Abstract

Multidimensional modelling and experimental measurements are performed to study the early stages of diesel combustion. Numerical simulation is realised by means of a customised version of the KIVA 3 code, including the Shell model for auto-ignition. Experimentally, a spectroscopic analysis of the burning mixture is carried out under real operating conditions on a diesel engine equipped with an optically accessible combustion chamber. Changing the fuel injection law makes for auto-ignition to occur in environments characterised by different values of mixture pressure and temperature. Dependence of the ignition delay time upon this last variable is shown to follow a law with a negative temperature coefficient in the middle range of values. By means of natural chemiluminescence spectra, OH, CH and HCO radicals are detected as products of the reactions of thermal decomposition of the hydrocarbon molecules preceding auto-ignition. Distribution of the radicals’ emission intensity within the combustion chamber permits the localisation of auto-ignition sites. These are found to be in good agreement with the points of high energetic chemical activity, individuated numerically, under all the considered operating conditions. Experimentally identified radicals and fictitious species entering the reduced kinetic scheme employed within the numerical simulation are shown to exhibit an analogous behaviour regarding the trend with respect to time of the total amount of concentration, and, in a spatial sense, their distribution within the combustion chamber at the time of auto-ignition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The oxidation process of a hydrocarbon is the result of about a thousand chemical reactions between over a hundred different species. Modelling this phenomenon by detailed kinetic mechanisms would imply the knowledge of a large amount of kinetic data, whose determination is not as immediate, even for quantum chemistry, due to the small difference between the high energetic levels of reacting molecules. Several simplifications to detailed kinetic schemes have been discussed, especially after the development of experimental techniques has led to the possibility to recognise and measure the instantaneous concentration of chemical species of major importance under real operating conditions of combustion systems (Horning 2001; Cheskis 1999). Nowadays, the auto-ignition process of main hydrocarbons is described by eliminating marginally contributing reaction paths by sensitivity analysis of the chemical scheme. The resulting reactions number, therefore, is lowered to some tenths.

Tenths of reactions, however, still represent a big effort for available computational resources if chemical processes occur in three-dimensional turbulent flows, as in internal combustion engines. The simulation of combustion, and the calculation of the species transport and mixing phenomena, regard premixed, partially premixed and/or non-premixed conditions, and must account for the complex interactions between turbulence and combustion. The hydrocarbon combustion releases heat and, thereby, generates flow instability by buoyancy and gas expansion, thus, enhancing the transition to turbulence, whereas turbulence increases the mixing process and, thereby, enhances combustion. Two-phase flows and liquid evaporation also have to be considered in engines when mounting direct injection chambers.

Indeed, in internal combustion engines, the prediction and control of the whole combustion process, and, in particular, of the hydrocarbon auto-ignition, is fundamental to a smooth, efficient and low pollutant emission operation. Auto-ignition, namely, the low-temperature kinetics of the fuel–air mixture, is triggered by rapid compression in diesel engines, by pressure waves due to very fast heat release in spark ignition engines. A preview of this process has been a matter of study for a long time.

Early works were devoted to only characterising auto-ignition in a macroscopic way, by specification of the ignition delay time, and have recently been overwhelmed by more detailed models. These are based on simplifications of either the chemical kinetics or the fluid dynamics, effected by empirical comparisons between the time and length scales characteristic of the chemical processes with the time and length scales typical of the turbulent transport phenomena. Chemical reactions usually concentrate in thin layers of a width that is typically smaller than the Kolmogorov scale, and have time scales that are very short compared to the time scales characteristic of the turbulent transport processes (which, indeed, is true close to chemical equilibrium). The model by Magnussen and Hjertager (1977), as an example, is based on the eddy dissipation concept, and evaluates the rate of combustion on the grounds of the rate of intermixing on a molecular scale of the eddies containing reactants and those containing hot products (in other words, by the rate of dissipation of these eddies). The flamelet assumption (Wan et al. 1997), on the other hand, considers the turbulent flame brush as composed by an ensemble of laminar flamelets, whose position is singled out by the mixture fraction field. The consequent simplification to the governing equations allows the consideration of kinetic schemes in greater detail with respect to models based on the eddy dissipation concept. The flamelets models need to assume the similarity between properties of commercial fuels and one-component reference hydrocarbons (generally, n-heptane to simulate diesel fuel and n-octane to simulate gasoline combustion), whereas the eddy dissipation models consider poly-component hydrocarbons, but involve some model constants to be tuned on experimental bases.

The application of the eddy dissipation models has strongly benefited from the work of Halstead et al. (1977), who made substantial progress in capturing the essential features of the auto-ignition process, rather than in constructing a rigorous model. A reduced kinetic scheme made of only eight reactions between real and generic species is applied under a defined threshold value of the local value of temperature, whereas the Magnussen model is applied at high temperature. Several works are found involving this so-called Shell model, or some slight modifications, such as those made by Sazhin et al. (1998a, 1998b, 2000).

Until the present day, validation of the Shell model has been made by only comparing the predicted and the measured ignition delay time. The behaviour of the various reactants with respect to time or space has been approximately discussed in the existing literature, due to both the fictitious nature of the species entering the model and the difficulty of measuring chemical compounds over the whole combustion cycle, starting from the early oxidation reactions until the formation of products.

Recently, the availability of optically accessible engines has allowed the employment of spectroscopic techniques under real operating conditions, as well as the recognition, in the combustion process, of both main intermediate compounds and products. This has laid down a new scenario to assess even simplified numerical models for phenomena occurring in internal combustion engines.

Between optical techniques, laser induced fluorescence (LIF) is known to be a valuable tool in the study of auto-ignition, especially for its capability to detect formaldehyde, an intermediate generated during the early stage of oxidation and rapidly depleted during the high-temperature degenerate branching reactions. Individuation by LIF of radicals such as OH or CH suffers strong interference with light scattered by fuel droplets and fluorescence by poly-aromatic hydrocarbons (PAH) (Zhao and Ladommatos 2001; Dec and Coy 1996). As an alternative to LIF, chemiluminescence has also been used to study auto-ignition, since, as emphasised in Henein (1976), Edwards (1992) and Dec and Espey (1995), some natural-flame emission is detected prior to the time when the first indicated combustion-induced pressure rise occurs, hence, prior to the commonly defined crank angle (CA) of auto-ignition. Chemiluminescence has been exploited to measure ignition delay time in rapid-compression machines or in shock tubes (Coats and Williams 1979; Ciezki and Adomeit 1993). The history of emission at bands typical of OH and CH radicals has been followed and related to the history of pressure. The resulting ignition delay has been shown to be in agreement with numerical simulations and to exhibit the typical negative temperature dependence upon mixture temperature in the intermediate range of values of this variable. Moving to the context of studies concerning diesel combustion, after some initial attempts aimed at recognising emission bands of molecules by means of single fibre-optic probes (Nagase and Funatsu 1988; Ayoma et al. 1993), chemiluminescence has been employed in concomitance with high-speed imaging to investigate chemical reactions preceding the grey-body emission of soot particles (Dec 1997; Dec and Espey 1998).

The present study regards chemiluminescence measurements effected in the early stage of the fuel oxidation process in a diesel engine, and couples this experimental analysis with multidimensional modelling. The numerical simulation is performed by means of a customised version of the KIVA 3 code (Amsden et al. 1993), which includes the Shell model for auto-ignition (Halstead et al. 1977). The main scope of the paper is to highlight the role of recognisable radicals in localising cool-flame reactions and auto-ignition within the combustion chamber. Three of the species taking part in the numerical scheme, namely, a radical formed from the fuel, a branching agent and a labile intermediate species, considered as fictitious by authors of the model (Halstead et al. 1977), are compared to chemiluminescence measurements.

After a phase of code assessment based on recovering test bench data under motored conditions, one particular firing condition is chosen in order to tune constants entering the low-temperature and the high-temperature kinetic models of combustion. Predictability of the code is tested by verifying the correspondence between the computed and the indicated values of pressure over a wide range of operating conditions, without modifying any of the involved parameters.

Experimentally revealed radicals and fictitious species entering the reduced kinetic scheme employed within the numerical simulation are shown to exhibit an analogous behaviour. This regards the trend with respect to time of the total amount of concentration, and, in a spatial sense, their distribution within the combustion chamber at the time of auto-ignition.

Major combustion features, such as the negative temperature dependence of the ignition delay time trend with respect to the mixture temperature and the location of the zone of the combustion chamber interested by the cool-flame reactions, are achieved in all the considered operating conditions.

2 Experimental setup

2.1 Engine

A single-cylinder, water-cooled, naturally aspirated, four-stroke diesel engine, having a displacement of 750 cm3, a bore of 100 mm and a stroke of 95 mm, is used in this study. In order to realise optical access points, the engine was modified by placing the combustion chamber externally, above the cylinder, and connecting it to the main chamber via a 60-mm-long tangential duct. In order to preserve the original compression ratio, namely 22.3:1, the standard piston, having a toroidal bowl, was replaced with a flat one. A schematic representation of the engine configuration is given in Fig. 1. The engine specifications are given in Table 1.

The engine is equipped with a single-hole nozzle, with a diameter of 0.34 mm, located centrally on the top of the divided chamber. Fuel is injected at a pressure of 28 MPa. Although the employed nozzle is larger than for automotive-sized engines, it is chosen in such a way to allow the injection of fuel amounts resembling those used in real systems. The external chamber has the same volume of the original piston-bowl (21.3 cm3) and a cylindrical geometry with a height of 28 mm and circular bases with a diameter of 30 mm. Three wide optical access points are realised: two of them coincide with the bases of the cylinder (ϕ=30 mm), and the third, shown in Fig. 1b, is in the orthogonal direction with a width of 10 mm and a height of 30 mm.

A strong air vortex is generated within the combustion chamber due to the presence of the tangential duct and the pressure difference with respect to the main chamber. Laser Doppler anemometry (LDA) measurements, described in a previous paper (Astarita et al. 1999), show an almost solid body rotation occurring with an axis placed well in correspondence of the chamber axis. This swirl flow experiences an increase in its angular velocity during the compression stroke until top dead centre (TDC), and a decrease during the expansion stroke as the piston inverts its movement. The swirl ratio here is defined as the ratio between the equivalent solid-body angular velocity of the fluid around the axis of the combustion chamber, recorded for the piston being at TDC, and the crankshaft rotational speed. The value of the swirl ratio in Table 1 is evaluated under motored engine conditions on the grounds of the measurements reported in Astarita et al. (1999).

The engine can be operated continuously for several minutes, limited only by the increase of the cylinder head temperature. Since the windows are shielded by the rotating airflow, they do not need to be taken off and cleaned frequently. The air temperature at the intake is heated to 310 K.

Two water-cooled quartz-piezoelectric pressure transducers measure the combustion pressure both in the external and in the main chamber. A Hall effect sensor detects the injector needle lift. A piezoelectric pressure transducer is located in the injector to measure the injection pressure.

2.2 Test conditions

The experimental investigation is carried out at an engine speed of 2,000 rpm using commercial diesel fuel, as specified in Table 2. For each data set, the cylinder pressure, needle lift and injection pressure are recorded at 0.1° CA increments and ensemble-averaged over 16 consecutive combustion cycles.

The start of fuel injection (SOI), defined as the CA where the injector needle lift is at 5% of its maximum value, is varied from 22.8° to 5.6° before TDC (BTDC), in order to take into consideration operating conditions exhibiting the pressure at the start of combustion (PSOC) occurring at different instants of time. The CA of the PSOC is evaluated as the CA where a minimum in the rate of change of pressure occurs in the indicated pressure cycle. This CA is where auto-ignition occurs, since the energy release due to combustion exothermic reactions begins to exceed the energy losses due to the evaporative process of fuel. Consequently, the ignition delay is measured as the difference in CA between the SOI and the PSOC. Its evaluation has a resolution of one tenth of a degree. The consequent error affecting the ignition delay is on the order of 8.3 μs, since, at the considered speed, 1° CA corresponds to 83.3 μs.

Two load conditions are realised; the lower one with an injected mass per stroke equal to 9.6 mg and the higher one with an injected mass per stroke equal to 16.7 mg. Although slightly greater than for real working conditions, the values chosen for the air-to-fuel ratio avoid the formation of soot particles and having an obscuring effect on the optical detection procedure.

In order to discuss the results, five representative conditions are examined at low load, as reported in Table 3, where they are indicated with labels from A1 to A5. The ignition delay varies between 800 μs and 383 μs. As the SOI is delayed, the PSOC gets closer to the TDC and the injected mass until the PSOC itself, Mf%, decreases, indicating a progressive reduction of the amount of fuel participating in the premixed phase of combustion with respect to that participating in the non-premixed phase.

In the high-load condition, only the case indicated as B3 in Table 3 is considered. The choice of this case is made in order to make a comparison with case A3. As evidenced in Fig. 2, where the trends of pressure and injector needle lift are shown, fuel is injected starting from the same CA, but is of longer duration in case B3.

2.3 Optical apparatus

Optical measurements are performed by means of the experimental apparatus shown in Fig. 3.

In order to follow the temporal and spatial evolution of the diesel spray and the combustion process, images are acquired with a colour CCD video camera. The camera has a video chip resolution of 640×480 pixels and a maximum recording rate of 15 Hz. Measurements are carried out at 16,000 frame/s with an exposure time of 42 μs. A high-luminosity continuous-wave (CW) halogen lamp is used to highlight the spray. Synchronization between the engine and the CCD video camera is obtained by the unit delay connected to the signal coming from the engine shaft encoder.

Flame emission signals are collected and focussed with a UV-grade fused silica bi-convex lens (20 cm focus length) on the entrance slit (250 μm) of a spectrograph (f/4 with 15-cm focal length). This is equipped with a grating of 300 g/mm, blazed at 300 nm, with a dispersion of 19 nm/mm at 500 nm. The spectral image formed on the spectrograph exit plane is matched with a gated intensified CCD (ICCD) camera (512×512 pixels), with each pixel of size 20×20 μm2. A Mercury-vapour lamp is used to calibrate the wavelength of the spectrograph ICCD. The spectral efficiency of the optical setup is calibrated in the ultraviolet and the visible region by a Deuterium lamp and a Tungsten lamp, respectively.

The natural flame emission is detected with the spectrograph placed at the central working wavelength of 380 nm and the intensifier gate duration of 15 μs, in order to have a good accuracy in the timing of the onset of combustion. The spectrometer entrance slit width allows the resolution of spectral features on the order of 0.5 nm. Consequently, species exhibiting thin emission bands, such as the OH or the CH radicals, whose emission is well centred at 309 nm and 431 nm, respectively, are suitable to be identified. Quantitatively, the emission intensity is evaluated by selecting peak heights and subtracting the background signal due to the dark noise.

Reconstructed maps of the emission intensity within the combustion chamber are able to be drawn, taking into account that the spatial resolution of the ICCD camera has dimensions of 0.1×1 mm for each pixel. In order to minimise the statistical uncertainty due to the cycle-by-cycle variations, emission spectra are detected in sets of 30 from 30 separate combustion cycles. Each measurement is subjectively selected as being representative of its respective set.

3 Experimental results

3.1 Spray break-up and mixing

Figure 4 represents the middle section of the chamber, with the image taken normally to its axis. The position of the injector, the connecting duct and the points indicated with letters from A to H, relevant to the localisation of the liquid jet tip and the auto-ignition, are reported. These points are indicated explicitly in the figure since the region of major interest within the combustion chamber is where the connecting duct enters the chamber itself.

The dynamics of the fuel jet is highlighted in Fig. 5. On the right-hand side, a sequence of three images of the jet is reported, as taken by the CCD camera from the frontal window at three instants of time after the SOI (ASOI). The engine is in the operating conditions indicated as case A3 in Table 3: the PSOC occurs at 5.8° ASOI, 7° BTDC. The fuel, entering the combustion chamber from the top, is strongly deviated by the counter-clockwise airflow. This is due to air pushed through the connecting duct within the chamber by the piston’s upward motion. The visible liquid is surrounded by vapour, whose penetration, as time progresses, is far beyond the tip of the spray, as shown in the central column of Fig. 5. The three central images represent the distribution of the fuel in the vapour phase. The curves are iso-levels of concentration normalised with respect to the maximum value. The images on the left represent the distribution of the fuel in the liquid phase, also normalised with respect to the maximum value. The procedure to measure the concentration of the fuel in the liquid and the vapour phase is described by Astarita et al. (1999) and Suzuki et al. (1993), and is based on measurements of light extinction. Figure 6 reports the location of the liquid phase and the iso-level curves of the normalised concentration of the fuel in the vapour phase at the PSOC, for the same case of Fig. 5.

Images of the fuel jet for the case of low load and PSOC at 7° BTDC at different crank angles ASOI: a normalised concentration of the fuel in the liquid phase; b location of the liquid phase and iso-level curves of the normalised concentration of the fuel in the vapour phase; c digitally recorded image

The penetration of the liquid phase grows almost linearly with respect to time, or CA, until a maximum value is reached. This is evidenced in Fig. 7, where the jet penetration is shown to stay constant after an initial linear growth. The penetration of vapour extends through the region of the chamber close to the connecting duct. The flow within the combustion chamber increases the rate of entrainment of air into the fuel jet, hence, it enhances mixing and fuel vaporisation. These intense vaporisation and mixing phases play a determinant role, since the related cooling prevents the increase of temperature and increases the duration of the regime preceding the appearance of the visible flame.

3.2 Auto-ignition

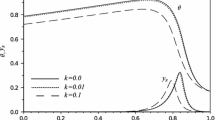

Figure 8 shows the trend of the ignition delay as a function of the PSOC. Changing the PSOC corresponds to changing the conditions of pressure and temperature in the environment where the auto-ignition takes place. As the PSOC gets closer to the TDC, a decrease of the ignition delay is observed. An opposite behaviour is found in the middle range of values. Since the mean values of pressure and temperature within the engine combustion chamber increase towards the TDC, the S-shaped curve of Fig. 8 may be assumed to represent the dependence of ignition delay upon temperature. Therefore, the ignition delay exhibits a negative coefficient in the middle range of values of the temperature.

When chemiluminescence measurements are considered, a scenario arises as described in the following, independently to the instant of time of the SOI. The early stage of combustion is spectrally characterised by a weak flame emission, detected mainly in the near ultraviolet range, attributed to exothermic reactions. The spectral features of the HCO and CH radicals are resolvable around 0.5° CA before the PSOC, whereas peaks typical of the OH radical appear in spectra recorded at some points of the measurement grid, at instants of time which are found to coincide well with the instant of the PSOC. Errors in the events’ coincidences are as low as 0.1° CA.

Figure 9, as an example, represents the emission spectra between 280 nm and 480 nm, detected close to the connecting duct at various instants of time. The operating condition under examination is the one denoted as A3 in Table 3. Emissions typical of the CH radical and a large band around 400 nm, denoting the presence of the HCO radical, are found at 0.5° CA before the PSOC, namely at 7.5° BTDC. A peak at 309 nm arises at the PSOC, which is typical of the OH radical. The three species are also found at 1° after the PSOC.

While the identification of the OH and CH radicals is straightforward, due to the well localised position of the peaks of emission in the considered range of wavelengths, the presence of the HCO radical may be not so clear. The emission band of this radical is broad and almost coincident with that of formaldehyde, a species largely referred to in studies on auto-ignition reactions. The formaldehyde emission band, indeed, has a broad peak centred at about 430 nm, but decreases sharply to very low levels for wavelengths shorter than about 320 nm and longer than 640 nm. The signals in Fig. 9 are not low below 320 nm, which, indeed, is in the middle of the emission band of the HCO radical, between 295 nm and 360 nm. The appearance of HCO seams more realistic with respect to that of formaldehyde. This aspect is believed to be not surprising, due to the quite high value of the air-to-fuel ratio of the burning mixture under examination, which is in agreement with the statements of Dec and Espey (1998).

Local measurements of emission intensity, such as those described above, can be used to reconstruct two-dimensional images of the spatial distributions of the OH, CH and HCO radicals in the combustion chamber. The situation relative to case A3 of Table 3 is represented in Fig. 10 at the instant of time of auto-ignition, namely, 7° BTDC. By comparing Figs. 10 and 6, it is evident that the greatest chemical activity occurs far from the tip of the liquid, in a region characterised by a large amount of fuel in the vapour phase well mixed with the air entrained in the spray by the swirl. The CH radical appears more diffused than other radicals, spreading towards richer regions.

Changing the SOI leads us to draw analogous conclusions in cases A1, A2, A4 and A5, although the sequence of events is obviously shifted in time in advance or in delay, depending on the case. The strongest emission intensity by the radicals is always localised around the point indicated with a letter H of Fig. 4, although the values of emission intensity changes as the PSOC gets closer to TDC. This is due to the influence of the amount of the premixed phase of combustion on the production of intermediate radicals. Figure 11, as an example, represents the maximum between the values of the OH emission intensity recorded at the PSOC in the various locations of the combustion chamber, as a function of the PSOC itself. As the premixed phase of combustion decreases with respect to the non-premixed one, the OH amount increases. The emission intensity of the CH and HCO radicals has an analogous behaviour.

The performed experiments confirm previous findings about the presence of naturally emitting species prior to the occurrence of auto-ignition, as reported by Dec (1997) and Dec and Espey (1998), and cited references therein. In addition, within the present context, the radical that may more realistically represent a spectral marker to identify the start of the combustion process in both a spatial and a temporal perspective is recognised as the OH radical.

4 Numerical simulation

The numerical simulation of the engine under study is performed using a customized version of the KIVA 3 code (Amsden et al. 1993) working on a mesh of 44,367 cells. At the beginning of the computation, the air pressure, temperature and turbulent kinetic energy are assumed to be uniform throughout the chamber, the duct and the cylinder, and are chosen according to experimental data. The ratio between the equivalent solid-body angular velocity of the fluid around the cylinder axis and the crankshaft angular rotational speed is assumed to be equal to zero. The value of the ratio between the equivalent solid-body angular velocity of the fluid within the combustion chamber around its axis and the crankshaft’s angular rotational speed, previously defined as the swirl ratio, results from computation in the absence of fuel spray. This was shown in a previous paper to be in agreement with experimental data (Astarita et al. 1998).

In the phase of code assessment, various spray break-up models were tested and the results were compared with images recorded by UV–Vis light absorption from Astarita et al. (1998, 1999). Not only with tetradecane but also with diesel fuel (df2 of KIVA), it was found that the best performance, from the numerical point of view, is obtained by using the model by Reitz (1987), with values of the involved constants chosen in accordance with experimental findings.

As previously mentioned, reactions preceding auto-ignition are simulated by means of the Shell model (Halstead et al. 1977). Ignition following a degenerate branching reaction is assumed to occur in eight steps at locations of space where the values of temperature are below the chosen threshold of 1,000 K. The auto-ignition process is hypothesised as involving five chemical species, three of which, R, B and Q, are fictitious and not suitable of specific identification: R is the radical formed from the fuel, B is the branching agent and Q is a labile intermediate species. The assumed reaction scheme is the following:

where RH is the hydrocarbon of the kind C n H2m and P is the product consisting of CO, CO2 and H2O. The variation with respect to time of the concentration [M] of the M species is given by:

In Eq. 12, p is obtained from the overall product balance, namely:

with:

The following formulae hold:

The rate constants in Eqs. 9, 10, 11, 12 and 13 are defined as:

where i is equal to p1, p2, p3, q, B, t and:

Ro is the universal gas constant.

The value of the constants A i , E i , Af1, Ef1, Af2, Ef2, Af3, Ef3, Af4, Ef4, x1, y1, x3, y3, x4 and y4, appearing within the above formulae are chosen starting from those defined by Halstead et al. (1977), and with reference to case A3 of Table 3, based on agreement between the computed mean pressure within the combustion chamber and the measured pressure. Table 4 reports the employed values of these constants.

A change to the model of high-temperature chemistry is also made in order to account for the strong mixing occurring in the system under study. The contribution due to turbulence to the characteristic time of the reaction is varied by increasing the value of the delay coefficient f of the model described by Abraham et al. (1985). The formula f=[1−exp(r)]/0.532 is used, with r being the ratio of the amount of product to the total of reactive species.

Predictability of the code is assessed by checking the correspondence between the computed and the measured pressures in cases A1, A2, A4 and A5 of Table 3, without modification to any of the involved constants.

Regions of more intense chemical activity are found to be reasonably predicted, as shown in Fig. 12, which represents the computed distribution of the concentration of the intermediate species in the simulation of case A3 of Table 3 at the PSOC. Note the analogy of the spatial location of maximum concentration of R, B and Q, and the maximum emission intensity of the OH, CH and HCO radicals. The two-dimensional images of Fig. 12 are drawn after integration of the value of concentration along the axis of the combustion chamber, in analogy to the intrinsic integration along the line of sight, which is typical of chemiluminescence measurements.

In agreement with experimental findings, changing the SOI makes for auto-ignition to occur always in the richest fuel vapour region, with a temporal shift with respect to the case A3.

A meaningful comparison between the numerical simulation of the various operating conditions concerns the mean value of the in-chamber temperature, a quantity which is not measured experimentally. Computed values are represented as a function of the PSOC in Fig. 13 for the five cases from A1 to A5 of Table 4, where the numerically evaluated ignition delay is also reported. The predicted value of ignition delay coincides with the measured one, as compared with Fig. 8. It is evident that the code aides to highlight the negative temperature coefficient of the trend of ignition delay. This quantity, in fact, decreases with increasing temperature, but at different rates depending on the range of values of this last variable.

5 Discussion

A hydrocarbon oxidation that is totally insensitive to the details of the process, following a simple stoichiometric reaction to form final products and release heat, is a reasonable representation of the combustion process only at high values of burning mixture temperature. Branching reactions and degenerate branching, with underlying chemical mechanisms strongly affected by several variables, certainly contribute to reconstruct a more realistic scenario.

Recognised features of the hydrocarbon oxidation process are the dependence upon temperature and the formation of intermediates, mainly OH radicals (Benson 1981). At temperatures on the order of 1,000–1,100 K, the dominant path to the formation of OH is known to be the decomposition of H2O2 (Warnatz et al. 1996). At lower values, which are of major importance in internal combustion engines, the decomposition of H2O2 is quite slow, and other, more complicated, chain branching reactions have to be hypothesised. These include the formation of peroxy radicals by the addition of molecular oxygen to the hydrocarbon radicals. Successively, by external H abstraction, peroxy radicals form hydroperoxy compounds (ROOH), which then give rise to RO and OH. Alternatively, by internal H abstraction, peroxy radicals form intermediate compounds (R’O2H), which then react to aldehydes or ketones and OH according to a chain propagation.

Since the external H atom abstraction is slower than the internal one, further addition of oxygen molecules to R’O2H is needed to explain the occurrence of a negative temperature coefficient in the dependence of ignition delay time upon temperature. Due to instability, the compounds resulting from this further addition of oxygen molecules may decompose back to the reactants at higher temperatures in a degenerate chain branching reaction (Warnatz et al. 1996).

Since the OH radicals have a determinant role in terminating reactions, and being that the appearance of the OH radical is strongly related to the presence of branching agents, between the three fictitious species involved in the Shell model, the one denoted with the letter B is believed to be the determinant to gain insight into the auto-ignition process.

Figure 14 highlights the role of the B species. The rate of change of the concentration of B, made dimensionless with respect to the injected fuel, is plotted with respect to time at locations from A to H of Fig. 4, as computed by simulation case A3 of Table 3. It is evident that some curves exhibit a maximum. On the grounds of the information that the PSOC is at 7° BTDC, by searching for the curve with a maximum just at 7° BTDC, it is found that it is relative to the point indicated with the letter H in Fig. 4. By comparing Fig. 4 with Fig. 10, it is evident that the maximum in the rate of change of the numerically computed concentration of the branching agent occurs in correspondence with the points of the combustion chamber where the experimentally measured OH radicals, at their first temporal appearance, have a maximum in emission intensity. This good correspondence between the numerically derived information and the experimental evidence is of a certain importance to localise auto-ignition in both a temporal and a spatial sense. This reasoning applies to all the considered operating conditions. The case A3 is chosen as a representative one.

Rate of change of concentration of species B at points A–H of Fig. 4 in the case of low load and PSOC at 7° BTDC

Not only at a local level, but also integrating over the whole volume of the combustion chamber, intermediate species forming before the appearance of final products of combustion have a major role. Figure 15, in fact, represents the trend with respect to time of the global amount of species R, B and Q for case B3, here considered as better resembling real operating conditions. The total emission of OH, CH and HCO radicals, obtained by adding values over all the measurement points, is also represented. The total emission intensity relates to the concentration of emitting radicals. The behaviour with respect to time of both the experimentally identifiable species and the numerically computed products of the early fuel oxidation has similar features. The start of combustion, at 7° BTDC, is characterised by a sharp increase of both the concentration of R, B and Q, and the emission intensity of the OH, CH and HCO radicals. As already pointed out, this instant of time corresponds to a minimum in the engine’s rate of heat release. This is represented, as computed by means of the KIVA code for case B3, in Fig. 16. A second variation in the curve of Fig. 15 at about 5.5° BTDC is observed, which is almost coincident with a point of minimum in the curve of Fig. 16. This instant of time should correspond to the start of the flame regime, hence, it can be assumed to be a second characterizing feature of the combustion process. Starting from this instant of time, the radicals deplete sharply in favour of products. Indeed, a decrease is observed in both the numerically computed total concentration of the fictitious species and the experimentally measured emission intensity of radicals.

The analogous behaviour of intermediates leads to the conclusion that the experimental measurements are suitable to clarify the role of the fictitious species entering the Shell model for auto-ignition. The comparison between the relative amount of the total emission of the radicals and the total concentration of the fictitious species is believed to be of great importance. The OH radicals are known to arise from fiction into radicals of branching agents. A correspondence in the spatial sense of the OH emission intensity and the branching agent concentration at the instant of time of auto-ignition is not surprising, and constitutes a further confirmation of the predictability of the numerical code in use. However, a one-to-one correspondence between OH, CH and HCO and R, B and Q, can not be stated by just relying on the present investigation, although it is clear that all of them are indicative of high energetic chemical activity.

6 Conclusions

Numerical simulation and experimental measurements are performed to study the pre-flame reactions of the hydrocarbon oxidation process in a diesel engine. Patterns suitable for simplifying some of the most complex phenomena occurring within the combustion chamber are identified by comparing test bench data, chemiluminescence measurements and results of computations. The computations are performed by means of a customised version of the KIVA 3 code, including the Shell model for auto-ignition.

Within the system under examination, a strong airflow enhances the fuel vaporisation and mixing. The resulting combustion process closely resembles that occurring in diesel engines equipped with high-pressure injection systems. Different operating conditions are considered by varying the time of the start of injection and the load.

In all the considered cases, the early stage of combustion appears spectrally characterised by a weak flame emission, detected mainly in the near-UV range. The spectral features of the HCO and CH radicals are resolvable at about a 0.5° crank angle (CA) before the start of combustion, whereas peaks typical of the OH radical appear in correspondence to the pressure start of combustion.

The peaks of emission intensity of the radical species are found to coincide well, in both a temporal and a spatial sense, with the maxima of concentration of the intermediate species entering the reduced kinetic model. Depletion of both experimentally identified radicals and fictitious species of the numerical model is also found to coincide and to synchronise with the start of the high temperature reactions, leading to the formation of products.

A simultaneous experimental and numerical approach, such as the one performed within the present work, may fill some of the intrinsic limitations of the separate use of each of these techniques. Chemiluminescence has the intrinsic limitations of integrating the signal along the line of sight and of being as valuable as the acquisition system in use. Multidimensional engine modelling needs constants tuning and is, somehow, not detachable from an experimental investigation. A coupling of the two leads us to achieve the major features of diesel combustion, such as the negative temperature dependence of the ignition delay time in the middle range of values of this variable and the location of the zones interested by the pre-flame reactions within the combustion chamber.

References

Abraham J, Bracco FV, Reitz RD (1985) Comparisons of computed and measured premixed charge engine combustion. Combust Flame 60:309–322

Amsden AA, O’Rourke PJ, Butler TD (1993) KIVA-3: a KIVA program with block-structured mesh for complex geometries. Los Alamos National Laboratory, technical report LA-12503-MS

Astarita M, Corcione FE, De Maio A, Vaglieco BM, Valentino G (1998) An interpretation of high swirl diesel combustion based on optical diagnostics and 3D numerical calculations. In: Proceedings of the 4th international symposium on diagnostics and modeling of combustion in internal combustion engines (COMODIA’98), Kyoto, Japan, July 1998, p 149

Astarita M, Corcione FE, Vaglieco BM, Valentino G (1999) Optical diagnostics of temporal and spatial evolution of a reacting diesel fuel jet. Combust Sci Technol 148:1–16

Ayoma T, Hokuto H, Kotoh R, Senda J, Fujimoto H (1993) Combustion characteristics determined by use of chemiluminescence in diesel flame. SAE technical note 9305067

Benson W (1981) The kinetics and thermochemistry of chemical oxidation with application to combustion and flames. Prog Energy Combust Sci 7:125–134

Cheskis S (1999) Quantitative measurements of absolute concentrations of intermediate species in flames. Prog Energy Combust Sci 25:233–252

Ciezki HK, Adomeit G (1993) Shock-tube investigation of self-ignition of n-heptane–air mixtures under engine relevant conditions. Combust Flame 93:421–433

Coats CM, Williams A (1979) Investigation of the ignition and combustion of n-heptane–oxygen mixtures. In: Proceedings of the 17th international symposium international on combustion, The Combustion Institute, Pittsburgh, Pennsylvania, pp 611–621

Dec JE (1997) A conceptual model of DI diesel combustion based on laser-sheet imaging. SAE paper 970873

Dec JE, Coy EB (1996) OH radical imaging in a DI diesel engine and the structure of the early diffusion flame. SAE paper 960831

Dec JE, Espey C (1995) Ignition and early soot formation in a DI diesel engine using multiple 2D image diagnostics. SAE technical paper series 950456, vol 104 p 853

Dec JE, Espey C (1998) Chemiluminescence imaging of auto-ignition in a DI diesel engine. SAE paper 982685

Edwards CF, Siebers DL, Hoskin DH (1992) A study of the auto-ignition process of a diesel spray via high speed visualization. SAE technical paper series 920108, vol 101 p 187

Halstead MP, Kirsch LJ, Quinn CP (1977) The auto-ignition of hydrocarbon fuels at high temperatures and pressures—fitting of a mathematical model. Combust Flame 30:45–60

Henein NA (1976) Analysis of pollutant formation and control and fuel economy in diesel engines. Prog Energy Combust Sci 1:165

Horning DC (2001) A study of the high-temperature auto-ignition and thermal decomposition of hydrocarbons. Report no. TSD-135, Stanford University

Magnussen BF, Hjertager BH (1977) On mathematical modeling of turbulent combustion with special emphasis on soot formation and combustion. In: Proceedings of the 16th international symposium on combustion, The Combustion Institute, Pittsburgh, Pennsylvania, pp 719–729

Nagase K, Funatsu K (1988) Spectroscopic analysis of diesel combustion flame by means of streak camera. SAE paper 881226

Reitz RD (1987) Modeling atomization processes in high pressure vaporizing sprays. Atomisation Spray Technol 3:309–337

Sazhina EM, Sazhin SS, Heikal MR, Marooney C (1998a) The Shell auto-ignition model: applications to gasoline and diesel fuels. Fuel 78:389–401

Sazhina EM, Sazhin SS, Heikal MR, Babushok VI, Johns RJR (1998b) A detailed modelling of the spray ignition process in diesel engines. Combust Sci Technol 160:317–344

Sazhina EM, Sazhin SS, Heikal MR, Marooney C, Mikhalovsky SV (2000) The Shell auto-ignition model: a new mathematical formulation. Combust Flame 117:529–540

Suzuki M, Nishida K, Hiroyasu H (1993) Simultaneous concentration measurement of vapor and liquid in an evaporating diesel spray. SAE paper 930863

Wan YP, Pitsch H, Peters N (1997) Simulation of auto-ignition delay and location of fuel sprays under diesel-engine relevant conditions. SAE paper 971590

Warnatz J, Maas U, Dibble RW (1996) Combustion—physical and chemical fundamentals, modeling and simulation, experiments, pollutant formation. Springer, Berlin Heidelberg New York

Zhao H, Ladommatos N (2001) Engine combustion instrumentation and diagnostics. Society of Automotive Engineers Inc., Warrendale, Pennsylvania

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Costa, M., Vaglieco, B.M. & Corcione, F.E. Radical species in the cool-flame regime of diesel combustion: a comparative numerical and experimental study. Exp Fluids 39, 514–526 (2005). https://doi.org/10.1007/s00348-005-0968-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00348-005-0968-6