Abstract

A new optical method to seed a flow with elemental metal species is described and demonstrated using laser ablation. The unique ablation seeding approach is shown to generate free gas-phase metals in their atomic form, without the need for a spray or solvent. The technique can be used in both reactive and non-reactive environments, which solves a problem that has hitherto plagued the seeding of many flows. The ablative seeding approach has the potential to become a standard tool for chemical seeding, with a diverse range of application from flow tracing to atomic absorption spectroscopy (AAS).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Chemical elements are used in every industry in our society and every current environmental problem has an inherent chemical connection. Efficient chemical detection can be achieved by laser spectroscopy, which permits non-intrusive measurements. Laser spectroscopy often requires the use of a seeded chemical species, either directly as a flow tracer, or indirectly in the calibration process [1, 2].

The study of flows is of great interest to many branches of science and engineering. Despite the progress of computational modelling, experimental measurements remain fundamental to the study of fluid mechanics [3]. Key parameters of interest include concentration, temperature, pressure and velocity. A variety of laser-based measurement approaches have been developed to measure these parameters. For flow measurement, laser-induced fluorescence (LIF) is particularly attractive since it offers strong signal and can be used for all of the parameters listed above, most commonly for species concentration.

For the LIF technique a suitable tracer species is typically introduced into the flow [4]. For measurement in gaseous flows, it is preferable for the seeded species to also be gaseous to avoid large differences in Schmidt number and/or Stokes number.

A number of gaseous species have successfully been used as flow tracers using LIF. For example, iodine, nitric oxide and acetone have been demonstrated to exhibit suitable optical properties [5–7]. Nonetheless, these species have a number of disadvantages that limit their use, including toxicity, handling, predissociation and flammability.

Atomic seeding has the advantage of strong electronic transitions. Sodium is one example that has been used for both flow visualisation and velocity measurements, though the necessity for heating (prevapourising) and its reactivity can be a limitation [8]. Krypton has also emerged as a potential flow tracer, with many benefits [9]. Nevertheless, it is still in the early stages of development, with some inherent limitations, so that it is too early to assess how widely it will be adopted [3].

Many metals in their atomic form have desirable spectroscopic properties, such as strong optically accessible transitions, but are difficult to introduce directly. The seeding of elemental metals into a gaseous flow is currently achieved with nebulisers, which produce a fine spray of liquid solvent (often water) into which a metal salt is dissolved [10]. This approach typically requires a heat source, such as with a flame or plasma, to evaporate the solvent, though this is unnecessary for some systems [11]. Furthermore, it is also necessary for the metal salt to be converted to free atoms before detection is possible. This approach limits the zone of detection to regions of sufficiently high temperature, and the evaporation process also introduces significant thermal gradients.

An alternative approach for seeding atoms as a gas into a flow is through the use of laser ablation, which has been demonstrated in tokamak diagnostics [12]. Laser ablation involves the removal of material from a surface by the rapid heating provided by a focussed, pulsed, laser beam. This process releases a mixture of free atoms, cations, anions, electrons, molecules, particles and clusters. The release of neutral atoms is of particular importance, and has broader significance such as for thin-film deposition and the generation of atomic beams [13]. Such processes are generally performed in low-pressure environments. The potential application of laser ablation as a means to generate neutral metallic atoms for use as a flow tracer has not previously been reported. The present letter aims to demonstrate its feasibility at atmospheric pressure.

2 Experimental details

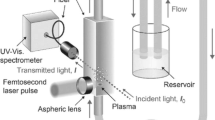

To assess the potential of the laser ablation products as a flow tracer, a laser ablator has been designed and constructed. The device consists of a metallic rod (∅ 10 mm) mounted to a motorised threaded shaft. The second harmonic from a Q-switched Nd:YAG laser is focussed to a point on the rod. The laser energy required for ablation is moderate, of order of millijoules per pulse. The motion of the rod consists of a combined rotational and translational motion, such that each laser pulse ablates a different point on the rod.

For this work, the rod material was chosen to be indium (In). Indium has a large oscillator strength and electronic transition states that are optically accessible to tunable laser sources. More importantly, indium has also been used as a suitable thermometry species for two-line atomic fluorescence (TLAF) measurements [14–16]. If the seeded indium could be used both as a flow tracer and for temperature measurement, this would have great potential, since it would avoid the need for an additional optical system. More generally, the principal presented in this work is relevant to other metals and to a range of other applications.

The indium products of the ablation process are transported from the ablator with the use of a carrier gas that passes through the ablator. In this work, the carrier gas was chosen to be natural gas (predominately methane). There is scope for other carrier gases to be used, depending on the purpose of the experiment. It has been observed that oxygen-containing species in the carrier gas should be avoided. Both air and carbon dioxide were observed to result in the final concentration of neutral indium atoms being insufficient to be detected. This can be explained by such species oxidising the metal atoms in the plasma generated by the ablation process.

The pulsed nature of the laser ablation process causes the concentration of indium leaving the ablator to be time-dependent. This effect was damped out by passing the carrier gas containing the indium through a ballast volume ∼100 times larger than the ablation chamber. When combined with a motorised stirrer, a homogeneous mixture of indium in the carrier gas was achieved. With this damping approach, the signal level is independent of the time delay between the ablation and fluorescence lasers. A further advantage of this arrangement is that the velocities in the ballast volume are sufficiently low to cause the larger particles to settle to the floor, so filtering them from the carrier gas stream.

The total seeding system comprises approximately 4 metres of pipe, as outlined in Fig. 1. The average residence time of indium-containing gas between the ablator and the nozzle is 22 seconds. This indicates that the neutral indium atoms produced are insensitive to reactions and self-collisions. Self-collisions would be problematic because indium dimers would be formed, which would not be detected with the LIF scheme adopted. Noteworthy too is that the entire ablator system operates at approximately atmospheric pressure.

Excitation of the neutral indium atoms was performed at 410.18 nm by an Nd:YAG-pumped dye laser. The laser beam was shaped into a sheet of 12 mm height and 0.2 mm thickness. Detection was with an intensified CCD camera through a 450-nm bandpass filter (with 10-nm bandwidth). Further details of the laser system are similar to those reported previously [15].

For the purposes of this feasibility study, the flow measurements were conducted in both a laminar non-reacting jet and a turbulent non-premixed flame. The challenges presented by the turbulence and reactions in such a flow restrict the applicability of many existing seeding methodologies, since many tracers undergo reactions in the flame front. Furthermore, even non-reacting tracers, such as alumina, are still affected by the flame front through changes in optical properties as a function of temperature [3]. The demonstration of the ablation technique under these demanding conditions highlights its advantages.

In the non-reacting case, a simple 8-mm diameter jet of natural gas was used. For the turbulent flames, the burner was an axisymmetric bluff-body burner, which has an outer diameter of 50 mm with a concentric jet diameter, d, of 3.6 mm [17]. The exit velocity of the fuel (natural gas) was 39 m/s.

3 Results

Figure 2 shows a single-shot fluorescence image of neutral indium atoms seeded into the non-reacting jet with the laser ablation technique. The size and location of the image are shown in relation to the jet diameter, d. This image clearly demonstrates that indium fluorescence is possible in the non-reacting ambient temperature jet flow. Noteworthy is that despite the ambient temperature and pressure conditions, signal from the indium atoms is achieved with the laser ablation seeding technique.

Figure 3 shows a series of typical single-shot fluorescence images of neutral indium atoms seeded into the flame with the laser ablation technique. The images are reported at three different heights (z) above the jet exit plane, non-dimensionalised by d as indicated by the vertical label. These images clearly demonstrate that, despite the presence of reactions, the seeding is suitable for imaging instantaneous turbulent structure that is present in many fluid mechanical processes.

No claim is made that the indium imaged in the flame (Fig. 3) acts as a conserved scalar marker. Indeed, the presence of reactions would likely prevent indium from being a conserved scalar across the reaction zone. To assess this issue is beyond the scope of the present work. Nonetheless, these results demonstrate that signal is possible despite the long residence times, considerable convection distances, and regions with significant mixing with the surrounding air and combustion products. Previous investigations with nebulising seeding have shown that the indium does not survive the high temperature oxidising side of the reaction zone, where it is consumed, but covers the critical regions up to, and including, stoichiometric [16]. Importantly, the present images also show that ablation seeding offers the distinct advantage over nebuliser seeding, in that it delivers indium in its atomic form in the low-temperature, non-reacting potential core region of the jet (0<z/d<3.3). This is not possible with established TLAF seeding approaches, which deliver the indium salt dissolved in solution [15].

The signal-to-noise ratio (SNR) is of particular importance for flow tracer measurements. In the potential core of the jet, the SNR is approximately 30:1, whilst downstream this value falls to approximately 10:1. It is also worth noting that tuning the fluorescence laser off-resonance reveals that the contribution of the interferences to the indium fluorescence signal is insignificant (≲1%).

The present results imply that the laser ablation method could potentially be used with other materials to provide alternative tracers to the indium chosen for the present feasibility study. Other metals may be more readily detected and/or offer other more favourable properties in other applications.

The ability of the ablation seeding technique to operate at atmospheric pressure, and under the harsh conditions of turbulent reacting flows, highlights the benefits of ablation seeding for use as a flow tracer and TLAF thermometry. Other applications include atomic-absorption spectroscopy (AAS), where it could provide a more accurate and reliable calibration tool, by obviating the need for, and complications associated with, the use of solvents and nebulisation.

4 Conclusion

In conclusion, laser ablation has been found to offer a new approach for seeding tracer species into flows at ambient temperature and pressure. This method has been found to successfully deliver neutral indium atoms far downstream in both a laminar non-reacting and a turbulent reacting jet in a way that also achieves a high signal-to-noise ratio. As such it overcomes many of the limitations of the existing approaches used to seed elemental-metal tracers into gaseous flows, which arise from the need to seed them as a dissolved salt in droplet form. Specifically, the new method avoids the generation of temperature gradients associated with the evaporation of seed droplets, the limitations of the droplets in following the flow, and provides for the first time an elemental marker within the low-temperature regions of the jet/flame. This shows that the method has wide general relevance and is worthy of development as a new class of seeding technique.

References

K. Kohse-Höinghaus, R.S. Barlow, M. Aldén, J. Wolfrum, Proc. Combust. Inst. 30, 89 (2005)

R.K. Hanson, Proc. Combust. Inst. 33, 1 (2011)

G.J. Nathan, P.A.M. Kalt, Z.T. Alwahabi, B.B. Dally, P.R. Medwell, Q.N. Chan, Prog. Energy Combust. Sci. 38, 41 (2012)

A.T. Hartlieb, B. Atakan, K. Kohse-Höinghaus, Appl. Phys. B 70, 435 (2000)

B. Hiller, R.K. Hanson, Exp. Fluids 10, 1 (1990)

W.G. Bessler, F. Hildenbrand, C. Schulz, Appl. Opt. 40, 748 (2001)

M.C. Thurber, R.K. Hanson, Exp. Fluids 30, 93 (2001)

R.B. Miles, E. Udd, M. Zimmerman, Phys. Lett. 32, 317 (1978)

A.G. Hsu, V. Narayanaswamy, N.T. Clemens, J.H. Frank, Proc. Combust. Inst. 33, 759 (2011)

Q.N. Chan, P.R. Medwell, P.A.M. Kalt, Z.T. Alwahabi, B.B. Dally, G.J. Nathan, Appl. Opt. 49, 1257 (2010)

I.S. Burns, J. Hult, G. Hartung, C.F. Kaminski, Proc. Combust. Inst. 31, 775 (2007)

J. Bakos, I. Földes, P.N. Ignácz, G. Kocsis, J. Szigeti, J. Kovács, Opt. Commun. 74, 374 (1990)

K. Alti, A. Khare, Laser Part. Beams 24, 47 (2006)

C.F. Kaminski, J. Engström, M. Aldén, Proc. Combust. Inst. 27, 85 (1998)

P.R. Medwell, Q.N. Chan, P.A.M. Kalt, Z.T. Alwahabi, B.B. Dally, G.J. Nathan, Appl. Opt. 48, 1237 (2009)

P.R. Medwell, Q.N. Chan, P.A.M. Kalt, Z.T. Alwahabi, B.B. Dally, G.J. Nathan, Appl. Spectrosc. 64, 173 (2010)

B.B. Dally, A.R. Masri, R.S. Barlow, G.J. Fiechtner, Combust. Flame 114, 119 (1998)

Acknowledgements

The authors wish to acknowledge the support of the Centre for Energy Technology (CET) and The University of Adelaide. The Australian Research Council (ARC) is also gratefully acknowledged for their funding support of this work through ARC Discovery and Linkage Infrastructure, Equipment and Facilities (LIEF) grant schemes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Medwell, P.R., Chan, Q.N., Dally, B.B. et al. Flow seeding with elemental metal species via an optical method. Appl. Phys. B 107, 665–668 (2012). https://doi.org/10.1007/s00340-012-5065-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5065-y