisotropy. Langmuir 31:7962–7969

Tang C, Zhang C, Liu J, Qu X, Li J, Yang Z (2010) Large scale synthesis of Janus submicrometer sized colloids by seeded emulsion polymerization. Macromolecules 43:5114–5120

Park J-G, Forster JD, Dufresne ER (2010) High-yield synthesis of monodisperse dumbbell-shaped polymer nanoparticles. J Am Chem Soc 132:5960–5961

Sacanna S, Korpics M, Rodriguez K, Colon-Melendez L, Kim S-H, Pine DJ, Yi G-R (2013) Shaping colloids for self-assembly. Nat Commun 4:1688

Sacanna S, Irvine WTM, Chaikin PM, Pine DJ (2010) Lock and key colloids. Nature 464:575–578

Wang Y, Wang Y, Zheng X, Yi G-R, Sacanna S, Pine DJ, Weck M (2014) Three-dimensional lock and key colloids. J Am Chem Soc 136:6866–6869

Klein MK, Saenger NR, Schuetter S, Pfleiderer P, Zumbusch A (2014) Shape-tunable core-shell microparticles. Langmuir 30:12457–12464

Liu D, Peng X, Wu B, Zheng X, Chuong TT, Li J, Sun S, Stuckyt GD (2015) Uniform concave polystyrene-carbon core-shell nanospheres by a swelling induced buckling process. J Am Chem Soc 137:9772–9775

Huang Y, Wang J, Zhou J, Xu L, Li Z, Zhang Y, Wang J, Song Y, Jiang L (2011) Controllable synthesis of latex particles with multicavity structures. Macromolecules 44:2404–2409

Okubo M, Takekoh R, Suzuki A (2002) Preparation of micron-sized, monodisperse poly(methyl methacrylate)/polystyrene composite particles having a large number of dents on their surfaces by seeded dispersion polymerization in the presence of decalin. Colloid Polym Sci 280:1057–1061

Fujibayashi T, Okubo M (2007) Preparation and thermodynamic stability of micron-sized, monodisperse composite polymer particles of disc-like shapes by seeded dispersion polymerization. Langmuir 23:7958–7962

Hosseinzadeh S, Saadat Y, Abdolbaghi S (2012) Preparation of novel and unique nonspherical particles with almond-shell-like shape via dual-seeded dispersion polymerization in the presence of saturated hydrocarbon droplets. Colloid Polym Sci 290:847–853

Okubo M, Minami H, Morikawa K (2001) Production of micron-sized, monodisperse, transformable rugby-ball-like-shaped polymer particles. Colloid Polym Sci 279:931–935

Okubo M, Minami H, Morikawa K (2003) Influence of shell strength on shape transformation of micron-sized, monodisperse, hollow polymer particles. Colloid Polym Sci 281:214–219

Bourgeat-Lami E, Tissot I, Lefebvre F (2002) Synthesis and characterization of SiOH-functionalized polymer latexes using methacryloxy propyl trimethoxysilane in emulsion polymerization. Macromolecules 35:6185–6191

Shim SE, Cha YJ, Byun JM, Choe S (1999) Size control of polystyrene beads by multistage seeded emulsion polymerization. J Appl Polym Sci 71:2259–2269

Saravanamuttu K, Blanford CF, Sharp DN, Dedman ER, Turberfield AJ, Denning RG (2003) Sol-gel organic-inorganic composites for 3-D holographic lithography of photonic crystals with submicron periodicity. Chem Mater 15:2301–2304

Mock EB, DeBruyn H, Hawkett BS, Gilbert RG, Zukoski CF (2006) Synthesis of anisotropic nanoparticles by seeded emulsion polymerization. Langmuir 22:4037–4043

Acknowledgements

We thank the National Natural Science Foundation of China (Nos. 51302109, 21671081, and 21502070), Natural Science Foundation of Jiangsu Province of China (BK20130144), and Fundamental Research Funds for the Central Universities (JUSRP51626B) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

.

ESM 1

(DOCX 773 kb)

Rights and permissions

About this article

Cite this article

Wang, L., Li, H., Shi, G. et al. Synthesis of SiOH-functionalized composite particles with buckled surface by seeded emulsion polymerization. Colloid Polym Sci 295, 471–478 (2017). https://doi.org/10.1007/s00396-017-4026-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-017-4026-8