Abstract

The potential of laser ablation in conservation of paper artifacts of cultural interest is under investigation since the second half of nineties. However, the works carried out on the topic are relatively a few as compared with those dedicated to stone, metal and painted artworks. Furthermore, in the latter cases, widespread applications have been successfully carried out, whereas laser cleaning of aged paper is still far from the conservation practice. There are serious risks to produce short- and/or long-term chemical alterations and/or mechanical damages at relatively low fluences. Here, we report a systematic investigation on laser removal of mold growths from prepared and naturally aged paper samples. Fundamental wavelength and second harmonic of QS Nd:YAG laser are tested and compared through optical and spectroscopic characterizations. This allowed defining optimized irradiation conditions and foreseeing further improvements from pulse duration optimization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Among issues correlated to the conservation of paper artifacts, biodeterioration is certainly one of the most important and still not resolved. Since paper is constituted of organic fibers, it represents a nutrition source for many microorganisms, such as molds and bacteria, whose enzymatic and reproductive activities cause discoloration and structural deteriorations. The removal of these microorganisms is therefore a mandatory conservation task.

Mechanical and chemical approaches do not allow the complete solution of the typical cleaning problems and involve serious drawbacks. This discloses some application perspectives for laser cleaning, which was explored in some extent along the last decade. However, the fragility of the paper substrate makes laser treatment of paper artifacts much more difficult than for stone sculptures, metal artifacts and wall paintings for which this approach is relatively well established [1]. The control of the laser interaction effects must be significantly higher in order to avoid damages to the cellulose fibers, which can get very sensitive to laser exposure under deterioration conditions.

Several experimentations have been dedicated to the topic using different types of lasers [2–8]. UV excimer laser radiation (248, 308 nm) [9] was found to be the most suitable to remove microscopic layers [10], but it resulted to be particularly harmful because of the risks of oxidation of cellulose fibers, as well as of invasive ablation at relatively low fluences [6, 7].The best results have been achieved using Nd:YAG laser’s second harmonic (532 nm) [8, 11]. In order to reduce the photooxidation of cellulose, laser irradiation was assisted with ethanol. This procedure has provided satisfactory results in comparison with the conventional bleaching treatment using KMnO4, and also allowed a drastic reduction in the application time and a considerably improvement in selectivity.

Second and third harmonics of Q-switched Nd:YAG lasers were used in order to clean old paper samples with foxing. The use of laser irradiation in order to remove selective foxing is a very challenging goal. In 2003, the removal of foxing marks from a medieval map using a molecular fluorine laser at 157 nm has been reported [12], which has not be followed by further applications. Recent studies [13, 14] have shown that also for this conservation problem, laser radiation at 532 nm has significant potential and the removal of foxing stains can be achieved using laser fluences around 1 J/cm2.

However, despite the encouraging results achieved at 532 nm since many years ago [4], to date, the technique has not found relevant practical applications because of several open problems such as those concerning the long-term effects of laser irradiation and the availability of reliable operative solutions.

For this reasons, in the present work after investigating the interaction of 532 laser radiation with pure cellulose, with or without the gelatin sizing, we focused on the removal of biodeteriogens, which represents a significant conservation problem of paper artifacts not satisfactorily addressed using traditional techniques. Irradiation tests were carried out using suitable setup and laser parameters in order to evaluate short- and long-term effects, by means of accelerated aging. A close comparison between 1,064 and 532 nm was performed. Afterward, fungi proliferations were induced on the paper samples, which were carefully characterized and then subjected to laser removal tests. We considered the biological characterization of the fungal growth of fundamental importance since the laser interaction strongly depends on the optical properties of the organism under irradiation. The cultural procedure allowed selecting a single species biological growth of Aspergillus Fumigatus. The investigation of the safe removal of this biodeteriogen from paper is reported here for the first time. The results achieved provide a step ahead with respect to the state of the art and concretely support the significant potential of Nd:YAG laser’s second harmonic in conservation of paper artifacts.

2 Materials and methods

Whatman n° 1 filter papers, constituted of 99 % of α-cellulose devoid of adhesive or other additives. For these reasons, Whatman filters represent the best reference samples for investigating the laser–cellulose interaction, as well as for optimizing chemical treatments of paper artifacts. These filters have 55 mm diameter, 88 g/m2 weight and 180 μm thickness, and the constituent cellulose has a degree of polymerization of 1,230 [15]. Whatman paper samples were chosen for the experiments in order to study selectively the effect of laser radiation on cellulosic fibers thus avoiding the contribution of impurities and additives generally found in common paper sheets. Some of these samples were sized using an animal gelatin powder by Merck, in accordance with a procedure described by Barrett et al. [16]. Untreated and sized Whatman filters were then artificially aged following two methodologies commonly used for paper artifacts described in the regulation protocols UNI 9080 and UNI ISO 5630-3. Briefly, the UNI 9080 describes the procedures for dry thermal aging of paper materials maintaining a 105 ± 2 °C stable temperature for 24, 48 or 72 ± 1 h in the absence of light. Whereas the UNI ISO 5630-3 describes a treatment of hydrothermal aging maintaining a 80 ± 0.5 °C stable temperature and a relative humidity of 65 ± 2 % for 6 days in the absence of light.

Microbiological growth was induced on aged and non-aged samples furnishing environmental and nutritional optimal conditions: for this purpose, Whatman samples were stored for 30 days at moderate temperature between 25 and 30 °C [17] with 100 % relative humidity. Sources of carbon (cellulose) and nitrogen (soil) were provided as well.

Irradiation tests were conducted using the fundamental (1,064 nm) and the second harmonic (532 nm) emission of a Q-switched (QS) Nd:YAG laser with a pulse duration of 7 ns. Both the laser sources were coupled into a 1.5-mm-core-diameter optical fiber (length of about 5 m), which was terminated with a imaging endpiece allowing for calibrated spot diameter variations. Alteration thresholds were determined applying 100 laser shots on the same spot at 1, 2 (only for QS 532) and 5 Hz pulse repetition rate. Such a procedure was chosen in order to make these systematic irradiation tests comparable with operative procedure adopted, which involved the gradual ablation of biodeteriogens using many laser pulses at low pulse repetition rate (see below). Experimental tests were carried out at seven selected fluences between 0.6–5.7 and 1–6.7 J/cm2 for laser emissions at 1,064 and at 532 nm, respectively.

Regarding the laser setup, a suitable fiber-coupling setup was arranged in order to homogenize the laser beam distribution and then to achieve a precise control of the radiant exposure to the target. The collimated output laser beam (∅ = 6 mm) was coupled into a large core diameter fiber (∅ = 1,5 mm) by means of a telescopic demagnification of a factor 1/4 using two plano-convex lenses with focal lengths of 80 and 20 mm, respectively. The homogenized beam at the fiber output was eventually imaged onto the paper surface under treatment using a single lens-handpiece, which allowed a fine control of the final spot diameter. In this way, the maximum pulse energy released to the target was about 50 mJ, which allowed a sufficiently wide variation in the operative fluence.

Samples before/after aging and laser treatment were characterized by using UV–VIS optical microscopy (OM), reflectance spectroscopy, colorimetry, environmental scanning electron microscopy (ESEM) and vibrational spectroscopy such as attenuated total reflectance-Fourier transform infrared (ATR-FTIR) and Raman in order to study chromatic, structural and chemical alterations.

OM was carried out with an optical microscope Nikon Eclipse E400; ATR-FTIR spectra were acquired using a BioRad FTS-40 spectrometer; and BS-ESEM images were carried out using ESEM Quanta-200 FEI instrumentation and Raman measurements using a portable instrumentation (model i-Raman by B&W Tek Inc., DE, USA) provided with a diode laser (785 nm). Molecular characterization of the fungal species was performed by means extraction of nuclear material (DNA) and its subsequent amplification procedure. The extracted DNA was amplified by PCR (polymerase chain reaction) using primers that recognize the nucleotide sequences that are located in the ribosomal DNA region. In particular, forward primer ITS5 and the reverse primer ITS4 [18] were used for the recognition. The amplified DNA was analyzed with those present in GenBank using Basic Local Alignment Search Tool (BLAST) search program of National Center for Biotechnology Information (NCBI, USA) in order to identify the species [19].

3 Results and discussion

3.1 Paper alteration tests

Laser tests on all non-aged, thermal-aged and hydrothermal-aged Whatman samples were carried out using the fundamental and the second harmonic emissions of a QS laser following the procedure described above. Paper filters showed slightly different alteration thresholds when irradiated with 1,064 and 532 nm. However, no significant changes for what concerns aged and non-aged samples irradiated at the same laser wavelength were observed. As mentioned above, 1,064 and 532 nm considerably reduce the photooxidation of cellulose fibers with respect to UV radiation. For this reason, the present operative conditions did not allow appreciating substantial changes in terms of photo-induced mechanisms between aged and non-aged pure cellulose (Whatman filters).

3.2 Laser irradiation of non-contaminated paper @ 532 nm

Photomechanical damages on papers filters induced by irradiation at 532 nm 2 or 5 Hz only at fluences ≥ than 6.7 J/cm2 were observed in back scattering (BS)-ESEM images. In particular, samples irradiated showed lifted fibers and broken or brittle fibrils. Regarding sized samples, the surface glue layer was removed showing the whitish color of paper underneath. However, chromatic and molecular changes were not detected by using reflectance and colorimetric measurements along with FTIR spectra or Raman spectroscopy. At lower fluences (5.3 J/cm2), mechanical damages were still visible, but restricted to the surface with the exception of sized samples, which did not show any damage. No photomechanical damages were observed by irradiating the samples with a fluence of 3.7 J/cm2.

3.3 Laser irradiation of non-contaminated paper @ 1,064 nm

Samples treated with the Nd:YAG fundamental harmonic at 1,064 nm showed photomechanical, photochemical and chromatic alterations. At fluence of 5.7 J/cm2, photomechanical damages were visible on irradiated samples by naked eye. At fluence of 4 J/cm2, photomechanical damages were visible only through BS-ESEM where a much larger number of fibers appear lifted, brittle and broken as compared to those observed after 532 nm laser treatment. Furthermore, when laser operates at 4–5.7 J/cm2, chemical alterations were also detectable through UV-optical microscopy (Fig. 1a). Chemical damages were strictly localized in the area of interaction with the laser irradiation generating fluorescence emission. Raman spectra (exc.785 nm) do not show relevant changes in the spectral region of carbonyl groups. However, the regions between 450 and 1,350 cm−1 show some differences between the untreated and irradiated samples.

Evaluation of long-term effects after irradiation using Nd:YAG laser’s fundamental wavelength (1064 nm). a UV-optical microscopy of Whatman paper sample irradiated at fluence of 5.7 J/cm2. Chemical damages are localized in the area of interaction with the laser irradiation generating fluorescence emission; b Raman Spectra of untreated and irradiated (fluence of 5.7 J/cm2) Whatman paper sample. Bands pointed out are subjected to small intensity variations due to molecular changes (see Table 1). c VIS-stereo-microscopy of sample irradiated at fluence of 5.7 J/cm2. Blackening of cellulose fibers surrounded by others clear reveal selective etching. d ATR-FTIR spectrum of a laser untreated Whatman sample. e ATR-FTIR spectrum of a laser treated Whatman sample: the increasing of the intensity of the band at 1,730 cm−1 is ascribable to the stretching vibration of the carbonyl group

In particular, substantial intensity and frequency changes observed in the spectra (Fig. 1b) could be ascribable to the decreasing of the lateral CH2 groups of cellulose or to the bonds breaking within the monomer unit and the β-glucosidic bond. Processes like these ones occur during cellulose oxidation and lead to the formation of carbonyl (C=O) groups [20]. In Table 1, vibrational assignments of the Raman bands subjected to intensity changes are reported [21].

In order to simulate long-term aging, samples irradiated with the Nd:YAG laser at 1,064 nm were subjected to a second hydrothermal-type aging process for 6 days. Irradiated area showed a pronounced brownish color after this second aging cycle. In particular, in sample irradiated at fluence of 5.7 J/cm2, blackening of cellulose fibers surrounded by clear zones was observed (Fig. 1c), which reveals selective etching. In the case of aged and sized samples, this effect appeared more restrained or, likely, less appreciable due to glue yellowing. ATR-FTIR spectra (Fig. 1e) show a strong increasing of the band at 1,730 cm−1 ascribable to the stretching vibration of the carbonyl group C=O [22, 23], suggesting that this effect is presumably due to a selective paper oxidation process. Selective darkening after long-term aging could be the result of an accelerated auto-oxidative process of cellulose. The origin of this selective phenomenon could be due to the formation of precursors of oxidized compounds developed in consequence of cellulose–laser interaction. Cellulose autoxidation occurs in the presence of radical initiators which, favored by high temperatures, activate radical chain reactions, leading to the formation of oxidized groups (carbonyls, hydro-peroxides, peroxyl and alkoxyl radicals), which are responsible for the yellowing. These radical chain reactions propagate along the polymer chain of the cellulose [24].

3.4 Mold removal

Since no damages were detected on paper samples irradiated, the QS Nd:YAG laser emission at 532 nm was preferred in order to perform mold ablation tests. After 30 days of culture, Whatman samples showed greenish and yellowish speckles and accretions on the surface ascribable to the presence of molds. In some samples, structural alterations and brittleness were also observed. Sized samples showed a marked molds growth on the surface, and for this reason, they were selected for tests. In this case, green speckles were mainly due to pigments contained in the conidia, while yellowish color of the fibers derived likely from the products of metabolism.

Observation through OM highlighted the presence of unicellular transparent and fluorescent structures of fungal nature, as well as fungal spherical spores. Observation of the sample at ESEM confirmed the presence among the cellulosic fibers of spores and fungal structures, characterized by a smooth wall.

Molecular identification performed by PCR identified this species as A. Fumigatus. This is a saprophytic fungus widespread in wet environment. It grows very quickly and tolerates high temperatures (i.e., 45 °C). It forms flat and dusty colonies initially green in color with a white border becoming gray after a few days. It contains the cellobiasi enzyme, and therefore, it is able to digest cellulose [25]. The A. fumigatus has a long colorless smooth-walled conidiophore with a hemispherical bulge called vesicle where phialides are formed; each phialide produces a chain of pigmented (dark green) and wrinkled globular conidia. The set of the vesicle, phialidi and conidia takes the name of conidial head of Aspergillus and has a cylindrical shape. Conidia form a long column above the conidiophores visible at the microscope (Fig. 2a).

a VIS-OM image of Aspergillus Fumigatus b VIS-OM image of cellulose fibers affected by biological growth. c VIS-OM image of cellulose fibers after laser cleaning treatment (fluence: 0.6 J/cm2). Most of contaminants were removed, and no damages were detected. d BS-ESEM image of cellulose fibers before laser cleaning treatment. e BS-ESEM image of cellulose fibers after laser cleaning treatment. Laser emission at 532 nm removes selectively the conidia

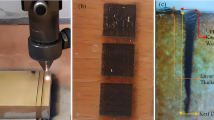

Laser cleaning tests were performed using the QS Nd: YAG laser emission at 532 nm. Samples were irradiated randomly in selected areas at a frequency of 1 Hz with several tens of laser pulses. Fluences between 0.2 and 0.6 J/cm2 were used, and air was blown on the sample surface along a direction almost tangential to the latter in order to avoid the redeposition of the bio materials during the removal process. The operative range of fluences employed in the treatment was well below the damage thresholds previously found for non-contaminated Whatman paper.

VIS-OM images showed a visible cleaning effect already at the lowest fluence tested (ca. 0.2 J/cm2), but the best results were obtained by using fluence of 0.6 J/cm2. Cellulose fibers were devoid of most of contaminants, and no damages were detected (Fig. 2c).

BS-ESEM images showed a high number of conidia (Fig. 2d) in the area untreated most of which were drastically removed by laser ablation. In particular, Fig. 2e shows that laser irradiation at 532 nm removed selectively the conidia as evidenced by the hemispherical cavities produced. Selective removal can be explained considering that pigmented conidia absorb laser radiation more strongly with respect to colorless conidiophores, which instead remained trapped within cellulose fibers.

4 Conclusions

Laser tests showed that pure and sized cellulose have high resistance to both fundamental and second harmonic QS Nd:YAG laser emission. Fluence thresholds are relatively high: 4 J/cm2 with QS Laser at 1,064 nm and 4.7 J/cm2 with the QS laser at 532 nm. Above these thresholds, photomechanical, chemical and optical alterations were observed.

Regarding Nd:YAG laser at 1,064 nm, despite evident alterations were observed on fibers surface when fluence above the damage threshold were applied, depolymerization does not occur, as for the laser at 532 nm. However, the fundamental wavelength (1,064 nm) produced oxidative processes of cellulose as it was highlighted by ATR-FTIR measurements.

Second harmonic emission of the QS Nd:YAG laser was successfully employed for the first time in order to remove A. fumigatus cultivated on Whatman paper samples. The results confirmed QS Nd:YAG laser at 532 nm with 10 ns of pulse duration is indeed more suitable for paper cleaning applications since cellulose has photomechanical damage thresholds higher if irradiated with visible than infrared light. Moreover, green laser radiation does not induce neither immediate nor long-term changes both in pure cellulose and sized samples.

References

S. Siano, J. Agresti, I. Cacciari, D. Ciofini, M. Mascalchi, I. Osticioli, A.A. Mencaglia, Appl. Phys. A 106, 419 (2012)

J. Kolar, M. Strlic, M. Marincek, Restaurator 21(9), 9–18 (2000)

J. Kolar, M. Strlic, D. Müller-Hess, A. Gruber, K. Troschke, S. Pentzien, W. Kautek, J. Cult. Herit. 4, 185s (2003)

H.M. Szczepanowska, W.R. Moomaw, JAIC 33, 25 (1994)

T.R. Friberg, V. Zafiropulos, Y. Petrakis, C. Fotakis, in Proceedings of the conference LACONA I, Lasers in the Conservation of Artworks, Restauratorenblätter (Special issue), p. 79 (1997)

W. Kautek, S. Pentzien, P. Rudolph, J. Kruger, E. Konig, Appl. Surf. Sci. 127–129, 746 (1998)

J. Kolar, M. Strlic, S. Pentzien, W. Kautek, Appl. Phys. A 71, 87 (2000)

E. Pilch, S. Pentzien, H. Madebach, W. Kautek, in LACONA V Proceedings, p. 19 (2005)

J. Kolar, M. Strlic, D. Müller-Hess, A. Gruber, K. Troschke, S. Pentzien, W. Kautek, J. Cult. Herit. 1, S221 (2000)

W. Kautek, S. Pentzien, J. Krüger, E. König, in Proceedings of the conference LACONA I, Lasers in the Conservation of Artworks, Restauratorenblätter (Special issue), p. 69 (1997)

S. Pentzien, A. Conradi, R. Koter, J. Krüger, Appl. Phys. A 101, 441 (2010)

E. Sarantopoulou, Z. Kollia, A.C. Cefalas, A.M. Douvas, M. Chatzichristidi, P. Argitis, S. Kobe, Appl. Surf. Sci. 253, 7884 (2007)

N.N. Brandt, A.Y. Chikishev, K. Itoh, N.L. Rebrikova, Laser Phys. 19, 483 (2009)

D. Ciofini, I. Osticioli, S. Micheli, L. Montalbano, S. Siano, in Proceedings of SPIE, vol 9065 (2013). doi:10.1117/12.2052820

S. Vicini, E. Princi, G. Luciano, E. Franceschi, E. Pedemonte, D. Oldak, H. Kaczmarek, A. Sionkowska, Thermochim. Acta 418, 123 (2004)

T. Barret, in Manchester 1992-Conference Papers, ed. by S. Fairbrass (Institute of Paper Conservation, Worcestershire, 1992), pp. 228–233

A. Rambelli, Fondamenti di micologia (Zanichelli, Bologna, 1987)

T.J. White, T. Bruns, S. Lee, J. Taylor, in PCR Protocols: A Guide to Methods and Application, ed. by M.A. Innis, D.H. Gelfand, J.J. Sninsky, T.J. White (Academic Press, San Diego, 1990), pp. 315–322

S.F. Altschul, T.L. Madden, A.A. Schäffer, J. Zhang, Z. Zhang, W. Miller, J.D. Lipman, Nucleic Acids Res. 25, 3389 (1997)

K. Schenzel, S. Fischer, Cellulose 8, 49 (2001)

J.H. Wiley, R.H. Atalla, Carbohyd. Res. 160, 113 (1987)

J. Caverhill, J. Stanley, B. Singer, I. Latimer, Restaurator 20, 57 (1999)

P. Calvini, A. Gorassini, Restaurator 23, 48 (2002)

S. Margutti, G. Conio, P. Calvini, E. Pedemonte, Restaurator 22, 67 (2008)

K.H. Domsh, W. Gamsh, A. Traute-Heidi, Compendium of soil fungi, vol. 1 (IHW-VERLAG, Eching, 1993), pp. 76, 94–98

Acknowledgments

The present study was carried out in the framework of the European Project CHARISMA (FP7 Capacities, Research Infrastructures, Grant Agreement No. 228330).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosati, C., Ciofini, D., Osticioli, I. et al. Laser removal of mold growth from paper. Appl. Phys. A 117, 253–259 (2014). https://doi.org/10.1007/s00339-014-8507-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8507-z