Abstract

Perovskite manganite La2/3Ca1/3MnO3 thin films were directly grown on MgO(100), Si(100) and glass substrates by pulsed laser deposition. From the XRD patterns, the films are found to be polycrystalline, single-phase orthorhombic. The metal–insulator transition temperature is 209 K for LCMO/MgO, 266 K for LCMO/Si and 231 K for film deposited on the glass substrate. The conduction mechanism in these films is investigated in different temperature regimes. Low-temperature resistivity data below the phase transition temperature (T P) have been fitted with the relation \( \rho = \rho_{0} + \rho_{2} T^{2} + \rho_{4.5} T^{4.5} \), indicating that the electron–electron scattering affects the conduction of these materials. The high-temperature resistivity data (T > T P) were explained using variable-range hopping (VRH) and small-polaron hopping (SPH) models. Debye temperature values are 548 K for LCMO/Cg, 568 K for LCMO/Si and 508 K for LCMO/MgO thin films. In all thin films, the best fitting in the range of VRH is found for 3D dimension. The density of states near the Fermi level N (E F) for LCMO/MgO is lower due to the prominent role of the grain boundary in LCMO/MgO and increase in bending of Mn–O–Mn bond angle, which decreases the double exchange coupling of Mn3+–O2–Mn4+ and in turn makes the LCMO/MgO sample less conducting as compared to the other films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The perovskite manganites La1−x Ca x MnO3 (LCMO) have been intensively studied due to their colossal magnetoresistive (CMR) properties [1–5]. LaMnO3, the parent compound of La1−x Ca x MnO3, is an insulator with an A-type antiferromagnetic (AFM) structure. With further doping (0.125 < x < 0.23), the canted antiferromagnetic (CAF) phase is transformed into a ferromagnetic insulating phase. As the doping concentration x increases, the static Jahn–Teller (JT) distortion weakens progressively and the system becomes metallic and ferromagnetic for x >0.23 [3]. T C is maximized at x = 1/3. The understanding of the CMR phenomenon, the metallic behavior and the strong ferromagnetic interactions is generally based on the double exchange (DE) model [6]. In this model, there is an exchange of electrons from neighboring Mn3+ to Mn4+ ions through oxygen when their core spins are parallel. However for the hole-doped manganites, the DE model alone cannot explain the resistivity and small polarons play a major role in the conductivity mechanism in the high-temperature paramagnetic (PM) region [7]. At higher temperatures (T > T P), the formation of polarons and their hopping between different valence states of Mn is not clear. In view of these facts, it is very much essential to investigate the phenomenon of electrical transport, both in the ferromagnetic and paramagnetic regions to arrive at a comprehensive model. The effect of sintering temperature [8] and grain boundaries [9] on the conduction mechanism of manganite perovskites are reported. In addition the conduction mechanism in La0.67Ba0.33Mn1−x Fe x O3 perovskites [10], double layered La2−2x Ca1+2x Mn2O7 manganite [11], La5/8Sr3/8MnO3 thin films [12] and La0.67Ca0.33Mn0.99Fe0.01O3 perovskite oxide [13] are studied. In the present work, we have attempted to study the effect of substrate on the conduction mechanism in La2/3Ca1/3MnO3 thin films prepared by pulsed laser deposition.

2 Experiments

La2/3Ca1/3MnO3 (LCMO) bulk polycrystalline samples were prepared via the solid state reaction and converted into the thin films by the pulsed laser deposition (PLD) technique using the Nd-YAG laser with a wavelength of 532 nm. The films were grown directly on MgO(100), Si(100) and corning glass substrates (Cg) under a O2 pressure of 12mTorr. During the deposition the substrate, the temperature was kept at 750 °C (700 °C for glass substrate) and, to avoid oxygen deficiency, a post-annealing at 700 °C for 4 h was made in air. The thickness of the films (<400 nm) was measured using a profilometer. The crystal structure of the films was characterized by X-ray diffraction (XRD, Philips). The electrical transport properties as a function of temperature were measured by a four-point method in the range of 100–300 K. Field emission electron microscopy (FESEM) was used to investigate the surface morphology of the LCMO films. A more detailed study of the structure and magnetic properties of these thin films has been reported elsewhere.

3 Results and discussions

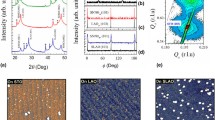

Room temperature X-ray diffraction (XRD) patterns of LCMO thin films are shown in Fig. 1. The XRD results show the polycrystalline growth for all thin films. The peaks were indexed to the orthorhombic space group Pnma.

Figure 2 shows the surface morphology of LCMO films. The surface of the films shows nano-crystalline microstructure and cauliflower-like morphology. No clear grain boundary is observed for LCMO/Cg. The film deposited on MgO and silicon show the cracked surface compared to the LCMO/Cg. These nano-cracks may be caused by the large lattice mismatch and the different thermal expansion coefficients between film and substrate. In addition, the LCMO/Cg film exhibited a smooth uniform microstructure with no cracks or defects observed. The average grain size of LCMO/Si, LCMO/Cg and LCMO/MgO were 56.14, 41.56 and 32.07 nm, respectively.

Figure 3 shows the normalized temperature dependence of the thin films in zero magnetic field in the temperature range of 100–300 K. All samples show metal–insulator transition behavior. As can be observed in Fig. 3, the LCMO/Si thin film displays two transition peaks. The first peak is found at 266 K and is referred to as \( T_{{{\text{p}}_{1} }} \). A second broad peak is found at a lower temperature of 173 K which is denoted as \( T_{{{\text{p}}_{2} }} \). The double maxima peaks may be explained by a model proposed by Zhang et al. [14]. In this model, the \( T_{{{\text{p}}_{1} }} \) reflects the intrinsic metal–insulator transition temperature, and the second peak at \( T_{{{\text{p}}_{2} }} \) refers to a grain boundary effect. \( T_{{{\text{p}}_{2} }} \) is not related to the metal–insulator-like transition of a granular system, but indicates interfacial tunneling due to the difference in magnetic order between the surface and body of one grain of perovskite. The phase transition temperature (T P) is 266 K for LCMO/Si, 209 K for LCMO/MgO and 231 K for LCMO/Cg thin film. It is found that the resistance of thin film deposited on a silicon wafer is higher as compared to the films deposited on glass and MgO (100) substrates. This might be due to less connectivity between grains and thick grain boundary in LCMO/Si. The nanocrack and high average grain boundary surface in the films deposited on Si(100) and MgO(100) enhanced the resistivity. The surface of the LCMO thin films is not so smooth as compared to the other thin films due to droplets, direct deposition and difference in deposition parameters.

4 Conduction mechanism

4.1 Low temperature range (T < T P)

Different conduction mechanisms of resistivity have been reported at low temperature (T < T P). Three of the most used equations were derived by different authors [15–17] as follows:

where ρ 0 is the temperature-independent part that is due to the domain, grain boundary and other temperature-independent mechanisms. The ρ 2 T 2 term corresponds to electron–electron scattering, the ρ 2.5 T 2.5 term arises due to electron–magnon scattering and ρ 4.5 T 4.5 is a combination of electron–electron, electron–magnon and electron–phonon scattering process in the ferromagnetic region [18]. The experimental resistivity data were fitted to the above equations. The quality of these fittings, in general, is evaluated by comparing the square of the linear correlation coefficient (R 2), obtained for each equation. The experimental data of LCMO thin films are best fitted with general polynomial Eq. (3). Fitting graphs and related data are shown in Fig. 4 and Table 1, respectively. From the fitting results it is found that the square of linear correlation coefficient R2 for both films is highest when the data are fitted by Eq. (3). Therefore, the conduction mechanism for all films at metallic regime seems to emanate from the electron–electron and electron–magnon (phonon) scattering processes. In addition, the electron–electron scattering term ρ 2 in Eq. (1) is larger than that of the electron–magnon (phonon) ρ 4.5 for all films. Therefore, the electron–electron scattering displays a major role in the conductivity of samples in the metallic regime. It is found that values of ρ 2 and ρ 4.5 are higher for LCMO/MgO thin film resulting in the increase of the scattering parameters as well as electron–electron and electron-magnon.as compared to the other films. In addition, the wide grain boundary region in LCMO/MgO and weak inter-grain connectivity in LCMO/Si increase ρ 0.

Resistivity vs. temperature for a LCMO/Cg, b LCMO/Si and c LCMO/MgO thin films below T P. The solid line representing the best fit to Eq. (1)

4.2 High temperature range (T > T P)

4.2.1 Small-polaron hopping (SPH) (T > θ D/2)

The small-polaron hopping model was used to explain the influence of small polarons on the conductivity using either adiabatic or non-adiabatic equations [19]:

where ρ 0 is residual resistivity and Ea is the polaron activation energy. In some cases, the linear correlation coefficient, R 2, values for both models are close to each other, and it is difficult to classify the systems into the adiabatic or non-adiabatic regime. Therefore, for finding the type of hopping, another mechanism is needed. By using Holstein’s relation [20], one can identify whether the hopping mechanism is in the adiabatic or non-adiabatic region. According to this relation, the polaron band width J should obey the following conditions:

\( J/\varphi > 1 \) for adiabatic hopping and \( J/\varphi < 1 \) for non-adiabatic hopping conduction:

Where φ is a critical polaron energy bandwidth.

The longitudinal optical phonon frequency \( \nu_{\text{ph}} \), is obtained from the relation; \( h\nu_{\text{ph}} = k_{\text{B}} \theta_{\text{D}} \). Furthermore, the condition for the small-polaron formation is J < E a/3 [20]. The resistivity data above T P is fitted to Eq. (4) by plotting ln (ρ/T) vs. 1/T (Fig. 5) and from the best fits, the half Debye temperature, θ D/2, as the temperature at which the slope changes from linearity can be determined. Therefore, θ D values are 548 K for LCMO/Cg, 568 K for LCMO/Si and 508 K for LCMO/MgO thin films as given in Table 2. To calculate the hopping energy, we re-plotted the resistivity curves as ln (ρ/T) vs. 1/T and from the slope of the straight line curve above θ D/2 and by by using Eqs. (4) and (5) the activation energy E a was calculated. It is clear from Table 2 that the average activation energy is higher for the film deposited on MgO. The ln (ρ/T) and ln (ρ/T 3/2) vs. (1/T) plot was drawn separately for all thin films, and the curves are shown in Fig. 6 and the related data are listed in Table 2. One can see from Table 2 that the hopping mechanism in LCMO/Si and LCMO/Cg films is in the adiabatic region, while for LCMO/MgO film the hopping mechanism is in the non-adiabatic region. It is found that LCMO/MgO thin film has higher value of activation energy on both adiabatic and non-adiabatic regime. This may be attributed to the oxygen deficiency that induces an increase in bending of Mn–O–Mn bond angle, thereby narrowing the bandwidth and enhancing the effective mass of the charge carrier. Due to this fact, the effective band gap increases with increasing oxygen deficiency. Therefore, higher values of activation energies are needed for the charge carriers to overcome this band gap [21]. In addition, the values for small-polaron coupling (γ P), which is a measure of electron–phonon interaction in these manganites, can be evaluated from the relation \( \gamma_{\text{P}} = 2E_{\text{a}} /h\nu_{\text{ph}} . \) Also from the values of γ P, we have evaluated the ratio of the polaron mass m P to the rigid lattice effective mass m* using the relation \( m_{\text{P}} = \, m*\exp \,\left( {\gamma_{\text{P}} } \right) \). The value of γ P is 5.02 for LCMO/Si, 7.38 for LCMO/MgO and 5.7 for LCMO/Cg as shown in Table 2. It has been suggested that a value of γ P >4 usually indicates strong electron–phonon interaction in solids. Therefore, strong electron–phonon interaction is observed for LCMO thin films. The highest value of γ P and m p/m* belongs to LCMO/MgO, due to strong electron–phonon interaction for the film deposited on MgO.

4.2.2 Variable-range hopping (VRH) \( (T_{\text{P}} < T < \theta_{\text{D}} / 2) \)

The variation of electrical resistivity with temperature above T P and θ D/2 may be explained on the basis of the variable-range hopping (VRH) model. According to the variable-range hopping model, the resistivity follows Eq. (7), where d = 3 represents the three-dimensional variable-range hopping conduction [22] .

where

The inverse of the localization length α was taken as 2.22 nm−1 as reported by Viret et al. [23] and N (E F) is the density of states near the Fermi level. The electrical resistivity data of all the samples of the present investigation at temperatures were fitted to Eq. (7) for d = 2, 3, and the estimated values of T 0 and N (E F) are given in Table 3. For all thin films, the best fitting in the range of VRH is found for the 3D dimension that is shown in Fig. 7. In addition; T 0 values for each film were calculated from the slopes of ln (ρ) vs. T −1/4 plot. As shown in Table 3, the calculated values of T 0 are significantly larger for LCMO/MgO than those for LCMO/Si and LCMO/Cg, whereas N (E F) is lower due to the prominent role of the grain boundary in LCMO/MgO and increase in bending of Mn–O–Mn bond angle, which decreases the double exchange coupling of Mn3–O2–Mn4+ and in turn makes the LCMO/MgO sample less conducting as compared with films deposited on Si(100) and glass substrates. In addition, the higher value of N (E F) for LCMO/Cg film may be explained on the basis of the higher conductivity of this film as compared to the other films. According to Jung [19], the electrical higher values of N (E F) are clear signatures of the applicability of the adiabatic hopping mechanism.

5 Conclusions

Polycrystalline single-phases of La2/3Ca1/3MnO3 thin films were directly grown on MgO(100), Si(100) and glass substrates by pulsed laser deposition. The transition temperature is 209 K for LCMO/MgO, 266 K for LCMO/Si and 231 K for films deposited on glass substrates. The electrical properties of the sample were understood with effective use of various models like resistivity fitting, variable-range hopping and small-polaron hopping models. The low-temperature resistivity data below phase transition temperature (T P) have been relatively well fitted with the relation \( \rho = \rho_{0} + \rho_{ 2} T^{ 2} + \rho_{ 4. 5} T^{ 4. 5} \), indicating the electron–electron scattering effects and the conduction of these materials. The high-temperature resistivity data (T > T P) were explained using VRH and SPH models. It is found that the hopping mechanism in LCMO/Si film is in the adiabatic region, while for LCMO/MgO and LCMO/Cg films the hopping mechanism is in the non-adiabatic region. In all thin films, the best fitting in the range of VRH is found for the 3D dimension. The density of states near the Fermi level N (E F) for LCMO/MgO film is lower due to the prominent role of the grain boundary.

References

J. Ma, M. Theingi, Q.M. Chen, H. Zhang, X. Gao, J.H. Yi, Adv. Mater. Res. 652, 576 (2013)

Y. Bitla, S. Kaul, EPL (Europhys. Lett.) 103, 57010 (2013)

M. Navasery, S.A. Halim, K.P. Lim, S.K. Chen, R. Abd-Shukor, Modern Phys. Lett. B 26, 1150039 (2012)

J. Ma, M. Theingi, H. Zhang, X. Ding, Y.J. Li, Q.M. Chen, Key Eng. Mater. 519, 220 (2012)

F. Hao, D. Jing, H. Xiao-Peng, C. Fang-Yi, C. Jun, Chin. J. Inorg. Chem. 29, 1617 (2013)

C. Zener, Phys. Rev. 82, 403 (1951)

J. Yang, B. Zhao, Y. Ma et al., Mater. Lett. 60, 3281 (2006)

G. Venkataiah, D. Krishna, M. Vithal et al., Phys. B 357, 370 (2005)

M. Shah, M. Nadeem, M. Idrees, M. Atif, M. Akhtar, J. Magn. Magn. Mater. 332, 61 (2013)

M. Baazaoui, S. Zemni, M. Boudard, H. Rahmouni, M. Oumezzine, A. Selmi, Phys. B 405, 1470 (2010)

A.K. Gupta, V. Kumar, N. Khare, Solid State Sci. 9, 817 (2007)

M. Navasery, G. Bahmanrokh, M. Erfani H, N. Soltani, A. Dehzangi, F. U D, A. Kamalianfar, S. Abdolmohammadi, S.K. Chen, K.P. Lim, L.A. Mehdipour, A. Anuar, Int. J. Electrochem. Sci. 8, 6905 (2013)

V. Dayal, P.V. Kumar, Solid State Commun. 158, 70 (2013)

N. Zhang, W. Zhong, D. Xing, Y. Du, Phys. Rev. B 56(13), 8138 (1997)

A. Banerjee, S. Pal, B. Chaudhuri, J. Chem. Phys. 115, 1550 (2001)

L. Pi, L. Zheng, Y. Zhang, Phys. Rev. B 61, 8917 (2000)

G.J. Snyder, R. Hiskes, S. DiCarolis, M.R. Beasley, T.H. Geballe, Phys. Rev. B 53, 14434 (1996)

H. Ahmed, S. Khan, W. Khan, R. Nongjai, I. Khan, J. Alloy. Compd. 563, 12 (2013)

W.-H. Jung, J. Mater. Sci. Lett. 17, 1317 (1998)

T. Holstein, Ann. Phys. 8, 343 (1959)

Y. Kalyana Lakshmi, P. Venugopal Reddy, J. Alloys Compd. 470, 67 (2009)

N. Mott, J. Non Cryst. Solids 1, 1 (1968)

M. Viret, L. Ranno, J. Coey, Phys. Rev. B 55, 8067 (1997)

Acknowledgments

The Ministry of Science, Technology and Innovation of Malaysia is gratefully acknowledged for the grant under Science Fund vote: 9199835.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Navasery, M., Halim, S.A., Dehzangi, A. et al. Electrical properties and conduction mechanisms in La2/3Ca1/3MnO3 thin films prepared by pulsed laser deposition on different substrates. Appl. Phys. A 116, 1661–1668 (2014). https://doi.org/10.1007/s00339-014-8295-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-014-8295-5