Abstract

In Forschung hast Du immer zu mir gesagt, “Schaffe etwas!”. Mein Chef, ich habe immer versucht Deinen Befehlen zu folgen. Ich widme Dir diese Veröffentlichung. Mensch, mit fünf und siebzig bist Du noch jung, schön Geburtstag!

The effect of ionic impurities on the electric field alignment of lamellar microdomains in polystyrene-block-poly(methyl methacrylate) diblock copolymer thin films was studied using transmission electron microscopy (TEM) and atomic force microscopy (AFM). At lithium ion concentrations greater than ~210 ppm, the microdomain morphology in block copolymers could be aligned in the direction of an applied electric field, regardless of the strength of interfacial interactions. Complete alignment of the copolymer microdomains, even those adjacent to the polymer/substrate interface, occurred by a pathway where the applied electric field enhanced fluctuations at the interfaces of the microdomains with a wavelength comparable to L o, the equilibrium period of the copolymer. This enhancement in the fluctuations led to a disruption of the lamellar microdomains into smaller microdomains ~L o in size, that, in time, reconnected to form microdomains oriented in the direction of the applied field.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thin films of block copolymers have attracted significant attention due to their potential use as templates, masks, and scaffolds for nanostructured materials [1, 2]. Controlling the orientation of the copolymer microdomains, however, is crucial. Electric fields have been shown to be an effective route towards achieving this control in thin films [3, 4, 5, 6, 7, 8]. By applying an electric field normal to the surface, the microdomains can be oriented along the direction of the applied field. The preferential interactions of the blocks with the interfaces present a barrier to this orientation that must be overcome in order to achieve the desired alignment [9, 10, 11]. The influence of interfacial energy on the microdomain orientation of symmetric diblock copolymers by an electric field has recently been discussed [12]. Complete alignment of the microdomains could be achieved only when the interfacial interactions were balanced. In all other cases, microdomains adjacent to the substrate were found to be oriented parallel to the substrate interface, whereas, in the interior of the film, the microdomains oriented in the direction of the applied field. These results were ascribed to a pathway-dependent alignment and the high energetic barrier to achieving complete reorientation of the microdomains adjacent to the surface. At the early stages of alignment, the microdomains adjacent to the substrate were oriented parallel to the surface. The field strength required to achieve full alignment of these microdomains exceeded the dielectric breakdown of the copolymers. Therefore, relying strictly on the difference in the dielectric constants of the microdomains to affect alignment was not possible. Consequently, an alternate alignment mechanism requiring lower electric field strength was needed.

Recently, we observed that an electric field could be used to induce a transition in the morphology, from spherical to cylindrical microdomains [13]. Tsori et al calculated the electric field strength necessary to effect this transition based on a dielectric constant theory, and found that the required electric field strength exceeded the dielectric breakdown of the copolymers. To explain the experimental observations, they proposed an alternative mechanism where ionic impurities may be responsible for inducing the observed morphological transition [14]. The concentration of ionic impurities required to reduce the critical field strength sufficiently to achieve alignment was quite low. These compelling arguments led us to undertake a systematic study of the influence of impurities on the microdomain alignment.

The effect of ionic impurities on the electric field alignment of lamellar microdomains of polystyrene-block-poly(methyl methacrylate) (PS-b-PMMA) thin films was studied using transmission electron microscopy (TEM) and atomic force microscopy (AFM). At lithium ion concentrations of ~210 ppm, the microdomains of the block copolymers could be aligned in the direction of an applied electric field, regardless of the strength of interfacial interactions. For films with thickness ~10L o (L o is the equilibrium period of the copolymer in the bulk), with lamellar microdomains oriented parallel to the surface throughout the film, an electric field-induced parallel-to-perpendicular transition of the lamellar microdomains was observed where the applied electric field enhanced fluctuations at the interfaces of the microdomains with a wavelength comparable to L o. The enhancement in the fluctuations led to a disruption of the microdomains into smaller microdomains ~L o in size that, with time, reconnected to form microdomains oriented in the direction of the applied field. This differentiates copolymers from polymer/polymer liquids, where the fluctuations enhanced by the electric field depended upon field strength, dielectric constant difference and differences in the interfacial energies of the two polymers [15, 16].

Experimental

PS-b-PMMA (M n=6.4×104, PDI=1.08), was prepared by typical anionic synthesis under a nitrogen atmosphere, using Schlenk techniques, and contained 50% (by volume) styrene. Prior to polymerization, a small amount of lithium chloride (LiCl) (~0.5 g) was added to decrease the propagation rate of the growing chain, for greater control over the polymerization. Precipitation of the polymer was achieved by pouring the solution into five times its volume of methanol and filtering. Size exclusion chromatography was performed against polystyrene standards using a Knauer SEC system with K501 HPLC pump, K2301 RI detector, and K2600 dual UV detector, equipped with three Plgel 5 μm columns (two mixed-D and one 50 Å). The elemental concentration of lithium impurity of the PS-b-PMMA diblock copolymer prepared this way is 210 ppm (as measured by Quantitative Technologies Inc with 1 ppm resolution). The purified diblock copolymers used in this study were cleaned by running the copolymer through three silica gel (70–230 mesh) plugs (3/4” diam × 5” tall). The polymer (0.5 g) was dissolved in 5 ml of HPLC grade toluene, passed through the plug once, and the first 10 ml fraction containing polymer was precipitated into methanol. This was repeated three times using fresh silica gel each time. The elemental concentration of lithium after purification is lower than 1 ppm.

Silicon substrates were modified by anchoring hydroxyl terminated random copolymers of styrene and methyl methacrylate with styrene fractions of 0.9, prepared by living free radical procedures [17, 18]. The difference in interfacial energy between PS and PMMA homopolymers with the modified substrates is approximately 0.9 dyne/cm (γ PMMA/sub−γ PS/sub≈0.9 dyne/cm). Films of PS-b-PMMA, ~300 nm, ~800 nm, and ~1 μm in thickness were prepared by spin-coating toluene solution of the copolymers onto the substrates. Films of ~800 nm were annealed at 170 °C for 3 days under vacuum.

The capacitor set-up for the electric field alignment used an aluminized Kapton film as the top electrode (positive electrode). A thin layer (20–25 μm) of crosslinked polydimethylsiloxane (PDMS) (Sylgard) was used as a buffer layer between the Kapton electrode and the copolymer thin film. The PDMS layer conforms to the electrode surface, eliminates air gaps between the top electrode and the copolymer film, and maintains a smooth surface of the copolymer film. The preparation of the crosslinked PDMS layer has been described previously [12]. A conductive silicon substrate with a ~2 nm native silicon oxide layer was used as the bottom electrode (ground/negative electrode). The silicon substrates were modified with a random copolymer of methyl methacrylate and styrene, as described above. The copolymer films were heated to 170 °C under N2 with an applied DC electric field of ~40 V/μm for 16 h, and then quenched to room temperature before removing the electric field. Tapping mode AFM was performed with a Dimension 3100, Nanoscope III from Digital Instruments Corp. For TEM, the copolymer films were heated to 170 °C under N2 with a ~40 V/μm applied electric field for a predetermined time, and then quenched to room temperature before removing the field. The samples were embedded in epoxy, microtomed with a diamond knife at room temperature and transferred to a copper grid. The thin sections were exposed to ruthenium tetraoxide for 35 min to enhance the contrast. Electron microscopy experiments were performed on a JEOL 100CX TEM at an accelerating voltage of 100KV.

Results and discussion

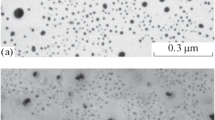

At present, it is unclear what influence ionic impurities have on the interfacial interactions and surface tensions in block copolymer thin films. With PS-b-PMMA, residual ionic impurities are, in general, present from anionic synthesis. Films (~800 nm) of the copolymer, before and after removal of lithium ions, were prepared and annealed at 170 °C for 72 h under vacuum. Figure 1 shows the cross-sectional TEM images of PS-b-PMMA thin films before (Fig. 1a) and after (Fig. 1b) lithium ion extraction. In both cases, lamellar microdomains were observed to align with the air/polymer and polymer/substrate interfaces, resulting from the lower surface energy of PS and preferential interaction of the PS blocks and the modified substrate. In this case, the presence of trace lithium ions (~210 ppm) did not significantly change the interfacial interactions between each block and the substrate.

Figure 2 shows a cross-sectional TEM image of a ~1 μm thin film spin-coated from a toluene solution of the copolymer after lithium ion extraction. The film was on a silicon substrate that had been modified with a random copolymer of styrene and methyl methacrylate with a styrene fraction of 0.9. The PS block preferentially segregated to the substrate. Mixed orientations of the microdomains were seen after annealing at 170 °C under a ~40 V/μm DC electric field for 16 h. PS preferentially segregated to the film surface and no topographic features were evident, with the exception of a surface roughness as measured by AFM. For the film of ~300 nm (~10L o) thickness, the lamellar microdomains were parallel to the surface regardless of the applied electric field. TEM experiments show results consistent with previous studies based on a dielectric mechanism, where complete alignment of lamellar microdomains could not be achieved using an electric field if the interfacial interactions were not balanced [12].

The mixed orientations of the microdomains arise from a pathway-dependent alignment and a high energetic barrier to achieving complete reorientation of the lamellae adjacent to the surface. The driving force for alignment, based on the dielectric constant difference between two blocks, is not strong enough to reorient the microdomains adjacent to the substrate, where fluctuations are suppressed by a surface field. In the presence of a trace amount of lithium ions, dissociated lithium ions primarily reside within the PMMA microdomains due to Li→O=C coordination bridges as measured by Kim and Tsori et al [19, 20]. Under an electric field, these ions migrate to the PMMA/PS interfaces, creating an effective dipole. The interaction of the applied field on these planar dipoles is much stronger than on simple dielectric bodies, and is sufficient to reorient the lamellar microdomains adjacent to the substrate.

Figure 3a shows a cross-sectional TEM image of a ~300 nm PS-b-PMMA thin film after annealing at 170 °C under a ~40 V/μm DC electric field for 16 h. The substrate had been modified with the same random copolymers as that shown in Fig. 2. The diblock copolymer had not been purified and contained 210 ppm residual lithium impurities, as measured by Quantitative Technology Inc. From the TEM image, it is seen that lamellar microdomains were aligned along the applied electric field direction throughout the entire film. Figure 3b shows AFM height and phase images of the film surface. Both PS (dark) and PMMA (bright) lamellae are visible on the surface, confirming the complete alignment. Figure 3c shows a cross-sectional TEM image of a ~1 μm film with the same treatment. Again, lamellar microdomains were fully aligned along the field direction. Therefore, in the presence of lithium ions (210 ppm), the applied electric field can overcome the interfacial interactions to achieve complete alignment.

Cross-sectional TEM (a) and height and phase AFM images (b) of a ~300 nm PS-b-PMMA thin film after annealing at 170 °C under a ~40 V/μm DC electric field for 16 h.( c) Cross-sectional TEM image of a ~1 μm PS-b-PMMA thin film after the same treatment. The copolymer contains 210 ppm of lithium residual impurity

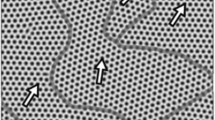

The effect of electric field-induced parallel-to-perpendicular transitions of lamellar microdomains was also studied in thin films (~10L o). Figure 4 shows cross-sectional TEM images of a ~300 nm film annealed at 170 °C under a ~40V/μm DC electric field for 6, 9, and 12 h, respectively. After spin-coating, the films were in a poorly ordered state. After 6 h, the lamellar microdomains were oriented parallel to the substrate interface throughout the film, as seen in Fig. 4a. Therefore, initially the surface field dominates in thin films, causing the microdomains to orient parallel to the surface. For copolymers without lithium ions, further annealing under an electric field did not change the microdomain orientation [21]. However, with lithium ions, the applied electric field was found to enhance fluctuations with a wavelength comparable to L o, and the lamellar microdomains began to break-up into smaller microdomains, as shown in Fig. 4b [12, 15, 16, 22, 23, 24]. This mainly occurred in the center of the film (away from both interfaces). At the interfaces, fluctuations were strongly suppressed by the surface field. With time, the electric field enhanced fluctuations on the lamellae adjacent to the substrate and disrupted the microdomains, as shown in Fig. 4c. With further annealing, these smaller microdomains reconnected to form lamellar microdomains aligned along the applied field direction, similar to that shown in Fig. 3a. For the study shown in Fig. 4, the diblock copolymer thin films were in a poorly ordered state initially. However, the same result was obtained by starting from the case where the lamellae were initially parallel to the substrate throughout the film.

From the set of images in Fig. 4, the parallel-to-perpendicular transition did not occur globally, but rather took place by a local movement of polymer chains. For those microdomains in the center of the film, it is easier for the electric field to enhance fluctuations. Therefore, the reorientation occurs more rapidly and only a minimum field strength is needed. However, for those adjacent to the interfaces, the fluctuations were suppressed, and consequently the reorientation required a much stronger driving force and was much slower. Having lithium ions changes the driving force from a simple difference in the dielectric constants to a dipole-field interaction. Therefore, the applied electric field is able to enhance fluctuations at the interfaces of the microdomains with a wavelength comparable to L o, and induce the parallel-to-perpendicular transition.

Overall, two cases for the effect of lithium ions on lamellar microdomain orientation in an electric field were presented. With very little to no lithium ions, the applied electric field (~40 V/μm) is not sufficient to reorient lamellar microdomains adjacent to the copolymer/substrate interfaces, and only mixed orientations could be observed. With 210 ppm of lithium impurities, the electric field was able to reorient the lamellar microdomains to achieve complete alignment. The minimum concentration of lithium ions necessary to achieve complete alignment is still under investigation.

The mechanism presented here should be applicable to other copolymer systems, and opens a new route for controlling microdomain orientation in thin films by applying an electric field. For those copolymer systems where two blocks have little or no dielectric constant difference in particular, electric field alignment may not occur based on a dielectric mechanism. The presence of selective ionic impurities in one block may be an effective and simple method to introduce electric field alignment.

Conclusions

The effect of ionic impurities on the electric field alignment of lamellar microdomains of polystyrene-block-poly(methyl methacrylate) (PS-b-PMMA) thin films was studied using TEM and AFM. At lithium ion concentrations less than 1 ppm, a mixture of lamellar microdomain orientations was found, if there is any preferential interfacial interactions with one block of the copolymer. At the copolymer/substrate interface, lamellar microdomains were oriented parallel to the surface and the electric field showed no effect. At lithium ion concentrations of ~210 ppm, the lamellar microdomains could be aligned in the direction of an applied electric field, regardless of the strength of interfacial interactions. Complete alignment of the copolymer microdomains, even those adjacent to the polymer/substrate interface, occurred by a pathway where the applied electric field enhanced fluctuations at the interfaces of the microdomains with a wavelength comparable to L o, the equilibrium period of the copolymer. The enhancement in the fluctuations led to a disruption of the microdomains into smaller microdomains ~L o in size, that, in time, reconnected to form microdomains oriented in the direction of the applied field.

References

Park M, Harrison C, Chaikin PM, Register RA, Adamson D (1997) Science 276:1401

Huang E, Rockford L, Russell TP, Hawker CJ (1998) Nature 395:757

Amundson K, Helfand E, Davis DD, Quan X, Patel SS, Smith SD (1991) Macromolecules 24:6546

Amundson K, Helfand E, Quan X, Smith SD (1993) Macromolecules 26:2698

Amundson K, Helfand E, Quan XN, Hudson SD, Smith SD (1994) Macromolecules 27:6559

Boker A, Knoll A, Elbs H, Abetz V, Muller AHE, Krausch G (2002) Macromolecules 35:1319

Morkved TL, Lu M, Urbas AM, Ehrichs EE, Jaeger HM, Mansky P, Russell TP (1996) Science 273:931

Thurn-Albrecht T, Schotter J, Kastle CA, Emley N, Shibauchi T, Krusin-Elbaum L, Guarini K, Black CT, Tuominen MT, Russell TP (2000) Science 290:2126

Anastasiadis SH, Russell TP, Satija SK, Majkrzak CF (1989) Phys Rev Lett 62:1852

Fredrickson GH (1987) Macromolecules 20:2535

Xu T, Hawker CJ, Russell TP (2003) (in preparation)

Xu T, Hawker CJ, Russell TP (2003) Macromolecules 36:6178

Xu T, Russell TP (2003) (in preparation)

Tsori Y, Tournilhac F, Andelman D, Leibler L (2003) Phys Rev Lett 90:145504

Lin ZQ, Kerle T, Baker SM, Hoagland DA, Schaffer E, Steiner U, Russell TP (2001) J Chem Phys 114:2377

Schafer E, Thurn-Albrecht T, Russell TP, Steiner U (2001) Europhys Lett 53:518

Mansky P, Liu Y, Huang E, Russell TP, Hawker C (1997) Science 275:1458

Hawker CJ (1996) Macromolecules 29:2686

Kim CS, Oh SM (2000) Electrochim Acta 45:2101

Tsori Y, Andelman D (2002) Macromolecules 35:5161

Xu T, Zhu Y, Gido SP, Russell TP (2004) Macromolecules (accepted)

Schaffer E, Thurn-Albrecht T, Russell TP, Steiner U (2000) Nature 403:874

Kyrylyuk AV, Sevink GJA, Zvelindovsky AV, Fraaije JGEM (2003) Macromol Theor Simul 12:508

Fukuda J, Onuki A (1995) J Phys II 5:1107

Acknoledgements

This work was funded by the Department of Energy Office at Basic Energy Science (DoE-FG02-GbER45612) and the NSF-MRSEC at the University of Massachusetts (DMR-0213695).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, T., Goldbach, J.T., Leiston-Belanger, J. et al. Effect of ionic impurities on the electric field alignment of diblock copolymer thin films. Colloid Polym Sci 282, 927–931 (2004). https://doi.org/10.1007/s00396-004-1109-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1109-0