Abstract

Miscibility with a linear T g–composition relationship was proven for blend of poly(butylene adipate-co-butylene terephthalate) [P(BA-co-BT)] with poly(4-vinyl phenol) (PVPh). In comparison to the blends of PBA/PVPh and poly(butylene terephthalate) (PBT)/PVPh, the Kwei’s T g model fitting on data for the P(BA-co-BT)/PVPh blend yields a q value between those for the PBA/PVPh and PBT/PVPh blends. The q values suggest that the interaction strength in the P(BA-co-BT)/PVPh blend is not as strong as that in the PBT/PVPh blend. Upon mixing the PVPh into the immiscible blend of PBA and PBT, the ternary PBA/PBT/PVPh blends only exhibits partial miscibility. Full-scale ternary miscibility in whole compositions is not possible owing to the significant ∆χ effect (χ ij – χ ik ). The wavenumber shifts of the hydroxyl IR absorbance band indicates that the H-bonding strength is in decreasing order—PBT/PVPh > P(BA-co-BT)/PVPh > PBA/PVPh—and shows that the BA segment in the copolymer tends to defray interactions between P(BA-co-BT) and PVPh in blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymers have been widely applied in the daily life such as raw materials of packaging, coating, and unit in the electric product. Although polymeric materials possess advantages of good processability and versatile end uses, they also induce serious pollutions after usage since most of the polymers are not easy to be degraded in the atmosphere condition or under the ground [1]. To reduce the pollutions caused by polymers, the environmentally friendly, biodegradable, or the so-called green polymers are gradually used in the recent years. A number of biodegradable polymers have been commercialized, such as poly(butylene succinate), poly(butylene succinate-co-butylene adipate) copolyester (trademark BionolleTM) [2], poly(lactic acid) (trademark NatureWorksTM) [3], poly(3-hydroxybutyric acid), and its copolyesters poly(3-hydroxybutyrate-co-hydroxyvalerate) [P(HB-co-HV)] with the trademark BiopolTM [4]. By staying in the environment with microorganism, these polymers can be converted into biomasses or carbon dioxide and water; therefore, the polymeric waste could be diminished stage by stage.

Poly(butylene adipate-co-44 mol% butylene terephthalate) [P(BA-co-BT)] was commercialized by BASF AG (Germany) on 1998 with the trademark as Ecoflex®. This copolymer contains two different ester structures on its backbone. The aliphatic structure, butylene adipate (BA) unit, of this polymer can enable it to be degraded into carbon dioxide and water with embedding underground. However, the butylene terephthalate (BT) moiety can further improve its mechanical and thermal properties by the inherent character of aromatic functional group. For understanding the physical property of this material which has highly potential for further application, several studies have been performed especially for the crystallization of P(BA-co-BT). Cranston et al. [5] and Kuwabara et al. [6] have investigated the crystalline/amorphous structure and molecular mobility of P(BA-co-BT) crystallized from the melt by X-ray diffraction and solid-state 13C nuclear magnetic resonance (NMR). Their results suggest that the butylene terephthalate units exist in both crystalline and amorphous region, on the other hand, all of butylene adipate units are in the amorphous region. Gan et al. [1] have also performed the discussions for solid-state structures, thermal properties, crystalline behavior, and spherulite morphologies within wide copolymer compositions of P(BA-co-BT)s. As mentioned above, even though the physical properties of P(BA-co-BT) had been widely investigated, few studies address the miscibility of P(BA-co-BT) with other polymers. The literature only contains limited discussion on phase-separation in blend of poly(l-lactic acid) with P(BA-co-BT) blends [7].

Poly(4-vinyl phenol) (PVPh), with a hydroxyl group at paraposition of the pendant phenyl ring [therefore also named poly(p-vinyl phenol)], is capable of interacting with proton-accepting functional groups in other polymers. It has been known to form miscible blends with other polymers such as poly(ethylene oxide) [8, 9], polymethacrylates [10] (e.g., poly(methyl methacrylate), poly(ethylene methacrylate), and poly(n-propyl methacrylate) (PnPMA)), poly(vinyl alkyl ethers) [8] (e.g., poly(vinyl methyl ether), and poly(vinyl ethyl ether)), poly(vinyl methyl ketone) [11]. In addition, PVPh can also form miscible blends with some aliphatic polyesters [12–15] (e.g., poly(ε-caprolactone) (PCL), poly(butylene succinate), poly(β-hydroxybutyrate), poly(ethylene adipate), and poly(butylene adipate) (PBA)) or with some aromatic polyesters [16, 17] (e.g., poly(ethylene terephthalate), poly(butylene terephthalate) (PBT), poly(trimethylene terephthalate), and poly(ethylene 2,6-naphthalene dicarboxylate)). Miscibility and specific interaction have been discussed for the copolymer/PVPh blends such as carbon dioxide-co-epoxy propane/PVPh [18], poly(2,2,3,3,3-pentafluoropropyl methacrylate-co-4-vinylpyridine)/PVPh [19], poly(methyl methacrylate-b-vinyl pyrrolidone)/PVPh [20], poly(2-vinyl pyridine-b-ethylene oxide) (P2VP-b-PEO)/PVPh [21], and poly(N-alkylitaconamic acid-co-styrene)/PVPh [22]. Among these systems, P2VP-b-PEO/PVPh blend reveals significant positive deviation from linear T g–composition relationship, which is attributed to the pronounced specific interactions between PVPh and copolymer segments [21].

Ternary miscibility in blends comprising three different polymers has been comparatively less studied. Recent studies on ternary polymer blends have resulted in more discoveries on miscible ternary blends [23–29]. For ternary polymer blends, full miscibility is less often than “closed-loop” immiscibility or only partial miscibility [30, 31]. This is especially true in cases where one of the three constituent polymers can form strong interactions with the other two polymers in the blends. In those cases, immiscibility is resulted owing to the ∆χ effect (χ ij – χ ik ), which may become significant and not negligible. In these situations, two effects may be competing in deciding the final phase behavior in ternary blends. The ∆χ effect tends to lead to immiscibility; on the other hand, in a ternary blend, it may also be argued that the third polymer capable of forming strong interactions may potentially act as a mutual common link for the other two polymers, leading to a “bridging effect” for forming a more homogeneous ternary mixture. These two views oppose each other, and for better understanding, one may need to weigh other factors on influencing the phase behavior of ternary mixtures.

In this study, copolyester of P(BA-co-BT), a newly commercialized product aiming for biodegradable applications, was used as a model copolymer for blending with PVPh to understand effects of BA and BT segments on interactions, miscibility, thermal behavior, and morphology. PVPh is known to interact favorably with both BA and BT segments, but interactions may differ for these two units. Comparisons were also made among the PBA/PVPh blend, P(BA-co-BT)/PVPh blend, and PBT/PVPh blend. Relevant analyses were performed in attempts to understand the influence of BA and BT segments on the thermal, phase morphology, and specific interactions. Furthermore, analyses was also performed by comparing the interaction and miscibility of PBA/PBT/PVPh ternary blend with that of P(BA-co-BT)/PVPh binary one, in which the PBA/PBT weight ratio in ternary system was estimated to be the same as the ratio of BA to BT segments in P(BA-co-BT) copolymer.

Experimental

Materials and blend preparation

P(BA-co-BT) was obtained from BASF AG (Germany), with a commercial name Ecoflex®, M w = 135,000 g/mol; T g ∼ −32 and T m ∼ 124 °C (measured with differential scanning calorimetric (DSC)), and density = 1.27 g/cm3. The copolymer’s relative molar fractions as determined by 13C solid-state cross-polarization/magic angle spinning NMR is 56 mol% BA and 44 mol% BT [5]. Poly(1,4-butylene adipate) (PBA with M w = 12,000 g/mol) was purchased from Sigma-Aldrich Co. (USA), with T g ∼ −62 °C and T m ∼ 56 °C (measured with DSC). PBT was supplied by G.E. Corp. (USA), with T g ∼ 34 °C and T m ∼ 224 °C (measured with DSC). PVPh, with M w = 22,000 g/mol, was purchased from Polysciences, Inc. (USA), with apparent T g = ∼149 °C (measured with DSC).

In this study, binary blends of P(BA-co-BT)/PVPh, PBT/PVPh, and ternary blends of PBA/PBT/PVPh were prepared by melt blending at high temperatures. Polymers of proper amounts (1 g or less per batch) were premixed in an aluminum holder at 200 °C (for P(BA-co-BT)/PVPh) or 245 °C (for PBT/PVPh and PBA/PBT/PVPh). The polymers in holder were placed on a hot stage (set at ∼200 °C or ∼245 °C). Stirring and blending were performed in dry nitrogen purge to minimize degradation. Well-blended materials were then pressed into thin uniform films for characterizations. Blends of PBA/PVPh were difficult by melt blending, thus were prepared by solution mixing instead, by using tetrahydrofuran. Polymers in solvent were dissolved at 4 wt.% and then cast at 45 °C onto flat glass or aluminum substrates for film forming. Films were air-dried for 24 h and then placed in a vacuum oven at 80 °C to completely degas the residual solvent from the film blend samples.

Apparatus and procedures

POM

A Nikon Optiphot-2 polarizing optical microscope (POM) equipped with a charge-coupled device digital camera and a Linkam THMS-600 microscopic heating stage with TP-92 temperature programmer was used to observe transition of phase behavior of the blend samples. Thin films from the melt-blended samples for investigations on the phase behavior were sandwiched between two glass slides. On the other hand, solution-blended samples for POM were solution-coated on glass substrate, covered with top glass, and pressed into films of proper thickness (ca. 10∼15 μm).

DSC

Thermal analysis and measurements for T g’s of blends were performed using Perkin-Elmer DSC-7 equipped with a mechanical intracooler under dry nitrogen purge. Scanning rates were 20 °C/min. All samples were pressed to flat films to ensure good thermal conduction and temperature distribution. Amorphous specimen by premelting/quenching treatment was then characterized for glass transition temperature.

FT-IR

Fourier-transform infrared spectroscopy (FT-IR; Nicolet Magna-560) spectroscopy was used to identify possible interactions between polyesters. All spectra were recorded at a resolution of 4 cm−1 with an accumulation of 64 scans in the range of 400∼4,000 cm−1. The blends were solution-cast as thin and uniform films from 2∼4 wt.% solutions directly onto KBr pellets at 35°C, hot-pressed into proper thickness, followed by necessary thermal treatments. Vacuum-dried KBr-cast film samples were used for IR measurements at ambient temperature.

Results and discussion

Miscibility with T g–composition relationship in P(BA-co-BT)/PVPh blends

Characterizations for miscibility in P(BA-co-BT)/PVPh blends were initiated with POM observations. The OM photos (for brevity, graphs not shown) revealed that all samples appeared optically transparent and homogeneous (at ×800). Furthermore, the blends were placed on a microscopy heating stage where the temperature was raised gradually in order to observe cloud-point transition. The result showed that no cloud-point or lower critical solution temperature phenomenon was observed up to about 300 °C, beyond which the samples gradually started to chemically degrade and it was no longer possible for discerning any physical transitions. Preliminary OM examinations showed a single-phase morphology for the P(BA-co-BT)/PVPh binary system.

Thermal analysis was performed to investigate the miscibility. Figure 1 shows the DSC traces (20 °C/min) revealing only a single T g (arrow-marked) for each of the P(BA-co-BT)/PVPh blends with different compositions as indicated on the DSC traces. This result provides evidence for proving miscibility in the P(BA-co-BT)/PVPh binary system. The OM and DSC results suggest that the blends with different compositions are all miscible, with intimately mixing among three polymeric segments of BA, BT, and VPh in the blends.

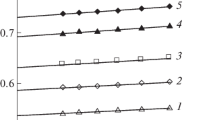

The T g’s values of P(BA-co-BT)/PVPh blends are also replotted again with respect to the PVPh composition. Figure 2 reveals the T g–composition relationship for the P(BA-co-BT)/PVPh blends. Additionally, the T g–composition data of PBA/PVPh and PBT/PVPh blends acquired from DSC thermograms (DSC traces not shown here for brevity) are drawn in the same figure for comparison. The T g–composition relationship can be well described by the Kwei equation [32] as Eq. 1, which is widely applied for characterizing the T g behavior in polymer blends with specific interactions. The Kwei equation is shown as follows:

where w 1 and w 2 are weight fractions of the two components in the blends, T g1 and T g2 represent the corresponding glass transition temperatures, and k and q are fitting parameters. Note that the first term on the right-hand side of Eq. 1 is the widely used Gordon–Taylor equation, which can be derived formally by using the additive rule of the entropy or the volume of the mixtures. Besides, the second quadratic term qw 1 w 2 is proportional to the strength of hydrogen bonding or specific interaction in the blends. The fitting leads to a result of k = 1 and q = −82, as estimated by the Kwei equation for the T g data of P(BA-co-BT)/PVPh blends. In the figure, two other relationships are shown for comparison: k = 1 and q = 5 by fitting with the T g data for the PBT/PVPh blend; k = 1 and q = −225 by fitting with the T g data for the PBA/PVPh blend. By judging from the q values estimated and demonstrated for three different binary blends, the interaction strength in the P(BA-co-BT)/PVPh blend is likely not as strong as that in the PBT/PVPh blend but is stronger than that in the PBA/PVPh blend.

Spectroscopy analyses on interactions in binary blends

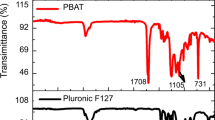

FT-IR characterization was carried out to explore the interactions in the P(BA-co-BT)/PVPh blends for qualitative and quantitative aspects. Figure 3 displays two IR spectra for P(BA-co-BT)/PVPh blends: (a) in hydroxyl-stretching region and (b) in carbonyl-stretching region. Figure 3a depicts the hydroxyl stretching band at 3,050–3,700 cm−1 of the PVPh component in the P(BA-co-BT)/PVPh blend. Two distinct IR absorbance bands in the hydroxyl-stretching region are seen for neat PVPh. The broad band at 3,334 cm−1 can be attributed to the hydrogen-bonded hydroxyl group (self-association), and a relatively narrow band at 3,530 cm−1 is assigned to the free (nonassociated) hydroxyl groups. Upon blending with P(BA-co-BT), the intensity of the free hydroxyl group band decreases, and the hydrogen-bonded hydroxyl group band of PVPh shifts to a higher frequency, indicating hydrogen-bonding interactions between the hydroxyl groups of PVPh and P(BA-co-BT). Note that the decrease of free OH stretching absorbance is also partially attributed to the decrease of PVPh content in the blends. Figure 3b shows the carbonyl-stretching region for IR absorbance of the P(BA-co-BT) component in the blend. The carbonyl-stretching absorbance exhibits two doublet bands (partially overlapped), which are the peak at 1,732 cm−1 and another closely spaced peak at 1,715 cm−1, representing the amorphous and crystalline portions, respectively, of the carbonyl absorbance of neat P(BA-co-BT) polyester. For the P(BA-co-BT)/PVPh blends with increasing PVPh content, the shoulder peak at 1,702 cm−1 gradually increases in intensity into a major peak with increase of the PVPh contents in blends. This fact indicates that, with increasing PVPh contents, more carbonyl groups of P(BA-co-BT) are involved in H-bonding interactions with the hydroxyl groups of PVPh. Such characteristics are also seen in other blend systems composed of semicrystalline polyesters with PVPh, such as PCL/PVPh and poly (β-propiolactone)/PVPh [8].

However, effects of BA and BT segments on the strength of H-bonding interactions in the P(BA-co-BT)/PVPh blend can be understood by further analyzing the hydroxyl-stretching band. Moskala et al. [8] have employed a term of frequency difference (Δν) between the free hydroxyl group and those of the hydrogen-bonded hydroxyl groups as a measure of the average strength of H-bonding interactions in the blends. This method was employed for estimating the H-bonding strength of the P(BA-co-BT)/PVPh blends. The IR characterization of PBT/PVPh and PBA/PVPh had been performed, but their spectra are not shown here for brevity. The Δν values for P(BA-co-BT)/PVPh blend in comparison with two binary blends PBT/PVPh and PBA/PVPh are 101, 103, and 95 cm−1, respectively. Two findings are pointed out. First, the Δν value of the P(BA-co-BT)/PVPh blend is intermediate between those for the PBT/PVPh and PBA/PVPh blends. This fact infers that both BA and BT units of the P(BA-co-BT) copolymer interact with PVPh, but probably with unequal strengths. Secondly, the average strength of H-bonding interactions is in decreasing order of PBT/PVPh (Δν = 103 cm−1) > P(BA-co-BT)/PVPh (Δν = 101 cm−1) > PBA/PVPh (Δν = 95 cm−1). This is consistent with the DSC result, which suggests that the interactions in the P(BA-co-BT)/PVPh blend are weaker than those in the PBT/PVPh blend but stronger than those in the PBA/PVPh blends. The BA segment reduces the H-bonding strength in the P(BA-co-BT)/PVPh blend because of the relatively weaker H bonding with PVPh in comparison to that between BT and PVPh.

Miscibility in ternary PBA/PBT/PVPh blends

A comparative study was conducted by using a ternary blend of PBA/PBT/PVPh for comparison to the earlier discussed results for the binary P(BA-co-BT)/PVPh blend. Preliminary OM characterization was performed to reveal the phase morphology of the blends. Figure 4 shows phase diagrams as revealed in OM micrographs for the ternary PBA/PBT/PVPh blends. The OM photographs for discerning the homogeneous vs. phase separation morphologies are also attached for illustration. The ternary PBA/PBT/PVPh compositions in the figure are labeled as series I and series II, respectively. Series I compositions are designed as the relative weight ratios of PBA/PBT/PVPh is 0.56x/0.44x/y, where 0.56x + 0.44x + y = 100. The ratio of PBA/PBT was delicately estimated to be equal to the BA to BT segment ratio of P(BA-co-BT) copolymer. On the other hand, series II samples mean the compositions of PBA/PBT/PVPh = x/y/40, which describes the ternary samples with a fixed PVPh content (40 wt.%) in the blends. OM characterization for the ternary blends indicates that the series I blends with lower PVPh contents (PVPh <40 wt.%) possess a heterogeneous morphology and remain phase separated up to 250 °C. By contrast, the blends with higher PVPh content in series I or blends in series II all display homogeneous morphology at both room temperature and molten state (250 °C). The OM characterization suggests that partial miscibility, rather than full miscibility, is typical for the ternary PBA/PBT/PVPh system.

The earlier preliminary OM characterization on samples indicated partial miscibility for PBA/PBT/PVPh blends with different compositions. Some blend compositions displayed a homogeneous phase, and DSC analysis was performed to confirm the phase behavior for those compositions with a homogeneous morphology as revealed in the OM graphs. For direct comparisons, Fig. 5 shows DSC traces for quenched PBA/PBT/PVPh ternary blends of different compositions of (a) series I: PBA/PBT/PVPh = 0.56x/0.44x/y and (b) series II: PBA/PBT/PVPh = x/y/40. Figure 5a displays DSC traces for quenched PBA/PBT/PVPh ternary blends of series I samples (PVPh ≥40 wt.%). A single and composition-dependent T g (dependent on PVPh content) for each composition is presented in the figure, and it also provides the positive evidence for miscibility in series I blends at the PVPh content that is equal to or higher than 40 wt.%. Figure 5b shows DSC traces for quenched PBA/PBT/PVPh ternary blends of series II. All these DSC traces show that there is only a single composition-dependent T g (increasing with higher PBT contents) for all compositions as indicated on the DSC traces. The result suggests that these blend compositions in series II, with fixed PVPh content of 40 wt.% in the ternary PBA/PBT/PVPh blends, are all miscible.

The Fox equation is generally adopted for describing the T g–composition relationships for miscible polymer blends with homogeneous phase morphology. For ternary blends, the Fox equation can be described as \( \frac{1}{{{T_{\text{g}}}}} = \frac{{{w_1}}}{{{T_{\text{g1}}}}} + \frac{{{w_2}}}{{{T_{\text{g2}}}}} + \frac{{{w_3}}}{{{T_{\text{g3}}}}} \). Figure 6 shows quantitative comparison between the experimental ternary blend T g vs. the calculated T g according to the Fox equation for single T g miscible compositions of series I and series II. Agreement between these two sets of values suggests that blend T g data are well fitted with the model prediction. These results show that all ternary blends investigated in this study possess similar T g–composition relationship and that all of them are similarly miscible. Quantitative comparisons of interaction strengths among the ternary blends were further investigated using IR spectroscopy, as will be discussed in the sections below.

IR characterization of interactions

The H-bonding interactions in the ternary blends composed of PVPh and two proton-accepting polyesters (PBA and PBT) are expected to be complex owing to the presence of two H-bonding pairs (PVPh–PBA and PVPh–PBT) in the system. Figure 7 shows FT-IR spectra in hydroxyl-stretching region for PBA/PBT/PVPh blends for different compositions of (a) series I: PBA/PBT/PVPh = 0.56x/0.44x/y (y ≥ 40) and (b) series-II: PBA/PBT/PVPh = x/y/40. In Fig. 7a, with mixing with PBA and PBT, the intensity of the free hydroxyl group band decreases and the hydrogen-bonded hydroxyl group band of PVPh shifts to a higher frequency. This evidence reveals presence of H-bonding interaction between the hydroxyl groups of PVPh and carbonyl groups of PBA and PBT. Note that the decrease of free OH stretching absorbance is partially resulted from the decrease of PVPh content in the blends. Figure 7b depicts OH stretching region of PBA/PBT/PVPh = x/y/40 when the PVPh content is fixed at 40 wt.% with various PBA/PBT = x/y ratios in the ternary blends. The blends containing 40 wt.% PVPh are in a miscible state; thus, the results reveal that the positions of the hydrogen-bonded OH stretching bands in PBA/PBT/PVPh = x/y/40 are almost the same or similar. As described in the earlier IR investigation for P(BA-co-BT)/PVPh blends, frequency shifts of the OH absorbance adequately correlate with the strengths of H bonding. Similar argument can be made on the present ternary PBA/PBT/PVPh system, where the hydrogen-bonded OH stretching absorbance for the PVPh component does not change significantly with respect to the PBA/PBT weight ratios in the ternary blends, for example, ν OH = 3,412 vs. 3,410 cm−1 for PBA/PBT/PVPh = 10/50/40 vs. 50/10/40, respectively. The fact suggests that with a fixed high PVPh content (≥40 wt.%) in the ternary blends, sufficient H-bonding interaction can sustain homogeneity in blends by presenting similar strength of H-bonding interaction regardless of the PBA/PBT ratios. The ∆χ effect, which may be significant at low PVPh contents, can be minimized by introducing high PVPh contents in the ternary blends to lead to phase homogeneity. Thus, even with its –OH bonding capacity to both PBA and PBT polyesters, PVPh at low contents only has limited bridging effect to link mutually immiscible PBA and PBT.

It may be difficult to resolve the C=O stretching region in the ternary blends of PBA/PBT/PVPh because of the complex overlapping of the two C=O groups absorbance’s attributed to PBA and PBT, respectively. To simplify the analyses of C=O absorbance spectra in such cases, Zhang et al. [33] have proposed an analytical method in characterizing a PVPh/PVAc/PMA blend system, where they consider two absorbance bands in C=O stretching bands relating to the total free and H-bonded C=O absorbance bands for both C=O groups of PVAc and PMA. Similar approaches were adopted. Figure 8 shows FT-IR spectra in carbonyl-stretching absorbance region for PBA/PBT/PVPh blends for different compositions of (a) series I: PBA/PBT/PVPh = 0.56x/0.44x/y (y ≥ 40) and (b) series II: PBA/PBT/PVPh = x/y/40. Figure 8a presents the PBA/PBT/PVPh = 0.56x/0.44x/y series (PVPh ≥ 40 wt.%), revealing that C=O stretching IR band is attributed to the free C=O groups (at 1,730–1,732 cm−1), H-bonded C=O groups (at 1,701–1,702 cm−1), and crystalline C=O groups (at 1,714 cm−1). For further quantitative analysis, it should be noted that the crystalline C=O group (only revealed in the blends with relatively lower PVPh content) should also be considered as parts of the absorbance for free C=O groups since these groups are not involved in the H bonding with the OH group of PVPh as indicated by the spectral evidence. The intensity of H-bonded groups at about 1,702 cm−1 slowly increases with the PVPh content in the miscible ternary blends, inferring that more C=O groups are involved in H-bonding interaction with the OH groups of PVPh. A similar feature is also seen in the P(BA-co-BT)/PVPh blends as mentioned in the earlier discussion. Quantitative comparison for this characteristic is discussed in the following: Figure 8b shows FT-IR spectra in carbonyl-stretching region for PBA/PBT/PVPh = x/y/40 series. Curve fitting was used to separate the free and H-bonded C=O stretching bands to analyze quantitatively the C=O stretching absorbance in the blends. Plots of the fitting results by the general Gaussian equation for the specific compositions are shown as insets in the figure. Fractions of H-bonded C=O were then estimated from these results.

Table 1 summarizes the numerical curve-fitting results for the C=O IR peaks in the PBA/PBT/PVPh ternary blends. The fraction of hydrogen-bonded C=O, f b C=O, is associated with the areas of H-bonded (A b) and free (A f) C=O groups by following equations, which were earlier derived and used by some investigators [12]:

where a hb and a f are the absorptivities of the H-bonded and free C=O bands, respectively. Combination of Eqs. 2 and 3 yields a final expression:

The value of a hb/a f, from the literature [17], is 1.5 for the blends of PVPh with the polyester, from which the f b C=O values were then calculated. For the ternary blend of PBA/PBT/PVPh = 0.56x/0.44x/y series (y ≥ 40), f Cb = O (from 34.8% to 55.3%) clearly increases with the PVPh content in the blends. This indicates that the total fraction of H-bonded C=O groups of PBA and PBT increases with the introduction of the third PVPh constituent to the binary blend of PBA/PBT to form a ternary blend. By comparison, for the PBA/PBT/PVPh = x/y/40 series (e.g., PBA/PBT/PVPh = 10/50/40 and 50/10/40), almost equal f b C=O values (30.1% and 33.0%, respectively) were obtained by the curve fitting. This result again suggests that the similar H-bonding interactions are present in the miscible blend compositions containing at least 40 wt.% PVPh with a homogeneous phase. In addition, Table 2 also shows the curve-fitted results of carbonyl IR peaks for binary P(BA-co-BT)/PVPh and ternary PBA/PBT/PVPh blends. Similar values for the ratio of H-bonded C=O groups are obtained by the methodology mentioned above. These results provide further evidence that the H-bonding interactions in the miscible compositions of the ternary blends are comparable to those in the binary copolymer blends. Similar specific interactions exist in the binary P(BA-co-BT)/PVPh blend system as well as in ternary PBA/PBT/PVPh blend of high PVPh contents.

Conclusion

Blends of P(BA-co-BT) copolyester with hydroxyl-containing PVPh were proven to be miscible with specific interactions via hydrogen bonding between the homopolymer PVPh and copolyester segments. The Kwei equation reasonably describes the T g–composition relationship for P(BA-co-BT)/PVPh blends with q = −82, which is in the middle of that (q = 5) for the PBT/PVPh blends and that (q = −225) for the PBA/PVPh blends. In general, the average specific interactions in the P(BA-co-BT)/PVPh blend are weaker than those in the PBT/PVPh blend but stronger than those in the PBA/PVPh blend. The IR spectral result gives evidence that the H-bonding interaction exists between P(BA-co-BT) and PVPh. From the extent of IR wavenumber shifting of the OH group for the blends, the strength of H-bonding interaction was determined and ranked to be in order of PBT/PVPh > P(BA-co-BT)/PVPh > PBA/PVPh. The BA unit tends to lower the average strength of intermolecular H bonding in the P(BA-co-BT)/PVPh blend owing to the relatively weaker interaction between the BA segment of the copolymer and PVPh homopolymer.

In copolymer P(BA-co-BT), the PBA and PBT segments are linked to behave collaterally by covalent bonds, and the copolymer’s polarity is averaged in interacting with PVPh. When the covalent bond in P(BA-co-BT) is removed, such as replaced with two homopolymers of PBA and PBT, the interactions among PBA, PBT, and PVPh are dramatically different to lead to a different phase behavior. For this purpose, a comparative ternary (PBA/PBT/PVPh) blend was studied. Results show that only partial miscibility exists in the PBA/PBT/PVPh ternary blend, which is attributed to the ∆χ effect. Apparently, low contents of PVPh in the blends do not provide any bridging effect on linking two mutually immiscible polymers (PBA and PBT) into a miscible (or more compatible) state. Only at high contents of PVPh in the blends (≥40 wt.%), the ternary blends turn miscible. With high PVPh contents in the blends, sufficient H-bonding interactions can promote the ternary blend to a homogeneous state. That is, even with the –OH bonding capacity in PVPh to favorably interact with both PBA and PBT polyesters, PVPh at low contents in the ternary blend has only limited bridging effect.

References

Gan Z, Kuwabara K, Yamamoto M, Abe H, Doi Y (2004) Polym Degrad Stab 83:289

Ishioka R, Kitakuni E, Ichikawa Y (2002) Polyesters III: applications and commercial products. In: Doi Y, Steinbüchel A (eds) Biopolymer vol 4. Weinheim, Germany, pp 275–298

Gruber P, O’Brien M (2002) Polyesters III: applications and commercial products. In: Doi Y, Steinbüchel A (eds) Biopolymer vol 4. Weinheim, Germany, pp 235–249

Asrar J, Gruys KJ (2002) Polyesters III: applications and commercial products. In: Doi Y, Steinbüchel A (eds) Biopolymer vol 4. Weinheim, Germany, pp 53–90

Cranston E, Kawada J, Raymond S, Morin FG, Marchessault RH (2003) Biomacromolecules 4:995

Kuwabara K, Gan Z, Nakamura T, Abe H, Doi Y (2002) Biomacromolecules 3:390

Jiang L, Wolcott MP, Zhang J (2006) Biomacromolecules 7:199

Moskala EJ, Varnell DF, Coleman MM (1985) Polymer 26:228

Qin C, Pires ATN, Belfiore LA (1990) Polym Commun 31:177

Goh SH, Siow KS (1987) Polym Bull 17:453

Belfiore LA, Pires AT, Qin C (1991) Macromolecules 24:666

Moskala EJ, Howe SE, Painter PC, Coleman MM (1984) Macromolecules 17:1671

Belfiore LA, Qin C, Ueda E, Pires ATN (1993) J Poly Sci Part B Polym Phys 31:409

Qiu ZB, Fujinami S, Komura M, Nakajima K, Ikehara T, Nishi T (2004) Polymer 45:4515

Xing P, Dong L, An Y, Feng Z, Avella M, Martuscelli E (1997) Macromolecules 30:2726

Lee LT, Woo EM (2004) Polym Int 53:1813

Landry CJT, Massa DJ, Teegarden DM, Landry MR, Henrichs PM, Colby RH, Long TE (1993) Macromolecules 26:6299

Zhang ZH, Mo ZS, Zhang HF, Zhang Y, Na TH, An YX, Wang XH, Zhao XJ (2002) J Polym Sci Part B Polym Phys 40:1957

Huang HL, Goh SH, Wee ATS (2002) Polymer 43:2861

Lee HF, Kuo SW, Huang CF, Lu JS, Chan SC, Wang CF, Chang FC (2006) Macromolecules 39:5458

Lee LT, Woo EM, Hou SS, Förster S (2006) Polymer 47:8350

Urzua M, Leiva A, Alegria L, Gargallo L, Radic D (2007) Int J Polym Mater 56:687

Brannock GR, Paul DR (1990) Macromolecules 23:5240

Yau SN, Woo EM (1996) Macromol Rapid Commun 17:615

Tseng YC, Woo EM (1998) Macromol Rapid Commun 19:215

Pomposo JA, Calahorra E, Eguiazabal I, Cortazar M (1993) Macromolecules 26:2104

Jo WH, Kwon YK, Kwon IH (1991) Macromolecules 24:4708

Vanneste M, Groeninckx G (1994) Polymer 35:1051

Goh SH, Ni X (1999) Polymer 40:5733

Hong BK, Kim JY, Jo WH, Lee SC (1997) Polymer 38:4373

Rabeony M, Siano DB, Peiffer DG, Siakali-Kioulafa E, Hadjichristidis N (1994) Polymer 35:1033

Kwei TK (1984) J Polym Sci Polym Lett Ed 22:307

Zhang H, Bhagwagar DE, Graf JF, Painter PC, Coleman MM (1994) Polymer 35:5379

Acknowledgment

This work has been financially supported by basic research grants (NSC-95 2221 E006 183 and NSC 96-2221-E-006-011) in three consecutive years from Taiwan’s National Science Council, to which the authors express their gratitude.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, LT., Woo, E.M., Chen, WT. et al. Phase behavior and interactions in blends of poly[(butylene adipate)-co-poly(butylene terephthalate)] copolyester with poly(4-vinyl phenol). Colloid Polym Sci 288, 439–448 (2010). https://doi.org/10.1007/s00396-009-2142-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-009-2142-9