Abstract

The crystalline modifications α and β of polypropylene (PP) were studied by using polarized light microscopy (PLM), wide-angle X-ray diffraction (WAXD), and differential scanning calorimetry (DSC). Typically β crystals surrounded by α spherulites were observed at low temperature. With increasing temperature the β crystals melted and a new crystal appeared. More interestingly, the melting temperature of the new crystal was about 5 ° higher than that of α spherulites originally present in the sample formed isothermally. It was assumed that this new crystal was the recrystalline α crystal. This assumption was supported by the DSC results. Furthermore, the crystallization kinetics of the PP used was studied on the basis of the traditional Avrami analysis. As a result, the Avrami exponents of crystallization temperature from 120 to 130 °C ranged between 4.21 and 3.60, indicating that the crystallization mechanism of PP order melt was spherulitic growth and random nucleation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is generally known that polypropylene (PP) has complex polymorphism with crystalline modification, i.e. a monoclinic (α) form, including limit-order α 2 and limit-disorder α 1 [1, 2, 3, 4, 5, 6, 7, 8, 9], the trigonal (β) form [10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23], the triclinic (γ) form [24, 25, 26, 27, 28, 29, 30], and the mesomorphic (smectic) form [31]. The formation and mutual transformations of these forms are critically dependent on initial crystallization conditions and molecular weight. For example, the triclinic (γ) form normally needs high pressure and low molecular weight [15, 32, 33, 34]. The prevalent and most widely studied modification is the monoclinic (α) form, which is generally obtained by crystallization from solution or the melt, or even from recrystallization. The α form actually has two variants, i.e. two limiting modifications, limit-order α 2 and limit-disorder α 1 [1, 4, 7]. Radhakrishnan et al. obtained nearly pure α 2 form crystals with high tacticity in iPP [7]. Compared with the α form, the β form occurs much more rarely after bulk crystallization. However, unless using specific β-nucleating agents [12, 13] or as a result of special crystallization procedures, such as in a thermal gradient [14, 35], β form PP cannot be obtained at high levels and is always accompanied by α crystals. Because β form PP has a lower melting temperature and is less stable than the α form, crystalline phase transformation (from β to α form) would be a characteristic feature of β form PP. The phase transform process is very complicated, depending on the experimental temperature, the thermal history of the sample, etc. Varga et al. [10, 12, 13, 19] and Lotz et al. [18] have reported the original and complex melting and recrystallization behavior of β form iPP and analyzed it in terms of the α form nucleation potential of high and low temperature growth transitions. Recently, some results related to memory effects in β-iPP were reported [16, 17, 18, 19, 20]. Cho et al. used real-time in-situ X-ray diffraction to study memory effects in β-iPP during the heating and crystallization process. They found that lower melt temperature and longer hold time were needed in order to obtain a high percentage of pure and stable β-iPP. Moreover, the characteristic memory effect of the α form within the β phase cannot be nullified. The phase transformation is not only caused by the thermodynamic instability of the β modification, but also by the characteristic memory effect of α form. On the other hand, after Avrami proposed the theory of phase transition kinetics in 1940 [36, 37, 38], Evans gave similar equations for the growth of spheres and circles [39]. Morgan, Flory, and Mandelkern used these theories to study the crystallization of polymers [40, 41, 42, 43]. Today, the Avrami equation is still widely used to determine the Avrami exponent, the rate constant, and to study nucleation and mechanisms of crystallization.

In this study, polarized light microscopy (PLM) and differential scanning calorimetry (DSC) were used to explore the process of β–α recrystallization, and the melting behavior for α modifications presents in the PP formed isothermally and new crystals formed from β modifications.

Experimental

Sample characteristics and preparation

The polypropylene [type 5004, M w=3.72×105, M w/M n=5.4, density ρ=0.9 g cm−3, and melt flow index=3.3 g/10 min with a load of 5 kg (ASTM D1238)] used was obtained from Liaoyang Petrochemical Fiber (P.R. China). Thin PP films with thickness about 100 μm, were prepared by compression-molding of PP pellets at 180 °C with a pressure 90 kg cm−2 for 4 min. The films were used in all experimental tests.

Polarized light microscopy (PLM)

For optical microscope observation, a Leica DM LP optical microscopy with a Panasonic digital camera (type WV-BP330) in conjunction with a Linkam hot stage was used in this study. All optical micrographs presented in this paper were taken under cross-polarized light. The specimens were heated to 200 °C and kept at this temperature for 10 min to erase thermal history effects. The sample was then cooled at a rate of 10 °C min−1 to crystallization temperature, T c=130 °C. Keeping the temperature at T c for 15 min, the sample was preheated again at a rate of 10 °C min−1.

Wide-angle X-ray diffraction (WAXD)

The wide-angle X-ray diffraction patterns were analyzed on a Rigaku D/MAX 2500 V PC X-ray diffractometer in conjunction with a Rigaku PTC-20A hot stage, operating at 40 kV and 200 mA using CuKα radiation of wavelength 1.54 Å as the X-ray source. Samples were scanned at different temperatures in the 2θ range of 5–40°.

Differential scanning calorimetry (DSC)

A differential scanning calorimeter, Perkin–Elmer Diamond DSC instrument equipped with intracooler 2P, was used for thermal analysis. The sample was heated from 30 °C to 190 °C at a scanning rate of 80 °C min−1, and was held there for 2 min before quenching at a cooling rate of 200 °C min−1 to a desired isothermal crystallization temperature T c. After being held for a desired time, the sample was quenched to 10 °C below crystallization temperature (T c−10 °C); 1 min later, the sample was heated at a scanning rate of 10 °C min−1 to test its melting behavior.

Results and discussion

Figure 1 shows WAXD patterns for polypropylene at different scanning temperatures. The results reveal that the two crystalline modifications (α, β forms) coexisted in the samples at 50 °C and 130 °C. It is well known that the melting temperature of the crystal β form is about 155 °C. From Fig. 1 it is seen that the crystalline of β form disappeared, leaving only α form at 160 °C. At about 175 °C the crystalline α form melted. The relative amount of the β and α forms present in PP could be measured according to an empirical term K, as:

where H α1, H α2, and H α3 are the heights of the three strong equatorial α form peaks (110), (040), and (130), respectively, and H β the height of the strong single β peak (300). From Eq. (1) and Fig. 1, we obtain K β =16%.

It is well known that the conformation of the β form is very different from that of the α form; therefore the conversion (from β to α) requires the complete break up of the β form structure (such as melting) before the α form can develop [15]. So phase transformation from the metastable β modification to stable α modification could occur by recrystallization during the heating procedure. Figures 2a–e show the process of β recrystallization, the melting of the β crystal, the original α crystal, and new α crystal recrystallized from spherulites. Figure 2a shows that after isothermal crystallization at T c=130 °C for 15 min there are radial α modification and β modification spherulites in the samples. Furthermore, it is clear that the β modification spherulites are more brilliant than α modification spherulites, and the shape of the β modification was somewhat different from that of α modification. As is known, the melting temperature of the β modification (T mβ ) is lower than that of the α modification (T mα ) and is around 155 °C. From Fig. 2b we can see that the more brilliant spherulites have melted completely at 155 °C. This further indicates that this crystal is the metastable β modification. More interesting, in Fig. 2c we can see clearly that at 160 °C (after β modification spherulites have complete melted), new spherulites with ring structure (for convenience, we called it α′) begin to appear within the region of the β-modification spherulites. This process is the typical β–α recrystallization phenomenon. Figure 2d indicates that at 170 °C, the α spherulites originally present in the sample have melted completely, leaving only α′-modification spherulites. At heating temperatures up to 175 °C, the α′-modification spherulites become totally melted as shown in Fig. 2e, indicating that the melting temperature of α′-modification spherulites is about 5 °C higher than that of the original α-modification spherulites. This is because their crystallization temperatures are different. The crystallization temperature of α′-modification spherulites (T cα ′) is about 160 °C, whereas that of α-modification spherulites (T cα ) is only 130 °C. It is generally known that the higher crystallization temperature is, the higher the melting temperature would be. DSC results (Fig. 3) further support this conclusion. It is assumed that this α′-modification spherulites is α modification recrystallized from β-modification spherulites. Similar phenomena were observed by Varga [10]. It is reported that when heating began from the temperature of crystallization, the β modification did not recrystallize into the α form, but if the samples containing β-PP were cooled below a critical temperature before heating, partial melting would be accompanied by β–α recrystallization and finally they melted in the α form. In this study, we did not cool the sample to a critical temperature before heating. After crystallization at 130 °C, we heated the sample directly and also observed the β–α recrystallization phenomena.

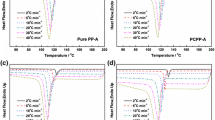

Figure 3 shows the DSC results for various isothermal crystallization temperatures of PP. It can be found that all the curves have double-melting endotherms. If the crystallization temperature (T c)<135 °C, the first melting endotherm belongs to the β modification and the second endotherm belongs to α modification. However, if T c>135 °C, both of the endotherms belong to α modification, the first belongs to the disorder-limiting structure (α 1), the other to the order-limiting structure (α 2). Figure 4 shows that the melting temperature (T m) of endotherms changes with crystallization temperature (T c). It can be seen that T m increases from 160.9 to 172.06 °C when T c is increased from 125 to 145 °C. These results suggest that the α′ spherulites is α modification recrystallized from β-modification spherulites.

DSC is generally used to follow the overall isothermal crystallization by measuring the heat released during the crystallization process. According to Eq. (2), the relative crystallinity θ(t) as a function of time t could be obtained. If we write it in its logarithmic form, we get Eq. (3).

where θ(t), k, t, and n are the relative crystallinity, the rate constant, reactive time, and Avrami exponent, respectively. By fitting the experimental data, the Avrami exponent n and the rate constant k can readily be extracted. Furthermore, t 0.5 is the half-time of crystallization, taken from the onset of crystallization until 50% completion, which is extracted directly from the plot of θ(t) versus time t.

Figures 5 and 6 show the relationship between the relative crystallinity and time at various isothermal crystallization temperatures. The relative fitting results from Eqs. (2) and (3) are listed in Table 1. It is seen that the Avrami exponent n ranged from 4.21 to 3.60, which does not seem to exhibit a definite overall correlation with T c. The rate constant k ranges from 0.61 to 1.93×10−4 and decreases with increasing crystallization temperature. Moreover, the Avrami exponent value depends on the dimensionality of the growth process, and on the kinetic order of nucleation. In this study n is around 4, suggesting that the nucleation and growth mechanisms are spherulite growth accompanied by random nucleation.

Conclusions

The recrystallization and isothermal crystallization of polypropylene were studied. X-ray results show that the PP used had two different crystal modifications, α and β, and the relative crystallinity of β modification in the two modifications is about 16%. The β–α recrystallization phenomenon of the PP was successfully observed by means of polarized light microscopy. Furthermore, the crystallization kinetics of the PP used were studied on the basis of the traditional Avrami analysis. As a result, Avrami exponents of crystallization temperature between 120 and 130 °C ranged from 4.21 to 3.60, suggesting that the mechanism of crystallization of molten PP was spherulitic growth and random nucleation.

References

Hikosaka M, Seto T (1973) Polym J 5:111

Napolitano R, Pirozzi B, Varriale V (1990) J Polym Sci Polym Phys 28:139

Corradini P, Napolitano R, Oliva L, Petraccone V, Pirozzi B, Guerra G (1982) Makromol Chem Rapid Commun 3:753

Mencik Z (1972) J Macromol Sci 6:101

Guerra G, Petraccone V, Corradini P, De Rosa C, Napolitano R, Pirozzi B, Giunchi G (1984) J Polym Sci Polym Phys 22:1029

Cheng SZD, Janimak JJ, Zhang A, Hsieh ET (1991) Polymer 32:648

Radhakrishnan J, Ichikawa K, Yamada K, Toda A, Hikosaka M (1998) Polymer 39:2995

Gu F, Hikosaka M, Toda A, Ghosh S, Yamazaki S, Arakaki M, Yamada K (2002) Polymer 43:1473

Auriemma F, De Ballesteros O, De Rosa C, Corradini P (2000) Macromolecule 33:8764

Varga J (1992) J Mater Sci 27:2557

Li HH, Jiang SD, Wang JJ, Wang DJ, Yan SK (2003) Macromolecules 36:2802

Varga J (1989) J Therm Anal 35:1891

Varga J (1986) J Therm Anal 31:165

Lovinger A, Chua J, Gryte C (1977) J Polym Sci Polym Phys 15:641

Turner-Jones A, Aizlewood J, Beckett D (1964) Makromol Chem 75:134

Cho K, Saheb D, Choi J, Yang H (2002) Polymer 43:1407

Riekel C, Karger-Kocsis J (1999) Polymer 40:541

Lotz B (1998) Polymer 39:4561

Varga J, Ehrenstein G (1996) Polymer 37:5959

Cho K, Saheb N, Yang H, Kang B, Kim J, Lee S (2003) Polymer 44:4053

Riekel C, Karger-Kocsis J (1999) Polymer 40:541

Liu J, Tang G, Qu G, Zhou H, Guo Q (1993) J Appl Polym Sci 47:2111

Ye CM, Liu JJ, Mo ZS, Tang GB, Jiang XB (1996) J Appl Polym Sci 60:1877

Morrow D, Sauter A (1966) Nature 211:514

Hikosaka M, Sato N, Hasegawa M, Seto T (1973) Jpn J Appl Phys 12:1293

Nakafuku C (1981) Polymer 22:1673

Lotz B, Graff S, Wittmann J (1986) J Polym Sci Polym Phys ED 24:2017

Brückner S, Meille S (1989) Nature 340:455

Meille S, Brückner S, Porzio W (1990) Macromolecules 23:4114

Lotz B, Graff S, Staupe C, Wittmann JC (1991) Polymer 32:2902

Miller R (1960) Polymer 1:35

Angelloz C, Fulchiron R, Douillard A, Chabert B (2000) Macromolecules 33:4138

Pérez E, Zucchi D, Sacchi M, Forlini F, Bello A (1999) Polymer 40:675

Mezghani K, Phillips P (1998) Polymer 39:3735

Pawlak A, Piorkowska E (2001) Colloid Polym Sci 279:939

Avrami M (1939) J Chem Phys 7:1103

Avrami M (1940) J Chem Phys 8:212

Avrami M (1941) J Chem Phys 9:177

Evans V (1945) Trans Faraday Soc 41:365

Morgan L (1954) Phil Trans 247:13

Mandelkern L (1958) Growth and perfection of crystals. Chapman and Hall, London

Flory P, McIntyre A (1955) J Polym Sci 18:592

Mandelkern L (1956) Chem Rev 56:903

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NSFC) for the General Program (50073023, 20274047, 50373044), the Major Program (50390090), and the Special Funds (20023003) and subsidized by the special Pre-Funds for Major Basic Research Projects (No.2002CCAD4000), the Special Funds for Major State Basic Research Projects (No. 2003CB615600) and the Project (KJCX2-SW-1107) of the Chinese Academy of Sciences. We also thank Prof. Yang Decai for helpful discussion.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yuan, Q., Jiang, W. & An, L. Study of β–α recrystallization of the polypropylene. Colloid Polym Sci 282, 1236–1241 (2004). https://doi.org/10.1007/s00396-004-1063-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-004-1063-x