Abstract

The preparation and characterization of active-loaded microparticles for cosmetic textile applications were studied in this work. The double emulsion diffusion/evaporation technique was served and the Eudragit® RS100 (ethyl acrylate and methyl methacrylate copolymers) was used as biodegradable polymer. Two actives molecules, vitamin E and Lauryl isoquinolinium bromide (LIB) were successfully loaded during the formulation. Obtained particles were spherical in shape with a little variable diameter about 1 μm and zeta potential of 55 mV. The cutaneous penetration of the particles was evaluated by dermal microdialysis, tape stripping, and punch-biopsy techniques from ex vivo human skin. LIB or vitamin E concentrations in the different layers of the skin were analyzed by high-performance liquid chromatography method. Finally, these particles were adsorbed onto a textile in optimized conditions. The scanning electron microscopy is used to confirm the total threads coverage by particles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, the preparation of particles, as new active carriers, which control the amount of drug released and their localization, has become an important field of research. The facilities provided by the nanotechnologies have opened many ways to present the active molecules, transfer them into the target and release them at the desired site. Nowadays, particle synthesis is widely based on biodegradable polymers, so the active molecules are loaded inside the particles, which allow their controlled release over prolonged time [1, 2]. Encapsulation techniques are used to improve the administration efficacy, reduce the toxicity, protect the drug, and control the release. Drug release from particles occurs either by diffusion through the matrix or by matrix degradation [3].

Cosmetic industries [4], in addition to medicine and pharmacy, are highly interested by nanotechnology and polymer capsules applications as new drug administration methods. In these cases, encapsulation is used to hide the active molecules inside the polymer cavity, protect it from the external environment, and control the amount released during the capsule life.

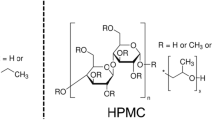

Eudragit® polymers are used to prepare particles containing active molecules for prolonged release [5]. Whereas, these polymers are insoluble in water, non-toxic, have low permeability, and pH-independent swilling, they are suitable inert carriers of drugs and active molecules [6, 7]. Various techniques have been used to encapsulate active molecules into Eudragit® particles. These techniques include double emulsion [8], nanoprecipitation [9], supercritical fluid [10], and spray drying [11]. Among them, double emulsion method [12] is widely used to synthesize drug-loaded polymeric particles. Here, W/O/W-type double emulsion was selected and several steps for its preparation are required: (1) first emulsion: an aqueous solution of the active molecule (the internal aqueous phase W1) is emulsified into an organic solution consisting of biodegradable polymer and organic solvent (this is the oil phase O). (2) Then, the obtained emulsion (W1/O) can be emulsified in second aqueous phase (external phase W2) to get the double emulsion (W1/O/W2). (3) The next step is the evaporation of organic solvent to solidify the polymer and result in the formation of solid polymeric particles, which entrap the active molecules. (4) The last step is the particles’ separation, usually by centrifugation or freeze-drying. In addition, double emulsion technique is suitable for both hydrophilic and hydrophobic [13] molecules.

The objectives of this study were to synthesize active-loaded polymeric particles of Eudragit® RS100 using double emulsion solvent diffusion and evaporation technique. Then, these particles were deposited onto the textile using the electrostatic forces. The adsorbed particles should resist against washing and release the active molecules over a prolonged period.

Firstly, we synthesized blank particles by a systematic study and investigated all the parameters that can affect the size and morphology of particles, such as the polymer amount, the stirring speed and time, the external phase volume and the water volume of final dilution. Obtained particles were then adsorbed onto negatively charged textiles. The textile was incubated with the particles’ suspension for a predetermined (or specific) time, and the adsorbed particles’ amount was evaluated using SEM and zeta potential. Different parameters of adsorption were investigated such as the pH of medium and the time of incubation. Secondly, we synthesized active-loaded particles; two actives, vitamin E and lauryl isoquinolinum bromide (LIB), were chosen respectively for their hydrating and anti-body hair growth effects. The encapsulation efficiency was analyzed by high-performance liquid chromatography (HPLC) method. The cutaneous penetration of the particles was evaluated by dermal microdialysis [14, 15], tape stripping, and punch-biopsy techniques from ex vivo human skin. LIB or vitamin E concentrations were determined in the different layers of the skin.

Materials and methods

Materials

Eudragit® RS100 (ethyl acrylate and methyl methacrylate copolymers), weight average molar mass: approx. 32,000 g/mol, was purchased from EVONIK (EVONIK, Germany). Vitamin E, LIB, dichloromethane (DCM), and poly(vinyl alcohol) (PVA) were obtained from Sigma-Aldrich. Deionized water was used throughout the study.

Preparation of particles

Eudragit® RS100 particles were prepared using double emulsion W/O/W method. To prepare the first emulsion, two types of homogenizer were used (Ultra Turrax® T-10, IKA® Werke, Staufen, Germany, and/or ultrasound). The steps of the general experiment were briefly as follows; 1 g of Eudragit® RS100 was dissolved in 5 ml DCM and emulsified with 1 ml water using Ultra Turrax® or ultrasound. The obtained emulsion W/O was injected in 30 ml water (with or without stabilizer PVA) and emulsified using Ultra Turrax® (T-25, IKA® Werke, Staufen, Germany). Then, the second emulsion W/O/W was poured into 100 ml water and magnetically stirred for 15 min (using simple magnetic bar). Finally, the double emulsion was evaporated to remove the organic solvent, DCM, and solidify the particles (rotary evaporator). The obtained particles were filtered on glass wool to remove the potential aggregations.

Optimization of particles’ size

We studied the influence of all synthesis parameters on the particles’ morphology and size.

The effect of polymer amount

The amount of Eudragit® dissolved in 5 ml of DCM varied from 0.25 to 1.5 g: Emulsions were prepared using 1 ml water for internal aqueous phase (W1) and 50 ml water for external aqueous phase (W2). The ultrasound was used to emulsify the first emulsion (70 % power and 1.5 min) and Ultra Turrax® to prepare the second emulsion (13,500 rpm for 15 min). Finally, the double emulsion was diluted in 100 ml water, stirred for 15 min, and evaporated to remove DCM.

The effect of Ultra Turrax speed and time (first emulsion)

The first emulsion was prepared initially using a small-size Ultra Turrax (T-10) and the effects of its speed and emulsification time were investigated. Speed varied from 13,500 to 24,500 rpm and used times were 2, 3, and 4 min.

The effect of ultrasound power and time (first emulsion)

Particles’ size of the first emulsion influences the finale particles’ size, so we studied the effect of ultrasound power and time on the finale particles’ size. One gram of Eudragit® was dissolved in 5 ml DCM and emulsified with 1 ml water using variation of ultrasound time. The second emulsion was prepared as previously described (Ultra Turrax®, 13,500 rpm for 15 min).

The effect of external aqueous phase volume

The volume of external aqueous phase, W2 was changed from 30 to 90 ml water and the particles were prepared using 1 g Eudragit® in 5 ml DCM. The first emulsion was prepared by ultrasound (70 % for 1.5 min) and the second emulsion was prepared by Ultra Turrax® (13,500 for 15 min).

The effect of final dilution volume

Particles prepared by double emulsion were diluted in water to help the organic solvent to diffuse outside the particles. The amount of water used for this dilution varied and the effect of this dilution on the particles’ size and morphology was investigated. The double emulsions were prepared as previously described.

Characterization of particles

Particles’ morphology

Scanning electron microscopy SEM, was performed with a Hitachi S800 FEG microscope, at the “centre technologiques des microstructures” CTμ at the University of Lyon. For the sample preparation, a drop of the sample was deposited on a flat steel holder and dried at room temperature overnight. The samples were coated under vacuum cathodic sputtering with platinum. The particles were examined using SEM under accelerating voltage of 15 kV.

Particles’ size analysis

Particles’ size and size distribution were measured with a laser diffraction particle size analyzer (Beckman Coulter LS 13 320). Samples were prepared by adding drops of aqueous particle suspension to the instrument container, already filled with distilled water.

Zeta potential analysis

The zeta potential of particles was measured using Zetasizer instrument (Zetasizer Nano S, Malvern®, UK). Particles were highly diluted in NaCl 1 mM and potential zeta was measured using special zeta cell DTS1070 (Malvern®, UK). Potential zeta, of particles, as a function of pH was measured using autotitrator (MPT-2, Malvern®, UK). Sample was highly diluted in NaCl 1 mM and potential zeta was measured between pH 3 and 11.

Cutaneous penetration

Encapsulation efficiency

Particles’ suspensions were centrifuged and the supernatants were removed and stored at −20 °C until analysis.

Ex vivo microdialysis

Microdialysis system consisted of a CMA/100® syringe pump and a CMA/140 microfraction collector (Phymep, France). Microdialysis probes (CMA/20®) had a 20-kDa cut off with a polycarbonate membrane (length 10 mm). The probes (3 per condition) were inserted into the dermis of ex vivo abdominoplastic skin fragments. Probes were perfused with Ringer’s lactate/3 % BSA solution at an optimal flow rate of 3 μl/min. The penetration areas were demarcated on the skin with metallic ring. Five hundred microliters of standard and encapsulated molecules were applied to the demarcated area of the skin. Samples were collected every 90 min over a period of 24 h and stored at −20 °C until analysis.

The depth of microdialysis probes in the skin was measured by ultrasound scanning.

Tape stripping and biopsies

D-squame® tapes (Monaderm, France) were applied and removed. Discs 1–10 were stored at −20 °C until analysis (disc 1 for skin surface and 2 to 10 for stratum corneum). Skin biopsies were realized and epidermis was separated from dermis by dispase incubation. Tissues were stored at −20 °C until analysis.

Sample analysis

Extraction

The content of vitamin E and LIB in the tape strips and biopsies was analyzed following extraction procedure [16]. Methanol was added to tape strips. Tubes were shacked during 10 min, centrifuged at 14,000×g for 10 min before collecting the supernatant. Human dermises or epidermises were weighted in glass tube. After homogenization using a dispersing Ultra Turrax®, methanol was added, shaken, and sonicated for 10 min. After centrifugation at 14,000×g for 10 min, the supernatant was collected. The concentration of vitamin E and LIB in dialysates was measured without pre-treatment.

Vitamin E quantification

Vitamin E was assayed by HPLC using a Shimadzu Prominence HPLC system equipped with a pump model LC-20AB, an autosampler model SIL-20A. Double detection was used: photodiodoarray detector model SPD-M20A (Shimadzu, France) coupled with a triple quadripole TSQ Vantage (ThermoFisher, France). Separation was performed on a Prevail C18 column (150 × 4.6 mm, 3.1 μm, Alltech, Deerfield, IL, USA) using mobile phases composed of acetonitrile:0.05 % phosphoric acid solution (35:65, v/v) at a flow rate of 1 ml/min and of acetonitrile (100 %). UV detection wavelength of 285 nm was used for vitamin E detection and quantification. Standard solutions of the drugs were prepared in methanol or acetonitrile, and linearity was achieved over the range of 1–100 μg/ml (r 2 > 0.99) [17].

LIB quantification

LIB was analyzed by HPLC-DAD. The column used was a C18 Xterra, 5 μm (4.6 × 150 mm, SN°: T32753G) and the system was a P4000 pump coupled with a UV6000LP diode array detector (Thermo Separation Products, Les Ulis, France).The acquisition software was ChromQuest (Thermo Separation Products, Les Ulis, France). The mobile phase was composed of 60 % acetonitrile and 40 % ammonium formate (0.1 M, pH = 3.5) with a flow rate of 1 ml/min. The quantification was done at 335 nm. The retention time was 4.8 min and the volume of injection was 20 μl. Linearity was obtained in the range 0.1 to 10 μg/ml (r 2 > 0.99) [18].

Statistical data

Statistical analyses were performed using a two-way ANOVA (for microdialysis) and one-way ANOVA (for tape stripping and biopsies), followed by a Fischer test.

Active-loaded particles and adsorption onto textile

Two active molecule models used were the vitamin E and lauryl isoquinolinum bromide (LIB). Particles were prepared as described above and the active molecules were added to the first emulsion (W1/O). In our case, the actives are hydrophobic and soluble in the organic phase. Therefore, the actives were added to the organic phase. In the case of hydrophilic active, they can be added in the internal aqueous phase.

The obtained particles were incubated with small pieces (1 cm2) of fabrics, polyamide. Next, the pieces were immersed in distilled water to remove the excess of particles. The optimum conditions of adsorption were investigated by testing the pH of medium and incubation time. Particle-treated textiles characterized by SEM and surface zeta potentials were determined before and after particles’ adsorption.

Results and discussion

Particles’ preparation

Double emulsion diffusion evaporation (W1/O/W2) technique was used to prepare the particles. The first emulsion W1/O was formed by emulsification of organic solution of a polymer containing the active molecules with an aqueous solution. Then, the second emulsion formed by emulsifying the first one (W1/O) with an aqueous solution of PVA. Size and morphology of the obtained particles depend on several factors such as the following:

-

The droplet size of the first emulsion.

-

The organic solvent and its diffusion into the external aqueous phase.

-

The volume of the external aqueous phase.

-

Stabilizer and its concentration.

-

Homogenizer used, its speed and treatment time.

Usually, particles obtained by double emulsion, using a mechanical homogenizer, have a minimum size of 10 μm [19]. This is due to the limited efficient of the mechanical homogenizer to produce very small droplets.

In this study, particles were prepared by two different ways, the preparation of the first emulsion only, using the Ultra Turrax® and the ultrasound.

The particles prepared using Ultra Turrax® were big in size, between 10 and 40 μm, and those that were prepared using ultrasound had sizes in the range of 1 μm, as shown in Fig. 1.

These results are due to the high fragmentation power of ultrasound, which formats small drops (W1/O). In addition, as it is shown in the Fig. 1, the surface properties are also different. The particles obtained by Ultra Turrax® were porous, with big pores, while the particles obtained by ultrasound had smooth surfaces with few and small holes. As the same quantity of polymer was used in both cases, walls of the small particles were thicker than walls of the big particles, so the solvent evaporation is more effective in the case of big particles, which produced bigger holes in the particles walls. The specific surface area of small particles was higher than that in the big particles, so the contact area between organic and aqueous phases in small particles was larger than that in the big particles. Therefore, the organic solvent diffusion to the aqueous phase was faster in the case of small particles, which lead to rapid solidification of the polymer matrix. This is a second reason why big particles were more porous than the small ones. Size distribution in both cases was wide.

As known that the particles prepared by emulsification process have non-uniform (polydisperse) sizes and to improve the uniformity, an expenditure of high energy for longer duration is required. Here, for our desired applications, polydispersity was not a big problem so it was not so necessary to spend high energy for a long time to get better results.

After these preliminary studies, we decided to use ultrasound in the first emulsification step since our target size was 1 μm, which was achieved by the ultrasonication (without any stabilizer).

Particles’ size optimization

The effect of polymer amount

Different quantities of polymer were used to prepare particles, 0.25, 0.5, 1, 1.5, and 2 g Eudragit® RS100. Table 1 resumes the results of preparations using different quantities of polymer.

Slight increasing trend in particle size was observed as polymer amount was increased from 0.25 to 1.0 g, but this slight increase was followed by a sudden large increase in particle size (~13 μm) which was observed at 1.5 g of polymer. The viscosity became more important, so the energy needed for the fragmentation is greater than the supplied.

At higher concentration, 2 g and more, particles’ formation was not observed due to the high viscosity of organic solution. It is obvious that the particles’ size was highly sensitive to the polymer concentration, due to the absence of surfactant or stabilizer agent so the particles’ coagulation was effective at high polymer concentration. Yang et al. [19] found similar results where it was observed that the polymer concentrations of 16.7 and 33.3 mg/ml gave particles’ diameters of 97.9 and 125.8 μm, respectively.

The effect of other parameters, ultrasound, external aqueous phase, and final dilution phase

Ultrasound was used to emulsify the first emulsion W1/O; the drops were prepared without surfactants or stabilizers and poured directly into the external phase to prepare the second emulsion. Generally, droplets size of the first emulsion does not affect the final particles’ size (in condition that the droplets’ size is relatively smaller than the final particles [20, 21]). To study the effect of ultrasound onto the particles’ size, two polymer concentrations were chosen, 0.25 and 1 g. Particles were prepared using double emulsion diffusion/evaporation; with the first emulsion being prepared using ultrasound at 70 %. Ultrasonication times were varied from 1.5 to 6.0 min and the results are displayed in Table 2.

It was clear that the ultrasound time at these conditions showed no effect on the final particles’ size even with different polymer concentrations. By comparing these particles with the particles prepared using Ultra Turrax® over all the experiments, we found that the average particles’ size is 40 μm. This was due to the size of first droplets formulated by Ultra Turrax®. Even with high speed (24,000 rpm), these droplets were too big and the final particles were so far from 1 μm. These results suggested that in these conditions, we could not mechanically reach to very small droplets to have submicron particles in the final step.

In addition, the effect of the external phase on the particles’ size was investigated. The volume of the external phase varied from 30 to 90 ml. Table 3 shows the average particles’ sizes of particles prepared with different external phase volume.

Changing the volume of the external phase increased slightly the particles’ size. In this case, increasing the external phase volume decreased the efficacy of homogenizer, so the average particles’ size was bigger with extra volume of external aqueous phase. Moreover, for completing the investigation of the external water effect on the particles’ size, the effect of dilution with excess volume of water was also studied.

The volume of external phase is important in this process of particles’ formulation, specially its effect on the size and morphology. The process of polymer solidification depends on removing the organic solvent, which can be done by extraction and evaporation. Extraction step depends on the miscibility between the organic solvent and water [16]. In this study, the double emulsion was diluted with water after the second emulsion preparation to help the organic solvent diffusion into the external aqueous phase and start the polymer solidification. This pre-solidification step has an effect on the final particles’ morphology [16]. Table 4 shows the results obtained by variation in the volume of water used to dilute the W1/O/W2 emulsion.

Results in Table 4 showed that the dilution step had no effect on the average particles’ size and adding more water only slightly decreased the average particles’ size. This was due to the poor solubility of DCM in water, 1.3 g/100 ml at 20 °C (ethyl acetate 8.2 g/100 ml at 20 °C). Moreover, the used external aqueous phase did not contain any surfactant or a stabilizer agent, which could help to increase the DCM solubility in water.

Characterization of particles

The morphology and the surface characteristics of obtained particles were observed using scanning electron microscope. Figure 2 shows the SEM photographs of particles prepared by double emulsion diffusion/evaporation. It was seen that the particles were spherical in shape, polydisperse, and with rough surface, which can be related to the diffusion and evaporation processes applied after the particles’ synthesis.

In addition, zeta potential values of prepared particles were measured using ZetaSizer, and it was found that these values were almost stables and independent of formulation recipe. The zeta potential values were between 45 and 55 mV. This independence of formulation method was due to the usage of the same polymer in all preparations and absence of any stabilizer agent or surfactant, which could modify the electrostatic characteristics of particles’ surface.

Study of the encapsulation efficiency and skin penetration

Here, we studied the encapsulation efficiency and the penetration of active-loaded microparticles through the skin using microdialysis, tape stripping, and punch-biopsy techniques. Two actives, vitamin E-loaded particles and LIB-loaded particles, and two standard solutions (as control) were used in this work. Particles’ suspensions were centrifuged and the supernatants were removed to study the encapsulation efficiency. The actives’ concentration in the supernatants showed that the encapsulation efficiency was 98 % for vitamin E and 100 % for LIB (data not illustrated). For vitamin E, results obtained by dermal microdialysis are shown in Fig. 3.

The dermal penetration kinetic of vitamin E-loaded particles was different from the control, with a significant slower initial penetration and a significant higher concentration found at 9 vs 6 h for the control (Fig. 3a). The area under the curve was significantly larger with vitamin E-loaded particles compared with that in the control, indicating an increased dermal penetration (Fig. 3b). Results obtained by tape stripping and biopsies are shown in Fig. 4. The content of vitamin E in the skin layers, after 24 h of application, were not significantly different between the two formulations.

For LIB, results obtained by dermal microdialysis are shown in Fig. 5. The dermal penetration kinetic of LIB-loaded particles was different from the control, with a significant slower initial penetration and a significant higher concentration found at 18 vs 13 h 30 for the control (Fig. 5a). The area under the curve was significantly larger with LIB-loaded particles compared with that in the control, indicating an increased dermal penetration (Fig. 5b). Results obtained by tape stripping and biopsies are shown in Fig. 6. The content of LIB was significantly decreased in the skin surface and increased in the epidermis layer after 24 h of application of LIB-loaded particles compared with that in the control.

The content of LIB in the dermis, after 24 h of application, was not significantly different between the two formulations and LIB was not detected in the stratum corneum.

All these results proved that the encapsulation process is good and does not modify the cutaneous penetration of actives.

Adsorption onto the textile

According to the zeta potential results, the obtained particles are positively charged, ≈+50 mV and the textiles target of this treatment are negatively charged, so we supposed that the particles could be easily adsorbed by electrostatic interaction onto the textile threads. To study this interaction and get a maximum adsorption of particles onto the threads, the particles were adsorbed by a sample incubation of textile pieces (1 g of pieces of 1 cm2) in 30 ml of aqueous particle suspension for 1 h. Then, the textile pieces were removed and immersed for a short time in distilled water to remove the excess particles. Textile pieces were dried and analyzed by SEM. Figure 7 shows the SEM photographs of textiles before and after particles’ adsorption.

In this study, we investigated the effect of time and pH on the adsorption efficiency. Figure 8 shows the zeta potential values of particles and textile as a function of pH. As seen in Fig. 8, the range of pH between 5 and 9 was the best condition to perform the interaction between particles and textile because in this area, the difference of zeta potential values was at maximum. The time effect was studied also and we found that interaction was fast and did not require a long time (30–60 min are enough). Figure 7 shows that the threads were very well coated by particles in these conditions. Hence, these results suggested a very good distribution of loaded actives onto the textile threads.

Conclusion

The successful preparation of active-loaded microparticles was achieved using the double emulsion diffusion/evaporation technique and the polymer Eudragit® RS100. A systematic study of particles’ formulation and size optimization was performed to identify the optimum formulation recipe. Obtained particles were characterized and studied by SEM, which confirmed the spherical morphology of particles with rough and porous surfaces. Controlling the particles’ diameter could control the particles’ surface and the pores’ size. Active molecules (vitamin E and LIB) were successfully loaded during particles’ synthesis and their skin penetration aptitude was confirmed in addition to the total active conservation. Finally, particles’ adsorption onto a negatively charged textile was studied and a complete coverage of threads with particles was accomplished.

In summary, we prepared positively charged microparticles, which can be loaded with active molecules and can be stably adsorbed onto a negatively charged textile. Particle-activated textiles have promoted applications in cosmetic and pharmaceutical industries.

References

Freiberg S, Zhu XX (2004) Polymer microspheres for controlled drug release. Int J Pharm 282:1–18. doi:10.1016/j.ijpharm.2004.04.013

Tran V-T, Benoît J-P, Venier-Julienne M-C (2011) Why and how to prepare biodegradable, monodispersed, polymeric microparticles in the field of pharmacy? Int J Pharm 407:1–11. doi:10.1016/j.ijpharm.2011.01.027

Uhrich KE, Cannizzaro SM, Langer RS, Shakesheff KM (1999) Polymeric systems for controlled drug release. Chem Rev 99:3181–3198. doi:10.1021/cr940351u

Rosen M (2005) Delivery system handbook for personal care and cosmetic products: technology, applications and formulations. William Andrew

Khan MS, Vishakante GD, Bathool A (2012) Development and characterization of brimonidine tartrate loaded Eudragit nanosuspensions for ocular drug delivery. J Colloid Sci Biotechnol 1:122–128. doi:10.1166/jcsb.2012.1008

Pignatello R, Bucolo C, Puglisi G (2002) Ocular tolerability of Eudragit RS100® and RL100® nanosuspensions as carriers for ophthalmic controlled drug delivery. J Pharm Sci 91:2636–2641. doi:10.1002/jps.10227

Ibrahim HK, El-Leithy IS, Makky AA (2010) Mucoadhesive nanoparticles as carrier systems for prolonged ocular delivery of gatifloxacin/prednisolone bitherapy. Mol Pharm 7:576–585. doi:10.1021/mp900279c

Sipos P, Csóka I, Srčič S, et al. (2005) Influence of preparation conditions on the properties of Eudragit microspheres produced by a double emulsion method. Drug Dev Res 64:41–54. doi:10.1002/ddr.10425

Das S, Suresh PK, Desmukh R (2010) Design of Eudragit RL 100 nanoparticles by nanoprecipitation method for ocular drug delivery. Nanomed Nanotechnol Biol Med 6:318–323. doi:10.1016/j.nano.2009.09.002

Chattopadhyay P, Huff R, Shekunov BY (2006) Drug encapsulation using supercritical fluid extraction of emulsions. J Pharm Sci 95:667–679. doi:10.1002/jps.20555

Esposito E, Roncarati R, Cortesi R, et al. (2000) Production of Eudragit microparticles by spray-drying technique: influence of experimental parameters on morphological and dimensional characteristics. Pharm Dev Technol 5:267–278. doi:10.1081/PDT-100100541

Ogawa Y, Yamamoto M, Okada H, et al. (1988) A new technique to efficiently entrap leuprolide acetate into microcapsules of polylactic acid or copoly(lactic/glycolic) acid. Chem Pharm Bull (Tokyo) 36:1095–1103

Matos M, Gutiérrez G, Coca J, Pazos C (2014) Preparation of water-in-oil-in-water (W1/O/W2) double emulsions containing trans-resveratrol. Colloids Surf Physicochem Eng Asp 442:69–79. doi:10.1016/j.colsurfa.2013.05.065

Mary S, Muret P, Makki S, et al. (1999) A new technique for study of cutaneous biology, microdialysis. Ann Dermatol Venereol 126:66–70

Leveque N, Robin S, Makki S, et al. (2001) Iron concentrations in human dermis assessed by microdialysis associated with atomic absorption spectrometry. Biol Pharm Bull 24:10–13

Tavakkol A, Nabi Z, Soliman N, Polefka TG (2004) Delivery of vitamin E to the skin by a novel liquid skin cleanser: comparison of topical versus oral supplementation. J Cosmet Sci 55:177–187

Cichewicz A, Pacleb C, Connors A, et al. (2013) Cutaneous delivery of α-tocopherol and lipoic acid using microemulsions: influence of composition and charge. J Pharm Pharmacol 65:817–826. doi:10.1111/jphp.12045

Dhananjeyan MR, Bykowski C, Trendel JA, et al. (2007) Simultaneous determination of procaine and para-aminobenzoic acid by LC-MS/MS method. J Chromatogr B Anal Technol Biomed Life Sci 847:224–230. doi:10.1016/j.jchromb.2006.10.004

Yang Y-Y, Chung T-S, Ping Ng N (2001) Morphology, drug distribution, and in vitro release profiles of biodegradable polymeric microspheres containing protein fabricated by double-emulsion solvent extraction/evaporation method. Biomaterials 22:231–241. doi:10.1016/S0142-9612(00)00178-2

Crotts G, Park TG (1995) Preparation of porous and nonporous biodegradable polymeric hollow microspheres. J Control Release 35:91–105. doi:10.1016/0168-3659(95)00010-6

Meng FT, Ma GH, Qiu W, Su ZG (2003) W/O/W double emulsion technique using ethyl acetate as organic solvent: effects of its diffusion rate on the characteristics of microparticles. J Control Release 91:407–416. doi:10.1016/S0168-3659(03)00273-6

Acknowledgments

This work has been achieved in the frame of Texactiv research program and has been supported by French public agency, OSEO.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bitar, A., Zafar, N., Valour, J.P. et al. Elaboration of sponge-like particles for textile functionalization and skin penetration. Colloid Polym Sci 293, 2967–2977 (2015). https://doi.org/10.1007/s00396-015-3704-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3704-7