Abstract

Four types of triblock glycols [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5, Mn=3,000] were synthesized by end-capping reactions of ɛ-caprolactone (CL) and poly(ethylene) glycol (PEG, Mn=2,000), poly(tetramethylene adipate) glycol (PTAd, Mn=2,000), poly(tetramethylene) glycol (PTMG, Mn=2,000), or polypropylene glycol (PPG, Mn=2,000)]. Waterborne polyurethanes (WBPUs) were prepared by polyaddition reaction using 4,4-dicyclohexylmethane diisocyanate (H12MDI), 2,2-bis (hydromethyl) propionic acid (DMPA), ethylene diamine (EDA), triethyl amine (TEA), and the triblock glycol. Studies have been conducted on the effects of triblock glycol type on the colloidal properties of dispersion, the hardness and mechanical properties of WBPU films, the water vapor permeability (WVP), and water resistance (WR) of WBPU-coated nylon fabrics. The WVP (%WVP based on control nylon fabric) of WBPU-coated nylon fabrics based on (CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5 and (CL)4.5-PPG-(CL)4.5 were 3,975(81), 3,115(62), 3,124(64), and 2,569(52) g/m2 day (%), respectively. However, the WBPU based on (CL)4.5-PEG-(CL)4.5 was not applicable for coating material, because its dispersion and film had relatively high viscosity (3,000 cps at 50°C) and low mechanical properties, respectively. In this work, the triblock glycols (CL)4.5-PTMG-(CL)4.5 and (CL)4.5-PTAd-(CL)4.5 were found to be desirable glycols for water vapor permeable coating materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Waterborne polyurethane (WBPU) dispersions have been used for a wide range of commercial applications such as adhesives or coatings for various substrates [1–4]. The earliest use for WBPU dispersions, i.e. as a coating for textiles, is still one of the largest market areas for them. In the applications of breathable coating fabrics, water vapor permeability was the most important factor. Generally, the properties of WBPU are greatly affected by the composition and chain length/structure of soft segments [5–11].

It is well known that the ester type polyol-based PU gives better mechanical properties, whereas the ether type polyol-based PU shows better hydrolysis resistance, softness, and water vapor permeability (WVP). To improve the physical properties, a mixed or special type polyols as soft segments of PU were used for imparting polyurethanes with specific properties [12–15]. Xiu et al. [11] used ester–ether copolydiol (polypropylene oxide and maleic anhydride) as mixed soft segments to study the influence of soft-segment structure and molecular weight on the physical properties of polyurethane–urea. Polyester–ether based polyurethane–urea displayed a higher Young’s modulus and lower elongation than polyester-based or polyether-based PU, primarily due to the larger interface within domains . Chen et al. [12] studied the PU properties with poly(propylene) glycol–poly(ethylene) glycol (PPG–PEG) as mixed soft segments of PU, and showed that PU with higher PEG content could increase the moisture permeability of the PU films, while the mechanical properties were not affected. In an effort to improve the mechanical properties and WVP of WBPU, Yen and Kuo [16– 18] used the triblock copolyols PCL–PEG–PCL as the soft segment in the preparation of WBPU. They found that the PCL–PEG–PCL-based WBPU had better film softness and fabric WVP properties than the WBPU synthesized by blending PCL and PEG as the soft segment [16]. They found that the WVP of WBPU-coated nylon fabrics increased with increasing soft-segment content and the molecular weight of PEG in PCL–PEG–PCL [17]. However, the mechanical property of cast film decreased with increasing PEG molecular weight [17]. The balance in physical properties between the WVP and mechanical properties requires further improvements. They also found that the higher NCO/OH molar ratio yields better mechanical properties and WVP for WBPU cast film [18]. We also prepared WBPU based on triblock glycol(CL)4.5-PTMG-(CL)4.5 as a soft segment [19, 20]. Triblock glycol-based WBPU-coated nylon fabrics were found to have higher WVP compared with polyol blends (PPG/PCL, PTMG/PCL, PPG/PTAd, PTMG/PTAd) and solo glycol (PTMG, PPG, PTAd, PCL) based fabrics [19]. The WVP of WBPU-coated nylon fabrics increased with increasing soft-segment content [20]. Generally, the character of the soft segment must be carefully adjusted to match the required property profile of the final application. However, research on the influences of block copolymer type soft segment on the properties of WBPU can hardly be found.

In this study, four different triblock glycols, [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5, Mn=3,000], were synthesized by end-capping reaction of four different polyols (PEG, PTAd, PTMG and PPG, Mn=2,000) and ɛ-caprolactone (CL), according to Piero’s synthesis [21]. Four kinds of WBPU were prepared from 4,4-dicyclohexylmethane diisocyanate (H12MDI), 2,2-bis(hydroxylmethyl) propionic acid (DMPA), ethylene diamine (EDA), triethyl amine (TEA), and four triblock glycols as soft segment. This paper focuses on the effects of the triblock glycol types on the colloidal properties of dispersion, hardness and thermal/mechanical properties of WBPU films, the WVP, and water resistance(WR) of WBPU-coated nylon fabrics.

2 Experimental

2.1 Materials

Poly(ethylene ether) glycol (PEG, Mn=2,000, Korea Polyol), poly(tetramethylene ether) glycol (PTMG, Mn=2,000, BASF Korea), poly(tetramethylene) glycol (PTAd, Mn=2,000, Hosung Chemex), poly(propylene) glycol (PPG, Mn=2,000, Korea Polyol), and CL (Aldrich Chemical) were distilled at 95°C under vacuum before use. 4,4-dicyclohexylmethane diisocyanate (H12MDI, Aldrich Chemical), EDA (Junsei Chemical), TEA (Junsei Chemical), and N-methyl-2 pyrrolidone (NMP, Junsei Chemical) were used after dehydration with 4 Å molecular sieves for 1 week. DMPA (Aldrich Chemical), dibutyltin dilaurate (DBTDL, Aldrich Chemical), thickener (L75N, Bayer), and hardener (Desmodur DA, Bayer) were used without further purification.

2.2 Synthesis of triblock glycols

The triblock glycol [(CL)4.5-Polyols (PEG, PTAd, PTMG, PPG (Mn=2,000)-(CL)4.5] were obtained by the reaction of the stoichiometric amount of polyols (Mn=2,000, 0.05 mol) and CL (0.45 mol) under mild stirring with nitrogen gas atmosphere for 48 h at 180°C. Then, the reaction mixture was distilled to remove the unreacted component CL in vacuum condition at 190°C. The CL/polyols mol ratio was 9. The triblock glycols with the yield above 95% were obtained. The average molecular weight of triblock glycol synthesized here was about 3,000 g/mol. Their molecular weights were almost the same as theoretical values (Mn=3,000).

2.3 Synthesis of waterborne polyurethane (WBPU)

The WBPUs based on four triblock glycols [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5, Mn=3,000] were synthesized using the prepolymer mixing process [1]. The triblock glycol was placed in a 4-necked round-bottom flask equipped with a thermometer, a stirrer, an inlet of dry nitrogen, a condenser, and a heat jacket, and then degassed under vacuum at 90°C for 30 min. Then DMPA/NMP (1/1 wt ratio) was added to the flask, and the mixture was allowed to cool to 45°C under moderate stirring. Then, H12MDI was added to the flask, and heated to 85°C under moderate stirring. The reaction mixture was allowed to react at 85°C until the theoretical NCO content was reached. The change of NCO content during reaction was determined using a standard dibutylamine back-titration method (ASTM D1638). MEK (20 wt%) was added to the NCO-terminated prepolymer mixture to adjust the suitable viscosity of the solution. And then, TEA was added to the reaction mixture for neutralizing the carboxyl group of the NCO-terminated polyurethane prepolymer. After 30 min of neutralization reaction, distilled water (60 or 70 wt%) was added to the reaction mixture under vigorous stirring. The neutralized prepolymer was chain-extended by dropping EDA at 40°C for 1 h and the reaction continued until NCO peak (2,270 cm−1) in IR spectra had completely disappeared. The aqueous dispersions (40 or 30 wt% solid content) were obtained by evaporating MEK and then by adding the adequate amount of water.

2.4 Preparation of films and WBPU-coated nylon fabrics

Films were prepared by pouring the aqueous dispersion into a Teflon disk at ambient conditions. The films (typically about 0.5 mm thick) were dried in vacuum at 50°C for 3 days and stored in a dessicator at room temperature.

Preparation of WBPU-coated nylon fabrics were formulated from WBPU, thickener (L75N, 0.5 wt%), and hardener (Desmodur DA, 5 wt%). The coating materials were coated to nylon fabrics using steel bar, and then cured at 85°C for 5 min. The thickness of coated PU layer was about 0.04 mm.

2.5 Characterization

Particle-size analysis was done using lazer-scattering equipment (Autosizer, Melvern IIC, Malvern Worcester, UK). A few drops of the dispersion were diluted in distilled water before the measurement. The viscosity of WBPU dispersions was measured at 25°C using a Brookfield digital viscometer (Model LVDV-II+, MA,USA). An FT-IR spectrometer (Nicolet Impact 400D, Madson, WI,USA) was used to identify the structure of WBPU and TBG. For each IR spectrometer sample, 32 scans at 4 cm−1 resolution were collected in the absorbance model. The thermal behavior of triblock glycols was examined by using a DSC (220C, Seiko, Japan) at a heating rate of 10°C/min under nitrogen atmosphere. The water vapor permeability was determined using an evaporation method described in ASTM E 9663-T. The water resistance was determined using a low-range hydrostatic pressure method described in KS K 0591.

3 Results and discussion

Sample designation, composition, and solid content of four triblock glycols [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5, Mn=3,000] are listed in Table 1. The yields of all the triblock glycols synthesized here were above 95%. The average molecular weights of the triblock glycols (Mn=3,000) were almost the same as the theoretical value based on the feed ratio of reactants.

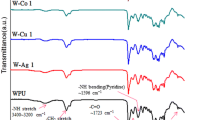

Figure 1 shows IR spectra of triblock glycols [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5, Mn=3,000] prepared in this study. The triblock glycols were identified by the characteristic peaks of carbonyl group at 1,730 cm−1 and ether group at 1,112 cm−1. The DSC curves of four triblock glycols synthesized here are shown in Fig. 2. The triblock glycols have two melting peaks. This might be due to the presence of two different crystalline domains assigned to CL component-rich block and polyol (PEG, PTAd, PTMG and PPG) rich block. The higher melting temperatures (38.3, 44.5, 37.9, and 38.4°C) might be attributed to the melting peak of polyol (PEG, PTAd, PTMG, and PPG) rich domains, respectively. However, the CL-rich domains in triblock glycols might have smaller melting peaks at lower temperature.

Generally, the particle size of WBPU decreases with increasing hydrophilic component in polyurethane [22]. It is generally known that the average particle size is not directly related to the physical properties of WBPU cast film [23]. Larger particles are preferred in surface coating for rapid drying and smaller ones are desirable when the deep penetration of dispersion into a substrate is essential. The particle sizes and viscosity of WBPUs prepared in this study are shown in Fig. 3. The (CL)4.5-PEG-(CL)4.5 based sample had a very small particle size of about 26 nm; however, the particle sizes of (CL)4.5-PTMG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, and (CL)4.5-PPG-(CL)4.5 based samples were 181, 195 and 211 nm, respectively. The lower particle size of (CL)4.5-PEG-(CL)4.5 based sample is due to the higher hydrophilicity of PEG component compared with PTMG, PTAd, and PPG components. In general, the viscosity of WBPU is governed by the hydrophilicity, in addition to external factors such as shear force and temperature. Smaller particles will lead to larger hydrodynamic volume, and therefore, induced higher viscosity. The viscosity of (CL)4.5-PEG-(CL)4.5 based sample with solid content 30 wt% was about 3,000 cps at 50°C. The viscosity of (CL)4.5-PEG-(CL)4.5 based sample was too high to measure at room temperature. However, the viscosities of WT-PTMG, WT-PTAd, and WT-PPG dispersion samples with solid content 40 wt% were 33, 13, and 10 cps at room temperature, respectively. The higher viscosity of (CL)4.5-PEG-(CL)4.5 based dispersion sample is also attributed to the higher hydrophilicity of PEG component compared with PTMG, PTAd, and PPG components. Relatively larger particles and lower viscosities of WT-PTMG, WT-PTAd and WT-PPG dispersion samples are preferred in surface coating for rapid drying. On the other hand, the (CL)4.5-PEG-(CL)4.5 based dispersion sample having high viscosity(3,000 cps at 50°C) was not applicable to coating material.

Figure 4 shows the decomposition of the C=O and N–H stretching bands of IR spectrum for typical WBPU film. The hydrogen-bonding fraction (XB) can be calculated from total peak area (CT) and the peak area of hydrogen-bonding C=O or N–H groups (CB) as follows: XB=CB/CT, where CT=(a+b+c) for C=O and CT=(a+b) for N–H and CB=(b+c) for C=O and CB=(b) for N–H. The values of XB C=O and XB N-H was significantly increased in the order of WT-PEG>WT-PTAd>WT-PTMG>WT-PPG (see Fig. 5). The film sample WT-PEG containing hydrophilic PEG component had the highest hydrogen-bonding index. On the other hand, ester-type component (PTAd) based sample had higher hydrogen-bonding index than ether-type component (PTMG and PPG) based samples. The hydrogen-bonding index of PTMG component based sample was higher than that of PPG components based sample with a side methyl group. These results indicate that the extent of hydrogen bonds in WBPU is mostly dependent on the polarity and linearity of WBPU chain.

Hardness reflects the resistance to local deformation, which is complex properties, related to crosslinking density, plasticity/elasticity, strength/modulus, and properties of the matrix. The hardness of WBPU film samples prepared in this study is shown in Fig. 6 and Table 2. It was found that the hardness of film samples decreased in the order of WT-PEG>WT-PTAd>WT-PTMG>WT-PPG. Among the four film samples using four different triblock glycols, the film sample based on hydrophilic PEG component had the highest hardness. The samples based on ester-type component (PTAd) had higher hardness than samples based on ether-type components (PTMG and PPG). The hardness of PTMG component based sample was higher than that of PPG-based sample having side methyl group. The increase of hardness was found to be the same trend as the increases of hydrogen-bonding index.

Figure 7 shows the stress–strain curves of film samples prepared in this study. The initial tensile modulus of film samples decreased in the order of WT-PTAd>WT-PEG>WT-PTMG>WT-PPG. The increase of initial tensile modulus was also the same trend as the increases of XB and hardness, except sample WT-PEG. Generally, the ester-type polyol-based PU gives better mechanical properties. On the other hand, the PU based on PTMG having regular chain structure shows better mechanical properties compared with the PU based on PPG containing a side methyl group. As might be expected from this point of view, the tensile strength and elongation at break were found to decrease in the order of WT-PTAd>WT-PTMG>WT-PPG>WT-PEG. The lowest values of the tensile strength and elongation at break of CT-PEG sample might be due to the high water vapor absorbency of PEG component.

The WVP, WR, and %WVP of the WBPU-coated nylon fabrics (WBPU coating layer: about 0.04 mm) and control-nylon fabric are shown in Fig. 8 and Table 2. The WVP and WR of the control-nylon fabric were 3,975 g/m2day and 0 mmH2O, respectively. The WVP of WBPU-coated nylon-coated fabrics based on (CL)4.5-PEG-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, and (CL)4.5-PPG-(CL)4.5 were 3,975, 3,124, 3,115, and 2,569 g/m2 day, respectively. The %WVP (based on control fabric) of these samples was 81, 64, 62, and 52%, respectively. However, the WR of all these samples was about 300 mmH2O. The WVP of WBPU-coated fabric samples decreased in the order of CT-PEG>CT-PTMG>CT-PTAd>CT-PPG. In general, the ether-type polyol-based PU shows better WVP. Besides, it is generally believed that the high hydrophilicity gives better WVP. From this point of view, the decreasing order of WVP is mostly to be expected. The sample CT-PEG based on PEG component had the highest WVP. However, the sample based on (CL)4.5-PEG-(CL)4.5 was not applicable for coating material, because it had high viscosity and low mechanical properties. Thus, it is concluded that the triblock glycols (CL)4.5-PTMG-(CL)4.5 and (CL)4.5-PTAd-(CL)4.5 are desirable glycols for WBPU coating materials.

4 Conclusions

Waterborne polyurethanes were prepared by polyaddition reaction using 4,4-dicyclohexylmethane diisocyanate (H12MDI), DMPA, EDA, TEA, and four types of triblock glycol as a soft segment. Four types of triblock glycols such as (CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5 were used. The effects of the triblock glycol types Mn=3,000 g/mol, [(CL)4.5-PEG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, (CL)4.5-PTMG-(CL)4.5, and (CL)4.5-PPG-(CL)4.5] on the colloidal properties of dispersion, hardness and mechanical properties of WBPU films, the WVP, and WR of WBPU-coated nylon fabrics were investigated. The (CL)4.5-PEG-(CL)4.5 based sample has a very small particle size about 26 nm, while (CL)4.5-PTMG-(CL)4.5, (CL)4.5-PTAd-(CL)4.5, and (CL)4.5-PPG-(CL)4.5 based samples have almost the same particle size of about 200 nm. The viscosity of (CL)4.5-PEG-(CL)4.5 based dispersion sample with solid content of 30 wt% was about 3,000 cps at 50°C. So, (CL)4.5-PEG-(CL)4.5 based dispersion sample is not applicable for coating material. However, the viscosities of WT-PTMG, WT-PTAd, and WT-PPG dispersion samples with solid content of 30 wt% were 33, 13, and 10 cps at room temperature, respectively. It was found that relatively larger particles and lower viscosities of these samples are preferred in surface coating for rapid drying. The hydrogen-bonding index (XB\ C=O and XB\ N-H) and hardness of film samples decreased in the order of WT-PEG>WT-PTAd>WT-PTMG>WT-PPG. The WVP of WBPU-coated fabric samples decreased in the order of WT-PEG>WT-PTMG>WT-PTAd>WT-PPG. However, the WR of all samples was found to be about 300 mm H2O. In this work, considering the viscosity and mechanical properties of WBPU film samples and the WVP of WBPU-coated nylon fabrics, it is concluded that the triblock glycols (CL)4.5-PTMG-(CL)4.5 and (CL)4.5-PTAd-(CL)4.5 are desirable glycols for WBPU coating materials in this work.

References

Dieterich D (1981) Progr Org Coatings 9:281

Frisch KC, Klempner D (1987) In: Advances in urethane science and technology ,vol 10, p 121

Oertel G (1994) Polyurethane handbook. Carl Hanser, New York, p 25

Hepburn C (1992) Polyurethane elastomers. Applied Science, New York, p 81

Reischl A (1979) US Patent 4,137,360

Holker JR, Jeffries R, Lomax R (1983) US Patent 4,367,327

Morrison ID, Ross S (2002) Colloidal dispersions. Wiley , New York, p 62

Kim BK, Lee YM (1992) Colloid Polym Sci 270:956

Lee YM, Lee JC, Kim BK (1994) Polymer 35(5):1095

Prelini C, Traviti A, Gambini T, Stefanoli V (1991) US Patent 5024674

Xiu Y, Wang D, Hu C, Ying S, Li J (1993) J Appl Polym Sci 48:867

Chen CT, Zatoz RF, Chang PJ, Tobosky AV (1972) J Appl Polym Sci 16:2105

Cooper SL, Phillips RA, Stevenson JC, Nagoajan MR (1998) J Macromol Sci Phys B 27(2–3):245

Cooper SL, Yu XH, Nagoajan MR, Grasel TG, Grasel PE, Gibson PE (1985) J Appl Polym Sci 30:2319

Ahn TO, Jung S, Jeong HM, Lee SW (1994) J Appl Polym Sci 51:43

Yen MS, Kuo SC (1996) J Appl Polym Sci 61:1639

Yen MS, Kuo SC (1997) J Appl Polym Sci 65:883

Yen MS, Kuo SC (1998) J Appl Polym Sci 67:1301

Kwak YS, Park SW, Lee YH, Kim HD (2003) J Appl Polym Sci 89:123

Kwak YS, Kim HD (2002) Fibers Polym 3(4):153

Piero C, Mario T, Fulvio A, Maurizio P, Massimo P (1987) Polymer 28:831

Chen W, Krisch KC, Kenney DJ, Wong SJMS (1992) Pure App Chem 29:567

Lee YM, Kim TK, Kim BK (1992) Polymer International 23:157

Acknowledgements

This work was performed through a program for cultivating graduate students in regional strategic industry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwak, Y.S., Kim, E.Y., Kim, H.D. et al. Comparison of the properties of waterborne polyurethane-ureas containing different triblock glycols for water vapor permeable coatings. Colloid Polym Sci 283, 880–886 (2005). https://doi.org/10.1007/s00396-004-1230-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1230-0