Abstract

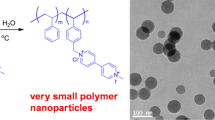

Polychloromethylstyrene nanoparticles of sizes from 12.0 ± 2.3 to 229.6 ± 65 nm were prepared by the emulsion and miniemulsion polymerization of chloromethylstyrene in an aqueous continuous phase in the presence of potassium persulfate as initiator, sodium octylbenzenesulfonate as surfactant, and hexadecane as costabilizer for the miniemulsion polymerization process only. The influence of various polymerization parameters (e.g., concentration of the monomer, initiator, the crosslinker monomer, and the surfactant) on the properties of the particles (e.g., size, size distribution, and yield) has been elucidated. The polychloromethylstyrene nanoparticles formed via the emulsion polymerization mechanism possess smaller diameter and size distribution than those formed under similar conditions via the miniemulsion polymerization mechanism. Other differences between these two polymerization mechanisms have also been elucidated. For future study, we wish to use these nanoparticles for the covalent immobilization of bioactive reagents such as proteins to the surface of these nanoparticles for various biomedical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanometer-sized polymeric particles of narrow size distribution have attracted much attention in the scientific community due to their potential applications such as ion adsorbents [1], diagnostics [2], drug carriers [3], etc. Vinylic monomers are commonly used for preparing organic polymeric nanoparticles since they may contain enormous possible functional side groups to the double bond. The common mechanisms for preparing these nano-sized particles are based on the emulsion or miniemulsion radical polymerization of the desired vinylic monomers.

In a classical emulsion polymerization mechanism [4–8], the monomer is insoluble, or scarcely soluble, in the aqueous continuous phase and emulsified with the aid of a water-soluble surfactant so that its concentration is above the critical micelle concentration (CMC). The initiator is soluble in the continuous phase, but not in the monomer phase. Under these conditions, the monomer is present in the aqueous mixture mainly in three forms: droplets, “dissolved” in the surfactants' micelles, and molecularly dissolved in the continuous phase. The initial locus of the polymerization process is in the continuous phase, where the initiator is present. The oligoradicals formed in the medium can be absorbed by the monomer-containing micelles and subsequently changing the main loci polymerization to the micelles' interior. In this way, the primary particles grow gradually until the monomer is consumed or the radicals disappear. The size of the latex particles thereby produced is usually in the range of 50–300 nm.

Miniemulsion polymerization [9–14] has become quite an important process in recent years for preparing nano-sized particles. This kind of polymerization offers possibilities such as the creation of hybrid particles by the encapsulation of inorganic materials [13, 15, 16], development of controlled free-radical polymerization [17], and other polymerization chemistries [18–20] in aqueous dispersed systems. Generally, in miniemulsion polymerization, miniemulsion droplets of 50 to 500 nm of the monomer and the costabilizer in the aqueous continuous phase are prepared by shearing a system containing the monomer, the costabilizer, the water soluble surfactant, and the initiator. The surfactant is used in sufficient quantity to provide the droplets with colloidal stability against coalescence while maintaining its concentration below the CMC to avoid micellar nucleation. Hydrophobic costabilizer molecules (e.g., hexadecane (HD) [21]) retard the degradation by Ostwald ripening of the miniemulsion droplets [21], and subsequent propagation reaction occurs primarily in the miniemulsion droplets. Each of these droplets can be regarded as an individual nanophase reactor. It has been known that in miniemulsion polymerization, particle nucleation mechanisms are based on droplet nucleation and homogeneous nucleation. The droplet nucleation mechanism suggests that the droplets formed during the emulsification step are polymerized directly via a radical that enters these monomer droplets and reacts with the monomer existing there. The homogeneous nucleation is a second possible mechanism for miniemulsion polymerization, in which latex seeds are created from oligomers in the water phase, and the monomer is brought to the nucleation site by diffusion [22]. The challenge inherent in choosing a system to stabilize the droplets is to reduce or eliminate the homogeneous nucleation. Homogeneous nucleation can be kept to a minimum by producing droplets with a high surface area.

In a previous study by our group [23, 24], we described the synthesis of polychloromethylstyrene (PCMS) micrometer-sized particles of narrow size distribution by the dispersion polymerization of chloromethylstyrene (CMS) in a mixture of ethanol and dimethyl sulfoxide [23]. In addition, we also described the synthesis of polystyrene/polychloromethylstyrene, PS/PCMS, and polystyrene/poly(chloromethylstyrene-divinylbenzene) (PS/P(CMS-DVB)) core-shell composite microspheres of narrow size distribution, by the seeded emulsion polymerization of CMS or CMS and DVB in the presence of the PS core microspheres [24]. The present manuscript describes in detail the synthesis of PCMS nanoparticles of narrow size distribution, by the emulsion and miniemulsion polymerization of CMS in an aqueous continuous phase in the presence of potassium persulfate (PPS) as the initiator, sodium octylbenzenesulfonate (SOBS) as the surfactant, and HD as the co-stabilizer for miniemulsion polymerization only. The influence of various polymerization parameters (e.g., concentration of the monomer, initiator and the surfactant, type and concentration of the crosslinker monomer and sonication duration) on the properties (e.g., size, size distribution and polymerization yield) of the particles has been established.

Experimental

Chemicals

The following analytical-grade chemicals were purchased from Aldrich and used without further purification: PPS (99%), CMS (97%), ethylene glycol dimethacrylate (EGDMA; 98%), DVB (80%) and HD (99%). SOBS (99%) was purchased from Alfa Aesar. Water was purified by passing deionized water through an Elgastat Spectrum reverse osmosis system (Elga Ltd., High Wycombe, UK).

Synthesis of the PCMS nanoparticles by the emulsion polymerization process

In a typical experiment, PCMS nanoparticles with an average dry diameter of 28.0 ± 3.5 nm were prepared by adding 0.2 mL of CMS (2%, w/v), 5 mg of PPS, and 0.08 g of SOBS to 10 mL of water. For the polymerization of the CMS, the mixture was shaken at 70 °C for 3 h. The resulting particles were washed of excess reagents (e.g., PPS and SDS) by intensive centrifugation cycles with water and then ethanol. Dried PCMS nanoparticles were then obtained by ethanol evaporation. The effect of various polymerization parameters, e.g., monomer, initiator, and surfactant concentrations, type and concentration of the crosslinker monomer, size and size distribution, and the polymerization yield of the CMS to produce the particles, was also elucidated.

Synthesis of the PCMS nanoparticles by the miniemulsion polymerization process

In a typical experiment, PCMS nanoparticles with an average dry diameter of 97.0 ± 15.3 nm were prepared by adding 0.2 mL of CMS (2%, w/v), 0.032 mL of HD, 5 mg of PPS, and 0.02 g of SOBS to 10 mL of water. In order to obtain emulsion droplets of the monomer and the costabilizer in the aqueous continuous phase, the resultant mixture was homogenized for 1 min by using a VCX-750 ultrasonic processor (Sonic and Materials, 750 Watt, Tihorn 20 KHz) operated at 25% amplitude. An ice bath was used to avoid heating and prevent polymerization during the sonication. For polymerization, the mixture was shaken at 70 °C for 3 h. The resulting particles were washed of the excess reagents by intensive centrifugation cycles with water and then ethanol. Dried PCMS nanoparticles were then obtained by ethanol evaporation. The effect of various polymerization parameters, e.g., sonication duration, monomer, initiator, and surfactant concentrations, and type and concentration of the crosslinker monomer, on the diameter and size distribution and the polymerization yield of the CMS to produce the particles was also elucidated.

Characterization of the PCMS nanoparticles

Fourier transform infrared (FTIR) analysis was used for obtaining information on the composition of the particles. FTIR was performed with a Bomem FTIR spectrophotometer (model MB100, Hartman & Braun). The analysis was performed with 13-mm KBr pellets that contained 2 mg of the detected material and 198 mg of dry KBr. The pellets were scanned over 200 scans at a 4-cm−1 resolution.

Transmission electron microscope (TEM) images were used for measuring the dry size and size distribution of the particles. TEM images were obtained with a JEOL-JEM 100SX electron microscope with 80–100-kV accelerating voltage. Samples for TEM imaging were prepared by placing a drop of the diluted sample on a 400-mesh carbon-coated copper grid. The average size and size distribution the dry particles were determined by measuring the diameter of more than 200 particles with image analysis software from AnalySIS Auto (Soft Imaging System GmbH, Germany). The hydrodynamic diameter and size distribution of the nanoparticles dispersed in an aqueous phase were measured with a submicron particle analyzer (model N4 Plus, Coulter Electronics Ltd., England). Cl analysis of the various particles was obtained through the services of the analytical laboratory of the Hebrew University, Jerusalem. Each Cl analysis was repeated at least four times for each of the tested nanoparticles. Surface elemental analysis was obtained by X-ray photoelectron spectroscopy (XPS; model AXIS-HS, Kratos Analytical, England), using Al Kα lines, at 10−9 Torr, with a take-off angle of 90°. Each Cl surface analysis was repeated at least six times for each of the tested particles.

The weight percent polymerization yield of the CMS to PCMS nanoparticles was calculated from the following expression:

where W PCMS is the weight of the dried PCMS nanoparticles and W CMS is the initial weight of the CMS monomer. The bulk and surface weight percent of the PCMS fraction of the PCMS nanoparticles was calculated from the following expressions [24]:

where 23.2 is the Cl percentage in pure PCMS, % Cl was obtained from the elemental analysis, and % surface Cl from the XPS measurements.

The bulk and surface weight percent of the initiator and the surfactant fraction of the PCMS nanoparticles were calculated by reducing from 100 the weight percent of the PCMS fraction.

Results and discussion

In the present manuscript, PCMS nanoparticles were prepared via emulsion and miniemulsion polymerization processes. In both mechanisms, the formed PCMS nanoparticles were free of traces of the monomer, as verified by FTIR, by the lack of the C = C double-bond stretching band at about 1,623 cm−1. In order to compare the particles formed by the two mechanisms, similar polymerization conditions were applied. The concentration of the surfactant (SOBS) was above its CMC (1.0 × 10−2 mol/L or 0.29 wt.%) [25, 26] for the emulsion polymerization and below for the miniemulsion, with the use of the hydrophobic costabilizer (HD) for the miniemulsion process only. In order to optimize the miniemulsion polymerization conditions, we first examined the effect of the diameter of the emulsion droplets by changing the duration of the sonication on the size and size distribution of the formed PCMS nanoparticles, as shown in Fig. 1. This figure demonstrates by TEM images that increasing the sonication time decreases the size, while the size distribution of the produced PCMS nanoparticles remained similar. For example, when the sonication time increased from 1 min to 6, 12, and 30 min (Fig. 1a–d, respectively), the dry diameter and size distribution of the formed PCMS nanoparticles changed from 97.0 ± 15.3 to 88.5 ± 12.5 and 72.1 ± 15.9 and 50.0 ± 13.4 nm, respectively. When increasing the duration of the sonication, the size of the emulsion droplets decreases, thereby resulting in the formation of PCMS nanoparticles of decreasing average diameter. Figure 1 also demonstrates the correlation between the sonication duration and the shape of the formed PCMS nanoparticles. At a sonication duration of 1 min, uniform PCMS nanoparticles of spherical shape were obtained, as shown in Fig. 1a. On the other hand, a sonication duration of 6 min or above leads to the formation of an anomalous shape, “void-containing” PCMS nanoparticles, as shown in Fig. 1b–d [27, 28]. This observation of the effect of sonication time on the shape, size, and size distribution of the formed PCMS nanoparticles led us to continue the study with the miniemulsion polymerization process with a sonication duration of 1 min, according to the description in the “Experimental” section. It should also be noted that the miniemulsion polymerization of 2% CMS according to the “Experimental” section, in the absence of the hydrophobic costabilizer (HD), resulted in the formation of PCMS nanoparticles of significantly larger size and size distribution than those formed in the presence of the HD—116.8 ± 31.5 and 97.0 ± 15.3 nm, respectively.

TEM photomicrographs of the PCMS nanoparticles prepared by miniemulsion polymerization of 2% CMS for different sonication periods: 1 (a), 6 (b), 12 (c), and 30 (d) min, according to the “Experimental” section

Figure 2 presents TEM images (a and c) and typical hydrodynamic size histograms (b and d) of the PCMS nanoparticles prepared by emulsion (a, b) and miniemulsion (c, d) polymerization of 2% CMS, according to the “Experimental” section. A careful examination of these figures shows that the dry diameter and size distribution of the PCMS nanoparticles, as shown by the TEM images, are 28.0 ± 3.5 nm for the emulsion polymerization and 97.0 ± 15.3 nm for the miniemulsion process, while the hydrodynamic diameter and size distribution of PCMS nanoparticles dispersed in the aqueous continuous phase, as shown by the size histograms, are 46.6 ± 7.4 nm for the emulsion polymerization and 121.4 ± 24.2 nm for the miniemulsion polymerization. In both polymerization processes, the hydrodynamic diameter is significantly larger than the dry one. This difference is probably due to the fact that the hydrodynamic diameter also takes into account the surface-adsorbed solvent molecules, as was already reported in a few previous publications [24, 29]. Figure 2 clearly indicates that the diameter and size distribution of the PCMS nanoparticles obtained by the emulsion polymerization is significantly lower than that obtained by the miniemulsion polymerization, e.g., the dry size and size distribution of the nanoparticles formed by emulsion and miniemulsion polymerization are 28.0 ± 3.5 and 97.0 ± 15.3 nm, respectively. The lower average diameter of the PCMS nanoparticles obtained via the emulsion polymerization process may indicate a better surface adsorption and protection of these particles by the SOBS surfactant molecules. It is also interesting that the ratio (hydrodynamic diameter)/(dry diameter) of the PCMS nanoparticles obtained by the emulsion polymerization is 1.7, while that obtained by miniemulsion is 1.2. This behavior illustrates the preferred adsorption of water molecules on the surface of the nanoparticles obtained by the emulsion polymerization mechanism, rather than the particles obtained by the miniemulsion process.

TEM photomicrographs (a, c) and size histograms (b, d) of the PCMS nanoparticles prepared by emulsion (a, b) and miniemulsion (c, d) polymerization of 2% CMS, according to the “Experimental” section

The PCMS nanoparticles are composed of two main fractions: (1) the PCMS fraction and (2) the initiator and the surfactant fraction. Table 1 summarizes the bulk and surface concentrations of Cl and the above two fractions of the PCMS nanoparticles. The table does not report on the S concentration of the PCMS nanoparticles since the value was low and within the error margin of the measurements. The bulk composition of the PCMS nanoparticles was obtained from Cl elemental analysis, as described in the “Experimental” section. The PCMS nanoparticles obtained by both emulsion and miniemulsion polymerization contain a similar bulk Cl content, 17.9% and 17.5%, respectively. This similarity in the Cl analysis, according to the equation shown in the experimental part, indicates that the particles formed by the emulsion and miniemulsion polymerization routes had similar compositions. For example, Table 1 shows that the particles formed by the emulsion polymerization was composed of 77.1% of the PCMS fraction and 22.9% of the initiator and the surfactant fraction and those prepared by the miniemulsion polymerization comprised 75.4% of the PCMS fraction and 24.6% of the initiator and the surfactant fraction. The surface composition of these particles was obtained by XPS measurements from the Cl analysis, as described in the “Experimental” section. The sampling depth of XPS is limited by the effective mean-free path of electrons escaping from the surface. At a take-off angle normal to the surface, the effective sampling depth is approximately 2.5λ, where λ is the mean-free path. For organic substances, λ ≈ 20 Å, so XPS may provide the composition of ca. 50 Å of the outermost surface of these particles [30]. The typical XPS survey spectrum obtained for the PCMS nanoparticles shows a chlorine peak (Cl2p) at ca.198 ev. The chlorine peak belongs only to the PCMS polymer chain fraction of the surface. Table 1 indicates that the surface composition of the PCMS nanoparticles formed by the emulsion and miniemulsion routes is substantially different. The surface of the particles formed by the emulsion and miniemulsion polymerization processes was composed of significantly less Cl than the bulk of these particles, 11.2% and 13.6% surface Cl, respectively. These Cl contents, according to the equation shown in the experimental part, indicate that the surface of the particles prepared by the emulsion polymerization process was composed of 48.3% of the PCMS fraction and 51.7% of the initiator and the surfactant fraction, while the surface of the particles prepared by the miniemulsion polymerization comprised 58.0% of the PCMS fraction and 42.0% of the initiator and the surfactant fraction. We assume that this difference in the surface composition is mainly due to the higher amount of the surfactant SOBS adsorbed onto the surface of the PCMS nanoparticles formed by the emulsion polymerization route. This observation supports the fact that the formed PCMS nanoparticles possess a significantly lower diameter (28.0 ± 3.5 nm) than that formed under similar conditions via the miniemulsion polymerization mechanism (97.0 ± 15.3 nm).

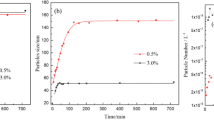

Effect of the monomer volume

Figure 3a shows the effect of the CMS volume on the dry diameter and size distribution of the PCMS nanoparticles formed by the emulsion and miniemulsion polymerization mechanisms. According to this figure, in both polymerization routes, increasing the CMS volume leads to an increase in the diameter and the size distribution of the formed PCMS nanoparticles. For example, in the emulsion polymerization mechanism, raising the volume of CMS from 0.1 to 0.5 and 0.8 mL increases the nanoparticles' size and size distribution from 20.3 ± 2.5 to 40.1 ± 5.8 and 42.5 ± 7.4 nm, respectively, whereas an additional increase in the monomer volume to 1.2 and 2 mL leads to a milder increase in the diameter and size distribution, 42.8 ± 8.4 and 43.2 ± 8.5 nm, respectively. Similarly, an increase in monomer volume in the miniemulsion polymerization process from 0.1 to 0.5, 0.8, 1.2, and 2 mL increases the nanoparticles' size and size distribution from 90.4 ± 13.2 to 115.8 ± 10.4, 135.5 ± 37.0, 166.8 ± 45.0, and 229.6 ± 65 nm, respectively. Figure 3b shows the influence of the CMS volume on the polymerization yield of CMS to PCMS nanoparticles. This figure demonstrates a similar behavior for both polymerization mechanisms, e.g., increasing the CMS volume from 0.1 to 0.2, 0.5 ,and 2.0 mL leads to a marked increase in the emulsion polymerization yield from 45 ± 1.7% to 75 ± 2.6%, 87 ± 2.8%, and 94 ± 2.1 %, respectively, and for the miniemulsion polymerization process from 67 ± 1.6% to 74 ± 3.3%, 82 ± 2.1%, and 97 ± 1.7 %, respectively. It is possible to assume that the increase in the initial monomer volume in the emulsion and miniemulsion polymerization processes increases its concentration within the micelles or the droplets, resulting in an increase in the diameter and the polymerization yield of the formed particles [5]. The same tendency concerning the influence of styrene concentration on the size, size distribution, and polymerization yield of the polystyrene nanoparticles formed by emulsion polymerization was reported by Martinez et al. [31].

Influence of the CMS volume on the diameter and size distribution of the PCMS nanoparticles (a) and on the polymerization yield of the CMS to PCMS nanoparticles (b). The PCMS nanoparticles were prepared by emulsion and miniemulsion polymerization of different volumes of CMS, according to the “Experimental” section

Effect of the initiator concentration

Figure 4a shows the effect of PPS concentration on the dry diameter and size distribution of the PCMS nanoparticles formed by the emulsion and miniemulsion polymerization mechanisms. This figure illustrates that in both polymerization routes, increasing the PPS concentration leads to decrease in the diameter of the formed PCMS nanoparticles. On the other hand, increasing the PPS concentration in the emulsion polymerization process leads to an increase in the size distribution of the PCMS nanoparticles, while in miniemulsion polymerization, the opposite is observed. For example, an increase in the PPS concentration from 2.5% to 5% and 20% in the emulsion polymerization route leads to a decrease in the size and an increase in the size distribution of the particles from 28.0 ± 3.5 to 24.0 ± 9.4 and 18.5 ± 8.2 nm, respectively, and in the miniemulsion polymerization route, it leads to a decrease in both the size and the size distribution from 97.0 ± 15.3 to 95.0 ± 12.6 and 60.8 ± 5.5 nm, respectively. Figure 4b shows the effect of PPS concentration on the polymerization yield of CMS to PCMS particles. This figure shows that increasing the initiator concentration from 2.5% to 5% and 20% leads to an increase in the polymerization yield from 75 ± 2.6% to 85 ± 2.3% and 99 ± 2.1%, respectively, for the emulsion polymerization process and from 74 ± 3.3% to 92 ± 2.4% and 99 ± 2.2 %, respectively, for the miniemulsion polymerization process. A similar effect of the initiator concentration on the size and the polymerization yield of particles formed by the emulsion polymerization of butyl acrylate and methyl methacrylate was previously reported by Sajjadi and Brooks [32]. It is possible to assume that an increase in the initiator concentration may increase the oligomeric radicals' concentration, thus producing more numerous, although smaller, particles. On the other hand, the reversal behavior of the size distribution of the nanoparticles produced by the emulsion and miniemulsion polymerization routes as a function of the initiator concentration is not yet clear. The increase in the size distribution as the initiator concentration increases may be explained by the increase in the growth rate of the oligomeric chains as the initiator concentration increases, thus favoring secondary nucleation during the particle growth stage, which increases the particles' size distribution. The decrease in the size distribution as the initiator concentration increases may be explained by the increased surface concentration of the residue of the PPS \( \left( {-{\hbox{SO}}_4^ - } \right) \) as the initial PPS concentration increases. This leads to an increased electrostatic repulsion and prevents the coalescence of the nanoparticles, thereby leading to a smaller particle diameter with a narrower size distribution [12].

Influence of the initiator concentration on the diameter and size distribution of the PCMS nanoparticles (a) and on the polymerization yield of the CMS to PCMS nanoparticles (b). The PCMS nanoparticles were prepared by emulsion and miniemulsion polymerization of 2% CMS in the presence of different PPS concentrations, according to the “Experimental” section

Effect of the surfactant concentration

Figure 5 illustrates the effect of SOBS concentration on the dry diameter and size distribution of the formed PCMS nanoparticles prepared by emulsion and miniemulsion polymerization routes. This figure shows that for both polymerization mechanisms, increasing the surfactant concentration leads to the formation of PCMS nanoparticles of a smaller size and a narrower size distribution. For example, an increase in the SOBS concentration from 0.3% to 1.0% and 1.8% for the emulsion polymerization (Fig. 5a) leads to a decrease in the diameter and size distribution of the PCMS nanoparticles from 43.2 ± 15.8 to 23.0 ± 3.2 and 16.3 ± 2.5 nm, respectively. Similarly for the miniemulsion polymerization process, increasing the SOBS concentration from 0.02% to 0.05% and 0.1% (Fig. 5b) leads to a decrease in the diameter and size distribution of the PCMS nanoparticles from 176.0 ± 67.8 to 144.9 ± 43.5 and 109.3 ± 20.5 nm, respectively. A similar effect of the surfactant concentration on the diameter and the size distribution of nanoparticles prepared by the emulsion polymerization of 2-methacryloyloxyethyl(2,3,5-triiodobenzoate) and acrylonitrile was previously reported by Galperin et al. [8] and Boguslavsky et al. [5]: A higher surfactant concentration results in more numerous surfactant molecules adsorbed onto the monomer droplets and the formed nuclei, thereby leading to better electrostatic protection against coalescence and other growing processes.

Influence of the SOBS concentration on the diameter and size distribution of the PCMS nanoparticles prepared by emulsion (a) and miniemulsion (b) polymerization processes. The PCMS nanoparticles were prepared by polymerization of 2% CMS in the presence of different concentrations of SOBS, according to the “Experimental” section

Effect of the crosslinker monomer type and the ratio [CMS]/[crosslinker monomer]

To avoid partial or complete dissolution of the PCMS in organic solvents, crosslinked nanoparticles were produced by the emulsion and miniemulsion copolymerization of the CMS with the crosslinker monomer, EGDMA or DVB. This was accomplished by keeping the total monomer (CMS and EGDMA or DVB) weight percent constant (2%), while the weight percent ratio between the two monomers was altered. The effect of the weight percent ratio [CMS]/[EGDMA or DVB] on the diameter and size distribution of the formed PCMS nanoparticles is illustrated in Table 2. This table demonstrates for the crosslinked nanoparticles produced by emulsion polymerization, for both crosslinker monomers, that decreasing of the weight percent ratio [CMS]/[EGDMA or DVB] decreases the average diameter while does not affect the size distribution of the formed PCMS nanoparticles. For example, in the absence of a crosslinker monomer and in the presence of a weight percent ratio [CMS]/[EGDMA] of 49%, 19%, and 4 %, the particle size of the nanoparticles formed by the emulsion polymerization process decreases from 28.0 ± 3.5 to 25.0 ± 4.4, 17.0 ± 2.8, and 12.0 ± 2.3 nm, respectively, and the size of those prepared by the miniemulsion polymerization process decreases from 97.0 ± 15.3 to 90.1 ± 14.6, 81.5 ± 13.5, and 73.1 ± 12.3 nm, respectively. This behavior may be explained by the formation of more crosslinked nuclei, which are therefore more difficult to grow by monomer swelling. Table 2 also demonstrates for the crosslinked nanoparticles produced by the miniemulsion polymerization that the diameters of the nanoparticles formed in the presence of the crosslinker [DVB] are significantly lower than those formed in the presence of a similar weight percent of EGDMA. This is in contrast to the results of the crosslinked nanoparticles produced by the emulsion polymerization process. For example, at a weight percent ratio of [CMS]/[EGDMA or DVB] of 49% and 4%, the diameters of the nanoparticles formed in the presence of DVB are 60.3 ± 11.3 and 45.2 ± 8.2 nm, respectively, while those formed in the presence of EGDMA are 90.1 ± 14.6 and 73.1 ± 12.3 nm, respectively. This difference in the behavior of the crosslinked nanoparticles produced by the emulsion and the miniemulsion polymerization processes should be further investigated.

Summary and future work

The present study describes the synthesis and characterization of PCMS nanoparticles ranging from tens of nanometers up to a few hundred with a relatively narrow size distribution and a high conversion rate (ca. 99%). The nanoparticles were formed by the emulsion and miniemulsion polymerization mechanisms of CMS in an aqueous continuous phase. The effect of various polymerization parameters on the size and size distribution and on the polymerization yield of the produced PCMS nanoparticles has been elucidated. A comparison between the nanoparticles produced by the emulsion and miniemulsion polymerization has been performed. For future study, we wish to convert the chloromethyl groups of these nanoparticles to other functional groups such as hydroxyls, primary amines, thiols, and aldehydes. These functional groups will then be used for the covalent immobilization of bioactive reagents such as proteins, enzymes, antigens, antibodies, and drugs to the surface of these nanoparticles, via various activation methods. The potential use of these bioactive-conjugated PCMS nanoparticles for various biomedical applications (e.g., specific cell labeling and cell separation, diagnostics, etc.) will then be investigated.

References

Behan N, Birkinshaw C, Clarke N (2001) Biomaterials 22:1335–1344

Saxena V, Sadoqi M, Shao J (2004) Int J Pharm 278:293–301

Venier-Julienne MC, Benoit JP (1996) Pharm Acta Helv 71:121–128

Chonde Y, Liu LJ, Krieger IM (1980) J Appl Polym Sci 25:2407–2416

Boguslavsky L, Baruch S, Margel S (2005) J Colloid Interface Sci 289:71–85

Chen YW, Kang ET, Neoh KG, Greiner A (2005) Adv Funct Mater 15:113–117

Cen L, Neoh KG, Cai Q, Kang ET (2006) J Colloid Interface Sci 300:190–199

Galperin A, Margel D, Baniel J, Dank G, Biton H, Margel S (2007) Biomaterials 28:4461–4468

Asua JM (2002) Prog Polym Sci 27:1283–1346

Kermabon-Avon G, Bressy C, Margaillan A (2009) Eur Polym J 45:1208–1216

Schork FJ, Poehlein GW, Wang S, Reimers J, Rodrigues J, Samer C (1999) Colloids Surf A 153:39–45

Taniguchi T, Takeuchi N, Kobaru S, Nakahira T (2008) J Colloid Interface Sci 327:58–62

Tiarks F, Landfester K, Antonietti M (2001) Langmuir 17:5775–5780

Yildiz U, Landfester K (2008) Polymer 49:4930–4934

Csetneki I, Faix MK, Szilagyi A, Kovacs AL, Nemeth Z, Zrinyi M (2004) J Polym Sci Part A Polym Chem 42:4802–4808

Erdem B, Sudol ED, Dimonie VL, El-Aasser MS (2000) J Polym Sci Part A Polym Chem 38:4431–4440

Qiu J, Charleux B, Matyjaszewski K (2001) Prog Polym Sci 26:2083–2134

Barrere M, Ganachaud F, Bendejacq D, Dourges MA, Maitre C, Hemery P (2001) Polymer 42:7239–7246

Barrere M, Landfester K (2003) Macromolecules 36:5119–5125

Taden A, Antonietti M, Landfester K (2003) Macromol Rapid Commun 24:512–516

Anderson CD, Sudol ED, El-Aasser MS (2003) J Appl Polym Sci 90:3987–3993

Bechthold N, Landfester K (2000) Macromolecules 33:4682–4689

Baruch-Sharon S, Margel S (2008) J Appl Polym Sci 108:3727–3737

Baruch-Sharon S, Margel S (2009) Colloid Polym Sci 287:859–869

Monticone V, Favoriti P, Lemordant D, Treiner C (2000) Langmuir 16:258–264

Ardizzone S, Orlandi M (1995) J Electroanal Chem 391:181–185

Okubo M, Ando M, Yamada A, Katsuta Y, Matsumoto T (1981) J Polym Sci Lett Ed 19:143–147

Okubo M, Katsuta Y, Matsumoto T (1982) J Polym Sci Lett Ed 20:45–51

Goldshtein J, Margel S (2009) Polymer 50:3422–3430

Bamnolker H, Margel S (1996) J Polym Sci Part A Polym Chem 34:1857–1871

Martinez A, Gonzalez C, Porras M, Gutierrez JM (2005) Colloids Surf A 270:67–71

Sajjadi S, Brooks BW (1999) J Polym Sci Part A Polym Chem 37:3957–3972

Acknowledgments

These studies were partially supported by a Minerva Grant (Microscale & Nanoscale Particles and Films). The authors would like to thank Dr. Yossi Gofer from Bar-Ilan University, Department of Chemistry for his help in the XPS study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baruch-Sharon, S., Margel, S. Synthesis and characterization of polychloromethylstyrene nanoparticles of narrow size distribution by emulsion and miniemulsion polymerization processes. Colloid Polym Sci 288, 869–877 (2010). https://doi.org/10.1007/s00396-010-2209-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-010-2209-7