Abstract

Microwave-assisted degradation of dyes is being extensively investigated for wastewater remediation. The present work reports, for the first time, degradation of methyl orange (MeO) in neutral, acidic, and basic media under microwave irradiation using semiconducting polymer [poly(1-naphthylamine) (PNA)] nanotubes as catalyst in the absence of any light source. Degradation of the dye was followed spectrophotometrically and by total organic content (TOC) analysis. In the presence of poly(1-naphthylamine), microwave irradiation in 15 min caused 70, 84, and 64 % degradation at 280 nm, while at 460 nm the degradation values were 80, 96 and 78 % of MO in neutral, acidic, and basic media, respectively. The degradation of the dye in the absence and presence of PNA catalyst and in acidic, basic, and neutral media followed first-order rate kinetics. Rate constant, k, values were found to be slightly dependent on the pH of the dye solutions. Liquid chromatography–mass spectroscopy analysis confirmed that dye degrades into smaller fragments of low molar masses.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

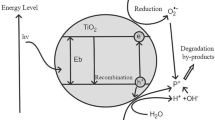

The removal of dyes from industrial effluents poses a major problem, although conventional treatment processes such as coagulation–flocculation [1–3] adsorption [4–6], membrane filtration [7–9] chemical oxidation [10–12], and so on are available. Most of these processes are however costly and particularly ineffective when treating wastewaters containing low concentrations of dyes. Considerable attention has been paid in recent years towards the photocatalytic degradation of organic pollutants using inorganic semiconductors such as TiO2 since the process results in complete mineralization under mild temperature conditions [13–15]. However, most of the inorganic semiconductors are active only in UV light which constitutes less than 5 % of the solar energy reaching the earth’s surface, and the generation of artificial UV light sources typically consumes large quantities of electrical power. Moreover, these inorganic semiconductors are also reported to cause toxic effects in marine plants, animals, and human cells [16–18]. Hence, the development of eco-friendly catalysts with high activity, low toxicity, and high stability is a major concern.

Lately, microwave (MW) energy has been applied to enhance photocatalytic or photochemical reactions for decomposing some volatile organic compounds (VOC) [19–21]. The improved catalytic activity under microwave irradiation is attributed to the polarization effect of the highly defected catalyst in the MW field that increases the transition probability of photon-generated electrons and reduces the probability of the electron–hole recombination on the semiconductor surface [22–24]. In our earlier work, we have reported the catalytic activity of nanotubes of poly(1-naphthylamine) (PNA) in the degradation of Commassie Brilliant Blue RG-250 (CB) dye by sonolysis as well as by sonophotocatalysis under solar irradiation [25, 26]. We have also reported the microwave-assisted degradation of dyes using microwave-synthesized polyaniline (PANI) and PNA/MMT nanohybrids [27, 28]. PNA as a microwave catalyst enhances dye degradation by almost two times compared to that under sonophotocatalytic condition [29].

In this study, we have attempted to investigate the effect of acidic, basic, and neutral pH media on the degradation of methyl orange (MeO) dye under microwave irradiation in the presence of PNA. The degradation was found to vary in acidic, basic, and neutral media. Mineralization up to 95 % in 40 min was confirmed by total organic content (TOC) analysis. With the help of liquid chromatography–mass spectroscopy (LC–MS) analysis, intermediates were identified, and a tentative degradation pathway of the dye was suggested. Dye under the present experimental setup was found to yield results better than the conventional degradation method.

Experimental section

Methyl Orange (MeO) dye (Sigma-Aldrich, USA) was used as received. 1-Naphthylamine (Sigma Aldrich, USA), ferric chloride (Sigma Aldrich, USA), sodium hydroxide (Sigma Aldrich, USA), acetone, chloroform, carbon tetrachloride, N-methyl-2-pyrrolidone (NMP), dimethylsulphoxide (DMSO), and dimethylformamide (DMF) (S.d. Fine Chem., Pvt. Ltd, India) were also used without further purification.

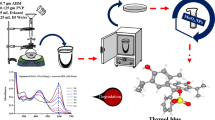

Preparation of PNA

PNA was prepared by dissolving 1-naphthylamine (3.2 mmol) and ferric chloride (0.8 mmol) in chloroform (10 mL) at −5 °C for 8 h while stirring continuously with a magnetic stirrer under nitrogen flow. The synthesized polymer was then purified by filtration (Millipore, type GN, 0.20-μm filter). PNA was then dried in vacuum oven at 60 °C for 72 h.

Preparation of MeO dye solutions and exposure to microwave irradiation in the presence and absence of PNA

MO dye of concentrations 150 and 50 mg/L was prepared by dilution of a stock solution of 500 mg/L in deionized distilled water and were labeled as MeO-150 and MeO-50, respectively. Then, 100 ml of the solutions was taken and exposed to microwave irradiation using Ladd Research Microwave oven model LBP-250, USA, fitted with a time and temperature controller, energy output—800 W, input power—1200 W. The temperature was controlled at 25 °C, and the solutions were exposed to microwave irradiation in a batch process for 3, 6, 9, 12, 15, 18, 21, and 24 min. The solutions were stirred by bubbling O2 through them. The experiment was repeated by adding PNA (300 mg) in each of 100 ml solutions of MeO-150 and MeO-50, respectively, which was then subjected to ultrasonication for 15 min. It was observed that under ultrasonication some amount of dye was adsorbed on PNA. In calculations of degraded dye, the adsorbed dye was discounted. The sonicated solutions were then exposed to microwave irradiation as earlier for the above intervals of time. Then, 10 mL supernatant of the PNA-MEO dye solution was taken in each case, centrifuged for 10 min at a speed of 5000 rpm, and analyzed. In another two sets, the pH of these solutions was adjusted to 3.5 and 10.0 using 0.1 N HCl and 0.1 N NaOH, respectively, for the degradation studies in acidic and basic media as above. Each experiment was done in triplicate, and the deviation from the mean value of the concentration of the dye at any time is shown by error bars. For kinetics analysis, the degradation data were plotted in Origin 6.1 program. Out of plots for different rate laws, the one ln C/C 0, vs time for the first-order rate law, gave the best fit of the data. The slope in this case gave the value of k, rate constant, and ordinate the value of R from which R 2 can be obtained. A value of R 2 higher than 0.995 gives over 98 % reliability of the data.

The catalyst after each run was washed with deionized distilled water and dried in hot air oven at 110 °C. Then, 1 mg of this PNA was dissolved in 10 ml of NMP, and UV–visible spectra were noted at 300 and 550 nm. The remaining catalyst was regenerated by treating with 1 N HCl overnight and then by drying it in a hot air oven at 110 °C. The degradation efficiency of the catalyst was observed to be 85 % compared to 90 % obtained with the fresh catalyst until 4 cycles under the same experimental conditions.

Characterization

The concentration of the dye was found out by measuring the absorbance of the solutions on a spectrophotometer model Shimadzu-UV-1800, Japan, and reading the concentration from a calibration curve. Mineralization was determined by measuring the total organic content (TOC) of the degraded dye at 5, 10, 15, 20, 25, and 30 min on Shimadzu TOC-5000A total organic carbon analyzer. LC–MS was conducted using a Finnigan LCQ ion trap mass spectrometer equipped with an electrospray ionization interface (ESI) source and operated in negative polarity mode fitted with a Genesis, C-18 column (4.6 × 250 mm) containing 4-μm packed particles (Alltech, Deerfield, Germany). Acetonitrile and 0.03 M ammonium carbonate buffer, pH 7.7, were used as eluents. The pump program was set as follows: isocratic 20 % acetonitrile: 80 % buffer held for 2 min; grading to 100 % acetonitrile over 10 min and held at 100 % for 7 min. The chromatograms were recorded at 280 and 460 nm. The diode array detector allowed for concomitant recording of spectra from 200 to 600 nm. The gradient HPLC separation was coupled with LC/MSD trap 6310 ion trap mass spectrometer (Agilent Technologies).

Results and discussion

Structural and morphological characteristics of PNA

The synthesized PNA was observed to polymerize through 1, 4 and 1, 5 linkages as reported in our earlier studies [30]. Molar mass of PNA determined by GPC model (Viscotek OmniSEC, UK) using polystyrene as standard was found to fall between 3527 and 4026 Da. BET surface area was analyzed using sorption system analyzer Quantasorb model QS-7 (Quantachrome Corp, NY, USA) and was found to be 95 m2/g for PNA. PNA revealed good solubility in acetonitrile, NMP, DMSO, and DMF, while it was found to be insoluble in acetone, chloroform, carbon tetrachloride, and deionized distilled water. The TEM of PNA reveals tubular morphology of varying length (Fig. 1). The nanotubes appear to be formed through the reorganization of fluffy mass. The length was found to vary between 560 and 800 nm, while the breadth was observed to be ranging between 80 and 130 nm.

Degradation of MeO dye in the presence and absence of PNA

The decrease in the absorbance intensities of dye solutions in acidic (pH = 3.5), basic (pH = 10.0), and neutral (pH = 6.5) levels at 280 and 460 nm is given as supplementary information. It is observed that in the absence of the catalyst, dye solutions showed different absorbance intensities in neutral, acidic, and basic solutions at the same concentration of the dye. Since MeO shows acid↔base equilibria, the concentration of absorbing species varies with pH. Table 1 shows that in 15 min of microwave irradiation, degradation occurred; as a result, the initial absorbance intensity in each of the acid, basic, and neutral solution decreased noticeably. As a first approximation, the decrease in absorbance intensity was taken proportional to the extent of dye degradation. The degradation in neutral, acid, and basic solutions at 280 nm was respectively found to be 21, 17, and 19 %; at 480 nm, the extent of degradation was found to be 16, 23, and 18 %. The degradation in the ultraviolet and visible regions was found to be matching. In the absence of catalyst under microwave irradiation, the average degradation was found to be as low as ≈19 %. In the presence of the catalyst, PNA, the absorbance intensity was found to decrease after equilibration of the dye with PNA in neutral, acid, and basic solutions. This decrease in the intensity of the dye is obviously caused by adsorption of the dye on PNA catalyst. For calculation of degradation efficiency and kinetics, the corresponding dye concentration was taken as initial concentration, C 0. The dye degradation at 260 nm in neutral, acid, and basic solutions was observed to be 90.4, 91, and 82.1 %. The same at 480 nm was respectively found as 90, 89.3, and 88.2 %. Thus, the degradation of the dye in the ultraviolet and visible regions is matching. Compared to the degradation in the absence of the catalyst, the same in the presence of PNA increased considerably in the neutral, acid, and basic solutions. Calculation of degree of dissociation using decrease in absorbance intensity does show some difference but not significant with pH. It is found more noticeable when more accurate analysis is done as discussed in the following section.

Table 1 gives degree of degradation at 280 and 460 nm of MeO in neutral, acid, and basic media. At 280 nm in the absence of the catalyst, the degradation of the dye was observed to be 25, 20, and 30 %, respectively. In comparison with the one calculated by decrease in absorbance intensity, it is 5–10 % higher. At 460 nm, the degradation was, respectively, 35, 33, and 20 %. At the later wavelength in neutral and acidic media, degradation was higher than at 280 nm. The degradation without catalyst under microwave irradiation apparently occurs through involvement of water molecules, which will be explained in a later section. In the presence of PNA catalyst, degradation in the three pH regions was considerably enhanced at both 280 and 460 nm. At 280 nm in the neutral, acid, and basic regions, the percent degradation was 70, 84, and 64 %, while at 460 nm it was 80, 96, and 78 %. The effect of pH on degradation of MEO in the presence of PNA was noticeable at both 280 and 460 nm. Over 10 % of difference in the degradation in the three pH regions matches with the two structures of MeO and their relative abundance. In the basic region, this difference is even more noticeable. In this region, the structure of MeO is different from that in the acidic region because of acid↔base equilibria. This brings about change in its degree of degradation. PNA, a semiconducting polymer, is thus found to enhance the rate of degradation and acts as a polymeric catalyst. Its structure does not seem to permit any chemical involvement in degradation of MO as the NH protons are tightly bound. This leads to the involvement of water molecules in the degradation which are adsorbed on its surface; this will be explained in a later section.

Kinetics of MeO dye degradation

The plots of ln C/C 0 vs. time (Fig. 2a–c) reveal the degradation kinetics of MeO and MeO-PNA under microwave irradiation in neutral (pH = 6.5), acidic (pH = 3.5), and basic (pH = 10.0) media, respectively. The kinetics was found to be of first order in all the cases. The plots of ln C/C 0 vs. time (Fig. 2a) reveal the degradation kinetics of MO-150 and MeO-PNA-150 under microwave irradiation in neutral medium. The kinetics was found to be of first order in all the cases. The rate constant (k) values at 280 nm for MeO-150 and MeO-PNA-150 were found to be 0.02 and 0.12, respectively, and at 460 nm, the k values were observed to be 0.03 and 0.2 for MeO-150 and MeO-PNA-150, respectively. In this case, k value for MeO-PNA-150 is higher than for MeO-150. It shows that degradation of MeO is much faster in the presence of PNA than in its absence. Moreover, degradation at 480 nm, that is, in the visible range, is faster than at 280 nm, UV range. This reveals that splitting of diazo group occurs faster than the aromatic rings. Figure 2b reveals the degradation kinetics of MeO-150 and MeO-PNA-150 in acidic medium. The kinetics was found to be of first order in all of the cases. The rate constant (k) values at 280 nm for MeO-150 and MeO-PNA-150 were found to be 0.01 and 0.07, respectively, and at 460 nm the k values were observed to be 0.02 and 0.15, respectively. Higher k values with MeO-PNA-150 indicates higher rate of degradation in acid medium also. Higher k values at 460 nm also show that in the visible region the degradation is faster, i.e., in this region, splitting of diazo group occurs faster. The rate constant (k) values at 280 nm for MeO-150 and MeO-PNA-150 in basic medium (Fig. 2c) were found to be 0.02 and 0.06, respectively, and at 460 nm, the k values were observed to be 0.03 and 0.12 for MeO-150 and MeO-PNA-150, respectively. The higher k value for MeO-PNA-150 indicates faster rate of degradation in this case. The degradation appeared to be faster at 460 nm than at 280 nm. This is caused by faster rate of degradation of diazo group. Compared with the rate of degradation in neutral and acid media, the values of the same are lowest in this case. This matches with our earlier observation that percent degradation in basic medium is the lowest. The degradation efficiency of the catalyst was observed to be 85 % compared to 90 % obtained with the fresh catalyst until 4 cycles under the same experimental conditions (supplementary information).

Mechanism of MeO dye degradation under microwave irradiation

In order to measure the OH● radicals generated under microwave, we used terephthalic acid (TA) which is a well-known OH● scavenger that does not react with other radicals, such as O2 −, HO2, and H2O2. The OH● radicals convert terephthalic acid to 2-hydroxyterephthalic acid (HTA) through the reaction C6H4(COOH)2 + OH● → C6H4(COOH)2OH, which can be detected by fluorescence measurement. HTA molecules emit light at λ = 425 nm, while TA molecules do not. Using the fluorescence intensity integrated over the wavelength and the calibration curve for known concentrations of OH● radicals (in the presence of 10−4 M of TA and 3 × 10−4 M of NaOH), we calculated the OH radical density in dye solution as a function of microwave irradiation time as shown in Fig. 3. The concentration of OH● radicals increased linearly with increasing time. The concentration of OH● radicals produced was observed to be higher in the presence of PNA than in its absence. This is because, in the dye solution, water molecules are preferentially adsorbed on the surface of PNA which also holds the sulphonate group of the dye molecules. The water molecules are adsorbed and anchored with two H atoms on the benzene moiety of the PNA molecules through attractive forces. Water molecules are also adsorbed and anchored on sulphonate group and dimethyl amino group of the dye molecules. Microwave radiations not only enhance the vibrations of various bonds but also rotate small molecules. The rotation produces immense strain on adsorbed water molecules which ultimately splits them into H● and OH● free radicals. These free radicals then attack dye molecules as shown in Scheme 1, fragment them into smaller molecules, and ultimately mineralize them.

LCMS analysis

The fragments of the degraded dye at 20-min retention time is shown in Scheme 1. The dye was taken as the parent dye designated as D in Scheme 1, while intermediates with decreasing molar masses, m/z, 229, 213, 125, 109, 70, and 40 were taken as the daughter intermediates. The above intermediates are labeled as F-1, F-2, F-3, F-4, F-5, and F-6 (Scheme 1). The dye was found to degrade to fragments of low m/z values under microwave irradiation. Above m/z 213, no prominent intermediate was found. These intermediates were assigned molecular structures matching with the corresponding m/z values. The intermediates revealed that degradation proceeded via elimination of two terminal methyl groups and hydroxylation of terminal N atom of the parent dye P through the attack of OH● free radicals. It was also accompanied by elimination of SO3 − group and hydroxylation of terminal carbon of the second benzene ring through OH● free radical participation which yielded F-1(m/z 229), 4-{(E)-[4-(hydroxyamino)phenyl] diazenyl}phenol. F-1 degraded into F-2 (m/z 213) by reduction of NHOH group by two H● free radicals giving ─NH2, finally yielding F-2, [(E)-phenyldiazenyl] aniline which degraded into F-3 (m/z 125) 4-(hydroxyamino) phenol by attack of one H● and one OH● free radicals on the first N atom of the diazo group attached to phenolic benzene ring. F-3 produced F-4 [4-aminophenol] by attack of two H● free radicals on each of the N and O atoms of F-3. F-4 is attacked on the second and sixth carbon of benzene ring by H● free radicals which splits benzene ring to give F-5 [buta-1,3-dien-2-0l]. By the attack of H● and OH● free radicals on F-5, F-6[methane diol] is produced. The end products obtained are mainly alcohols. We can thus conclude that in the present experimental setup, microwave irradiation degrades the dye into intermediates with low molar masses, ultimately leading to mineralization only in the presence of PNA.

Effect of amount of PNA and MeO dye concentration on degradation efficiency

The effect of the amount of PNA as catalyst in 150 ml of MeO dye is shown in Fig. 4a. As the catalyst dosage increased, an increase in the % degradation efficiency was observed up to 300 mg, which was 98 %. Beyond this amount, the removal efficiency was decreased to 80 %, showing that the excess amount of the catalyst decreased the % degradation efficiency of MeO dye. The convoluted portion of the curve in Fig. 4a shows saturation of catalyst surface by H● and OH● free radicals, and a further decrease indicates less microwave power available per PNA particle for generation of free radicals in the presence of excess catalyst. The effect of concentration of MO dye on its degradation was illustrated in Fig. 4b with varying MeO concentration from 50 to 450 ppm. The results showed that the degradation of MeO progressively decreased with increasing MO concentration in the absence of PNA, while in its presence, the decomposition slightly decreased from 50 to 250 ppm and then increased up to 350 ppm, beyond which it was again found to decrease slightly. The progressive decrease in the first case was caused by the same number of free radicals available for degradation of the increasing amount of the dye. The initial decrease in the second case occurred because of the increase in the concentration of the dye against a certain number of free radicals generated over a given amount of PNA. Beyond 250 ppm, greater attachment of the dye to PNA occurred, which enhanced the rate of degradation. At higher concentration, the dye covers part of the PNA particles which prevent free radical formation, causing a decrease in the rate of its degradation.

TOC analysis

The total organic content in mg/L gives the amount of organic material present in the analyte at different times during mineralization of the dye (Fig. 5). The MeO-150 dye solution was found to mineralize by 35 % on exposing to microwave irradiation up to 30 min. MeO-PNA-150 mineralized to 70 % by 30 min of microwave irradiation. Although the pure dye solution revealed degradation under microwave irradiation from the beginning of the experiment, but further degradation of some of the intermediates into smaller moieties is retarded due to factors related to energetics of the chemical reaction. PNA provides the surface for the adsorption of free radicals and intermediates and lowers their interaction energies, causing further degradation of the intermediates and resulting into mineralization.

Conclusion

Microwave irradiation was found to decolorize MeO dye in solution even in the absence of UV–visible radiation under neutral, acidic, and basic conditions in the presence of PNA as catalyst. MeO-150 revealed 35 % degradation in neutral media, while MeO-PNA-150 dye solution revealed 80, 96, and 78 % degradation in neutral, acidic, and basic media. PNA thus enhanced the degradation of the dye substantially. LC–MS technique recognized all intermediates formed during the degradation of methyl orange dye in the presence and absence of PNA and gave their molar masses, m/z values. Structural formulas were assigned to them. A tentative scheme of degradation of MeO was proposed. The methodology adopted in this study demonstrates the efficiency of microwave irradiation for remediation of wastewater effluent from textile industries. PNA was found to be active until four cycles.

References

Yeap KL, Teng TT, Poh BT, Morad N, Lee KE (2014) Chem Eng J 243:305

Liang CZ, Sun SP, Li FY, Ong YK, Chung TS (2014) J Membr Sci 469:306

Lau YY, Wong YS, Teng TT, Morad N, Rafatullah M, Ong SA (2014) Chem Eng J 246:383

Yagub MT, Sen TK, Afroze S, Ang HM (2014) Adv Colloid Interf Sci 209:172

Wang T, Kailasam K, Xiao P, Chen G, Chen L, Wang L, Li J, Zhu J (2014) Microporous Mesoporous Mater 187:63

Panic VV, Velickovic SJ (2014) Sep Purif Technol 122:384

Hai FI, Yamamoto K, Nakajima F, Fukushi K (2006) J Membr Sci 325(1):395

Karim Z, Mathew AP, Grahn M, Mouzon J, Oksman K (2014) Carbohydr Polym 112:668

Lara EA, Damas SB, Miranda MIA, Clar MII (2012) J Hazard Mater 209–210(30):492

Kim TH, Park C, Yang J, Kim S (2004) J Hazard Mater 112(1–2):95

Ribeiro RS, Fathy NA, Attia AA, Silva AMT, Faria JL, Gomes HT (2012) Chem Eng J 195–196(1):112

Türgay O, Ersöz G, Atalay S, Forss J, Welander U (2011) Sep Purif Technol 79(1):26

Li D, Zheng H, Wang Q, Wang X, Jiang W, Zhang Z, Yang Y (2014) Sep Purif Technol 123(26):130

Luan X, Wang Y (2014) Mater Sci Semicond Process 25:43

Bianchi CL, Colombo E, Gatto S, Stucchi M, Cerrato G, Morandi S, Capucci V (2014) J Photochem Photobiol A Chem 280(15):27

Reeves JF, Davies SJ, Dodd NJF, Jha AN (2008) Mutat Res Fundam Mol Mech Mutagen 640:113

Long TC, Saleh N, Tilton RD, Lowry GV, Veronesi B (2006) Environ Sci Technol 40(14):4346

Rinke H, Simon K (2006) Environ Sci Pollut Res 13(4):225

Takashima H, Ren L, Kanno Y (2004) Catal Commun 5:317–319

Drımalová E, Velebny V, Sasinková V, Hromádková Z, Ebringerová A (2005) Carbohydr Polym 61:420

Kataoka S, Tompkins DT, Zeltner WA, Anderson MA (2002) J Photochem Photobiol A 148:323

Horikoshi S, Hidaka H, Serpone N (2003) J Photochem PhotoBiol A 159(3):289

Horikoshi S, Hidaka H, Serpone N (2003) Chem Phys Lett 376(3–4):475

Horikoshi S, Sakai F, Kajitani M, Abe M, Emeline AV, Serpone N (2009) Phys Chem C 113(14):5649

Riaz U, Ashraf SM (2012) Sep Purif Technol 95(12):97

Riaz U, Ashraf SM (2011) Chem Eng J 174:546

Riaz U, Ashraf SM, Aqib M (2014) Arab J Chem 7(1):79

Riaz U, Ashraf SM, Ruhela A (2014) J Chem Eng Environ (in press)

Riaz U, Ashraf SM (2014) RSC Adv 4:47153

Riaz U, Ahmad S, Ashraf SM (2008) Des Mono Polym 11(2):201

Acknowledgments

The corresponding author, Dr. Ufana Riaz, also wishes to acknowledge the University Grants Commission (UGC), India, for granting major research projects via sanction no. F. No. 41-199/2012(SR). The author also wishes to acknowledge the sophisticated analytical instrumentation facility at All India Institute of Medical Sciences (AIIMS), which granted the use of the TEM facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

S. M. Ashraf is now retired.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 422 kb)

Rights and permissions

About this article

Cite this article

Riaz, U., Ashraf, S.M. & Farooq, M. Effect of pH on the microwave-assisted degradation of methyl orange using poly(1-naphthylamine) nanotubes in the absence of UV–visible radiation. Colloid Polym Sci 293, 1035–1042 (2015). https://doi.org/10.1007/s00396-014-3485-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-014-3485-4