Abstract

Studies document increases in biological nitrogen fixation (BNF) following applications of biochar. However, the underlying mechanisms for this response remain elusive. Greenhouse experiments were conducted to test the effects of biochar mineral nutrients, pH, and volatile matter (VM) on BNF in common beans (Phaseolus vulgaris L.). Biochars were produced from seven feedstocks pyrolyzed at either 350 or 550 °C. Biochars were treated with acid to reduce mineral nutrient contents, with acetone to remove acetone-soluble VM, with steam to reduce both the mineral and VM contents, or left untreated. The biochar additions at a rate of 15 t ha−1 resulted in an average 262 % increase in shoot biomass, 164 % increase in root biomass, 3575 % increase in nodule biomass, and a 2126 % increase in N derived from atmosphere (Ndfa) over the control. Simple mineral nutrients and soil acidity amelioration from the biochar were only to a minimal extent responsible for these increases (r 2 = 0.03; P = 0.0298, n = 201). Plant growth and Ndfa were significantly correlated with plant P uptake (r 2 = 0.22; P < 0.0001, n = 201). However, plant P uptake was not correlated with biochar P additions (P > 0.05). Improved P nutrition resulted from 360 % greater mycorrhizal colonization with biochar additions. Removal of acetone-soluble VM increased plant growth and Ndfa, and VM extracted from the biochar produced at 350 °C reduced the growth of rhizobia in yeast extract mannitol agar (YMA) medium. In contrast, acetone-soluble VM extracted from seven biochars produced at 550 °C increased the growth of rhizobium in the YMA compared to an acetone-residue control, suggesting differential effects of VM forms on rhizobia.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biological nitrogen fixation (BNF) is a critically important biological process that has a profound influence on nitrogen (N) cycling, soil fertility, and agricultural productivity. Mutualisms that result in BNF rely on an intricate interaction between the host legume and associated bacteria species collectively termed rhizobia. These mutualistic relationships are sensitive to a multitude of soil constraints, including soil nutrient limitations (Graham and Vance 2003), soil acidity (Graham 1992; Hungria and Vargas 2000), soil water status (Bordeleau and Prevost 1994; Giller and Cadisch 1995; Sprent 1972), and biotic factors (Peoples et al. 2009). In sub-Saharan Africa, tropical environmental conditions, old and highly weathered soils, and relatively little synthetic fertilizer use have led to systemic underperformance of legumes in smallholder farming systems (Jansa et al. 2011). In these systems, BNF is a primary strategy used to improve soil fertility while legumes provide a major portion of protein in the human (Broughton et al. 2003) as well as livestock feed. Biological N fixation in the legume/rhizobium symbiosis can be increased by applying lime to alleviate soil acidity (Ledgard and Steele 1992), by applying fertilizers to reduce key nutrient deficiencies, e.g., phosphorus (P) (Jansa et al. 2011), and by enhancing the potential of the rhizobia-legume symbiosis (Kahindi et al. 1997; Thies and Rillig 2009). One possible method to alter soil properties to increase BNF may be applying biochar to the soil (Rondon et al. 2007).

Biochar is a co-product of the thermal decomposition of organic material in a low-oxygen environment (pyrolysis). Biochar contains condensed structural carbon (C), ash, and residual volatile matter (VM) in varying quantities based largely on feedstock used, and time and temperature of pyrolysis (Keiluweit et al. 2010). An increasing number of agronomic studies on biochar is being published, though very few of these studies have targeted BNF in legumes following applications of biochar (Rondon et al. 2007; Tagoe et al. 2008) and none has demonstrated the mechanisms by which biochar influenced BNF. Potential mechanisms include: (i) nutrients added from the ash within biochar may alleviate plant and microbial nutritional deficiencies or cause toxicity (Rondon et al. 2007), (ii) changes in nutrient cycles (especially soil N) may increase or decrease the incentive to fix atmospheric N (Rondon et al. 2007), (iii) liming effects from biochar (often a higher pH in many biochars than in soil) may modify soil pH positively or negatively for BNF (Warnock et al. 2007; Lehmann et al. 2011), (iv) the adsorptive capacity of biochar may alter the biochemical signaling processes necessary to establish the symbiosis (Lehmann et al. 2011), and (v) certain compounds in the VM on biochar might stimulate or reduce soil microbial activity (Graber et al. 2010; Thies and Rillig 2009).

Physical and chemical properties of biochar produced from a variety of feedstocks and production conditions have been found to vary widely (Enders et al. 2012; Keiluweit et al. 2010; Rajkovich et al. 2012; Schimmelpfennig and Glaser 2012). Several studies have demonstrated a mineral fertilization effect and/or increase in soil pH from biochar additions (Deenik et al. 2011; Van Zwieten et al. 2010). However, the effects of biochar feedstock and production conditions on BNF are largely unknown.

Additionally, the influence of the VM on BNF is poorly quantified. Organic molecules contained in smoke can enhance seedling germination (Light et al. 2009). Some of these smoke-derived compounds are similar in structure to known microbial signaling molecules (Cesco et al. 2010; Cooper 2007). Other smoke-derived molecular analogues of microbial signaling compounds may be a constituent of the VM in biochar. If present, these molecules might have a stimulatory effect on nodulation and BNF. On the other hand, several studies have also shown a high adsorptive capacity of biochar for various organic molecules, such as pesticides (Yang and Sheng 2003; Hale et al. 2011). If plant and microbial signaling molecules are also adsorbed to the surfaces of biochar particles, this could reduce nodulation and potentially reduce BNF.

The objectives of the work presented here were to (i) quantify the effects of addition of contrasting biochars to a low-fertility soil on BNF of common bean, and (ii) partition the effects of nutrients added and/or adsorption and release of organic molecules on BNF. The hypotheses tested were that (i) fertilization effects of the biochar added may only in part lead to increased BNF, and (ii) the VM of biochar will have a stimulatory effect on nodulation and Ndfa.

Methods

Biochar production

Biochar was produced for two greenhouse experiments, Experiment 1 and Experiment 2. Sugarcane bagasse (Saccharum spp.), Eucalyptus saligna wood, Delonix regia wood, prunings of the tea bush (Camelia sinensis), maize stover (Zea mays), and maize cobs (Z. mays) were collected as biochar feedstocks from western Kenya during June and July of 2010. Rice hulls (Oryza sativa) were acquired from Lundberg Family Farms (Richvale, CA, USA). All feedstocks were air-dried and ground to pass through a 1-mm sieve prior to pyrolyzing. The ground feedstocks were pyrolyzed in bench-top pyrolysis units at either 350 or 550 °C. Two pyrolysis units were used for producing the biochar. One pyrolysis unit (Experiment 1) was based on a modified Fisher Scientific Isotemp programmable muffle furnace (Thermo Fisher Scientific, Waltham, MA, USA). A mild-steel cylinder (pyrolysis chamber) was placed inside the furnace chamber. A 6.35-mm (outer diameter) stainless steel tube was wrapped around the mild-steel cylinder to preheat sweep gases which was then introduced into the cylinder via a stainless steel compression fitting. The other end of the stainless steel tube exited the furnace to allow either the sweep gas or deionized water to be injected into the pyrolysis chamber. This pyrolysis unit was used at Cornell University to manufacture the biochar for Experiment 1. All of the biochars manufactured in this kiln were prepared using argon sweep gas at a rate of 1 L min−1 to maintain anaerobic conditions during pyrolysis.

A second pyrolysis unit was manufactured for the production of the biochar for Experiment 2. This pyrolysis unit was custom built using high-temperature refractory brick and electric heating coils connected to a programmable temperature controller. The interior metal cylinder of this unit was designed in the same fashion as the unit from Experiment 1. Oxygen-limited conditions in the pyrolysis chamber were maintained using a steam sweep at a rate of 500 mL min−1 injected once the maximum temperature had been reached. During pyrolysis, a motorized paddle assembly continuously agitated the feedstock for the duration of production. A ramp temperature rate of 5 °C min−1 and a maximum temperature dwell time of 2 h before cooling were used.

Modification of biochars

For each pyrolysis temperature and feedstock combination, a subsample of the biochar produced was treated either in the kiln after the maximum kiln temperature had been reached or after the biochar was removed from the kiln. After pyrolysis, one subsample of each biochar was leached with acetone using a biochar to acetone ratio of 1:10 (w/v). This was intended to remove a fraction of VM that may stimulate plant growth. Each biochar was mixed with acetone and shaken overnight on a reciprocal shaker in a 10-L screw-top Nalgene™ (Thermo Fisher Scientific) canister. After shaking, the mixture was filtered through a Whatman #42 filter paper (Whatman Inc., Piscataway, NJ, USA), placed in a ceramic Buchner funnel, and then dried in an oven overnight at 90 °C to evaporate any remaining acetone.

Another subsample of each biochar was leached with 2 N hydrochloric acid (HCl) to reduce its ash and mineral contents. These biochar subsamples were mixed with 2 N HCl at a ratio of 1:10 (w/v), shaken overnight in 10-L screw-top Nalgene™ (Thermo Fisher Scientific) canisters on a reciprocal shaker, and filtered through a Whatman #42 (Whatman Inc.) filter paper placed in a ceramic Buchner funnel. The biochar subsamples were then mixed with deionized water in a ratio of 1:10 (w/v) and allowed to equilibrate while being stirred continuously. The pH of each HCl-treated biochar subsample was readjusted to its original pH using a 1 N NaOH solution. The biochar subsamples were then filtered again through a ceramic Buchner funnel and leached with deionized water using 1 L/600 g biochar to remove excess sodium and chloride. The HCl/NaOH treated biochar subsamples were then placed in an oven at 60 °C until all of the water evaporated.

During pyrolysis, one batch of each biochar was treated with steam for 2 h, intended to reduce both the VM and the ashed minerals. Steam is used as an activation treatment to remove VM and ash in the process of manufacturing activated carbon (Ioannidou and Zabaniotou 2007; Stuart 1950; Wigmans 1989). Deionized water was injected into the pyrolysis unit once the furnace had reached maximum temperature. The water was injected at a rate of 10 mL min−1 for 2 h. A final batch of each biochar was left untreated. Biochar properties from Experiment 1 are presented in Table S1 and Table S2.

For Experiment 2, only two biochar feedstocks were used, E. saligna and D. regia, and pyrolyzed only at 550 °C. One subset of biochar from each of these feedstocks was left untreated. A second set of biochar was treated with HCl following the protocol previously described and the final pH was adjusted to the original pH of the biochar. A third set of biochar from these feedstocks was treated with HCl as mentioned above and left at low final pH values. Chemical properties from these biochars are presented in Table S3.

Soil and experimental setup

Both greenhouse experiments were established at the World Agroforestry Centre in Kisumu, Kenya, using four replicates. Experiment 1 was conducted in June 2011 and Experiment 2 was conducted as a follow-up in August of 2013. A humic Acrisol was collected from a site that had been converted to agriculture in 1900 (Kimetu et al. 2008; Kinyangi 2007; Ngoze et al. 2008). The field site was in Kapsengere village in western Kenya. The cropping system in the area is dominated by maize and common bean (Phaseolus vulgaris) production. The soil was air-dried, passed through a 2-mm sieve, and thoroughly homogenized. The principal chemical characteristics of the soil were: pH 5.5 (CaCl2) and 6.1 (H2O), sand 9 %, silt 32 %, clay 58 %, cation exchange capacity 395 mmolc kg−1, 24.0 mg g−1 total C, 2.1 mg g−1 total N, 3 mg kg−1 NO3 −, 6 mg kg−1 NH4 +, 27 mg kg−1 P, 4 mg kg−1 K, 25 mg kg−1 Ca, 2 mg kg−1 Mg, 8 mg kg−1 Mn, 1 mg kg−1 Fe, 5 mg kg−1 Al. This soil was used for both experiments.

In the first experiment, each of the prepared biochars was added separately to 2578 g soil at a rate equivalent to 15 t biochar ha−1 (33 g pot-1) and homogenized along with granular phosphorus (P) added at a rate equivalent to 1 kg P ha−1 in the form of triple super phosphate (Mea Fertilizer Ltd., Nairobi, Kenya). The P fertilizer was added to remove severe P limitations to BNF, while not adding too much as to mask any biochar effects. Each of the mixed soils was then added to plastic pots (0.17 m diameter by 0.14 m height), filling each pot to within 10 mm of the pot rim. Also included was a control treatment that received P but not biochar.

For Experiment 2, the same weight of soil and biochar was used as listed above. The fertilizer application in this experiment deviated from the initial experiment, as a fertilizer-only control was added. Synthetic fertilizer was added as a control on an equal basis to nutrients added with biochar produced from D. regia at 550 °C. This feedstock had the greatest total mineral nutrient content among all biochars of Experiment 1. Four grams of a fertilizer were prepared with the following mass percentages and added per pot: 20.6 % triple super phosphate, 20.5 % muriate of potash, 22.5 % calcium chloride, 27.5 % magnesium sulfate, 0.58 % manganese oxide, 0.35 % copper sulfate, 0.40 % zinc oxide, and 0.15 % sodium borate. The trial was performed in a completely randomized design with five replicates.

Irrigation and management

A drip irrigation system was installed in the greenhouse with one drip emitter per pot (The Drip Store, Vista, CA, USA). All pots were watered to maintain soil moisture at field capacity for the duration of the experiment. Field capacity (70 % water-filled pore space) was determined gravimetrically prior to irrigation.

Nodulating and non-nodulating isolines of the common bean (Phaseolus vulgaris L.), variety DOR 364 from CIAT (International Center for Tropical Agriculture, Cali, Columbia), were used. The non-nodulating isoline was used to quantify soil 15N uptake values to determine N derived from fixation (Ndfa) via the natural abundance method (Peoples et al. 2009). In Experiment 1, two seeds were planted per pot on 11 July, 2011, and thinned to one plant per pot on 18 July, 2011. The plants were harvested during peak flowering between 15 and 21 August, 2011. Experiment 2 was planted on 7 August, 2013 and harvested between 13 and 17 September, 2013. At harvest, the roots were separated from the shoots and washed. After washing, the nodules were separated from the roots, counted, and placed in a plastic bag containing silica gel desiccant. The roots were placed into separate paper bags and dried at 60 °C in a forced air oven.

Determination of b value

The b value, needed to quantify Ndfa, was determined at Cornell University, Ithaca, NY, USA. Two seeds of the nodulating isoline of P. vulgaris cv DOR 364 were placed into plastic pots filled with acid-washed vermiculite using seven replicates. The pots were placed under growth lamps continuously in a laboratory maintained at 22 °C. Plants were watered regularly with an N-free nutrient solution (Peoples et al. 2009). After the radicles emerged, the plants were inoculated with Rhizobium tropici strain CIAT899 and maintained under the growth lamps for 4 weeks. After 4 weeks, the plants were harvested and the shoots were separated from the roots. The plant tissue was finely ground and used to determine the b value (Peoples et al. 2009). Ndfa was determined through the following equation [Eq. 1]:

Where 15Nnn is the 15N content of the non-nodulating isoline, 15Nn is the 15N content of the nodulating isoline, and b is the 15N content of the b value.

Biochar analysis

Subsamples of all biochars prepared were ground with a mortar and pestle and sieved to reach a particle size of 149–850 μm. Each biochar was then analyzed for total nutrient content in duplicate using a modified dry-ashing technique (Enders and Lehmann 2012). Biochar ash and VM contents were determined in duplicate by proximate analysis using ASTM D1762-84 Chemical Analysis of Wood Charcoal. Hydrogen (H) was determined by combustion using a Hekatech HT Oxygen Analyzer interfaced to a PDZ Europa 20–20 isotope ratio mass spectrometer (Sercon Ltd., Cheshire, UK). Total oxygen (O) was calculated by difference (Enders et al. 2012) as follows [Eq. 2]:

The pH of all of the biochars was determined in 1:20 (w/v) deionized water. Biochar subsamples (1.0 ± 0.01 g) were weighed directly into 60-mL screw-top glass vials, filled with 20 mL of deionized water, and agitated on an orbital shaker table for 1.5 h. The slurry was mixed continuously with a stir bar while pH was measured. All analyses were performed in duplicate. Biochar properties are given in Tables S1 and S2.

Plant tissue analysis

Each plant sample was ground finely using a ball mill and homogenized. Total mineral nutrient uptake in shoots was determined by digesting tissue subsamples in concentrated HNO3 and 30 % H2O2 and analyzing the digests on an axially viewed ICP trace analyzer emission spectrometer (Thermo Electron, Waltham, MA, USA). Total N and C in shoot tissues were determined by dry combustion (PDZ Europa ANCA-GSL elemental analyzer, PDZ Europa 20–20 isotope ratio mass spectrometer, Sercon Ltd., Cheshire, UK). Nitrogen isotope ratios (14N/15N) in shoot tissues were measured by isotope ratio mass spectrometry (Sercon Ltd.).

Soil analysis

Soil mineral nutrient analysis was performed on the soil prior to biochar applications. Mineral N was extracted with 2 N KCl and quantified colorimetrically using a continuous flow autoanalyzer (Bran and Luebbe Autoanalyzer, SPX, Charlotte, NC, USA). Phosphorus was determined using the Olson-P extraction (Kuo 1996). Exchangeable nutrients were determined by Mehlich-3 extraction (Mehlich 1984). Cation exchange capacity was determined by ammonium acetate extraction buffered at pH 7 (Sumner and Miller 1996). All extracts were analyzed by ICP.

Soil pH was determined in either 1:2 deionized water (w/v) or 1:2 CaCl2. Two sets of soil subsamples (1.0 ± 0.01 g) were weighed directly into 60-mL screw-top glass vials. One set of vials were filled with 20 mL of deionized water, another set of vials were filled with 20 mL of 0.01 M CaCl2 prepared with deionized water. Both sets of filled vials were agitated on an orbital shaker table for 1.5 h. The slurry was mixed continuously with a stir bar while pH was measured. All analyses were performed in duplicate.

Rhizobium growth with acetone-soluble biochar extracts

The volatile material was extracted from the untreated biochars used in Experiment 1 with acetone. Thirty three grams of each of the seven biochars were placed into 1-L Nalgene™ (Thermo Fisher Scientific) wide-mouth screw-top bottles. To these bottles, 330 mL of acetone were added. The bottles were then shaken overnight. After shaking, the biochar/acetone mixture was filtered through Adventec® GC-50 filter discs (Toyo Roshi Kaisha, Ltd. Tokyo, Japan) placed in a ceramic Buchner funnel inserted in a 500-mL glass vacuum flask (Corning Glass, Corning, NY, USA). The acetone extracts in the glass vacuum flasks were placed on an 80 °C sand bath and evaporated until the total volume was just below 50 mL. Once the volume of each of the acetone extracts was below 50 mL they were quantitatively transferred into 50-mL Falcon™ conical polypropylene centrifuge tubes (Thermo Fisher Scientific) and returned to the sand bath until just before reaching total dryness. The extracts were suspended in 10 mL of sterile deionized water by vortexing small aliquots for 10 min on a mini vortexer M7 (Randnor, PA, USA). The emulsions, including an acetone/water control, were poured over 100 mm × 30 mm yeast extract mannitol agar medium (in four replicates). The plates were left inside a laminar flow hood with the lids off until all of the liquid had evaporated or imbibed. The plates were left to rest for 1 day before 100 μL of Rhizobium tropici (strain CIAT 899) were plated. Pure cultures of CIAT 899 in yeast extract mannitol broth were cultured overnight at 30 °C on an orbital shaker to turbidity. The cultures were then diluted to 10−6 and 10−7 with sterile deionized water and plated using the drop-plate method (Somasegaran et al. 1985). The plates were incubated at 22 °C for three days (no more colonies appeared with additional incubation time). The colony forming units were counted under a dissecting microscope.

Mycorrhizae colonization

In Experiment 2, 1 g of plant roots was taken from each plant at harvest, rinsed in deionized water, and stained following the protocol described by Koske and Gemma (1989). One gram of washed bean roots was placed into labeled 50-mL Falcon™ conical polypropylene centrifuge tubes (Thermo Fisher Scientific). To these tubes, 35 mL of 10 % KOH solution were added. Tubes were then placed in a 90 °C water bath for 15 min to clarify the roots. Roots in each tube were washed with two rinses of 40 mL deionized water. Then, 40 mL of 1 % HCl were added to each tube. The tubes were capped and allowed to sit overnight. The following day, the HCl solution was decanted and 40 mL of a trypan blue staining solution was added to each tube. The tubes were placed in a 90 °C water bath for 15 min. The stain was decanted and the roots were rinsed with 40 mL of 1 % HCl before a final 40 mL of an acidified glycerol destaining solution was added. The roots were transported from Kenya to Cornell University in the destaining solution for further analysis.

After destaining, four randomly selected 15-mm root fragments were removed and mounted in glycerol on glass microscope slides (VWR International, LLC. Radnor, PA, USA). Once mounted, root mycrorrhizae colonization was scored using the gridline intersect method at ×400 on a compound microscope (Brundrett et al. 1996).

Statistical analyses

All statistical analyses were performed with JMP software (SAS, Cary, NC). All procedures were performed at P < 0.05, unless otherwise indicated. Significant treatment effects were determined using the Tukey’s HSD test. Principal component analysis using selected biochar properties and plant and microbial responses were performed to examine the reason for greater BNF in the legumes.

Results

Greenhouse experiment 1

Plant and nodule biomass

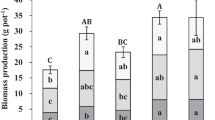

Shoot, root, and nodule biomass increased significantly (P = 0.0327, 0.0056, and 0.0006, respectively) in response to all biochar amendments relative to the unamended control (Table 1; Supplementary Table S4 for individual means). Shoot biomass increased between 263 and 293 %, root biomass increased between 134 and 178 %, and nodule biomass increased between 2953 and 4927 % relative to the unamended control for the averaged values pooled across temperatures and treatments (Table 1). Choice of feedstock used to produce the biochar significantly (P = 0.0327 and 0.0006, respectively) influenced plant and nodule biomass (Table 1). However, shoot biomass only varied with additions of biochar made from different feedstocks, not as a result of treatment of biochars post production or with different pyrolysis temperatures. In addition, extracting biochars with acetone caused a significant (P < 0.0001) increase in nodule biomass above the other biochar treatments.

Nodule number and nitrogen derived from fixation

Nodule number and Ndfa increased significantly (P < 0.0001, P = 0.0005) in response to all biochar additions (Table 2). When measured in total amounts (mg plant−1), biochar additions increased Ndfa between 1530 and 3022 % above the unamended control. When expressed as a proportion of total N, biochar applications increased Ndfa between 1066 and 1450 % above the unamended control. The proportion of Ndfa did not vary between plants after additions of biochars made from different feedstocks. In contrast, total amounts of Ndfa were on average 83 % greater with rice hull biochar than biochar obtained from Eucalyptus, maize cobs, or maize stover. Nodule number was, on average, 55 % greater with tea and Delonix biochar than with biochar produced from maize cobs or maize stover.

Pyrolysis temperature had a lesser effect on Ndfa than biochar feedstock. Additions of biochar produced at 550 °C only resulted in 15 % greater Ndfa amount per pot and 25 % greater Ndfa proportion in plants than those produced at 350 °C (Table 2). The number of root nodules was 15 % greater with additions of biochar produced at 550 °C than of biochar produced at 350 °C.

Post-pyrolysis extraction with acetone resulted in significantly (P < 0.0001, P < 0.0001, P = 0.0006, respectively) increased Ndfa (41–29 % amount of Ndfa, 23–86 % proportion of Ndfa) and nodule number (32–37 %) relative to the other three treatments (Table 2). Steam treatment of biochar did not significantly change Ndfa. However, acid extraction of biochars significantly (P < 0.0001) decreased Ndfa. In contrast, the number of root nodules did not differ after additions of untreated, steam treated, or acid-treated biochar.

Plant nutrient uptake

Plant nutrient concentration and total uptake was significantly (P < 0.05) affected by biochar feedstock for all measured plant nutrients (Table 3). Increases in plant tissue nutrient concentrations and nutrient uptake after biochar additions in comparison to the control were, 208 and 566 % for P, 0 and 321 % for K, 117 and 329 % for Ca, 115 and 340 % for Mg, and 117 and 294 % for Mn, respectively, when pooled across temperature and treatment. Phosphorus, Ca, and Mn uptake varied significantly with pyrolysis temperature, where plant P uptake and tissue concentrations were 22 and 18 % higher, respectively, in soils amended with biochar produced at 550 °C than at 350 °C (Table 3). In contrast, Ca concentration and uptake were 14 and 11 % greater, and Mn concentration and uptake were 14 and 19 % higher with biochars made at 350 °C than 550 °C, respectively. Post-pyrolysis modification of biochars did not result in large and consistent differences in foliar nutrient concentrations, except for P, Ca, and Mn.

In the principal component analysis, Ndfa, the number of root nodules, and nodule biomass were most closely correlated with plant tissue P and P uptake (Fig. 1). These metrics were to a lesser extent related to Ca and P in the biochar, biochar pH, and unrelated to plant tissue Mn and Ca contents.

Principal component analysis correlation biplot depicting the relationship between plant and microbial response variables and selected biochar chemical properties. Eigenvalues for the first two components are 3.82 and 2.94 and represent 27 and 21 % of the variability, respectively. Seventy four percent of the variability were contained in the first four components (see Table S6 for component loading values). Foliar nutrient contents are concentrations in the bean tissue, plant uptake are total nutrient uptake per pot, biochar nutrients are concentrations, and Ndfa is N derived from biological N fixation (mg pot−1)

Acetone-soluble biochar compounds and rhizobial growth plates

All of the YMA plates treated with acetone-soluble biochar residues from biochar produced at 350 °C resulted in no observable rhizobial growth, but rhizobia counts were not different from the control on YMA containing acetone extracts from biochar produced at 550 °C (Table 4; except for plates containing extracts from maize stover). Using a linear contrast, rhizobial growth was 19 and 20 % greater on plates treated with acetone-soluble VM extracts from biochars produced from Delonix (P = 0.0347) and rice hulls (P = 0.0447) at 550 °C, respectively, than the acetone-residue control. Acetone did not adversely affect the rhizobia, as growth on plates with acetone-residue did not differ from growth on untreated YMA plates.

Greenhouse experiment 2

Shoot biomass was significantly (P < 0.05) greater when inorganic fertilizer was added than when biochar was added. Shoot biomass after biochar application was not significantly different from the unamended control (Table 5). In contrast, nodule biomass and number were significantly (P < 0.05) greater when untreated biochar was added than either the fertilizer (no biochar with nutrient addition) or control treatments (no biochar without nutrient addition) (Table 5). No Ndfa was measured with inorganic fertilizer additions. Little Ndfa was measured (0.81 mg N pot−1, 1 % of N) in the unamended control. Ndfa was between 4.5 and 8.9 mg N pot−1 (8–18 % of N) with biochar additions (Table 5). Arbuscular mycorrhizal colonization in the plant roots grown in soil with the unmodified biochars was 65–71 % and 140–149 % greater than the no biochar fertilizer and no fertilizer control treatments, respectively.

Extracting nutrients from biochars without a pH drop decreased the Ndfa (mg N pot−1) by 52–59 % (Table 5). However, the pH of the biochar did not appear to play any role, as Ndfa was unchanged whether biochars had a pH of 4–5 or 8–11. Without extracting nutrients, all biochar additions significantly (P < 0.05) increased mycorrhizal colonization by 71–154 % compared to no nutrient additions. Similar to Ndfa, mycorrhizal colonization was not affected by biochar pH. Adding fertilizer without biochar did not affect root mycorrhizae colonization.

Discussion

Biochar effects on plant growth and nitrogen fixation

The significant increases in plant growth with any of the biochars mirror similar increases for experiments with highly weathered soils (Major et al. 2010; Steiner et al. 2007; Van Zwieten et al. 2010) and exceed the increases in BNF reported by Rondon et al. (2007). Several indications exist that P was the nutrient most strongly limiting plant growth in the studied soil. In addition, foliar P and plant P uptake provided the strongest relationship to greater nodulation and Ndfa. Increased P uptake with biochar additions has been reported previously as a result of high P contents in the biochar (Chan et al. 2008). Biochars may vary greatly in their P contents due to different feedstock properties and in addition biochar P contents often increase with pyrolysis temperature due to C, H, and O losses (Enders et al. 2012). Other studies have shown an interactive effect between biochar and soil P (Farrell et al. 2014). However, in our study, foliar P contents and plant P uptake were not related to P additions from the biochar.

Foliar Ca and Mn concentrations and uptake increased as a result of the addition of biochar from which nutrients had been extracted despite a significant reduction in its Ca content, in contrast to other nutrients. Also, despite pH adjustment after the acid extraction procedure, the biochar was found to have a substantially lower pH than those of the other post-pyrolysis treatments. Hollister et al. (2013) identified Ca species to be present in calcite form in biochar produced at 550 °C; it is possible that any remaining Ca in the biochar could have been dissolved from otherwise unavailable carbonates in the ash, which may not have been available to the plants at the native biochar pH, and Mn availability increased by lower pH. However, plant uptake of Ca and Mn were only weakly related to nodulation and Ndfa. Residual Cl from the acid treatment and Na from the pH adjustment may have had a negative effect on plant performance (Rajkovich et al. 2012) and BNF; but such an effect would only strengthen the argument that nutrient additions with the biochar were not related to the positive effects of biochar on BNF.

We hypothesized that the additions of plant limiting nutrients found in the biochar would increase plant growth, nodulation and BNF. While plant mineral nutrient uptake, and in the case of P also its foliar concentrations, significantly increased with biochar additions, the increase in plant mineral nutrition could not be directly related to mineral nutrient additions from the biochar. When mineral nutrients were applied to soil at the highest rate found in the biochar additions, plant growth increased to the response measured with biochar additions, but BNF did not increase. This indicates that mineral nutrients were indeed limiting in the studied soil and the alleviation of nutrient deficiencies improved plant growth. Conversely, when mineral nutrients were extracted from biochars, increases in N fixation with biochar additions did not disappear. These different lines of evidence suggest that biochar is altering the soil environment to enable increased BNF not merely related to nutrient additions from the biochar alone.

Reasons for increased nitrogen fixation with biochar

Mycorrhizal colonization and P nutrition of plants

Improved P nutrition of plants was the most likely explanation for greater Ndfa in response to biochar additions, albeit unrelated to the biochar P contents, as outlined above. One likely mechanism for greater P uptake found in the plants is an improved access to soil P (Vanek and Lehmann 2014) through the observed increase in mycorrhizal colonization. Mycorrhizae have a well-established connection to improved plant nutrient uptake, with particular relevance to P nutrition (Vance et al. 2000; Vance 2001), and several studies have documented greater mycorrhizal colonization after biochar additions to soil where P or other soil resources are limiting (Rillig et al. 2010; Solaiman et al. 2010; Vanek and Lehmann 2014). In our study, it remained unclear what the mechanism was for the greater mycorrhizal colonization with biochar additions. Several mechanisms have been hypothesized for the promotion of mycorrhizae with biochar (Lehmann et al. 2011; Warnock et al. 2007), such as an improvement of soil nutrient availability for mycorrhizae though our data do not support this hypothesis. Mycorrhizal colonization was not significantly different between unaltered biochar and biochar that had been leached of mineral nutrients. We also did not find significant differences between high or low pH biochars. Other proposed mechanisms include a shift in composition and activity of communities of other microorganisms that influence mycorrhizae (e.g., Mycorrhization Helper Bacteria) and biochar as a possible refuge for colonizing fungi. However, the design of our experiment did not test these hypotheses.

Amelioration of soil pH

Previous studies have documented the potential of biochar to ameliorate soil acidity and improve nutrient availability (Novak et al. 2009; Van Zwieten et al. 2010; Yuan and Xu 2011). While the biochar additions in our study significantly increased soil pH (albeit only by 0.3–0.4 pH units), biochar pH was not correlated with plant or microbial responses. In addition, some of the greatest plant and BNF responses were found from additions of acidic acid-treated biochar with a pH below the native soil pH, despite possible elevated levels of Cl due to the acidifying treatment. However, increases in pH of the studied acid soil close to biochar particles that are high in pH, undetectable by our bulk soil observations, could have altered nutrient availability locally. Since roots and mycorrhizae are found in this region around biochar particles (Vanek and Lehmann 2014), even local pH changes may have implications for nutrient uptake. This could not be ruled out in this study and may have contributed to the increases in plant and microbial responses.

Influence of volatile matter on rhizobial growth

The second hypothesis we tested was that the acetone-soluble compounds in biochar may stimulate rhizobial symbiosis. Our data did not support this hypothesis across all biochars. On the contrary, when the biochars were leached with acetone to attempt to reduce the volatile matter, the plant and microbial responses consistently increased over unaltered biochar. This suggests there is an acetone-soluble compound or compounds that were partially inhibitory to nodulation and possibly led to reduced Ndfa. In addition, when the acetone-soluble compounds were removed and tested directly with rhizobium this resulted in failure of bacterial growth on YMA plates treated with the acetone extracts from the biochar manufactured at the lower pyrolysis temperature (350 °C). This is direct evidence for the toxicity of some acetone-soluble volatile matter on rhizobium at the concentrations used in this experiment. In contrast, acetone-soluble extracts from biochar manufactured at the higher temperature (550 °C) did not have negative effects on rhizobial growth except from maize stover biochar. As the total VM defined by the ASTM method was greater in the biochar manufactured at the lower temperature than in the biochar manufactured at the higher temperature, it is possible that the toxicity of the acetone-soluble material was due to quantitative rather than qualitative differences. However, qualitative differences of VM properties in the low-temperature biochar were likely to have also occurred, but these differences were masked by the greater amounts of VM in the low-temperature biochar. The greater rhizobial growth with the high-temperature Delonix and rice biochars demonstrate that some VM fractions may have a stimulatory effect on rhizobium.

Greater nodule number and Ndfa seen in response to increasing pyrolysis temperature corroborated plant growth differences seen in other studies. Rajkovich et al. (2012) found maize growth increased as pyrolysis temperatures increased from 300 to 600 °C, but the authors could not correlate the changes in maize growth with VM or plant N uptake. In our study, biochar produced at 550 °C had lower total VM contents than biochar produced at 350 °C. In previous studies, VM has been correlated to reduced plant responses (Deenik et al. 2011) and microbial toxicity (Painter 1998). Some of the compounds isolated from VM are known to be phytotoxic (Fernandes and Brooks 2003; Fernandes et al. 2003). Others have reported compounds beneficial to plant germination in wood smoke (Light et al. 2009) or have hypothesized that there are chemicals in biochar that may stimulate plant growth at low doses (Graber et al. 2010). While our data supports the toxicity of some acetone-soluble VM from biochar, it cannot be concluded that the entire spectrum of VM in biochar was toxic to rhizobium. On the contrary, the acetone-soluble extracts from some of the biochars improved rhizobial growth. It is not known whether this stimulatory effect was from specific growth-inducing compounds or from the presence of larger amounts of metabolizable C (Penas-Cabriales and Alexander 1983).

While the acetone wash did not significantly reduce the total volatile content of the biochar as measured by the ASTM method, Deenik et al. (2011) extracted and identified phytotoxic compounds from biochar using acetone. These compounds reduced plant growth and N uptake and are known to be phytotoxic. Volatile matter according to the ASTM merely indicates the extent of carbonization, and is not sensitive enough to measure subtle biologically important changes in VM composition. However, the data suggest that the majority of the ASTM-defined VM has low solubility or is not soluble in acetone, and our conclusions about the effect of VM are restricted to the VM fraction that is extractable by acetone. It is also possible that the VM in the low-temperature biochars used in this experiment were toxic due to the concentrations present. It has been hypothesized that the VM in biochar might follow a hormetic response where the response depends on application rates; at low concentrations it may be beneficial and toxic at high concentrations (Graber et al. 2010). However, this hypothesis was not directly tested in this experiment. What is also not known is the biological activity of the VM remaining in the biochar after the acetone extraction.

Conclusion

Our results clearly demonstrated that biochar has the potential to significantly improve BNF and bean growth in the studied highly degraded and P-deficient soil. Mineral nutrient addition and soil acidity amelioration with biochar are only to a small extent responsible for the increased responses observed. Increased plant P uptake was most closely related to improved BNF which is most likely a result of the observed increases in arbuscular mycorrhizal colonization and not related to nutrient additions with biochar. Further work should be done investigating the mechanisms responsible for greater arbuscular mycorrhizal colonization. More investigations are also required to partition the effects of the VM other than the acetone-extractable fraction from the rest of the components of biochar. Biochar VM likely is highly heterogeneous and it is possible that other components of this material that are not extractable by acetone might be beneficial or detrimental to rhizobium. Field trials are also needed to determine the full potential of amending soil with biochar to BNF and bean yields.

References

Bordeleau L, Prevost D (1994) Nodulation and nitrogen fixation in extreme environments. Plant Soil 161:115–125

Broughton W, Hernandez G, Blair M, Beebe S, Gepts P, Vanderleyden J (2003) Beans (Phaseolus spp.)—model food legumes. Plant Soil 252:55–128

Brundrett M, Bougher N, Dell B, Grove T, Malajczuk N (1996) Working with mycorrhizas in forestry and agriculture, vol 32. Australian Centre for International Agricultural Research, Canberra

Cesco S, Neumann G, Tomasi N, Pinton R, Weisskopf L (2010) Release of plant-borne flavonoids into the rhizosphere and their role in plant nutrition. Plant Soil 329:1–25

Chan KY, Van Zwieten L, Meszaros I, Downie A, Joseph S (2008) Using poultry litter biochars as soil amendments. Aust J Soil Res 46:437–444

Cooper J (2007) Early interactions between legumes and rhizobia: disclosing complexity in a molecular dialogue. J Appl Microbiol 103:1355–1365

Deenik JL, Diarra A, Uehara G, Campbell S, Sumiyoshi Y, Antal MJ Jr (2011) Charcoal ash and volatile matter effects on soil properties and plant growth in an acid ultisol. Soil Sci 176:336

Enders A, Lehmann J (2012) Comparison of wet-digestion and dry-ashing methods for total elemental analysis of biochar. Comm Soil Sci Plant Anal 43:1042–1052

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Biores Technol 114:644–653

Farrell M, Macdonald LM, Butler G, Chirino-Valle I, Condron LM (2014) Biochar and fertiliser applications influence phosphorus fractionation and wheat yields. Biol Fertil Soil 50:169–178

Fernandes MB, Brooks P (2003) Characterization of carbonaceous combustion residues: II. Nonpolar organic compounds. Chemosphere 53:447–458

Fernandes MB, Skjemstad JO, Johnson BB, Wells JD, Brooks P (2003) Characterization of carbonaceous combustion residues. I. Morphological, elemental and spectroscopic features. Chemosphere 51:785–795

Giller K, Cadisch G (1995) Future benefits from biological nitrogen fixation: an ecological approach to agriculture. Plant Soil 174:255–277

Graber ER, Meller Harel Y, Kolton M, Cytryn E, Silber A, Rav David D, Tsechansky L, Borenshtein M, Elad Y (2010) Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 337:481–496

Graham PH (1992) Stress tolerance in Rhizobium and Bradyrhizobium, and nodulation under adverse soil conditions. Can J Microbiol 38:475–484

Graham PH, Vance CP (2003) Legumes: importance and constraints to greater use. Plant Physiol 131:872–877

Hale S, Hanley K, Lehmann J, Zimmerman A, Cornelissen G (2011) Effects of chemical, biological, and physical aging as well as soil addition on the sorption of pyrene to activated carbon and biochar. Environ Sci Technol 45:10445–10453

Hollister C, Bisogni JJ, Lehmann J (2013) Ammonium, nitrate, and phosphate sorption to and solute leaching from biochars prepared from corn stover (Zea mays L.) and oak wood (Quercus spp.). J Environ Qual 42:137–144

Hungria M, Vargas MAT (2000) Environmental factors affecting N2 fixation in grain legumes in the tropics, with an emphasis on Brazil. Field Crops Res 65:151–164

Ioannidou O, Zabaniotou A (2007) Agricultural residues as precursors for activated carbon production—a review. Renew Sustain Energy Rev 11:1966–2005

Jansa J, Bationo A, Frossard E, Rao I (2011) Options for improving plant nutrition to increase common bean productivity in Africa. In: Batonio A, Waswa B, Okeyo J, Maina F, Kihara J, Mokwunye U (eds) Fighting poverty in Sub-Saharan Africa: the multiple roles of legumes in integrated soil fertility management. Springer, New York, pp 201–240

Kahindi J, Woomer P, George T, de Souza MF, Karanja N, Giller K (1997) Agricultural intensification, soil biodiversity and ecosystem function in the tropics: the role of nitrogen-fixing bacteria. Appl Soil Ecol 6:55–76

Keiluweit M, Nico PS, Johnson MG, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253

Kimetu JM, Lehmann J, Ngoze SO, Mugendi DN, Kinyangi JM, Riha S, Verchot L, Recha JW, Pell AN (2008) Reversibility of soil productivity decline with organic matter of differing quality along a degradation gradient. Ecosystems 11:726–739

Kinyangi J (2007) Soil degradation, thresholds and dynamics of long-term cultivation: From landscape biogeochemistry to nanoscale biogeocomplexity. Dissertation, Cornell University

Koske R, Gemma J (1989) A modified procedure for staining roots to detect VA mycorrhizas. Mycol Res 92:486–488

Kuo S (1996) Phosphorus. In: Sparks DL, Page AL, Helmke PA, Loeppert RH, (eds) Methods of soil analysis: part 3—chemical methods. Soil Science Society of America Inc, Madison, pp 869–920

Ledgard S, Steele K (1992) Biological nitrogen fixation in mixed legume/grass pastures. Plant Soil 141:137–153

Lehmann J, Rillig M, Thies J, Masiello CA, Hockaday WC, Crowley D (2011) Biochar effects on soil biota—a review. Soil Biol Biochem 43:1812–1836

Light M, Daws M, Van Staden J (2009) Smoke-derived butenolide: towards understanding its biological effects. South African J Bot 75:1–7

Major J, Rondon M, Molina D, Riha S, Lehmann J (2010) Maize yield and nutrition during 4 years after biochar application to a Colombian savanna oxisol. Plant Soil 333:117–128

Mehlich A (1984) Mehlich 3 soil test extractant: a modification of Mehlich 2 extractant. Comm Soil Sci Plant Anal 15:1409–1416

Ngoze S, Riha S, Lehmann J, Verchot L, Kinyangi J, Mbugua D, Pell A (2008) Nutrient constraints to tropical agroecosystem productivity in long-term degrading soils. Global Change Biol 14:2810–2822

Novak JM, Busscher WJ, Laird DL, Ahmedna M, Watts DW, Niandou MAS (2009) Impact of biochar amendment on fertility of a southeastern coastal plain soil. Soil Sci 174:105–112

Painter TJ (1998) Carbohydrate polymers in food preservation: an integrated view of the Maillard reaction with special reference to discoveries of preserved foods in Sphagnum—dominated peat bogs. Carbohydrate Poly 36:335–347

Penas-Cabriales JJ, Alexander M (1983) Growth of rhizobium in soil amended with organic matter. Soil Sci Soc Am J 47:241–245

Peoples MB, Unkovich MJ, Herridge DF (2009) Measuring symbiotic nitrogen fixation by legumes. In: Emerich DW, Krishnan HB (eds) Nitrogen fixation in crop production. American Agronomy Society, Madison, pp 125–170

Rajkovich S, Enders A, Hanley K, Hyland C, Zimmerman AR, Lehmann J (2012) Corn growth and nitrogen nutrition after additions of biochars with varying properties to a temperate soil. Biol Fertil Soils 48:271–284

Rillig MC, Wagner M, Salem M, Antunes PM, George C, Ramke HG, Titirici MM, Antonietti M (2010) Material derived from hydrothermal carbonization: effects on plant growth and arbuscular mycorrhiza. Appl Soil Ecol 45:238–242

Rondon MA, Lehmann J, RamÌrez J, Hurtado M (2007) Biological nitrogen fixation by common beans (Phaseolus vulgaris L.) increases with bio-char additions. Biol Fertil Soils 43:699–708

Schimmelpfennig S, Glaser B (2012) One step forward toward characterization: some important material properties to distinguish biochars. J Environ Qual 41:1001–1013

Solaiman ZM, Blackwell P, Abbott LK, Storer P (2010) Direct and residual effect of biochar application on mycorrhizal root colonisation, growth and nutrition of wheat. Soil Res 48:546–554

Somasegaran P, Hoben H, Halliday J (1985) The NifTAL manual for methods in legume-rhizobium technology. University of Hawaii, Manoa

Sprent JI (1972) The effects of water stress on nitrogen—fixing root nodules. New Phytol 71:603–611

Steiner C, Teixeira WG, Lehmann J, Nehls T, Macedo JLV, Blum WEH, Zech W (2007) Long term effects of manure, charcoal and mineral fertilization on crop production and fertility on a highly weathered Central Amazonian upland soil. Plant Soil 291:275–290

Stuart K (1950) Activated carbon manufacture. US patent 2501700

Sumner ME, Miller WP (1996) Cation exchange capacity and exchange coefficients. In: Sparks DL, Page AL, Helmke PA, Loeppert RH, (eds) Methods of soil analysis: part 3—chemical methods. Soil Science Society of America Inc, Madison, WI, pp 1201–1229

Tagoe SO, Horiuchi T, Matsui T (2008) Effects of carbonized and dried chicken manures on the growth, yield, and N content of soybean. Plant Soil 306:211–220

Thies JE, Rillig MC (2009) Characteristics of biochar: biological properties. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology. Earthscan, London, UK, pp 85–105

Van Zwieten L, Kimber S, Morris S, Chan K, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246

Vance CP (2001) Symbiotic nitrogen fixation and phosphorus acquisition. plant nutrition in a world of declining renewable resources. Plant Physiol 127:390–397

Vance CP, Graham PH, Allan DL (2000) Biological nitrogen fixation: phosphorus-a critical future need? Curr Plant Sci Biotechn Agr 38:509–514

Vanek S, Lehmann J 2014 Phosphorus availability to beans via interactions between mycorrhizas and biochar. Plant Soil, publ online

Warnock DD, Lehmann J, Kuyper TW, Rillig MC (2007) Mycorrhizal responses to biochar in soil—concepts and mechanisms. Plant Soil 300:9–20

Wigmans T (1989) Industrial aspects of production and use of activated carbons. Carbon 27:13–22

Yang Y, Sheng G (2003) Enhanced pesticide sorption by soils containing particulate matter from crop residue burns. Environ Sci Technol 37:3635–3639

Yuan J, Xu R (2011) The amelioration effects of low temperature biochar generated from nine crop residues on an acidic Ultisol. Soil Use Manag 27:110–115

Acknowledgments

Financial support for this work was given by the NSF-Basic Research for Enabling Agricultural Development program (BREAD grant number IOS-0965336), the Fondation des Fondateurs, Towards Sustainability Foundation, Richard Bradfield Research Award, Mario Einaudi Center for International Studies, the Cornell Graduate School, NSEP Boren Fellowship, and the U.S. Borlaug Fellowship in Global Food Security. Any opinions, findings, conclusions, or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the donors. The authors would like to thank Dr. Steve Beebe of CIAT for providing the bean seeds, Dr. Steven Vanek for his invaluable discussions, Mr. Justo Otieno Owuor for assistance with the greenhouse management, and several anonymous referees for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 413 kb)

Rights and permissions

About this article

Cite this article

Güereña, D.T., Lehmann, J., Thies, J.E. et al. Partitioning the contributions of biochar properties to enhanced biological nitrogen fixation in common bean (Phaseolus vulgaris). Biol Fertil Soils 51, 479–491 (2015). https://doi.org/10.1007/s00374-014-0990-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00374-014-0990-z