Abstract

Graphene sheets can be effectively dispersed by a novel ionic liquid-based polyether, poly(1-glycidyl-3-methylimidazolium chloride) (PGMIC), in aqueous solution. The reduction of graphene oxide to graphene is confirmed by UV–Vis and Raman spectrum in aqueous solution of PGMIC. TEM image showed that the stable and uniform dispersion of graphene sheets were obtained. Both the TGA and AFM analysis indicated that the graphene sheet was covered by PGMIC. FTIR spectra demonstrated that n–π, cation–π interactions and electrostatic repulsions played important roles in the dispersion of graphene sheets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Graphene has received great interest due to their unique mechanical, thermal, electrical properties, and the potential of a variety of promising applications [1–6]. Although graphene has many remarkable properties, the major barrier for the utilizations of graphene sheets is the lack of an efficient approach to obtain abundant graphene sheets [7]. Different methods have been suggested to prepare graphene sheets including mechanical exfoliation, chemical vapor deposition, and epitaxial growth [8–10]. However, those methods are inadequate for the large-scale production because of the inefficiency. The chemical method is more reasonable to exfoliate graphene in solution to obtain single or few layered graphene sheets, because various wet processes such as spin-coating, spraying, and drop-casting are easily applicable by using solubilized carbon nanomaterials.

Graphene oxide (GO) is easily dispersed by water or polar organic solvents because GO contains many hydrophilic oxygen-containing groups (carboxyl, hydroxyl). However, the conductivity of the single layer of carbon lattice is lower [11]. After chemical reduction or de-oxygenation of GO to prepare graphene, the conductivity could be improved to a greater degree. Herein, many works of graphene were based on the chemical reduction of GO [12–15]. In recent years, great efforts have been made to obtain stable aqueous dispersion of graphene sheets by the covalent and noncovalent chemistry [16–19]. While covalent chemistry may leave some sp 3 carbons in graphene structure because of the covalent linkage, resulting the decreased electrical properties of graphene. The noncovalent chemistry is a better method for graphene dispersion. This method was usually carried out using hydrazine as a reductant [20] and polymer as a dispersant. Those polymers can be divided into two types, nonionic polymers and ionic polymers, which have different dispersion mechanisms. For the nonionic polymer, the major dispersion mechanism is attributed to hydrophobic interaction. The polyether is a typical nonionic polymer, which is widely used in graphene dispersion. Yoon et al. [21] demonstrated that the hydrophobic interaction between graphene and the nonionic polymer of poly(N-vinyl-2-pyrrolidone) is responsible for this solubilization of chemically reduced graphene in solution. Zu et al. [22] reported the formation of the stable aqueous copolymer-coated graphene solution is due to the noncovalent interaction between the hydrophobic PPO segments of the triblock copolymers (PEO-b-PPO-b-PEO) and the hydrophobic graphene surface, whereas the hydrophilic PEO chains extend into water. While the major reason of graphene dispersions by ionic polymers belongs to cation–π and/or π–π interactions and electrostatic repulsion, Jo et al. [23] reported that the stable aqueous suspension of reduced graphene oxide could be obtained by using a conducting polymer of poly(3,4-ethylene dioxythiophene)/poly(styrene sulfonate) (PEDOT/PSS). This approach involves the cooperative interactions of strong π–π interactions between two-dimensional graphene sheets and a rigid backbone of PEDOT and the intermolecular electrostatic repulsions between negatively charged PSS bound on the graphene sheets. Kim et al. [24] successfully obtained a stable dispersion of graphene sheets in an aqueous solution of poly(1-vinyl-3-ethylimidazolium) salts. The dispersion mechanisms could be classified into two aspects. On one hand, parts of imidazolium cations in the polymer chain function to bind the GO sheets. On the other hand, the cation–π and/or π–π interactions between cation groups and graphene play an important role. The stable suspension of graphene was prepared by ionic compounds, which can enhance chemical stability and electrical conductivity for advanced optoelectronic applications [25]. Up to now, the effect of ionic polyether, especially ionic liquid-based polyether, on the dispersion of graphene sheets remains unknown.

In the present work, a stable aqueous graphene sheet solution was investigated in the presence of poly(1-glycidyl-3-methylimidazolium chloride) (PGMIC). The introduction of imidazolium moieties into the PGMIC brings about electrostatic repulsions and cation–π interactions between imidazolium moieties and π-structure of graphene. And the hydrophobic chain could bind to the surface of graphene, while some of hydrophilic chain immerses in water. Our research may open up a new application prospect of ionic liquid-based polyether.

Experimental section

Materials

GO was purchased from XF Nano, Inc., China and used as received. Poly(epichlorihydrin) (M n = 3000) were prepared and purified according to the literature [26]. 1-methylimidazole was purchased from Acros Organics. Acetone, sodium hydroxide, and methanol are analytical-grade reagents, obtained from Sinopharm Chemical Reagent Beijing Co., Ltd. Hydrazine monohydrate (98 %) was purchased from Aladdin Chemical Reagent Co., Ltd. All chemicals were used without further purification. Distilled water was used throughout the experiments.

Synthesis of poly(1-glycidyl-3-methylimidazolium chloride) [27]

A mixture of poly(epichlorihydrin) (9.25 g) and 1-methylimidazole (12.32 g) in distilled water (6.0 ml) was stirred for 10 h under reflux. After evaporation of the solvent, the residue was washed three times with 20 ml of acetone/methanol (5:1). Then, the sample was dried at 50 °C in vacuum oven for 2 days.

Dispersion of graphene sheets

GO (5 mg) was uniformly dispersed in 20 ml water by ultrasound for 10 min (100 W and 40 kHz, KQ-250DB, Analytical Instrument Inc., China). Then, the pH values of the suspensions were adjusted to 12.0 ± 0.2 with 1 mol/L NaOH solution. PGMIC (200 mg) and hydrazine monohydrate were added into the suspensions and the temperature was maintained at 80 °C for 8 h. The GO in water is a bright brown-colored solution, while the solution obtains a dark color after the progress of reduction. Then, the solutions were sonicated for 10 min and the suspensions of graphene sheets were centrifuged for 10 min (4,000 rpm, LG10-2.4A, Beijing Lab Centrifuge Co., Ltd., China), and then the dark-gray supernatant was carefully decanted. The solution of PGMIC-G did not show any visible precipitation for more than 1 month.

Characterization

The optical absorbance of the graphene suspensions was measured by UV–Vis spectroscopy (Hitachi U-4100, Japan). The wavelength range from 200 to 600 nm was used to examine the absorbance of the aqueous solution of graphene sheets and each sample was diluted ten times by distilled water before measurements. Transmission electron microscopy (TEM) observations were performed on a JEM-1011 (Japan) with an accelerating voltage of 100 kV. The samples were prepared by dipping a copper TEM grid into the graphene dispersions (the sample was diluted 30 times) and dried at room temperature. Fourier transform spectra were obtained from a VERTEX-70 FTIR spectrometer (Bruker Optics, Germany) using KBr pellet in the range of 4,000 to 400 cm−1. The Fourier transform infrared (FTIR) measurements were carried out at 25.0 ± 0.1 °C. Thermogravimetric analyses (TGA) were carried out using a TA SDTQ 600 (TA Co, American) to investigate the thermal properties of samples. Studies were conducted under inert atmosphere of nitrogen using 5–10-mg samples at a heating rate of 10 °C/min in the range of room temperature to 600 °C. Raman analysis was done on a Raman spectrometer of Jobin-Yvon HR800 and AFM images were obtained from atomic force microscope of Nanoscope III A (USA). The microanalyses of C, H, and N were performed with Elementar Vario EI III.

Results and discussion

Dispersion of graphene in aqueous solution

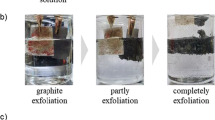

Figure 1 demonstrates photographs of the aqueous solutions of GO, graphene, and PGMIC–graphene (PGMIC-G). The yellow–brown-colored solution of graphene oxide was obtained after ultrasound, which changed to black after treatment with the hydrazine hydrate, indicating that GO had been reduced to graphene. Figure 1b shows the graphene sheets in aqueous solution in the absence of ionic liquid-based polyether. It is worthy to note that the graphene sheets settled down within a few hours. The reason is that the self-association between graphene sheets happens during the reduction process. However, after PGMIC was added into the aqueous solution, a black macroscopic homogenous dispersion was obtained in Fig. 1c. The PGMIC-G solution was very stable at room temperature without any precipitation even after high-speed centrifugation and the homogeneous solution could keep stable for more than 1 month. The results indicate that the agglomeration of the sheets is stopped when the graphene sheets surface is covered with PGMIC. The process of graphene dispersion in aqueous solution of PGMIC is shown in Scheme 1.

UV–Vis and Raman spectrum

The UV–Vis spectra of GO, graphene, PGMIC, and PGMIC-G in aqueous solution are shown in Fig. 2. The spectrum of GO dispersion exhibits two characteristic features: a maximum at 231 nm, corresponding to π → π* transitions of aromatic C–C bonds, and a shoulder around 300 nm, assigned to n → π* transitions of C═O bonds [28]. When GO was reduced to graphene with hydrazine, the maximum of aromatic C–C bonds shifts to 267 nm and the absorption peak of carbonyl bond disappears due to increased conjugation. The absorption peak of PGMIC-G is broader than that of graphene or PGMIC, implying PGMIC is strongly attached to the graphene sheets surface [29].

The crystal structure of graphene is important for material performance. The crystal structure of graphite is damaged during the process of converting graphite to GO; while the ordered crystal structure and some defects are repaired via chemical reduction of GO [30]. The structure of GO, graphene, and PGMIC-G were investigated by Raman spectrum.

The Raman analysis of GO, graphene, and PGMIC-G is shown in Fig. 3. The G band is usually assigned to the E2g phonon of C sp 2 atoms, while the D band is a breathing k-point phonon of A1g symmetry [31]. The characteristic absorption peak of GO in the Raman spectrum are the G band at 1,605 cm−1 and the D band at 1,352 cm−1 [14]. Due to the extensive oxidation, the intensity of the D band at 1,352 cm−1 was stronger than G band [32]. The G band is narrowed and shifted to 1,584 cm−1 in (b), implying that GO has been reduced to graphene. The intensity ratio of D and G band (I D/I G) of GO is about 1.15, while the I D/I G of graphene increased to 1.36. This change of I D/I G suggests a decrease in the average size of the sp 2 domains [33]. The I D/I G of PGMIC-G was measured as 1.24, which is lower than that of graphene, indicating that PGMIC-G has decreased density of defects compared with graphene without PGMIC [34]. These results demonstrate that GO is well chemically reduced to graphene and the PGMIC-G has a more ordered structure. However, the Raman spectra are not significantly different between graphene and PGMIC-G, suggesting that PGMIC molecules are noncovalently physisorbed onto graphene sheets.

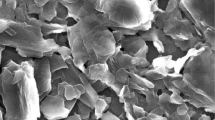

TEM and AFM measurements

TEM was used to investigate the level of the dispersion of graphene sheets in aqueous solution. As can be seen in Fig. 4, PGMIC-G is present as thin sheets with some folded area with diameters of a few micrometers, which is larger than most of the graphene sheets. This result demonstrates that graphene sheets could be well dispersed in aqueous solution by the aid of PGMIC. The selected area electron diffraction pattern was marked by the circles, which were composed of many diffraction spots. These spots make regular hexagons with different rotational angles, indicating a random overlay of individual graphene sheets coated with PGMIC [35]. These results indicate the uniform dispersions of graphene sheets could be obtained in aqueous solution.

In order to measure the dispersion degree of the graphene sheets in aqueous solution of PGMIC, AFM imaging of the dispersions (the sample was diluted 30 times) deposited onto silicon substrate was measured. The AFM analysis is shown in Fig. 5. The AFM image presented the lateral dimensions ranging from 0.1 to 1.5 μm and the irregularly shaped sheets of uniform thickness in Fig. 5a and b. The different lateral dimensions could be caused by ultrasound, which destroyed the structure of graphene sheet to a certain degree. The PGMIC-G sheets are individually dispersed with a thickness of about 5 nm. However, the GO sheet exfoliated in water is about 1 nm and the theoretical thickness of a single-layer graphene sheet is only about 0.91 nm [18, 36]. The thickness of PGMIC-G sheet is much greater than that of graphene and GO. It could be assigned to PGMIC molecules, which covered on the graphene sheets [37]. The increased thickness of PGMIC-G sheet implies that strong interactions exist between PGMIC and graphene.

Dispersion mechanism

Figure 6 exhibits the TGA data of PGMIC and PGMIC-G. PGMIC showed two mass losses, which took place at ∼200–300 °C and ∼300-400 °C. The phenomenon can be ascribed to the respective degradation for the side-chains and the backbone. The weight loss of PGMIC-G occurs from ∼250 to ∼350 °C, which can be attributed to the decomposition of the surface-bound PGMIC molecules and the oxygen functional groups in the graphene [38]. Due to the interaction between graphene and PGMIC, the weight loss is a slow and continuous process. And there is no weight loss around 168 °C, indicating the GO was completely reduced to graphene [33].

To further investigate the interaction between PGMIC and graphene, FTIR spectroscopy was used. FTIR spectra of GO, graphene, PGMIC, and PGMIC-G are shown in Fig. 7 and some significant changes are observed. The FTIR spectra of water-soluble GO sheets showed C═O (1,722 cm−1), C–O–C (1,044 cm−1), O–H (3,413 cm−1), carboxyl C–O (1,380 cm−1), and aromatic C═C (1,625 cm−1). When the PGMIC was added into the GO suspension, the electrostatic attractions could be caused by the interaction between imidazolium cations and the carboxylic acid groups at the edges of GO sheets. Some parts of imidazolium cations in the PGMIC chain bind to the GO sheets [24], and the intermolecular electrostatic repulsions is present between residual cationic charges in PGMIC bound on sheets. After the GO is reduced by hydrazine under alkaline conditions, the peak for C═O and C–O groups gradually decreased in intensity, indicating that the majority of the oxygen-containing groups of GO are gradually de-oxygenated after hydrazine reduction. Due to the introduction of imidazolium groups, the intensity of the 1,480–1,640 cm−1 region was enhanced in PGMIC-G. And the peak around 1,076 cm−1 was also increased, which is assigned to C–O–C groups of PGMIC. At the same time, a new peak was present in PGMIC-G, which is attributed to the C–Cl (742 cm−1) group, indicating that the graphene was covered with PGMIC. The band of the C–Cl group, which is present at 748 cm−1 in PGMIC, shifted to 742 cm−1 in PGMIC-G; and the peak of the C–O–C group, which is shown at 1,112 cm−1 in PGMIC, moved to 1076 cm−1 in PGMIC-G. These changes are due to the charge transfer from the lone pair of electrons on the C–Cl and C–O–C groups of the PGMIC to the aromatic C═C of graphene (n–π). The reason could be that the partial electrons escape from the low-lying anti-bonding acceptor orbital [39, 40]. These results show that the hydrophobic chain is bound to the surface of graphene. The region of the bands of cationic imidazolium group (1,526–1,688 cm−1, PGMIC) was shifted down to 1480–1640 cm−1 in PGMIC-G, indicating that the introduction of imidazolium moieties into the polyether brings about cation–π interactions between imidazolium moieties and the aromatic C═C of graphene. Through these interactions, the strong π–π and van der Waals interaction [41] between graphene layers are destroyed by PGMIC and the stable suspension of graphene was obtained in aqueous solution.

Conclusion

In summary, we have investigated the suspersion of graphene sheets in the aqueous solution of ionic liquid-based polyether. After the imidazolium moieties were introduced into the polyether, the graphene sheets could be well dispersed in aqueous liquid by this polymer. A more ordered crystal structure of graphene was obtained in PGMIC solution by reducing graphene oxide. The graphene sheets are covered by PGMIC in the uniform suspension. The cation–π interactions, n–π interactions, and electrostatic repulsions have played important roles in the dispersion of graphene by PGMIC. This work could provide insight into developing various ionic liquid-based polyethers to disperse graphene and other applications.

References

Geim AK, Novoselov KS (2007) Nat Mater 6:183–197

Lee C, Wei X, Kysar JW, Hone J (2008) Science 321:385–388

Balandin AA, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau CN (2008) Nano Lett 8:902–907

Lu YH, Chen W, Feng YP, He PM (2009) J Phys Chem B 113:2–5

Stankovich S, Dikin DA, Dommett GHB, Kohlhaas KM, Zimney EJ, Stach EA, Piner R, Nguyen ST, Ruoff RS (2006) Nature 442:282–286

Bunch JS, van der Zande AM, Verbridge SS, Frank IW, Tanenbaum DM, Parpia JM, Craighead HG, McEuen PL (2007) Science 315:490–493

McAllister MJ, Li JL, Adamson DH, Schniepp HC, Abdala AA, Liu J, Alonso MH, Milius DL, Car R, Prudhomme RK, Aksay IA (2007) Chem Mater 19:4396–4404

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Science 306:666–669

Kim KS, Zhao Y, Jang H, Lee SY, Kim JM, Kim KS, Ahn JH, Kim P, Choi JY, Hong BH (2009) Nature 457:706–710

Berger C, Song ZM, Li XB, Wu XS, Brown N, Naud C, Mayo D, Li TB, Hass J, Marchenkov AN, Conrad EH, First PN, De Heer WA (2006) Science 312:1191–1196

Park S, Ruoff RS (2009) Nat Nanotechnol 4:217–224

Liu JB, Fu SH, Yuan B, Li YL, Deng ZX (2010) J Am Chem Soc 132:7279–7281

Choi EY, Han TH, Hong JH, Kim JE, Lee SH, Kim HW, Kim SO (2010) J Mater Chem 20:1907–1912

Shen XP, Jiang L, Ji ZY, Wu JL, Zhou H, Zhu GX (2011) J Colloid Interface Sci 354:493–497

Lotya M, King PJ, Khan U, De S, Coleman JN (2010) ACS Nano 4:3155–3162

Lomeda JR, Doyle CD, Kosynkin DV, Hwang W-F, Tour JM (2008) J Am Chem Soc 130:16201–16206

Park S, Dikin DA, Nguyen ST, Ruoff RS (2009) J Phys Chem C 113:15801–15806

Xu YX, Bai H, Lu GW, Li C, Shi GQ (2008) J Am Chem Soc 130:5856–5857

Li D, Müller MB, Gilje S, Kaner RB, Wallace GG (2008) Nat Nanotechnol 3:101–105

Stankovich S, Piner RD, Chen XQ, Wu NQ, Nguyen ST, Ruoff RS (2006) J Mater Chem 16:155–158

Yoon S, In I (2011) J Mater Sci 46:1316–1321

Zu SZ, Han BH (2009) J Phys Chem C 113:13651–13657

Jo K, Lee T, Choi HJ, Park JH, Lee DJ, Lee DW, Kim BS (2011) Langmuir 27:2014–2018

Kim T, Lee H, Kim J, Suh KS (2010) ACS Nano 4:1612–1618

Xu YF, Wang Y, Liang JJ, Huang Y, Ma YF, Wan XJ, Chen YS (2009) Nano Res 2:343–348

Gao HJ, Duan M, Hu XQ, Gao ZF (2008) Polym Mater Sci Eng 3:56–59

Gao HJ, Zhang SH, Huang DP, Zheng LQ. Colloid Polym Sci. doi:10.1007/s00396-012-2619-9

Villar-Rodil S, Paredes JI, Martínez-Alonso A, Tascón JMD (2009) J Mater Chem 19:3591–3593

Ren LL, Liu TX, Guo JA, Guo SZ, Wang XY, Wang WZ (2010) Nanotechnology 21:335701–335707

Zhang WN, Wei H, Jing XL (2010) J Phys Chem B 114:10368–10373

Tuinstra F, Koenig J (1970) J Chem Phys 53:1126–1130

Ni ZH, Wang HM, Ma Y, Kasim J, Wu YH, Shen ZX (2008) ACS Nano 2:1033–1039

Wu YH, Yu T, Shen ZX (2010) J Appl Phys 108:071301

Tung TT, Kim TY, Shim JP, Yang WS, Kim H, Suh KS (2011) Org Electron 12:2215–2224

Zhu Y, Stoller MD, Cai W, Velamakanni A, Piner RD, Chen D, Ruoff RS (2010) ACS Nano 4:1227–1233

Chen C, Yang QH, Yang Y, Lv W, Wen Y, Hou PX, Wang M, Cheng HM (2009) Adv Mater 21:3007–3011

Rajesh C, Majumder C, Mizuseki H, Kawazoe Y (2009) J Chem Phys 130:124911–124916

Liu JQ, Yang WR, Tao L, Li D, Boyer C, Davis TP (2010) J Polym Sci Polym Chem 48:425–433

Najeeb CK, Chang J, Lee JH, Lee M, Kim JH (2011) J Colloid Interface Sci 354:461–466

Wise KE, Park C, Siochi EJ, Harrison JS (2004) Chem Phys Lett 391:207–211

Huang R (2011) Nat Nanotechnol 6:537–538

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (No. 50972080 and No. 91127017), and the National Basic Research Program (2009CB930101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, H., Zhang, S., Lu, F. et al. Aqueous dispersion of graphene sheets stabilized by ionic liquid-based polyether. Colloid Polym Sci 290, 1785–1791 (2012). https://doi.org/10.1007/s00396-012-2720-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-012-2720-0