Abstract

In the present work, graphene oxide (GO) was prepared by hummers method from natural graphite and modified with iron oxide nanoparticles. The structural order and textural properties of the graphene-based materials were studied by TEM, XRD, TG-DTA and FT-IR. Hydrogen adsorption measurements have been carried out at 77 or 87 K, and atmospheric pressure on graphene oxide and Fe3O4–graphene oxide materials. Hydrogen adsorption at 77 K and atmospheric pressure reached values in the order of 1.7 and 2.1 wt% for graphene oxide and Fe3O4–graphene oxide materials, respectively. The hydrogen adsorption capacities of the Fe3O4–graphene oxide materials compare favorably well with those attained with high-value carbon materials. The isosteric heat of adsorption (Q st) was investigated as a function of hydrogen uptake at 77 and 87 K over the pressure range of 0 to atmospheric pressure. The isosteric heat of adsorption for magnetic GO (9.7 kJ mol−1) was found to be higher than for GO (6.1 kJ mol−1).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Hydrogen is being considered as an ideal energy source for replacing fossil fuels, several technological and scientific issues are still matter of studies and improvements, and in particular, its storage is a challenge for material science [1]. The main problem with the use of hydrogen as a transportation fuel is the storage of hydrogen which currently cannot meet the storage targets (gravimetric capacity and volumetric capacity) set by the US Department of Energy (DOE) for on-board storage systems [2]. The conventional methods (liquefaction and compression) have been used to store hydrogen. Nevertheless, these methods pose problems such as large boil-off loss, the need for heavy containers, safety and high capital cost. In recent years, physisorption of hydrogen on carbon-based nanomaterials was investigated as potential hydrogen storage materials because of their high surface area, large pore volume and promising hydrogen adsorption properties. Carbon nanotubes [3, 4], activated carbon and carbon nanofibers [5–7], mesoporous carbon [8], carbon aerogels [9–11], carbide-derived carbon [12], carbon monoliths [13] or mechanically milled graphite [14] are a few representative carbonaceous adsorbents that have been evaluated for their hydrogen adsorption properties.

Graphene, the two-dimensional one-atom-thick crystal composed by carbon atoms arranged in honeycomb geometry, has some very important advantages. First of all, the sp2 covalent-bonding arrangement of the carbon atoms in the honeycomb structure allows efficient binding to hydrogen atoms [15]. Graphene is stable, robust and can be easily transported for long distances. At the same time, it is mechanically flexible enabling new charging/discharging strategies at room conditions that exploit the dependence of hydrogen–carbon binding on local curvature [16]. Graphene’s flexibility and unique electronic properties could allow integration of a hydrogen storage module into flexible and light, all-graphene-based devices.

It is proven that hydrogen can be adsorbed on graphene-based materials both by physisorption or by chemisorption [17]. In the case of physisorption, hydrogen interacts with the graphene-based materials with a rather weak binding energy of >0.1 eV [18]. High pressures and low temperatures are used to ensure reasonable storage stability. In the most promising conditions, H2 can form a compact monolayer on the graphene-based materials, yielding a high hydrogen storage capacity [19].

In order to reach higher capacities of hydrogen storage, metal/metal oxides have been introduced to carbon-based nanomaterial as a catalyst [20]. Based on the increased use of transition metals as a catalyst, investigations regarding the different performance of metals and metal oxides have been carried out in order to determine which is more effective as a catalyst [21]. Their corresponding transition metal oxides also show very efficient catalytic effects. In some cases, the effects are even greater in the oxides than in the elemental metal [22]. However, the exact mechanisms of the observed catalytic effects are not clear yet, and some controversy still exists. One explanation is that transition metal oxides interfaces act as catalysts to accelerate H-sorption kinetics and, in particular, the breaking up of the H2 molecule into absorbable monotonic hydrogen [23].

In this work, we prepared graphene oxide with high surface area by graphite powder as a precursor via modified Hummers’ method; after that, to obtain magnetic graphene oxide, additional modification was done using FeCl2·4H2O and FeCl3·6H2O. Moreover, we examined the effects of specific surface area and surface functional group on hydrogen uptake, which may aid to understand the H2 storage mechanism and direct the design of graphene-based hydrogen adsorbents. Finally, H2 sorption densities of the materials at 77 and 87 K over the atmospheric pressure were investigated.

2 Experimental

2.1 Materials

Graphite powder (<20 μm) was purchased from Sigma-Aldrich, Germany, and used as-received. H2SO4 (>99 %), hydrochloric acid (AR grade), H2O2 (30 % (w/v)), KMnO4 (>99 %), iron (II) chloride tetrahydrate (FeCl2·4H2O), iron (III) chloride hexahydrate (FeCl3·6H2O) and ammonia solution (NH4OH) were all purchased from Sigma-Aldrich (St. Louis, MO, USA).

2.2 Synthesis of GO adsorbent

GO was synthesized from expandable graphite using a modified Hummers’ method [24]. One gram of graphite powder was added to 23 mL of concentrated H2SO4 in an ice bath. KMnO4 (3 g) was then added slowly with stirring and cooling to keep the temperature of the reaction mixture below 293 K. The temperature of the reaction mixture was increased and maintained at 308 K for 30 min. When 46 mL of deionized water was added slowly to this mixture, temperature was increased to 371 K. After 15 min, 140 mL of deionized water was added followed by 10 mL of 30 % H2O2 solution. The solid product was separated by centrifugation. It was washed repeatedly with 5 % HCl solution, until the sulfate ions are removed, and then washed with distilled water repeatedly, until it becomes free of chloride ions. The product was then filtered and washed 3–4 times with acetone to make it moisture free, and the residue was dried in an oven at 338 K overnight. The GO was suspended in water and exfoliated through ultrasonication for 3 h.

2.3 Chemical modification of GO by magnetite nanoparticles

GO was obtained by method as described by Thu et al. [25]. In a typical synthesis procedure (magnetite GO), 99.5 mg of FeCl2·4H2O and 270.5 mg of FeCl3·6H2O (molar ratio 1:2) were dissolved in 30 mL of deionized water under sonication for 5 min. This mixture was added to 30 mL of GO and thoroughly stirred for 30 min at room temperature. To this solution, 2 mL of NH4OH was then added drop-wise to reach a mild alkaline pH (10–11). The mixture turned from light brown to dark brown and finally black color, indicating the formation of Fe3O4. The suspension was then heated to 353 K and kept at that temperature for 1 h. Upon the completion of the reaction, the as-prepared magnetic GO was magnetically separated and washed with water several times to obtain clean products. Alternatively, magnetic GO can be collected by centrifugation or paper filtration.

2.4 Characterization

The morphology and surface structure of GO and magnetic GO were examined by X-ray diffraction (XRD, Philips Xpert MPD, Co Kα irradiation, λ = 1.78897Å), JEM-2100F transmission electron microscope (TEM) and the Fourier transform infrared spectra (DIGILAB FTS 7000) instrument under attenuated total reflection (ATR) mode using a diamond module. The composition and thermal properties of GO and magnetic GO were determined by TGA with a PL thermal sciences model PL-STA using a heating rate of 10 K/min from room temperature to 1,073 K under Ar. The measurements were conducted using approximately 3 mg samples, and then, weight retention/temperature curves were recorded.

Volumetric nitrogen sorption studies were taken at 77 K using a Micromeritics ASAP 2020 system. Before measurements, the samples were degassed below 1.33 Pa at 90 °C for 1 h and heated (10 °C/min) to 350 °C for 10 h. The specific surface area (SBET) was calculated by the BET method in the relative pressure range of 0.04–0.20. Total pore volume (V t) was calculated at relative pressure p/p o = 0.98. The microporous volume (V mi) was determined by applying Dubinin–Radushkevich (DR) analyses on the corresponding isotherms in the relative pressure range 10−4–10−2. The volume of pores smaller than 1 nm (V < 1 nm) was determined by the cumulative pore volume in the relative pressure range 10−6–10−4 using Horvath–Kawazoe (HK) method. The meso- and micropore sizes of samples were analyzed by the Barrett–Joyner–Halenda (BJH) and HK methods, respectively.

2.5 Hydrogen adsorption

A Quantachrome Autosorb 1 apparatus was used to measure the hydrogen adsorption isotherms at 77 and 87 K from 0.05 to atmospheric pressure. The isotherm consists of 20 points of adsorption and 20 points of desorption. The hydrogen adsorption capacity was determined using the value of the adsorbed volume at atmospheric pressure and the ideal gas equation. High purity hydrogen was used in this study.

3 Results and discussion

3.1 Characterization of the GO and magnetic GO samples

Figure 1 shows the nitrogen adsorption–desorption isotherms of GO and magnetic GO, which are used to investigate the surface area and porous structure. The surface area of magnetic GO and GO calculated by the Brunauer–Emmett–Teller (BET) theory, which explain the physical adsorption of gas molecules on a solid surface [26], are 741.2 and 541.2 m2/g, respectively, which is the same size of graphene oxide reported in the literature [27].

As shown in Fig. 2a, the broad and relatively weak diffraction peak at 2θ = 10.5° (d = 0.87 nm), which corresponds to the typical diffraction peak of graphene oxide adsorbent, is attributed to the (002) plane. The XRD patterns of magnetic GO showed 2θ = 29.86°, 35.41°, 43.39°, 53.83°, 57.14°, 62.79°, respectively (Fig. 2b), suggesting the presence of magnetic phase in the composites (it confirms that the crystalline phase composition of magnetic GO is solely made up of cubic-Fe3O4). Moreover, graphene peak of pristine GO (Fig. 2a) has been changed to broad amorphous peak in magnetic GO (Fig. 2b), which shows that the structure of GO partially damaged during modification by iron oxide nanoparticles.

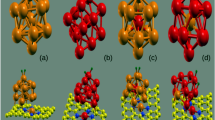

Representative TEM image of the obtained magnetic GO is showed in Fig. 3a. It can be seen that Fe3O4 nanoparticle has been coated on the GO surface consistently. It is observed that the size of the magnetic GO was about 17 nm with narrow distribution (Fig. 3b).

The FTIR spectra of GO and magnetic GO are shown in Fig. 4. Figure 4a, shows the presence of the oxygen-containing functional groups. The peaks at 1,380 and 1,630 cm−1 correspond to C–OH stretching and C=C stretching mode of the sp2 carbon skeletal network, respectively, while peaks located at 1,730 and 3,270 cm−1 correspond to C=O stretching vibrations of the COOH groups and O–H stretching vibration, respectively [28]. After modification, three representative peaks of the amide carbonyl group for magnetic GO at 1,647 (–CONH amide band I), 1,533 (–NH amide band II) and 1,455 cm−1 (C–N stretch of amide) appeared (Fig. 4b), implying that Fe3O4 nanoparticles were linked to GO surface by covalent bonding [29].

The TGA was also performed on GO and the magnetic GO adsorbents to find the Fe3O4 contents, the structure and thermal stability of the magnetic GO and the graphene oxide (Fig. 5a, b). The GO adsorbent shows two major mass loss at 473 and 858 K with 9 and 30 % weight loss, respectively. They are related to the elimination of oxygen-containing groups of graphene oxide and oxidation of carbon, respectively. For magnetic GO, it is clear that the thermal stability is much higher than pristine GO. It could be because of partial reduction of graphene oxide during modification by iron oxide nanoparticles. Two weight losses at 723 and 753 K are assigned to the loss of the residual solvent and the breakdown of the CONH group conjugated with Fe3O4 nanoparticles of the magnetic GO, respectively.

3.2 Hydrogen adsorption

Figure 6 shows the hydrogen adsorption–desorption isotherms for GO and magnetic GO collected at 77 and 87 K, while p/p o was from 0 to 1. It can be seen that at low pressures, the adsorption of H2 decreases with the increase in burn-off at both temperatures. The values obtained for the samples studied in this work are comparable to or, in many cases, better than other results obtained with higher cost carbon materials under the same experimental conditions [30]. The pristine GO absorbs a small amount of molecular H2 (1.3 wt% at 87 K and room pressure). However, a significant increase of H2 uptake (1.4 wt% at 87 K and room pressure) was observed in magnetic GO. It could be concluded that surface modification of GO adsorbents plays an important role in determining the porous structure and amounts of hydrogen adsorbed. As it has shown in Fig. 6, both the GO (1.7 wt% at 77 K and room pressure) and magnetic GO (2.1 wt% at 77 K and room pressure) reached to higher adsorption capacity at 77 K in contrast to 87 K, which is typically observed for hydrogen adsorption in porous carbons.

Researchers have shown the hydrogen adsorption capacities of different porous carbon materials at different temperatures and pressures, and related them with the textural properties of the studied materials. But surface functional group can act as other important factor. Zhao et al. [31] reported that hydrogen-uptake capacity can be remarkably enhanced in the presence of transition metals, as a result of the spill over of hydrogen molecules into carbon structures. The presence of Fe3O4 nanoparticles can also encourage the hydrogen uptake of magnetic GO by means of hydrogen-molecule spill over.

The isosteric heat is a direct indicator of the strength and heterogeneity of the interaction between the adsorptive and the adsorbent. There are various methods available to obtain the isosteric heat of adsorption, but the application of the Clausius–Clapeyron expression [32] is considered to be quite accurate and is frequently used. However, an accurate application of this method requires at least three closely spaced (in temperature) adsorption isotherms [33]. The isosteric heats of adsorption of the two adsorbents are calculated from the slope of the plot of ln P versus 1/T (according to the Clausius–Clapeyron equation), based on the polynomial fits of the Henry’s law regimes of the total adsorption isotherms. Compared to the unmodified GO (6.1 kJ mol−1) enhanced heat of hydrogen adsorption was observed in magnetic iron oxide containing samples, with the magnetic GO sample exhibiting a high values of around 9.7 kJ mol−1, which is higher than for typical activated carbon materials [34].

4 Conclusion

Magnetic GO was prepared with Fe3O4 nanocatalyst in order to investigate the capacity of iron oxides nanoparticles for increasing hydrogen storage. The structural order and textural properties of the GO and magnetic GO adsorbents were studied by XRD, nitrogen adsorption, FT-IR and TGA analyses. Volumetric hydrogen storage measurement of the GO and magnetic GO materials was performed at 77 and 87 K. The results show that magnetic GO has higher hydrogen adsorption in contrast to pristine GO. The enhancement in the hydrogen storage capacity of magnetic GO is maybe due to the improved spill-over mechanisms and uniform dispersion of iron oxide nanoparticles over the surface of GO adsorbent.

References

A. Züttel, Mater. Today 6, 24 (2003)

S. Hynek, W. Fuller, J. Bentley, Int. J. Hydrogen Energy 22, 601 (1997)

A.C. Dillon, K.M. Jones, T.A. Bekkedahl, C.H. Kiang, D.S. Bethune, M.J. Heben, Nature 386, 377 (1997)

A. Anson, M.A. Callejas, A.M. Benito, W.K. Maser, M.T. Izquierdo, B. Rubio, Carbon 42, 1243 (2004)

H. Kajura, S. Tsutsui, K. Kadono, M. Ata, Y. Murakami, Appl. Phys. Lett. 82, 1105 (2003)

M. Hirscher, M. Bechar, J. Nanosci, Nanotechnology 3, 3 (2003)

M.T. Mandoki, J. Dentzer, T. Piquero, S. Saadallah, P. David, C.V. Guterl, Carbon 42, 2744 (2004)

X. Shao, W. Wang, R. Xue, Z. Shen, J. Phys. Chem. B 108, 2970 (2004)

R. Fu, T.F. Baumann, S. Cronin, G. Dresselhaus, M.S. Dresselhausand, J.H. Satcher, Langmuir 21, 2647 (2005)

I.L. Moudrakovski, C.I. Ratcliffe, J.A. Ripmeester, L.Q. Wan, G.J. Exarhos, T.F. Baumann, J. Phys. Chem. B 109, 11215 (2005)

H.Y. Tian, C.E. Buckley, M. Paskevicius, D.A. Heppard, S.B. Wang, C.J. Webb, E.M. Gray, Int. J. Hydrogen Energy 17, 10855 (2011)

G. Yushin, R. Dash, J. Jagielo, J. Fischer, Y. Gogotsi, Adv. Funct. Mater. 16, 2288 (2006)

Y. Xia, R. Mokaya, J. Phys. Chem. C 111, 10035 (2007)

S. Orimo, G. Meyer, T. Fukunaga, A. Zuttel, L. Schlabch, H. Fujii, Appl. Phys. Lett. 75, 3093 (1999)

K.H. Liao, A. Mittal, S. Bose, C. Leighton, K.A. Mkhoyan, C.W. Macosko, ACS Nano 5, 1253 (2011)

Y. Liang, J. Frisch, L. Zhi, H. Norouzi-Arasi, X. Feng, J.R. Rabe, N. Koch, K. Mullen, Nanotechnology 20, 434007 (2009)

Y. Zhu, S. Murali, W. Cai, X. Li, J.W. Suk, J.R. Potts, R.S. Ruoff, Adv. Mater. 22, 3906 (2010)

D. Kim, S. Lee, Y. Hwang, K.-H. Yun, Y.-C. Chung, Int. J. Hydrogen Energy 39, 13189 (2014)

C. Ataca, E. Akturk, S. Ciraci, H. Ustunel, Appl. Phys. Lett. 93, 043123 (2008)

M. Zielinski, R. Wojcieszak, S. Monoeverdi, M. Mercy, M.M. Bettahar, Int. J. Hydrogen Energy 32, 1024 (2007)

Y.X. Yang, L. Bourgeois, C.X. Zhao, D.Y. Zhao, A. Chaffee, P.A. Webley, Microporous Mesoporous Mater. 119, 39 (2009)

D. Chen, L. Chen, S. Liu, C.X. Ma, D.M. Chen, L.B. Wang, J. Alloys Compd. 372, 231 (2004)

A.R. Yavari, J.F.R. de Castro, G. Heunen, G. Vaughan, J. Alloys Compd. 353, 246 (2003)

W.S. Hummers, R.E. Offeman, J. Am. Chem. Soc. 1339, 80 (1958)

T.V. Thu, A. Sandhu, Mater. Sci. Eng. B 13, 189 (2014)

S. Brunauer, P.H. Emmett, E. Teller, J. Am. Chem. Soc. 60, 309 (1938)

G. Gollavelli, C.C. Chang, Y.C. Ling, ACS Sustain Chem. Eng. 1, 462 (2013)

L.H. Ai, C.Y. Zhang, Z.L. Chen, J. Hazard. Mater. 4559, 19 (2007)

D. Depan, B. Girase, J.S. Shah, R.D.K. Misra, Acta Biomater. 3432, 7 (2011)

R. Chahine, T.K. Bose, Int. J. Hydrogen Energy 19, 161 (1994)

D. Zhao, Q. Huo, J. Feng, B.F. Chmelka, G. Stucky, J. Am. Chem. Soc. 120, 6024 (1998)

R.K. Agarwal, J.S. Noh, J.A. Schwarz, P. Davini, Carbon 25, 219 (1987)

T. Vuong, P.A. Monson, Langmuir 12, 5425 (1996)

Acknowledgments

The authors thank the Research Council at the Azad University for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moradi, S.E. Enhanced hydrogen adsorption by Fe3O4–graphene oxide materials. Appl. Phys. A 119, 179–184 (2015). https://doi.org/10.1007/s00339-014-8944-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8944-8