Abstract

We demonstrate that long-range surface plasmon waveguide biosensors are useful to monitor the quiver of immobilized live bacteria in buffer and in human urine. First, the biosensor captures bacteria selectively, based on gram, using antibodies against gram adsorbed on the surface of the waveguide through Protein G coupling. Then, analysis of the noise present on the optical output signal reveals quiver of bacteria immobilized on the waveguide. Live bacteria produce a noisy signature compared to baseline levels. The standard deviation over time of the optical power output from the biosensor increased by factors of 3–60 over that of the baseline level for Staphylococcus epidermidis and Escherichia coli immobilized selectively on waveguides.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The culture of bacteria on an agar plate is generally used to determine the number of living bacteria (colony forming units—CFUs) in a sample. This is the standard technique for the diagnosis of many human infections, including urinary tract infection [1]. Other techniques such as nitrite dipsticks [2] offer indirect measurements of bacterial activity through the conversion of nitrate to nitrite, but not all bacteria generate nitrite. Flow cytometry can provide a rapid evaluation of bacteria concentration to levels less than 105 bacteria/ml [3,4,5], but such tests do not inform about bacterial activity (viability). Staining combined with flow cytometry can provide a selective count [6] but provides no evidence of the detected bacteria’s activity other than reaction with the stain.

Long-range surface plasmon-polariton (LRSPP) waveguides are compelling as label-free biosensors because of their high sensitivity and their ability to detect analyte over a large dynamic range in mass (from proteins to cells). They were used to detect the formation of protein adlayers [7], to selectively detect human red blood cells based on type [8], to detect Dengue infection in patient blood plasma [9, 10], and leukemia in patient sera [11]. These sensors were also used to selectively detect bacteria in human urine by adsorption on a surface functionalized with antibody against gram (lipopolysacchharide for gram-negative bacteria or lipoteichoic acid for gram-positive bacteria) [12]. Other label-free biosensors, such as surface plasmon resonance (SPR) biosensors [13,14,15] and LRSPP resonance biosensors [16, 17], have been used to detect bacteria in clean fluids. To date, none of these have been used to monitor bacterial activity or assess bacterial viability. Yet in most applications involving the detection of bacteria, it is imperative to determine whether they are alive or dead as dead bacteria are generally not threatening.

Here, we investigate the ability of label-free LRSPP waveguide biosensors to detect bacterial activity by simply monitoring the noise component of the biosensor signals generated by immobilized live bacteria in buffer and in human urine. Experimental results demonstrate significantly increased signal variations (noise) relative to baseline levels, indicative of quiver or growth, thus providing a means to assess bacteria viability.

2 Materials and methods

2.1 Chemical and biochemical reagents

Unless stated otherwise, all chemicals were acquired from Sigma-Aldrich (S-A), including: Phosphate-buffered saline (PBS, 0.01 M, pH 7.4), 2-isopropanol semiconductor grade (IPA), acetone HPLC grade ≥99.9%, glycerol (electrophoresis grade), sodium dodecyl sulfate (SDS, 71725-50G) and LB broth (Lennox). Distilled deionized water (DIH2O) was obtained from a Barnstead™ Nanopure™ system (D11931). Our PBS Glycerol (PBSG) buffer solutions were filtered through Millex-GP filters (PES membrane 0.22 μm).

Our labeling convention to identify prepared solutions is to use an acronym, concatenated with a date in the format mmdd where mm and dd are the month and day of creation (2015), as listed in Table 1. Labeled fluid VialGprot consisted of Protein G (P4689-1MG, 100 μg/ml) dissolved in PBSG0206 and was used to functionalize the bare gold surface of a die. Labeled fluid VialGNeg consisted of antibody against gram-negative bacteria (Abcam, AB41202, 50 μg/ml, targets lipopolysaccharide on the bacteria membrane) dissolved in PBSG0206. Labeled fluid VialGPos consisted of antibody against gram-positive bacteria (Abcam, AB20344, 50 μg/ml, targets lipoteichoic acid on the bacteria membrane) dissolved in PBSG0206. These solutions were used with protein G to produce an antibody-functionalized surface [11].

A human urine sample was collected from the donor on the day of experimentation [18]. The urine sample was centrifuged at 3000 rpm for 7 min and the supernatant filtered through Millex-GP filters.

Escherichia coli XL1 Blue (ECOLI, gram negative) and Staphylococcus epidermidis ATCC 12228 (SEPI, gram positive) bacteria were donated by the Canadian Blood Services (CBS). Inoculation of bacteria into LB Broth was done aseptically in the CAREG laboratory of the University of Ottawa. Weekly cultures of the bacteria were grown in 10 ml vials and incubated at 37 °C. The cultured bacteria were centrifuged at 3000 RPM for 7 min and the supernatant removed with a syringe and replaced with a PBS, PBSG or a filtered urine test solution as required by the experiment.

2.2 Biosensors

The detailed process applied to fabricate the biosensors is given in [19]. Briefly, the biosensors consist of a Au stripe, 5-μm-wide and 35-nm-thick, embedded in Cytop on a 4-inch Si wafer. Spin-coating and curing were used to create the Cytop claddings, and Au evaporation and lift-off were used to define the Au features. The top Cytop cladding was etched to the Au stripe surface to define the fluidic channel. Figure 1a shows an optical microscope image of an array of straight waveguide biosensors in a fluidic channel. The biosensors were excited by butt-coupling to a polarization-maintaining optical fiber and the output monitored using an infrared camera and a power sensor as described in [12]. Figure 1b gives a sketch of the optical and fluidic assembly adopted.

2.3 Die cleaning

Sensor dies were cleaned by ultra-sonication (FB-11201, Fisher Scientific) in heptane for 5 min to remove possible debris. The dies were then left immersed in two sequential acetone baths for 5 and 30 min to completely remove the dicing photoresist. After thorough washing in IPA and drying with N2, the dies were placed in a digital UV ozone system (PSD-UV-4, Novascan) to remove any possible organic matter from the Au surface. The dies were then washed intensely with IPA and DIH2O followed by Nitrogen (N2) drying. Cleaned sensor die, once mounted in the test jig, was all primed with DIH2O before incorporating them into the test system. Tweezers and vials were cleaned using a similar process.

2.4 Surface functionalization

The sensor dies were functionalized by immersion into VialGProt0206 solution for 20 min. Following this step, and for a gram-negative selective surface, a die was transferred into VialGneg0206 for 80 min, which resulted in the formation of a monolayer of gram-negative antibody. For a gram-positive selective surface, a die was transferred into VialGPos0206 for 80 min, which resulted in the formation of a monolayer of gram-positive antibody. Dies were stored in PBS vials until use.

3 Microscope observations

To capture images of bacteria activity, we used blanket Au-coated Si die, functionalized with an antibody. Specifically, one die functionalized with gram-positive antibody and one die functionalized with gram-negative antibody were used, as identified in the last two rows of Table 1 (Die0207Gneg and Die0207Gpos). Each die was then exposed to S. epi or E. coli via transfer into vials (VialSEPI0214 and VialECOLI0214) then placed on a slide without drying for microscopic observation. The residual solution on the die contained bacteria making it difficult to focus on the surface, so we diluted the residual with PBS (using a syringe).

The microscope image given in Fig. 2a shows E. coli bacteria immobilized on the Au surface of Die0207Gneg. Upon careful observation of an associated video (Online Resource 1), we note subtle fluctuations over time in the position of several E. coli bacteria about an immobilization point (quiver). Some bacteria are fixed at only one extremity, which allows them to quiver about their anchor point [20]. Figure 2b shows a microscope image of several E. coli bacteria immobilized on a Au stripe in a microfluidic channel on a biosensor chip. The Au stripe was functionalized with antibody against negative gram.

We surmise that quiver of bacteria would produce measurable changes in the output signal of the biosensor. Optically, the quiver of a bacterium produces a time-varying change in the local refractive index because the bacterium displaces sensing solution of comparatively lower refractive index (buffer or urine). The local refractive index is sensed by the propagating LRSPP, so fluctuations in the local index produce fluctuations in the attenuation of the LRSPP, and correspondingly, in the output power. Signals are compared to baseline levels before (or after) bacteria immobilization, so increased fluctuations can be used as an indication of bacterial quiver or activity.

4 Sensing results

The experimental protocol consists of injecting a sequence of fluids, some containing live bacteria, over the surface of a waveguide functionalized with antibody against either gram-positive or gram-negative bacteria [12]. Initially, buffer is injected to establish a stable low-noise baseline signal. Then, negative control bacteria (either live S. epi or E. coli) are injected and the flow stopped to allow bacteria to settle on the surface of the waveguide. After a settling time, buffer is injected (rinse step) and most of the bacteria are washed away—few remain immobilized due to non-specific binding. Then, the target bacteria (either live E. coli or S. epi, respectively) are injected and the flow stopped to allow bacteria to settle. After a settling time, buffer is injected (rinse step) but this time few bacteria are washed away—most remain immobilized due to antibodies on the waveguide bonding with antigen on the bacteria membrane. Finally, recovery of the initial baseline signal level is achieved by flowing SDS (wash step) to remove bound bacteria by breaking the antibody–antigen bond. The buffer used in the experiments was either filtered PBSG or urine.

The power detector used to monitor the biosensor output optical power provides an average measurement over its video bandwidth. The power sensor software averages 100 power measurements over one second, which is taken as the biosensor response. The power variation (signal variation) was computed as P out(t 0 + nΔt) − P out(t 0) where P out(t 0 + nΔt) is the output power at time nΔt after the reference time t 0 , n is an integer and Δt is the time interval between power samples (1 s). The reference time t 0 and reference power P out(t 0 ) are taken after a rinse step using filtered PBSG or filtered urine. The rinse steps lasted at least 3 min in order to completely remove any loosely bound material from the waveguide and microfluidic channel. After the rinse step, the waveguide has either negative control bacteria immobilized thereon by non-specific binding, or the target bacteria immobilized thereon via antibody-antigen bonds. We consider the signal variation over a 96 s timeframe (i.e., the variation over 96 average power measurements, with each average power obtained from 100 measurements taken over 1 s).

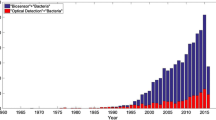

Figure 3 shows the signal variation caused by E. coli bacteria (gram negative), immobilized on a waveguide functionalized with antibody against gram-negative bacteria, under a 20 μl/min flow of filtered PBSG. The standard deviation of this signal is 50 nW. The baseline responses before bacteria immobilization, and after bacteria removal via the SDS wash, are observed to be significantly less noisy. The standard deviations of these signals are 0.8 and 2 nW, respectively. Comparing these signals and their standard deviations clearly reveals that bacterial activity can be monitored, as the immobilized bacteria increased significantly the signal variation (noise) over that of the baseline level—in this case by a factor of ~60 (50/0.8). This increase is attributed primarily to quiver of the immobilized bacteria, as discussed in Sect. 3. E. coli requires about 20 min (1200 s) to multiply and grow to full size in growth media, thus the 96 s observation timeframe, which corresponds to 8% of the growth time, may also produce a detectable change in signal. S. epi bacteria (gram positive), used as the negative control, also increased the signal variation, as observed in Fig. 3. The standard deviation of the S. epi signal is 10 nW. Table 2 summarizes the standard deviation of each signal.

Signal variation caused by E. coli bacteria immobilized on a waveguide functionalized with antibody against gram-negative bacteria in PBSG; S. epi used as a negative control. The baseline responses before and after bacteria immobilization are also shown. Filtered PBSG flows at 20 μl/min

Figure 4 compares signal variations for a waveguide functionalized with antibody against gram-negative bacteria, where filtered PBSG and filtered urine were used as sensing solutions. Baseline signals in PBSG and urine are provided for reference. E. coli was used as the positive control and S. epi as the negative control. The standard deviations of the signals are given in Table 2. Again, it is noted that immobilized bacteria increase the standard deviation, notably in this case by a factor of 9 for the detection of E. coli in urine, relative to the urine baseline. This increase is sufficiently large to be significant, although smaller than the factor of ~60 noted earlier (Fig. 3) for detection in PBSG. This may be due to less E. coli bacteria immobilized on the waveguide in urine compared to PBSG, or to less contrast in refractive index for bacteria in urine compared to PBSG.

Signal variation caused by E. coli bacteria immobilized on a waveguide functionalized with antibody against gram-negative bacteria in PBSG and in urine; S. epi used as a negative control. The baseline responses before and after bacteria immobilization are also shown. Filtered PBSG or urine flows at 20 μl/min

Figure 5 shows the signal variation caused by S. epi bacteria (gram positive), immobilized on a waveguide functionalized with antibody against gram-positive bacteria, under a 20 μl/min flow of filtered urine. The signal variation of the urine baseline before bacteria immobilization is also shown for reference, as is the signal variation due to non-specifically bound E. coli bacteria (negative control). Table 2 summarizes the standard deviation of each signal. We note that the standard deviation of the S. epi response is larger than that of the baseline signal by a factor of 3. This increase is sufficiently large to be significant, although smaller than the factor of 9 noted earlier (Fig. 4) for the detection of E. coli in urine. This may be due to less S. epi bacteria immobilized on the waveguide, or to the fact that S. epi is spheroidal and smaller than E. coli thus perturbing less the propagating LRSPP. Non-specifically immobilized E. coli bacteria produce a significantly larger standard deviation than that of the baseline response.

Signal variation caused by S. epi bacteria immobilized on a waveguide functionalized with antibody against gram-positive bacteria in urine; E. coli used as a negative control. The baseline response before bacteria immobilization is also shown. Filtered urine flows at 20 μl/min

The full sensor grams associated with Figs. 3, 4 and 5 indicate a larger response for the positive control bacteria, relative to the negative control bacteria, such that selective detection of bacteria based on gram, in PBSG and human urine, was achieved [12]. The signal variation (noise) and corresponding standard deviation reported herein and summarized in Table 2 indicate that bacterial quiver can also be detected, whether bacteria are immobilized selectively (antibody-antigen bond) or non-specifically.

The signal variations observed are attributable to the presence of live bacteria on waveguides, and although additional experimentation would be required to differentiate growth from quiver, both can be attributed to bacterial viability. Controls are provided throughout the experiments via SDS wash steps which cleaves the bonds between the sensing surface and bacteria, such that a stable and low-noise baseline signal is recovered. The viability of the bacteria used in the experiments was independently verified by growing samples of the bacterial solutions to determine the concentration levels (CFUs).

5 Conclusions

Our experiments demonstrate that LRSPP waveguides can detect the quiver of live bacteria immobilized thereon through increased noise on the output signal. Quiver of bacteria produce a time-varying change in the local refractive index, sensed by propagating LRSPPs which produce corresponding fluctuations in the output optical power. Signals are compared to baseline levels before bacteria immobilization, leading to conclusive indications of bacterial activity. The standard deviation over time (noise) of the output optical power from the biosensor increased by factors of 3–60 over that of the baseline level for S. epi and E. coli bacteria immobilized selectively on waveguides. E. coli bacteria produce more noise than S. epi, possibly due to their larger size. The measurements were taken in filtered PBSG and in filtered human urine.

References

G. Schmiemann, E. Kniehl, K. Gebhardt, M. Matejczyk, E. Hummers-Pradier, The diagnosis of urinary tract infection: a systematic review. Dtsch. Arztebl. Int. 107, 361–367 (2010)

J.A. Simerville, W.C. Maxted, J.J. Pahira, Urinalysis: a comprehensive review. Am. Fam. Phys. 71, 1153–1162 (2005)

M.A. Broeren, S. Bahceci, H.L. Vader, N.L. Arents, Screening for urinary tract infection with the Sysmex UF-1000i urine flow cytometer. J. Clin. Microbiol. 49, 1025–1029 (2011)

M. Marschal, M. Wienke, S. Hoering, I.B. Autenrieth, J.-S. Frick, Evaluation of 3 different rapid automated systems for diagnosis of urinary tract infection. Diagn. Microbiol. Infect. Dis. 72, 125–130 (2012)

J. Wang, Y. Zhang, D. Xu, W. Shao, Y. Lu, Evaluation of the Sysmex UF-1000i for the diagnosis of urinary tract infection. Am. J. Clin. Pathol. 133, 577–582 (2010)

M.A. Van Dilla, R.G. Langlois, D. Pinkel et al., Bacterial characterization by flow cytometry. Science 220, 620–622 (1983)

O. Krupin, H. Asiri, C. Wang, R.N. Tait, P. Berini, Biosensing using straight long-range surface plasmon waveguides. Opt. Express 21, 698–709 (2013)

O. Krupin, C. Wang, P. Berini, Selective capture of human red blood cells based on blood group using long-range surface plasmon waveguides. Biosens. Bioelectr. 53, 117–122 (2014)

W.R. Wong, O. Krupin, S.D. Sekaran, F.R.M. Adikan, P. Berini, Serological diagnosis of dengue infection in blood plasma using long-range surface plasmon waveguides. Anal. Chem. 86, 1735–1743 (2014)

W.R. Wong, S.D. Sekaran, F.R.M. Adikan, P. Berini, Detection of dengue NS1 antigen using long-range surface plasmon waveguides. Biosens. Bioelectr. 78, 132–139 (2016)

O. Krupin, C. Wang, P. Berini, Detection of leukemia markers using long-range surface plasmon waveguides functionalized with protein G. Lab Chip 15, 4156–4165 (2015)

P. Béland, O. Krupin, P. Berini, Selective detection of bacteria in urine with a long-range surface plasmon waveguide biosensor. Biomed. Opt. Expr. 6, 2908–2922 (2015)

B. Liedberg, C. Nylander, I. Lundstrom, Surface plasmon resonance for gas detection and biosensing. Sens. Act. 4, 299–304 (1983)

P.M. Fratamico, T.R. Strobaugh, M.B. Medina, A.G. Gehring, Detection of Escherichia coli O157:H7 using a surface plasmon resonance biosensor. Biotechnol. Technol. 12, 571–576 (1998)

Ö. Torun, İ.H. Boyac, E. Temür, U. Tamer, Comparison of sensing strategies in SPR biosensor for rapid and sensitive enumeration of bacteria. Biosens. Bioelectr. 37, 53–60 (2012)

M. Vala, S. Etheridge, J. Roach, J. Homola, Long-range surface plasmons for sensitive detection of bacterial analytes. Sens. Act. B 139, 59–63 (2009)

V. Chabot, Y. Miron, M. Grandbois, P.G. Charette, Long range surface plasmon resonance for increased sensitivity in living cell biosensing through greater probing depth. Sens. Act. B 174, 94–101 (2012)

ethics@uottawa.ca, Bureau d’éthique et d’intégrité à la recherche, 75 Ave. Laurier Est, Université d`Ottawa, K1 N 6N5, numéro de dossier H06–14–01, 23 juin 2014 (personal communication, 2014)

C. Chiu, E. Lisicka-Skrzek, R.N. Tait, P. Berini, Fabrication of surface plasmon waveguides and devices in Cytop with integrated microfluidic channels. J. Vac. Sci. Technol. B 28, 729–735 (2010)

Z. Suo, R. Avci, X. Yang, D.W. Pascual, Efficient immobilization and patterning of live bacterial cells. Langmuir 24, 4161–4167 (2008)

Acknowledgements

We are grateful to the Ontario Centres of Excellence (OCE) for funding this work under project number 21107. We are grateful to Canadian Blood Services (Sandra Ramirez, sandra.ramirez@blood.ca) for donating two bacteria strains: Escherichia coli (E. coli) XL1 Blue and Staphylococcus epidermidis (S. epi) ATCC 12228. We are grateful to Oleksiy Krupin for assistance with the application of the surface chemistries.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MP4 9863 kb)

Rights and permissions

About this article

Cite this article

Béland, P., Berini, P. Viability assessment of bacteria using long-range surface plasmon waveguide biosensors. Appl. Phys. A 123, 31 (2017). https://doi.org/10.1007/s00339-016-0625-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0625-3