Abstract

Deep ultraviolet photodetectors based on p-Si/n-Ga2O3 and p-Si/i-SiC/n-Ga2O3 heterojunctions were fabricated by laser molecular beam epitaxial (L-MBE), respectively. In compare with p-Si/n-Ga2O3 heterostructure-based photodetector, the dark current of p-Si/i-SiC/n-Ga2O3-based photodetector decreased by three orders of magnitude, and the rectifying behavior was tuned from reverse to forward. In order to improve the quality of the photodetector, we reduced the oxygen vacancies of p-Si/i-SiC/n-Ga2O3 heterostructures by changing the oxygen pressure during annealing. As a result, the rectification ratio (I F/I R) of the fabricated photodetectors was 36 at 4.5 V and the photosensitivity was 5.4 × 105% under the 254 nm light illumination at −4.5 V. The energy band structure of p-Si/n-Ga2O3 and p-Si/i-SiC/n-Ga2O3 heterostructures was schematic drawn to explain the physic mechanism of enhancement of the performance of p-Si/i-SiC/n-Ga2O3 heterostructure-based deep UV photodetector by introduction of SiC layer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

β-Ga2O3-based ultraviolet (UV) photodetectors [1–7], such as p–n junctions, metal–semiconductor–metal (MSM) and Schottky barrier structures, have attracted intensitive attentions due to the unique physical properties of β-Ga2O3, including a direct band gap of 4.9 eV, high transparency, low cost and high resistance to radiation. Compared with MSM photodetector, junction-based detector usually exhibits extraordinary behavior, such as large photoelectric responsivity and fast response speed. On the other hand, β-Ga2O3 shows a n-type semiconductor due to the presence of a donor band related to intrinsic oxygen deficiency [8, 9]. Thus, a p-Si/n-Ga2O3 heterojunction photodetector has been developed owing to the low cost of the Si substrate and easy fabricated for integrated circuits [7]. However, a large dark current is critical issues associated with the heterojunction photodetectors owing to the thick Si substrate [7, 10]. In fact, the dark current can be reduced by inserting an intrinsic (i) layer between p and n layers [11–14]. Recently, Chen et al. reported that the n-ZnO/p-Si NWs photodiodes exhibit high responsivity under a reverse bias by inserting an ultrathin SiO2 layer on top of Si NWs [15]. Alternatively, Guo et al. reported that n-ZnO/i-MgO/p-Si photodetector showed a rectification ratio of about 104 at 2 V and a dark current of 0.5 nA at −2 V [16]. Based on the literatures mentioned above, SiC as a wide band gap material is promised to be an appropriate hole blocking layer to improve photoelectric performances of p-Si/i-SiC/n-Ga2O3 photodetectors.

In this study, p-Si/n-Ga2O3 and p-Si/i-SiC/n-Ga2O3 UV photodetectors were fabricated by different oxygen pressure. The UV photodetectors exhibit advantageous photoelectric performances by introducing SiC layer and modulating oxygen vacancy, such as the increase in rectifying ratio and the enhancement of photoresponse property.

2 Experimental

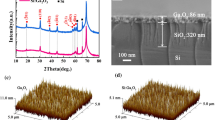

The p-Si/n-Ga2O3 and p-Si/i-SiC/n-Ga2O3 heterojunction photodetectors were fabricated using L-MBE technique. The laser ablation with a fluence of 5 J/cm2 was carried out with a repetition rate of 1 Hz by using a KrF excimer laser with a wavelength of 248 nm. The distance between target and substrate was 5 cm, and the substrate was rotated during deposition to improve the film uniformity. Two targets of pure Ga2O3 and pure SiC were employed to deposit Ga2O3 and i layer SiC thin films, respectively. The base pressure in chamber was 1 × 10−6 Pa. The substrate temperature was kept at 750 °C. For p-Si/i-SiC/n-Ga2O3 deposition in vacuum (p–i–n D in V), SiC film was deposited for 4000 pulse before the Ga2O3 film was deposited for 7000 pulse upon vacuum conditions, then annealing for 1 h under 1 Pa oxygen pressure. For p-Si/i-SiC/n-Ga2O3 deposition in O2 (p–i–n D in O2), SiC film was deposited for 4000 pulse upon vacuum conditions, and then, the Ga2O3 film was deposited for 7000 pulse under 1 × 10−3 Pa oxygen pressure, followed annealing for 1 h under 1 Pa oxygen pressure. And in order to avoid SiC layer oxidized, Ga2O3 film deposited 5 min upon vacuum conditions before under 1 × 10−3 Pa oxygen pressure. The thickness of the SiC films and Ga2O3 films were estimated by scanning electron microscope (SEM) to be about 70 and 400 nm, respectively. The crystal structure was measured by a Bruker D8 Advance X-ray diffractometer (XRD). The surface of thin film was checked in situ by means of reflection high-energy electron diffraction (RHEED). The oxygen vacancies of as-grown and post-annealing samples were investigated by X-ray photoelectron spectroscopy (XPS). Au/Ti (100 nm) and Au (100 nm) electrodes (radius = 1 mm) were successively sputtered as cathode for n-Ga2O3 thin film and anode p-type silicon substrate, a good ohmic contacts were achieved in both electrodes for all the detectors. The I–V curves and time-dependent photoresponse of the photodetectors were measured by Keithley 2450. A 6 W lamp was employed to provide the 254 nm UV for the photocurrent measurement.

3 Result and discussion

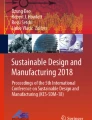

Figure 1 shows the XRD patterns of three samples. The peaks located at around 18.94°, 38.42° and 59.08° are observed, corresponding to β-Ga2O3 \((\overline{ 2} 0 1 )\), \((\overline{ 4} 0 2 )\) and \((\overline{ 6} 0 3 )\) orientations. The result indicates that the β-Ga2O3 is deposited with single orientation along the \((\overline{ 2} 0 1 )\) direction. No characteristic peak of SiC was observed, which reveals that the SiC thin film is amorphous. The inset image shows the RHEED pattern of p-Si/i-SiC/n-Ga2O3 deposition in O2. Conspicuous streak patterns imply that the Ga2O3 film has a good crystallized structure with smooth surface. The intensity of the diffraction peaks of p-Si/i-SiC/n-Ga2O3 deposition in O2 is higher to p-Si/i-SiC/n-Ga2O3 deposition in vacuum. It means that defect of the β-Ga2O3 thin film was reduced by decreasing oxygen pressure. However, oxygen pressure has not influenced the lattice parameters of films, for no shift of the β-Ga2O3 diffraction peaks position is observed in these samples. The growth condition of Ga2O3 thin film of p-Si/n-Ga2O3 is same with that of p-Si/i-SiC/n-Ga2O3 deposition in O2, and the p-Si/n-Ga2O3 photodetector was studied in our group in detail [7]. So, we mainly focused on the investigation of the samples with SiC layer in this study.

Figure 2 shows the O1 s peak of p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2, which can be divided into two components (I and II). The II peak that is usually associated with oxygen vacancy [6] is highly suppressed with higher oxygen pressure during film deposition, indicating that the oxygen vacancy concentration decreased. Thus, it is reasonable to infer that oxygen vacancy concentration in the β-Ga2O3 thin films can be tuned by using different oxygen pressure.

Figure 3b shows the I–V characteristics of p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2 under dark condition, in which the I–V curve of p-Si/n-Ga2O3 structure is also presented for comparison. The schematic drawing of fabricated prototype heterojunction UV photodetector is shown in Fig. 3a. The ohmic contact of Au/Ti/n-Ga2O3/SiC on a sapphire substrate and Au/Ti/SiC has been confirmed by the linear I–V curve under the same conditions (inset in Fig. 3b). The resistance of SiC is greater than that of Ga2O3. So, SiC layer plays the role of an appropriate electron-blocking layer in this work. A reverse rectifying behavior is observed in the conventional p-Si/n-Ga2O3 photodetector [7]. However, I–V characteristics of p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2 exhibit forward rectifying behavior by inserting i-SiC layer. Meanwhile, compared with the p-Si/n-Ga2O3 photodetector, the dark current of p–i–n structure (p-Si/i-SiC/n-Ga2O3 deposition in O2) is effectively reduced by three orders of magnitude owing to the insertion of i-SiC layer. Additionally, p-Si/i-SiC/n-Ga2O3 deposition in O2 shows a lower dark current than that of p-Si/i-SiC/n-Ga2O3 deposition in vacuum due to oxygen vacancy decrease.

a Schematic diagram of p-Si/i-SiC/n-Ga2O3 heterojunction photodetector; b I–V curves of p-Si/i-SiC/n-Ga2O3 heterojunctions photodetectors in dark that of conventional p-Si/n-Ga2O3 heterojunction detector is also presented for comparison. The insets, respectively, show I–V characteristics of the n-Ga2O3/SiC heterojunction (top left) and the SiC layer (bottom right) prepared on a sapphire substrate under vacuum condition

In order to further check the solar blind UV responsivity of the photodetector, we measure the I–V curves of p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2 in dark and under the 254 nm light illumination, respectively. The power density of 254 nm light is 12 μW/cm2. Figure 4a shows the I–V curves of photodetectors with log-linear scale. Compared with corresponding dark currents, the photocurrents of p-Si/i-SiC/n-Ga2O3 deposition in O2 and p-Si/i-SiC/n-Ga2O3 deposition in vacuum increase from 3.2 × 10−8 A and 2.2 × 10−6 A to 1.9 × 10−4 A and 7.4 × 10−4 A under the 254 nm light illumination at −4.5 V. The photosensitivity is defined as (I light–I dark)/I dark as a percentage (I light is the current of the detector when illuminated with a light, and I dark is the dark current). Under the 254 nm light illumination with a bias voltage of −4.5 V, the photosensitivity of the p-Si/i-SiC/n-Ga2O3 deposition in O2 is found to be 5.4 × 105%, which is much higher than that of p-Si/i-SiC/n-Ga2O3 deposition in vacuum (3.4 × 104%).

In Fig. 4b, the log–log scale plot of the injection currents for p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2 shows three different regions depending on the range of the junction voltage. In a very low voltage for V < −0.28 V (region I), the detectors show high resistance and a linear dependence of the current on the voltage (I–V) is observed, indicating that the transport mechanism obeys ohmic law. In region II, −0.28 V < V < −1 V, the currents increased exponentially following a relation I ~ exp(αV), which is usually observed in the wide band gap (p–n) detector due to a recombination tunneling mechanism [10]. By fitting the experimental data, the constant α of p-Si/i-SiC/n-Ga2O3 deposition in vacuum and p-Si/i-SiC/n-Ga2O3 deposition in O2 has been evaluated to be 0.6 and 0.57 V−1 (falling in the range of 0.45–1.45 V−1 for the semiconductor junctions), which explains the high carrier (electrons) injection. However, beyond −1 V, the current across the junction is dominated by the holes injection because the concentration and mobility of the holes in Si are higher than those of electrons in Ga2O3.

Before explaining the transport mechanism, it is necessary to understand the energy band diagram of the junction. Figure 5a shows the band diagram of the p-Si/i-SiC/n-Ga2O3 photodetector. The electron affinity of χ Ga2O3, χ SiC and χ p-Si was 4.0, 3.45 and 4.05 eV, respectively. The band gap of Ga2O3, SiC and p-Si was 4.9, 3.2, and 1.12 eV. According to the Anderson model, the conduction band offset of Ga2O3/SiC was ΔE c = 0.55 eV, and the valence band offset of SiC/p-Si was ΔE v = 1.48 eV.

Without the insulated layer, electrons will drift from p-Si to Ga2O3, while holes drift from Ga2O3 to p-Si under reverse bias. In contrast, most of the electrons and holes in depletion receive high energy from the strong electric filed in barrier region and collide with lattice atoms of barrier region. The electrons of valence are collided, creating conduction electron and valence hole. Thus, avalanche effect appeared in the depletion layer and produces a large number of carriers. It leads to the enhancement of reverse current [7].

The situations are different with the presence of the SiC appropriate electron-blocking layer. Under the reverse bias, most of the voltage will be applied on the SiC layer due to its dielectric nature. Thus, the bands of SiC will be bended, and the effective barrier in the vicinity of valence band is greatly increased. Consequently, electrons in the p-Si layer can cross the barrier and enter into the Ga2O3 layer, while holes will be confined in the Ga2O3 layer by large valence band offset between Ga2O3 and SiC due to the SiC dielectric layer (Fig. 5d). Under the positive voltage, the band offsets of Ga2O3/SiC was 0.55 eV, and the electrons in n-Ga2O3 were considerably larger than that of the p-Si, the plenty of electrons in the Ga2O3 layer absorbing energy though the SiC barrier enter into p-Si layer (Fig. 5e). Ultimately, the current under the positive bias is greater than the one under the reverse bias.

When the detector at a reverse bias is illuminated by 254 nm light, the light is absorbed in the depletion region near i-SiC/n-Ga2O3 interface; the photo-generated carriers are extracted to the outer circuit. The photo-generated holes cross the barrier into the p-Si. On the other hand, our Ga2O3 film is highly transparent above 250 nm, meaning that electrons–hole pairs are produced in the p-Si layer when it absorbs UV photons. The photo-generated electronics cross the barrier into the Ga2O3 layer. Therefore, the photocurrents greatly increase (Fig. 5f). Under the positive voltage, the photo-generated electronics cross the barrier into the p-Si layer. Therefore, parts of light cross the Ga2O3 layer into the p-Si, electronics and holes produced in the p-Si. These photo-generated electronics cross the SiC barrier into the Ga2O3 (Fig. 5g).

4 Conclusion

The p-Si/i-SiC/n-Ga2O3 heterojunction-based photodetectors were fabricated by inserting SiC appropriate electron-blocking layer between Ga2O3 film and p-Si substrate. The oxygen vacancies were reduced by changing the annealing process. After introduction of SiC layer and reduction in oxygen vacancies, the performance of the photodetector was obviously improved. The experimental results reported here demonstrated a potential application of p-Si/i-SiC/n-Ga2O3 heterojunction in photoelectronic devices. And the process described here might be also helpful for design and fabrication photoelectronic devices based on Ga2O3.

References

L. Li, E. Auer, M. Liao, X. Fang, T. Zhai, U.K. Gautam, A. Lugstein, Y. Koide, Y. Bando, D. Golberg, Nanoscale 3, 1120–1126 (2011)

Y.H. An, D.Y. Guo, S.Y. Li, Z.P. Wu, Y.Q. Huang, P.G. Li, L.H. Li, W.H. Tang, J. Phys. D Appl. Phys. 49, 285111 (2016)

Y.H. An, D.Y. Guo, Z.M. Li, Z.P. Wu, Y.S. Zhi, W. Cui, X.L. Zhao, P.G. Li, W.H. Tang, RSC Adv. 6, 66924 (2016)

R. Suzuki, S. Nakagomi, Y. Kokubun, N. Arai, S. Ohira, Appl. Phys. Lett. 94, 222102 (2009)

Y.H. An, X.L. Chu, Y.Q. Huang, Y.S. Zhi, D.Y. Guo, P.G. Li, Z.P. Wu, W.H. Tang, Prog. Nat. Sci: Mater. 26, 65–68 (2016)

D.Y. Guo, Z.P. Wu, Y.H. An, X.C. Guo, X.L. Chu, C.L. Sun, L.H. Li, P.G. Li, W.H. Tang, Appl. Phys. Lett. 105, 023507 (2014)

X.C. Guo, N.H. Hao, D.Y. Guo, Z.P. Wu, Y.H. An, X.L. Chu, L.H. Li, P.G. Li, M. Lei, W.H. Tang, J. Alloy. Compd. 660, 136–140 (2016)

J. Varley, J. Weber, A. Janotti, C. Van de Walle, Appl. Phys. Lett. 97, 142106 (2010)

Y.H. An, Y.S. Zhi, W. Cui, X.L. Zhao, Z.P. Wu, D.Y. Guo, P.G. Li, W.H. Tang, J. Nanosci. Nanotechnol. 17, 1–4 (2017)

M.L. Lee, P.F. Chi, J.K. Sheu, Appl. Phys. Lett. 94, 013512 (2009)

H. Zhu, C.X. Shan, B. Yao, B.H. Li, J.Y. Zhang, Z.Z. Zhang, D.X. Zhao, D.Z. Shen, X.W. Fan, Y.M. Lu, Z.K. Tang, Adv. Mater. 21, 1613–1617 (2009)

J.C. Carrano, T. Li, P.A. Grudowski, C.J. Eiting, D. Lambert, J.D. Schaub, R.D. Dupuis, J.C. Campbell, Electron. Lett. 34, 692–693 (1998)

Y. Irokawa, B. Luo, J. Kim, J.R. LaRoche, F. Ren, K.H. Baik, S.J. Pearton, C.C. Pan, G.T. Chen, J.I. Chyi, S.S. Park, Y.J. Park, Appl. Phys. Lett. 83, 2271–2273 (2003)

J.D. Hwang, D.H. Wu, S.B. Hwang, Photon. Technol. Lett. IEEE 26, 1081–1084 (2014)

C.Y. Huang, Y.J. Yang, J.Y. Chen, C.H. Wang, Y.F. Chen, L.S. Hong, C.S. Liu, C.Y. Wu, Appl. Phys. Lett. 97, 013503 (2010)

T.C. Zhang, Y. Guo, Z.X. Mei, C.Z. Gu, X.L. Du, Appl. Phys. Lett. 94, 113508 (2009)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51572033, 61274017, 51572241 and 11404029).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

An, Y., Zhi, Y., Wu, Z. et al. Deep ultraviolet photodetectors based on p-Si/i-SiC/n-Ga2O3 heterojunction by inserting thin SiC barrier layer. Appl. Phys. A 122, 1036 (2016). https://doi.org/10.1007/s00339-016-0576-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0576-8