Abstract

A mathematical modeling approach was proposed combining the capabilities of response surface methodology (RSM) and desirability function (DF) and implemented successfully in production of printing toner particles. Toner powders were systematically synthesized through suspension copolymerization process. Applying RSM, a series of experiments were designed and toner particles were prepared and the effects of monomer ratio, colorant and surfactant content on the particle size (PS), particle size distribution (PSD), thermal and colorimetric properties (∆E) of the resulting toner were monitored and discussed. The second-order models corresponding to each target characteristic, i.e., PS, PSD, and ∆E of different types of toner powders, were obtained by individual optimization to express variation of each property in terms of polymerization parameters. Applying statistical calculations, the best reduced models were identified to be fed in the second step of optimization. Since toners with appropriate PS, PSD, and CP were needed, we applied multi-objective optimization based on DF approach. The results show that exact tuning of toner properties is closely possible with the aid of hybrid mathematical model developed in this work. Noticeably, desirabilities are very close to 100 %.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Toners are black printing particles based on a polymer resin [mainly poly(styrene-co-acrylic acid)], a colorant (mainly carbon black, Fe3O4), and various additives (charge control agent, silica) which are used in digital electrophotographic printing [1]. The merit of electrophotographic printing lies in its relatively low manufacturing cost, convenience, and high quality of produced image over alternatives in many applications [2]. However, the quality of images produced through the assigned technique strongly depends on the degree to which microstructural and spectroscopic properties of toner printing particles are controlled. From a utility point of view, toners possessing small particle size with a quite narrow distribution fashion are essential for achieving high-resolution images [3]. Meanwhile, toners with good color properties are the result of careful selection and fine tuning of material and operational variables [4].

In a series of publications, we synthesized variety of printing toners through emulsion aggregation, suspension, emulsion, and mini-emulsion techniques and obtained black and color toners exhibiting a wide range of physical and color characteristics [5–7]. We also produced and characterized toners with specific applications like ceramic and fluorescence toners manipulating the type and content of colorant [8, 9]. After we recognized the main and interactive influences of either materials or operational variables, a series of toner particles were developed through systematically designed experiments by response surface methodology (RSM) [10, 11]. Regardless of polymerization route, application of RSM disclosed that obvious complexities are associated with simultaneous control of reaction conversion, thermal, microstructural, and color properties of manufacture toners. Overall, our investigations disclosed that control of toner morphology while keeping sufficiently high the conversion of reaction is indeed difficult.

In a previous work, we implemented RSM to investigate the effects of agitation rate, production time, and heating rate on particle size (PS), PS distribution (PSD) and color characteristics (∆E) of toners manufactured through emulsion aggregation [11]. Applying linear, second-order, and third-order approximation functions, the mentioned properties were optimized over the experimental range of explanatory variables. The analysis of variance (ANOVA) was served through which p value and “lack-of-fit” criteria were obtained to assess the reliability of predictions. In this manner, some reduced models were obtained to detect individually variations in the PS, PSD, and ∆E of the produced toners. Though the results were quite interesting and somehow surprising from a practical point of view, difficulties associated with the control of emulsion aggregation brought serious complications to precision matching. It was realized that the RSM cannot solely provide detailed information about dependency of toner properties on operational variables, either independently or concurrently.

In the current work, we propose a mathematical approach for fine tuning of black toner properties through suspension polymerization. We hybridized RSM and desirability function (DF) techniques for multi-criteria optimization of toner properties. First, application of overlaid contour plots in case of RSM visualized the nature of variations in morphological and color characteristics and specified the amount of carbon black, monomer ratio, and surfactant content needed for achieving the desired properties, individually. Moreover, we disclosed the order of importance of the aforementioned parameters specifying their main and interactive effects on each response variable, i.e., PS, PSD, glass transition temperature (T g), and ∆E of the produced toners. After the linear, linear with interaction, and quadratic interpolating functions were examined, the equivalent reduced model was obtained for each response. The reduced models were then transferred to the second step of optimization based on DF approach, where very unique solutions were obtained for multi-criteria optimization of color and physical properties.

2 Theory of RSM and DF approaches

In a number of previous works, we applied RSM to design and optimize solutions of different problems [11–13]. Application of RSM demands implementation of first- or second-order regression over experimental data gathered in accord with the Design-Expert software. The interpolating functions typically used by the RSM are as follows:

where x and η are the changing and response variables and ε reveals error in response variable η. The coefficients of linear model (generally saying β j where j takes values 1, 2, …, k) in Eq. (1) take the individual effects of explanatory variables, while β ii and β ij in Eq. (2) take interaction between variables. When the interaction between variables is of vital importance, the use of second-order model provides more insights into the nature of process behavior. In the current work, we applied three-level three-factor Box–Behnken design (BBD) for the prediction of PS, PSD, T g , and ∆E of the produced toners. The “lack-of-fit” and coefficient of determination (R-squared or R 2) criteria were used for the analysis of variance (ANOVA) to investigate the predictability of models [14, 15].

In the second step of optimization, we applied DF approach to multi-objective optimization of color characteristics of the toners [16, 17]. Accordingly, material parameters were set to yield the most desirable toner with predetermined characteristics.

Basically, a desirability function d i (Y i ) allocates real numbers between 0 and 1 to the values of response Y i (x), with d i (Y i ) = 0 and d i (Y i ) = 1, signifying a completely undesirable and an exactly desirable or ideal response value, respectively. The individual desirabilities assigned to each response are then used to calculate overall desirability D as follows:

In Eq. (3), d i , with i = 1, … , p, are individual desirability functions, while w i are priorities in the importance of d i functions. When all responses are on predetermined target (d i = 1), D takes the maximum value (D = 1), and D value of zero exhibits that at least one response has taken a value outside of the specified limits (d i = 0, for any i), unless the multiplicative combination of d i gives a value less than or equal to the lowest value of d i . Therefore, when D takes value in between 0 and 1, the goodness of multi-objective optimization will be featured by the distance from the upper and lower limits. The desirability approach consists of three steps: (1) conducting all experiments and fitting response model for the whole responses; (2) defining individual desirability functions for each response; and (3) maximizing the overall desirability D with respect to the factors under control.

Derringer and Suich proposed individual desirability functions based on three response types as follows: (1) nominal-the-best (NTB); (2) larger-the-best (LTB); (3) smaller-the-best (STB) [17]. In case of NTB, which has been applied in this work, the individual desirability is defined as:

In Eq. (4), s and t are nonzero parameters that give direction for the shape of d function, and U and L are the upper and the lower specification limits assigned to the response y, respectively. The above function transforms the response into quantities taking values in between 0 and 1. Accordingly, d = 1 if and only if y = T, while d = 0 for y < L or y > U [18].

3 Experimental

3.1 Materials and methods

Styrene (St) and n-butylacrylate (BA) monomers were obtained from Urmia petrochemical (Iran) and Merck (Germany), respectively. Sodium dodecyl sulfate (S) surfactant, benzoyl peroxide (BPO), and azobisisobutyronitrile (AIBN) initiators were provided by Akzo Nobel (China) and Merck (Germany). The 1,6-hexanediol diacrylate (HDDA) cross-link agent was purchased from Merck (Germany), while polyvinylalcohol (PVA) stabilizer was obtained from air products (China). Carbon black (CB) colorant was provided by Degussa (Germany) under the trade name of Printex® U. The above components are used based on parts by weight (phr) with respect to 100 parts of weight of monomers; following the above order, the amounts of materials in phr were 20, 80, 1.2, 1, 2, 6, and 4, respectively. Noticeably, the above-mentioned chemicals were all used as received, except St, which was washed with a 10 wt% NaOH solution so as to remove hydroquinone inhibitor.

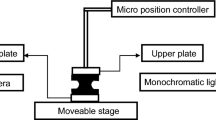

Material parameters have a considerable effect on the properties of printing toners produced through suspension polymerization of St and BA, individually and/or mutually [19]. Among parameters affecting the quality of toner, St/BA molar ratio, and CB and S contents were found to be more effective [20]. To the best of authors’ knowledge, the literature lacks a systematic study of material parameters on the properties of toner. In particular, the complex nature of mutual effects of material parameters has not been addressed yet. Applying RSM, fifteen experiments are designed to capture the effects of foregoing material parameters on the PS, PSD, T g, and ∆E of toners. Figure 1 provides a schematic view of polymerization setup implemented in this work for synthesizing toner polymeric particles.

Inspired from well-documented recipes, St and BA monomers together with S, PVA, CB, and other integrant were properly mixed prior to suspension polymerization using a mechanical homogenizer for 15 min at 8000 rpm [18]. Distilled water as polymerization media facilitated either the contact between St and BA monomers and other ingredients or heat transfer. The homogenized mixture was subsequently moved to a three-necked glass reactor. The reaction was performed with the aid of nitrogen purging at 70 °C for 6 h at an agitation speed of 400 rpm. The pigmented particle was precipitated from the mixture through centrifugation with deionized water. The powers were dried in a vacuum overnight and sored for characterization. The material parameters’ level, the appearance of toners, and their properties are illustrated in Fig. 2.

3.2 Characterization

The measured characteristics of synthesized toners are given in Fig. 2. To collect the assigned values, toners resulted from suspension polymerization were centrifuged and then dispersed in water through sonication for 2 min to break down the possible aggregates. The prepared dispersions were applied to conduct PS and PSD on a particle size analyzer (PSA, Malvern Mastersizer 2000, England). This apparatus enables tracking particles having diameter between of 0.02 and 2000 μm. The PSD was quantified by the criterion of span, as follows:

In Eq. (5), D50 specifies the situation where at least half (50) of the particles take diameters equal to or less than the predetermined size in μm. The same was the case for D90 and D10 criteria. The colorimetric investigation was carried out by means of Ihara SpectroCam (Japan).

The spectral reflectance factor of toner was first determined by X-Rite Spectrophotometer SP64 (d/8º, SCI) and then transformed into CIELAB colorimetric coordinates (L*, a*, and b*) with the aid of CIE standard illuminant D65 and CIE 1964 standard colorimetric observer (10°). The difference between color of toner and an ideal black was lastly calculated on the basis of metric ΔE [21]:

Basically, a rise in L* value stands for an improved lightness, while a positive and negative ∆a* demonstrate a color shift toward red and green, respectively. Likewise, a positive ∆b* implies a color shift toward yellow, whereas a negative ∆b* implies a color shift toward blue.

Thermal behavior assessment was conducted on a PerkinElmer differential scanning calorimeter (DSC, USA). For this purpose, samples (~5 mg) were loaded into an aluminum pan and sealed with a covering closure. Measurements were taken under nitrogen atmosphere, over a temperature range of 0–150 °C, and at a heating rate of 10 °C/min.

4 Results and discussion

The complex nature of distinct and mutual effects of material parameters on the toner properties, either individually or concurrently, brings about serious difficulties in the way optimization of process. Previous investigations regarding toner production revealed that RSM is an acceptable tool for optimization of toner properties [10, 11]. It has also been realized that the interpolating functions, in their normal form as proposed by the Design-Expert software, are not essentially adequate for proper prediction of responses. In such situations, the use of reduced form of the assigned function would be of higher reliability [22]. As described in theoretical section, the merit of combined application of RSM and DF lies in providing the ability of optimizing responses of interest both individually and simultaneously. After the reduced models proposed by the RSM, they are fed in the second step of optimization into the DF space to make possible multi-objective optimization of responses. It should be emphasized that the success/failure of multi-criteria optimizations depends strongly on to what extent the experimentalist identifies the interrelationship between process variables and target responses. For synthesizing black toner, the performance of the product is pertinent to success in controlling both physical and color properties. For instance, there might be a situation where PS, PSD, and ∆E of the produced toner have values in the desired range specified by the toner producers, but the obtained particle lacks the ability of being printed as a consequence of thermal properties not being suitable for fusing. From a technical standpoint, such products are not classified as toner. Thus, toner properties (PS, PSD, T g, and ∆E) are first optimized individually by RSM to obtain four reduced models responsible for optimizing each response over the experimental range of material parameters. To achieve the criteria for exact tuning of toner properties, three pairs of responses are defined to be optimized simultaneously. In this regard, single- and multi-objective optimization condition is determined based on RSM and DF approaches. In principal, multi-objective optimization has been carried out based on the reduced models yielded from RSM. Implementation of DF methodology for three binary responses defined as (PS, PSD), (PS, ΔE), and (PSD, ΔE) enables producing different grades of toners in which physical or physical–color characteristics are given the chance for cooperation among themselves to be tuned together. In this way, it is attempted to tune toner properties through multi-objective optimization as closely as possible.

4.1 Individual optimization of toner properties by RSM

The analysis of RSM includes obtaining predictive function and model coefficients and then documentation of optimum operating conditions. The quadratic model was found to be the best among all studied functions for the prediction of each toner characteristic. This has been realized from the significance and fitness analyses in terms of R 2 and “lack-of-fit” criteria. In order to compare such data sets, the linear relationship between the predicted values obtained from interpolating function is compared with actual values. Figure 3 compares the predicted values of PS, PSD, ΔE, and T g due to RSM with actual experimental results, thereby showing an acceptable consistency between two sets of data. By comparison with R 2 values of different responses in Table 1, Tables S1 to S2, PS with R 2 of 0.9737 has the minimum deviation with respect to the 45º line. This is representative of the significance of PS among toner characteristics. Table 1 summarizes the ANOVA for the reduced quadratic model obtained for PS, in which p value of the model is meaningful (<0.0001).

In a similar manner, predictors are meaningful and the p value of the “lack-of-fit” (0.2483) replies on the reliability of the model. The R 2 value of 0.9737 indicated that 97.37 % of the variability of the experimental data are expressed by the obtained model, which is reasonably adequate. The second-order model predicting the PS of toner is expressed through Eq. (7).

According to Eq. (7), material parameters of St/BA molar ratio, and CB and S content individually govern the PS of toner, while no interaction between them was detected by the RSM.

The reduced model predicting the PSD of toner is given in Eq. (8).

Similar to case of PS, no mutual effects between material parameters can be seen in the predictive model obtained or PSD optimization. On the other hand, the reduced interpolating functions obtained for T g and ΔE (Eqs. (9) and (10), respectively) reveal both individual and two-factor interaction coefficients:

Tables S1 to S3 in the supporting information (SI) provide support for adequacy of models in terms of ANOVA.

We applied reduced models to find the relationship between influential parameters among monomer ratio, carbon black, and surfactant content and responses. Notably, PS and PSD are governed by the aforementioned parameters, while T g and ΔE are additionally affected by the interaction between material factors.

In general, due to the relatively high specific surface area assigned to CB and its considerable activity, it can easily be absorbed on the surface of particles formed at the early stage of polymerization or oligoradicals in the polymerization media. Consequently, the free radicals in the growing particles will have less chance to be grown further. As a result of this, CB assists in formation of small chains which lower T g of black particle [23, 24]. On the other hand, at low content of free radicals, attachment of monomer to growing chains will be intensified, leading to lengthening of growing chains. The imbalance between aforementioned effects will determine the value of glass transition temperature. In case of ΔE, the interactive nature of reduced model might be fueled by the fact that ΔE brings itself the effect of PS and PSD, or because of intricate nature of this response.

The use of inorganic components such as CB in suspension polymerization causes reduction in monomer droplets and assists in accumulation of dead radicals due to the coagulation of primary radicals and those adhered to the surface of CB [25]. Hence, introduction of CB prevents the growth of such active centers depending on the size of the particles and interfacial interactions [23]. In the same way, the presence of more stable St droplets in the aqueous phase helps in maintaining hydrophobicity dominance leading to a uniform size distribution of monomer droplets, thereby a drop in PSD.

4.2 Multi-objective optimization of toner properties by RSM and DF

When producing printing toner, it is of vital importance to be able to control concurrently physical and color characteristics. The likelihood of multi-objective optimization of toner properties has been investigated based on multi-objective circumstances defined as (PS, PSD), (PS, ΔE), and (PSD, ΔE). Individual optimization of T g as response variable discussed in the previous section confirmed that this response takes values lying in the range that fusion takes place properly. Bearing in mind this opportunity, different binary targets are defined to be optimized simultaneously.

4.2.1 PS and PSD

Simultaneous optimization of PA and PSD responses is equivalent of exact controlling of physical properties of toner. We used overlaid plots given by RSM and desirability functions to assess the possibility of exact tuning of PS and PSD. Figure 4 shows overlaid plots obtained by RSM for the PS and PSD at constant levels of CB (1, 3, and 5 phr) with \(2.5 \le {\text{PS}}\;(\upmu{\text{m}}) \le 3.5\) and \(1 \le {\text{PSD}}\; ( {\text{Span)}} \le 2\) [contours (a), (b), and (c), respectively], as well as with \(4.5 \le {\text{PS}}\;(\upmu{\text{m}}) \le 5.5\) and \(1 \le {\text{PSD}}\; ( {\text{Span)}} \le 2\) (contours (d), (e), and (f), respectively, in the order mentioned above for CB content). These intervals are meaningful from a practical point of view according to well-known toner producers. Such kind of representation provides some more information about the effects of changing variables. Basically, a contour plot is used to visualize graphically optimal parameter setting circumstances. When multiple responses are to be optimized, one needs to find regions where requirements simultaneously meet the desired targets, namely operating window. By overlaying critical response contours on a single contour plot, one can visually search for the best compromise.

Overlaid plots of RSM illustrating the optimized regions yielded at constant CB level for controlling PS and PSD in the range of A \(2.5 \le {\text{PS}}\; (\upmu{\text{m)}} \le 3.5\) and \(1 \le {\text{PSD}}\;({\text{Span}}) \le 2\) specified with contours (a–c); and B \(4.5 \le {\text{PS}}\; (\upmu{\text{m)}} \le 5.5\) and \(1 \le {\text{PSD}}\; ( {\text{Span)}} \le 2\) specified with contours (d–f). a CB = 1, b CB = 3, c CB = 5, d CB = 1, e CB = 3, f CB = 5

In general, high-quality laser printers need to be fed by a smaller particle size. The aim is to enhance the homogeneity and uniformity of toners of smaller as well as narrower particle size and charge distribution. To assess the quality of printing toner in terms of PS, Gundlach law can be employed [26]. Accordingly, the average PS of toner is inversely proportional to the density of the imposed dot. To achieve perfect reproduction of an image at higher dpi resolutions, a small PS is required. Typically, an original PS of around 12 μm ends in a print resolution of 300 dots per inch (dpi). Smaller toners of about 5 μm size are required to have an image with improved resolution of 600 dpi, and finally toners with the particle size about 5 μm size ends in a print resolution of 1200 dpi [27]. The yellow region in the overlaid plots illustrates the circumstance for St/BA and S content at which concurrent controlling of PS and PSD responses in the preferred limits is possible. According to Fig. 4, RSM fails to address conditions needed for producing desired toners with controlled physical properties. This is while DF approach provides opportunity for developing such toners with different physical properties. Based on DF approach, PS and PSD responses are transformed into desired variables taking values in the range 0–1. We considered two scenarios for PS with target values (T PS) of 3 and 5, respectively, nominated as the first and second scenarios for binary response (PS, PSD). The smallest and largest values observed in the experiments for the PS were 1.55 and 12.84, respectively. These values were considered as the lower and upper limits of PS in the desirability function. Hence, desirability \(d_{1}\) was defined as:

Likewise, the second response variable PSD was considered as \(d_{2}\) desirability function:

The overall desirability generally defined through Eq. (3) was then correlated with partial desirability functions \(d_{1}\) and \(d_{2}\) as follows:

The best solutions among those proposed by the Design-Expert software for the two binary targets of PS and PSD described above are listed in Table 2.

As can be seen, the results are sorted with respect to the goodness of overall desirability D. According to data in Table 2, in contrast to RSM, the DF can properly optimize both PS and PSD for predefined target scenarios. Particularly interesting is that material parameters proposed by the DF for obtaining each target binary (PS, PSD) are completely different. This could not be principally obtained, or even imagined when applying RSM for multi-criteria optimization of PS and PSD. Basically, industries are looking for the best condition needed to control all properties at the same time. This task is always undertaken by infinitesimal manipulation of one parameter when others are held constant. The use of DF elucidated that there might be completely different conditions for producing toners with very similar properties to the predetermined imaginary product. To visualize in a better way the performance of DF approach, contour lines of the D for both scenarios defined fro (PS, PSD) binary target are plotted in Fig. 6 for two different surfactant contents (Fig. 5).

The figure demonstrates that toners with PS of about 5 µm can be attained at either low or high level of monomer. It is also apparent from the figure that lower surfactant content is more helpful in receiving higher desirabilities.

4.2.2 PS and ∆E

The last two cases examined through multi-objective optimization reflect the possibility of exact tuning of physical and color characteristics. Figure 6a shows an overlaid plot for PS and ΔE, with contours for which \(2.5 \le {\text{PS}} \le 3.5\) and \(0.3 \le \Delta E \le 0.5\), while Fig. 6b displays contours for which \(4.5 \le {\text{PS}} \le 5.5\) and \(0.3 \le \Delta E \le 0.5\).

Overlaid plots of RSM illustrating the optimized regions yielded at constant CB level for controlling PS and ΔE in the range of A \(2.5 \le {\text{PS}}\; (\upmu{\text{m)}} \le 3.5\) and \(0.3 \le\Delta {\rm E} \le 0.5\) specified with contours (a–c); and B \(4.5 \le {\text{PS}}\; (\upmu{\text{m)}} \le 5.5\) and \(0.3 \le\Delta E \le 0.5\) specified with contours (d–f). a CB = 1, b CB = 3, c CB = 5, d CB = 1, e CB = 3, f CB = 5

The results show that simultaneous optimization of PS and ∆E with RSM can hardly be imagined for the first case and is completely impossible for the second case. This has the meaning that manipulation of parameters with the aim of achieving defined binary target (PS, ∆E) is nearly an awkward objective. On the other hand, DF can properly find the best solutions with 100 % accuracy. Similar to the previous section, the overall desirability can be defined as:

where \(d_{1}\) and \(d_{4}\) are the individual desirability related to \(y_{1}\) (PS) and \(y_{4}\) (∆E), respectively.

The individual desirabilities are also defined as below:

In this regard, the quantities of changing variables are manipulated to meet the highest D value, as carefully as possible close to unity. This has been done by Design-Expert software. A number of the best solutions among the whole proposed by the software for defined scenarios are listed in Table 3. As can be seen, the results are sorted in accord with desirability and are extraordinarily good.

It is well understood for those working in the field that simultaneous optimization of PS and color characteristics are of high practical importance. Comparison between contour plots in Fig. 7 notifies that likelihood of exact tuning of PS and ΔE depends sensitively on the quantities of target responses. The possibility of manipulating CB and St/BA ratio in a wide range is another illustrative advantage when using DF instead of RSM.

The overall desirability is plotted in the form of contour lines for both cases, as in Fig. 7.

4.2.3 PSD and ∆E

Figure 8 shows an overlay plot for PSD and ΔE with contours for which \(1 \le {\text{PSD}} \le 2\) and \(0.3 \le\Delta E \le 0.5\).

Similar to previous cases, the overall desirability can be defined as:

where \(d_{2}\) and \(d_{4}\) are the individual desirability related to \(y_{2}\) (PSD) and \(y_{4}\) (\(\Delta E\)), respectively, and are defined earlier through Eqs. (12) and (16).

The quantities of changing variables are manipulated to meet the highest D value described in (17). The best solutions the scenario considered in this case are listed in Table 4, indicating an excellent optimization.

To visualize overall desirability, contour lines of the overall case are plotted in Fig. 9. This binary target has similarly been met by the use of DF approach.

5 Conclusion

Black printing particle are manufactured through suspension polymerization of St with BA based on experimental design approach of RSM, and their physical (PS and PSD), thermal (T g), and color (ΔE) properties are measured. Samples were prepared based on varying amounts of St/BA monomer ratio, CB, and surfactant content, as material parameters. Mathematical single- and multi-objective optimization by RSM followed by multi-objective optimization by DF approach provided useful insights into the nature and possibility of optimization of toner properties. In case of single-objective optimization, we obtained reduced quadratic models which properly detected the effect of material parameters on each considered characteristic. Nevertheless, RSM was found to be unable to propose material parameters needed for exact tuning of (PS, PSD), (PS, ΔE), and (PSD, ΔE) binary targets, in which DF was successful with 100 % desirability. In case of multi-objective optimization by DF, different scenarios were defined for each binary set of targets based on authentic documents. The likelihood of obtaining such targets was assessed for the first time in this work and demonstrated how intricate/unpredictable could be the interplay between material parameters and binary responses.

References

H. Kipphan, Handbook of Print Media: Technologies and Production Method (Springer, Berlin, 2001)

R.H. Leach, Printing ink Manual (Springer, Berlin, 2007)

G. Marshall, Recent Progress in Toner Technology (Society for Imaging Science and Technology, Springfield, 1997)

N. Ohta, M. Rosen, Color Desktop Printer Technology (Taylor & Francis Group, New York, 2006)

F. Andami, M. Ataeefard, F. Najafi, M.R. Saeb, from suspension to emulsion and mini-emulsion polymerisation: controlling particle size, particle size distribution, and roundness of printing toner. J. Pigment Resin Technol. 45(6) (2016, in press)

Z. Bazrafshan, M. Ataeefard, F. Nourmohammadian, Physicochemical colorants effects on polymeric composites printing toner. J. Pigment Resin Technol. 43(5), 245–250 (2013)

M. Ataeefard, Production of black toner through emulsion aggregation of magnetite, carbon black, and styrene-acrylic co-polymer: investigation on the effect of variation in components. J. Compos. Mater. 49, 1553–1561 (2015)

M. Ataeefard, F. Nourmohammadian, Producing fluorescent digital printing ink: investigating the effect of type and amount of coumarin derivative dyes on the quality of ink. J. Lumin. 167, 254–260 (2015)

M. Ataeefard, A. M. Arabi, Coloring of tiles with laser printer toner: toner designing based on ZrSiO4: Pr pigment 1st International Conference on Tile, Ceramic and Sanitary Ware, Tehran, Iran, 29–30 Nov. 2014

Z. Bazrafshan, M. Ataeefard, F. Nourmohammadian, Modeling the effect of pigments and processing parameters in polymeric composite for printing ink application using the response surface. Prog. Org. Coat. 58, 68–73 (2015)

M. Ataeefard, M.R. Saeb, A multiple process optimization strategy for manufacturing environmentally friendly printing toners. J Clean Prod 108, 121–130 (2015)

A.S. Pakdel, M.R. Behbahani, M.R. Saeb, H.A. Khonakdar, H. Abedini, M. Moghri, Evolution of vinyl chloride conversion below critical micelle concentration: a response surface analysis. J Vinyl. Addi. Technol. 21, 157–165 (2015)

M.R. Saeb, M. Moghri, H.A. Khonakdar, U. Wagenknecht, G. Heinrich, Fusion level optimization of rigid PVC nanocompounds by using response surface methodology. J. Vinyl. Addi. Technol. 19, 168–176 (2013)

D.C. Montgomery, Design and Analysis of Experiments (Wiley, New York, 2005)

M. Somasundaram, R. Saravanathamizhan, C. Ahmed Basha, V. Nandakumar, S. Nathira Begumd, T. Kannadasan, Recovery of copper from scrap printed circuit board: modelling and optimization using response surface methodology. Powder Technol. 266, 1–6 (2014)

N.R. Costa, J. Lourenço, Z.L. Pereira, Chemometr. Intell. Lab. Syst. 107, 234–244 (2011)

I.J. Jeong, K.J. Kim, Eur. J. Oper. Res. 195, 412–426 (2009)

M. Ghaedia, S. Hajatib, M. Zareea, Y. Shajaripoura, A. Asfarama, M.K. Purkait, Removal of methyl orange by multiwall carbon nanotube accelerated by ultrasound devise: optimized experimental design. Adv. Powder. Technol. 26(4), 1087–1093 (2015)

F. Andami, M. Ataeefard, F. Najafi, M.R. Saeb, Fabrication of black printing toner through in situ polymerization: an effective way to increase conversion. Prog. Color Color. Coat. 8, 115–121 (2015)

P. Ding, A.W. Pacek, K. Abinhava, S. Pickard, M.R. Edwards, A.W. Nienow, A process for the manufacture of chemically produced toner (CPT). II. Effect of operating conditions. J Ind. Eng. Chem. Res. 44(16), 6004–6021 (2005)

M. Fairchild, Color Appearance Models, 2nd edn. (Wiley, New York, 2005)

R.H. Myers, D.C. Montgomery, M. Ch, Anderson-Coo (Wiley, New York, 2011)

S. Kiatkamjornwong, P. Pomsanam, Synthesis and characterization of styrenic-based polymerized toner and it’s composite for electrophotographic printing. J. Appl. Polym. Sci. 89, 238–248 (2002)

H. Liu, S. Wen, J. Wang, J. Zhu, Preparation and characterization of carbon black-polystyrene composite particles by high-speed homogenization assisted suspension polymerization. Appl. Polym. Sci. 123, 3255–3260 (2011)

J. Yang, T. Wang, H. He, F. Wei, Y. Jin, Particle size distribution and morphology of in situ suspension polymerized toner. Ind. Eng. Chem. Res. 42, 5568–5575 (2003)

G. Galliford, Chemically Prepared Toners—A Study of Markets and Technologies (Galliford Consulting and Marketing, Ventura, 2006)

N. W. Goon, Synthesis of chemically produced toner (CPT) by emulsion aggregation process, Master Thesis, University of Malaya, 2010

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ataeefard, M., Shadman, A., Saeb, M.R. et al. A hybrid mathematical model for controlling particle size, particle size distribution, and color properties of toner particles. Appl. Phys. A 122, 726 (2016). https://doi.org/10.1007/s00339-016-0242-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0242-1